Tunneling and assembling structure and construction method of comprehensive pipe gallery

A technology of comprehensive pipe gallery and construction method, which is applied in basic structure engineering, underwater structures, excavation and other directions, can solve the problems of long cycle, high cost, and large impact on the surrounding environment, so as to improve efficiency, economy and good economy. The effect of benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The features of the present invention and other related features will be described in further detail below through embodiments in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

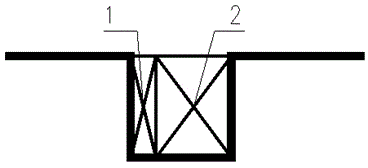

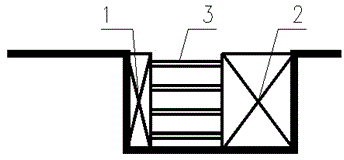

[0034] The invention provides a tunneling and assembling structure of a comprehensive pipe gallery, comprising: a shield backing device and a U-shaped shield machine located in a foundation pit. Wherein, the shield backing equipment is located at the first end in the foundation pit, and the U-shaped shield machine is located at the second end in the foundation pit; the foundation pit is formed by excavation.

[0035] Such as figure 2 , Figure 8 In an example shown in the figure, the foundation pit is an initial pit formed by excavating the initial section of soil (such as figure 1 , Figure 7 ), then there are no other intermediate components between the shield back equipment 1 and the U-shaped shield machine 2.

[0036] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com