Prefabricated bridge pier and construction method thereof

A prefabricated assembly and pier technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems that the construction period and construction quality cannot be taken into account, and achieve the effects of shortening the construction period, high overall rigidity, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following is attached figure 1 To attach Figure 5 The present invention is further described in detail with specific examples.

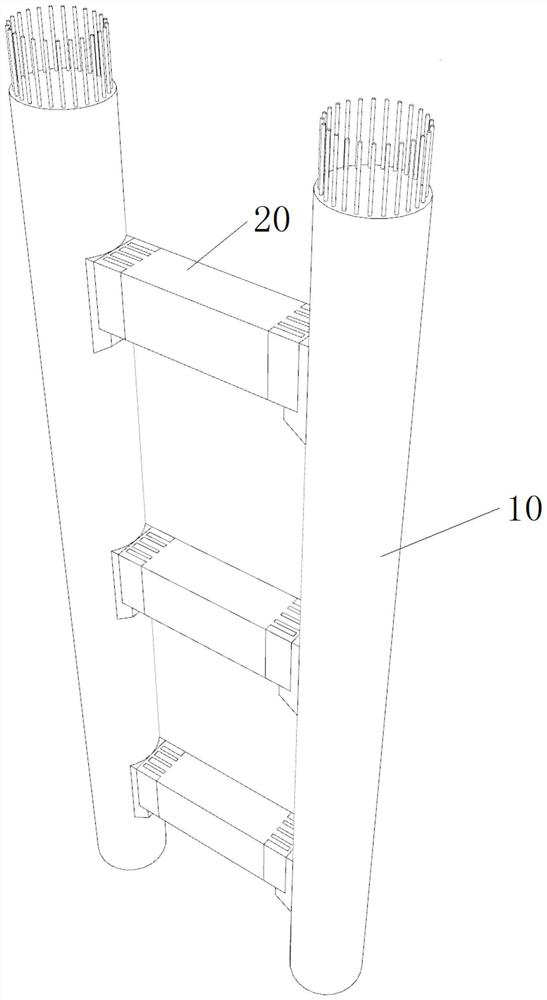

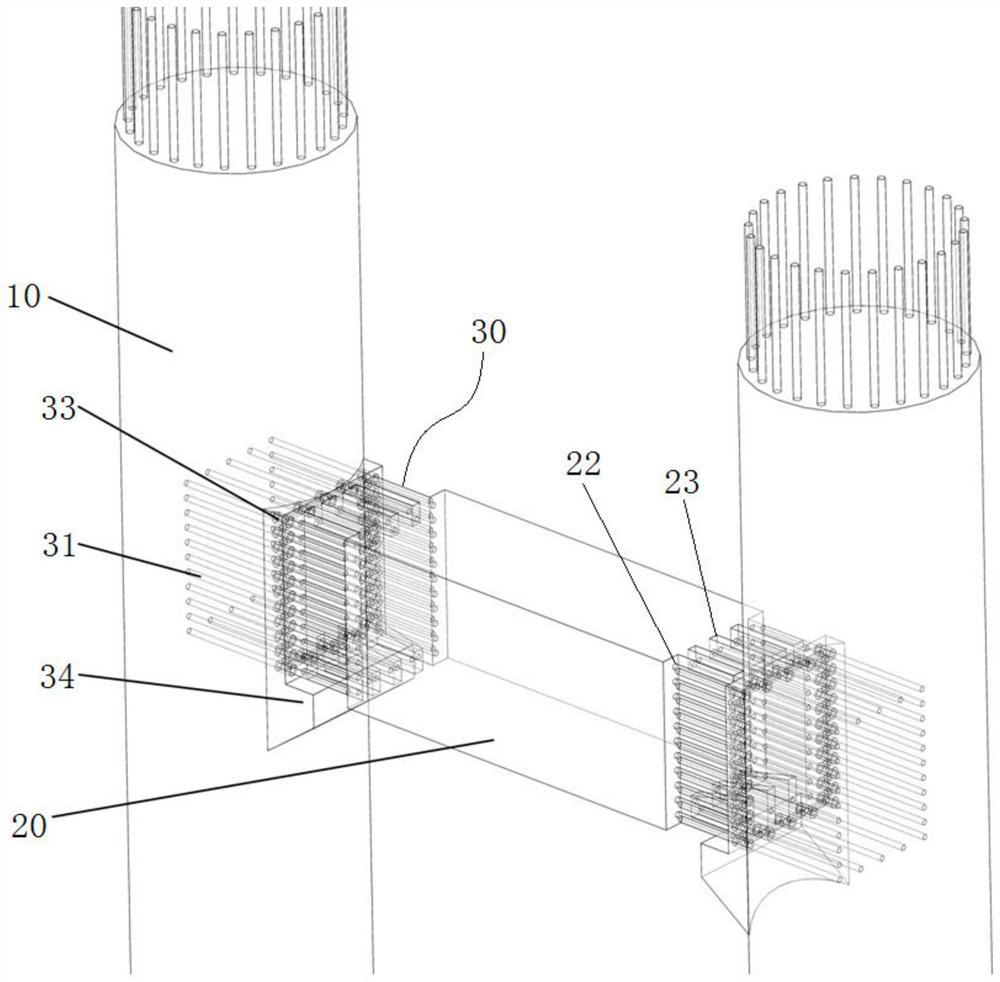

[0055] Such as figure 1 The shown prefabricated bridge pier includes two pier columns 10 , two connecting components 30 and two prefabricated tie beams 20 .

[0056] The two piers 10 are arranged at intervals along the first direction, that is, the horizontal direction, and the interval between the two piers 10 is determined according to design requirements, which is not specifically limited in this embodiment.

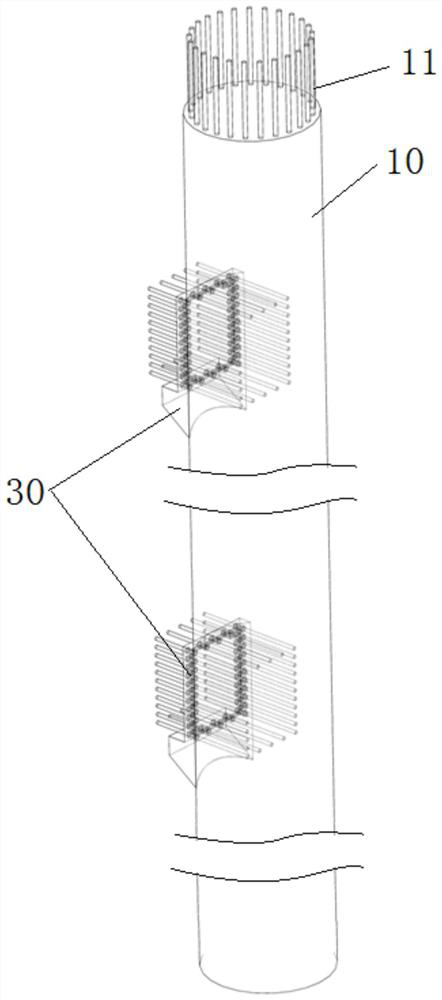

[0057] The two connection assemblies 30 are arranged at intervals along the height direction of the pier column 10 . Each connecting assembly 30 includes two opposing connecting pieces respectively arranged on the side walls of the two piers 10 , and the two connecting pieces on the same connecting assembly 30 are at the same height. The connection piece and the pier column 10 are integrally poured and formed, that is, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com