Fin rapid winding and welding-free air conditioner watch cooling coil

A welding-free, surface cooler technology, applied in the direction of indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problems of hidden leakage of welding points, low production efficiency, labor-intensive welding of elbows at the end, etc. , to achieve the effect of exempting personal health hazards, prolonging service life and solving hidden dangers of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

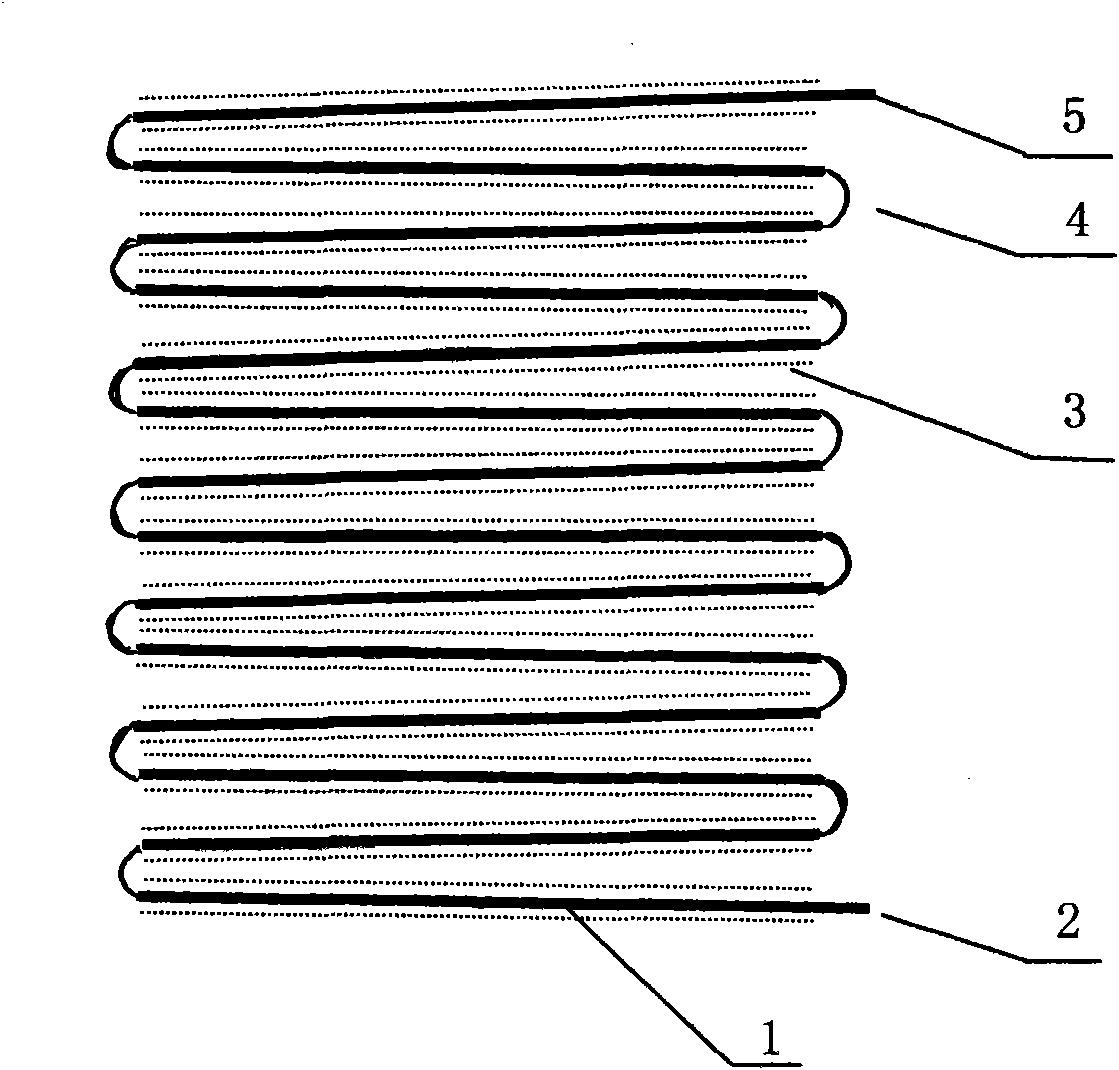

