Drainage method and device

A technology of drainage device and predetermined position, applied in drainage, safety device, earthwork drilling, etc., can solve the problems of inability to discharge water in gas drainage holes, affecting gas drainage effect, and excessive water accumulation in gas drainage holes, etc., so as to improve operation efficiency. and gas extraction efficiency, saving operation time, and ensuring the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

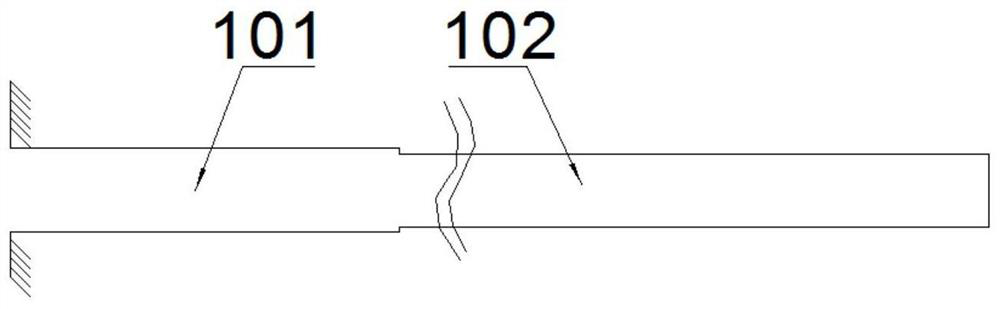

[0020] The technical solution of the present application will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

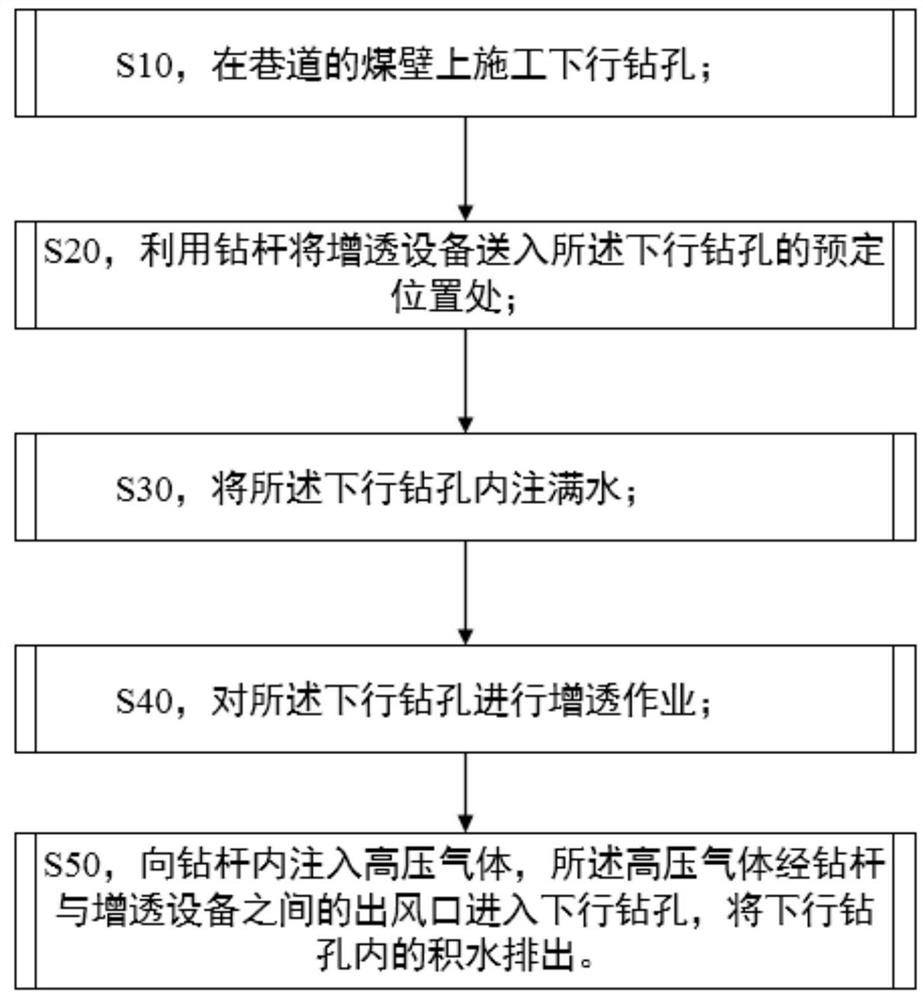

[0021] figure 1 Shows the flowchart of the drainage method of the present application, as figure 1 Shown, the drainage method that the application provides, it comprises:

[0022] S10, constructing a descending borehole on the coal wall of the roadway;

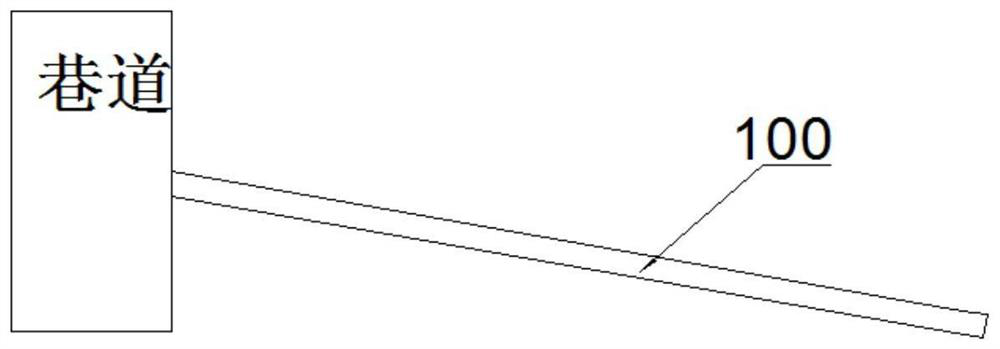

[0023] Such as figure 2 As shown, the downhole 100 is a borehole formed by drilling from a position close to the earth's surface to a position far away from the earth's surface.

[0024] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com