Method for coaxially connecting FRP reinforcements by FRP connecting pipe and expansive cement

A coaxial connection and expansion cement technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problem that FRP bars do not have weldability, cold bendability, extrusion strength and interlayer performance, and are not suitable for use Solve problems such as tying lap joints to achieve the effect of easy quality control, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

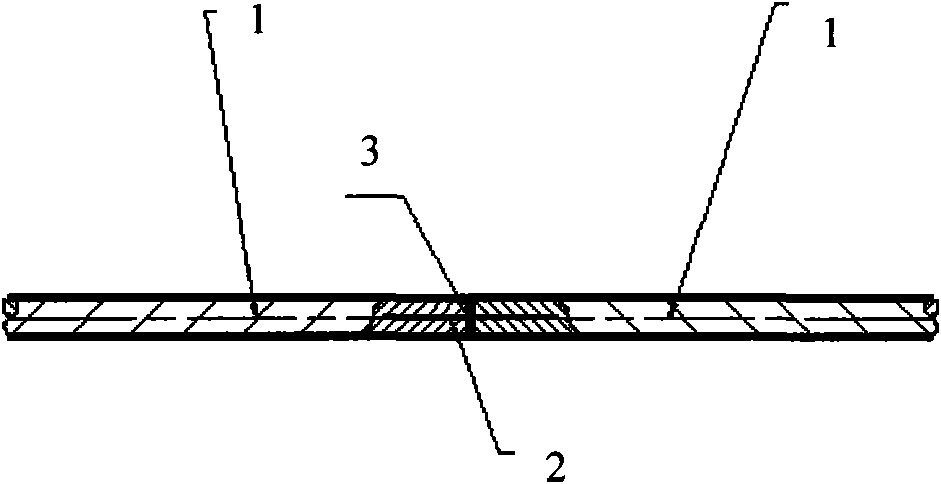

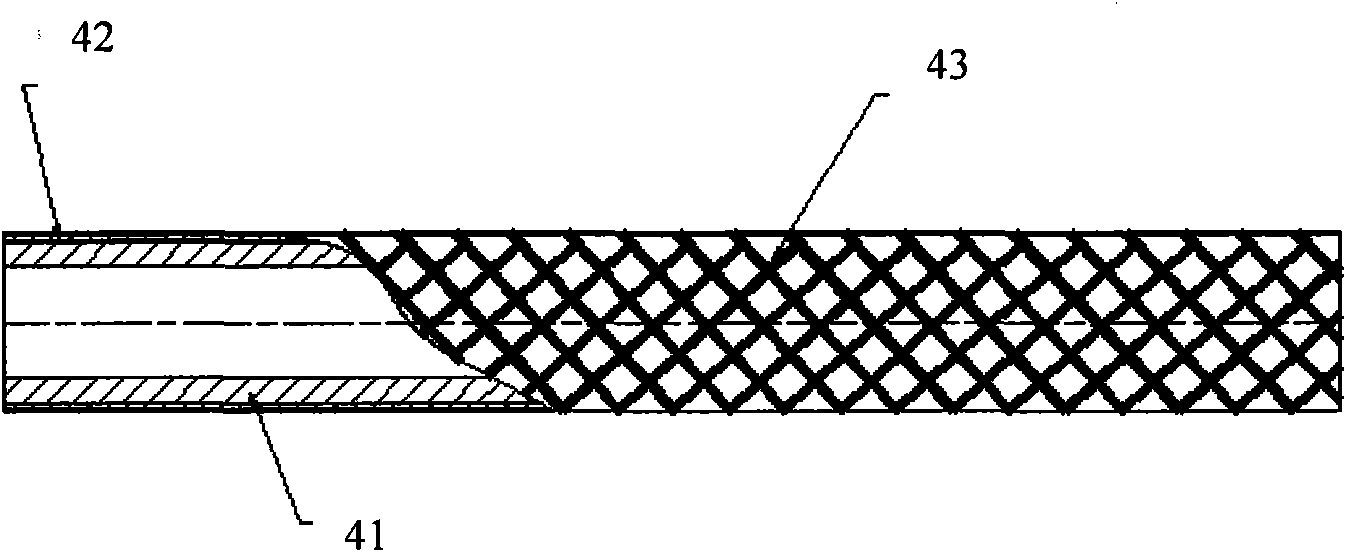

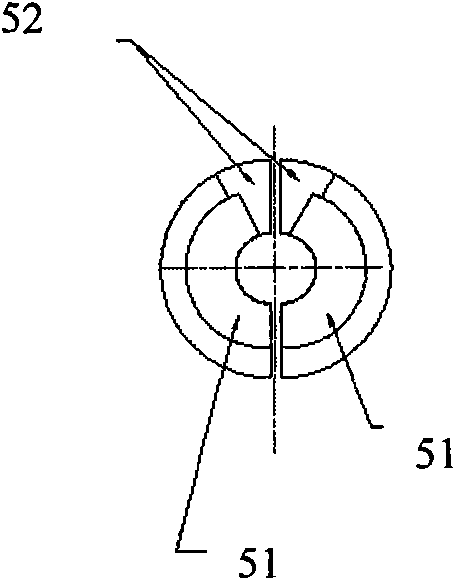

[0034] Drill a coaxial hole with a diameter of 3 to 6 mm in the center of the end of the two FRP tendons 1 to be connected. Wires such as steel wires 2 are coated with 502 instant glue and immediately inserted into the holes at both ends. After a few seconds, the coaxial positioning of the two FRP bars 1 is completed (such as figure 1 ). According to the requirements that the FRP connecting pipe 4 should have a tensile capacity not lower than that of the FRP tendon body, and that the anchorage glued surface between the FRP connecting pipe 4 and the connected FRP tendon 1 can effectively transmit a load not lower than the bearing capacity of the FRP tendon body , design and prepare FRP connecting pipe 4, the reinforcing material of FRP connecting pipe 4 can be glass fiber, carbon fiber, aramid fiber, basalt fiber or its fabric, etc., and its mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turgor pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com