Ramp lifting ramp construction device

A technology for construction devices and ramps, which is applied in the direction of ramps, building structures, and ladder-like structures, can solve problems such as slow construction speed, and achieve the effects of improving construction efficiency, simple structure, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

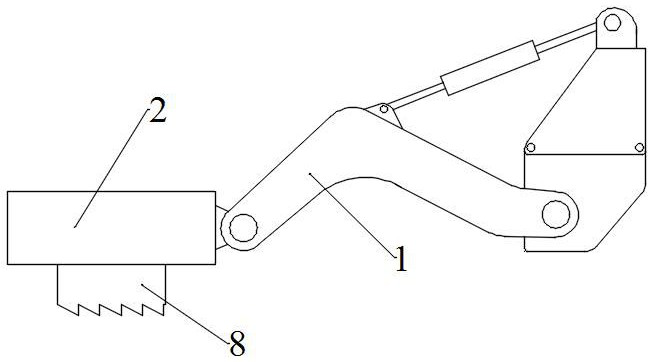

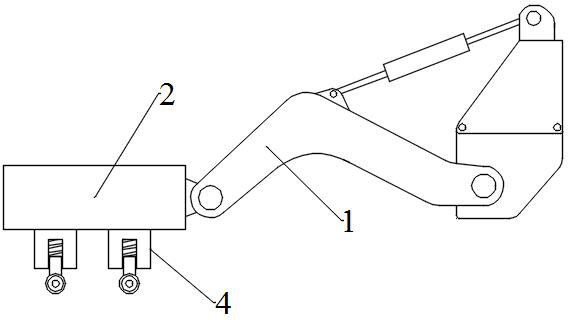

[0029] A ramp construction device, such as figure 1 As shown, it includes a mechanical arm 1, a mounting frame body 2, a linear drive device, a driving seat 5, and a driving device 8. The mechanical arm 1 is connected to the mounting frame body 2, and the linear drive device is arranged on the mounting frame body 2. , the linear driving device drives the driving seat 5 to move linearly along the length direction of the mounting frame body 2; the bottom of the driving seat 5 is provided with a shank device 8, and the bottom of the shank device 8 is provided with a serrated shank On the other hand, the driving base 5 is slidingly connected with the lifting device 8, and the driving base 5 and the lifting device 8 are directly provided with a lifting drive device.

[0030] During the use of the present invention, the overall mobile construction of the installation frame body 2 is driven by the mechanical arm 1. The driving structure of the mechanical arm 1 is the prior art, so it...

Embodiment 2

[0032] This embodiment is optimized on the basis of embodiment 1, such as Figure 7 As shown, the lifting drive device is a cylinder, the cylinder is arranged on the drive base 5, and the drive end of the cylinder is connected to the top of the driving device 8. Sliding cavities 13 are respectively provided on both sides of the driving seat 5 , and sliding protrusions are respectively provided on both sides of the sliding device 8 .

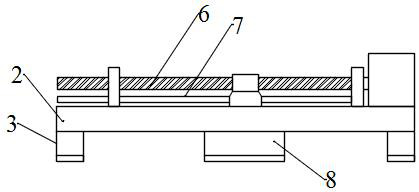

[0033] Further, as image 3 As shown, the linear drive device includes a lead screw 6 and a drive motor. The mounting frame body 2 is provided with a lead screw 6 for rotation, and the drive motor drives the lead screw 6 to rotate. The drive base 5 passes through the lead screw 6 nut Connect with lead screw 6. The screw 6 is rotatably connected with the mounting bracket body 2 through a bearing seat.

[0034] Further, as image 3 As shown, guide rods 7 are provided on both sides of the lead screw 6 respectively, and the driving seat 5 is slid...

Embodiment 3

[0039] This embodiment is optimized on the basis of embodiment 1, such as Figure 4-Figure 6 As shown, the lifting driving device includes an electromagnetic device 10, a magnet layer 11, and a buffer spring. The two sides of the driving seat 5 are respectively provided with sliding chambers 13, and the two sides of the said sliding device 8 are respectively provided with sliding protrusions. From the above, the electromagnetic device 10 is arranged on the top of the sliding cavity 13 , the magnet layer 11 is arranged on the top of the sliding protrusion correspondingly, and a buffer spring is arranged between the magnet layer 11 and the electromagnetic device 10 .

[0040]Further, the linear drive device includes a lead screw 6 and a driving motor, the mounting frame body 2 is provided with a lead screw 6 for rotation, the drive motor drives the lead screw 6 to rotate, and the drive base 5 passes through the lead screw 6 nut Connect with lead screw 6.

[0041] Further, guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com