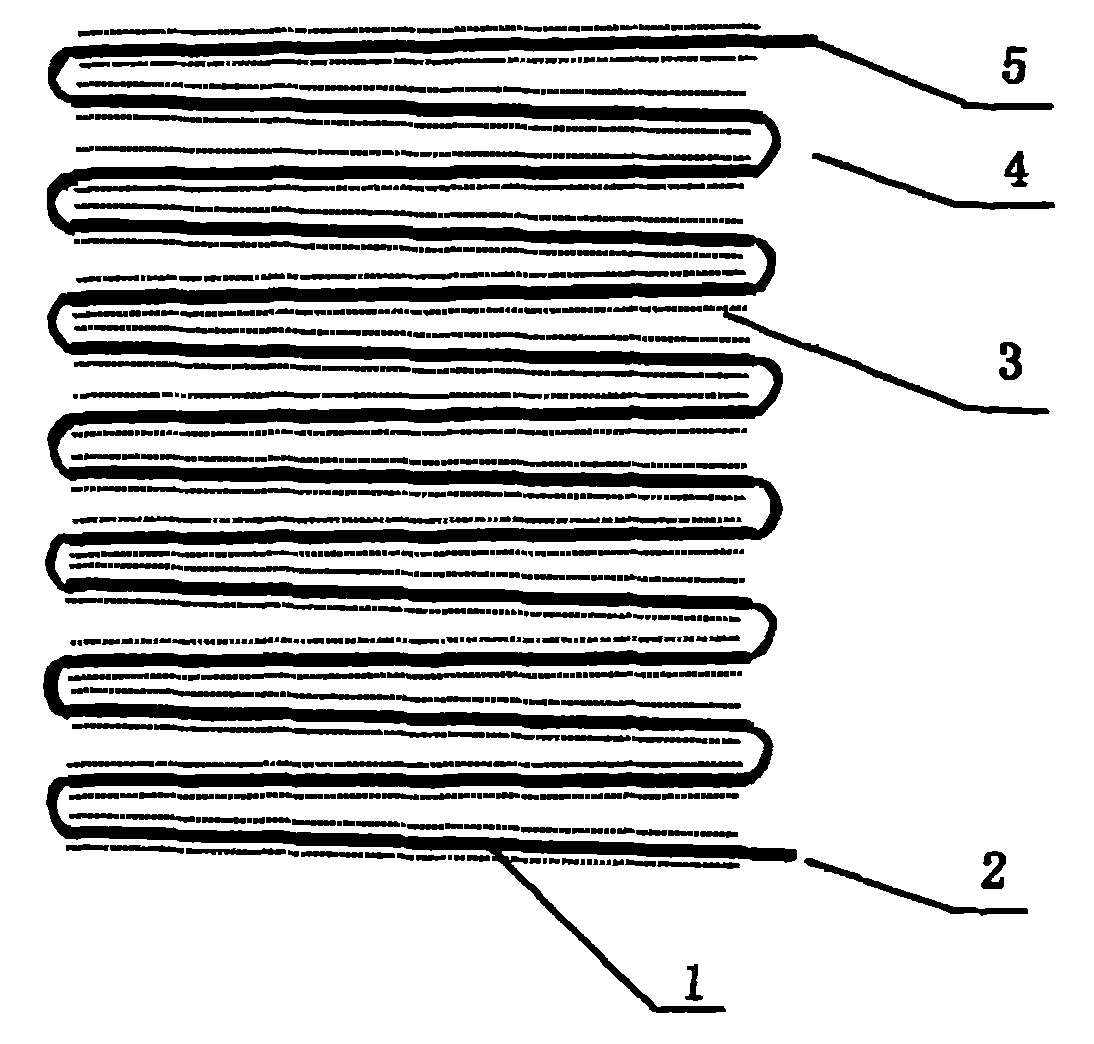

[0009] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0010] It can be seen from the accompanying drawings that the fins of this scheme are wound and weld-free air-conditioning surface coolers, including copper tubes (1) with aluminum fins (3), and water outlets (2) of the copper tubes (1) The connecting elbow (4) constitutes a whole radiator, which is supplied with water by the water inlet (5) to achieve the purpose of cooling and heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com