Rapid construction device for wall decorative panels

A technology for construction devices and wall decoration, applied in nailing tools, manufacturing tools, nails, etc., can solve problems such as low construction efficiency, difficult to guarantee construction accuracy, and inapplicability, and achieve improved construction efficiency, compact structure, and avoidance of shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

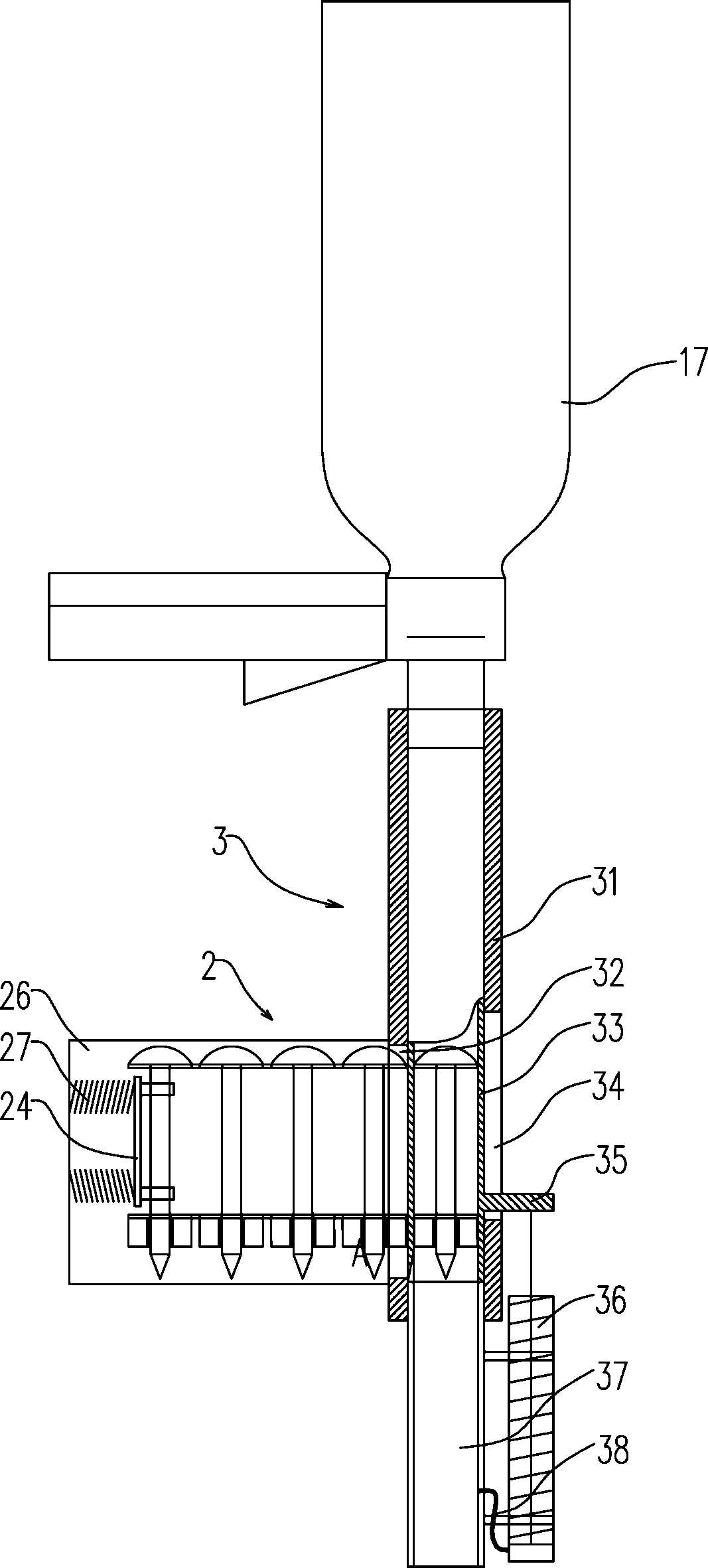

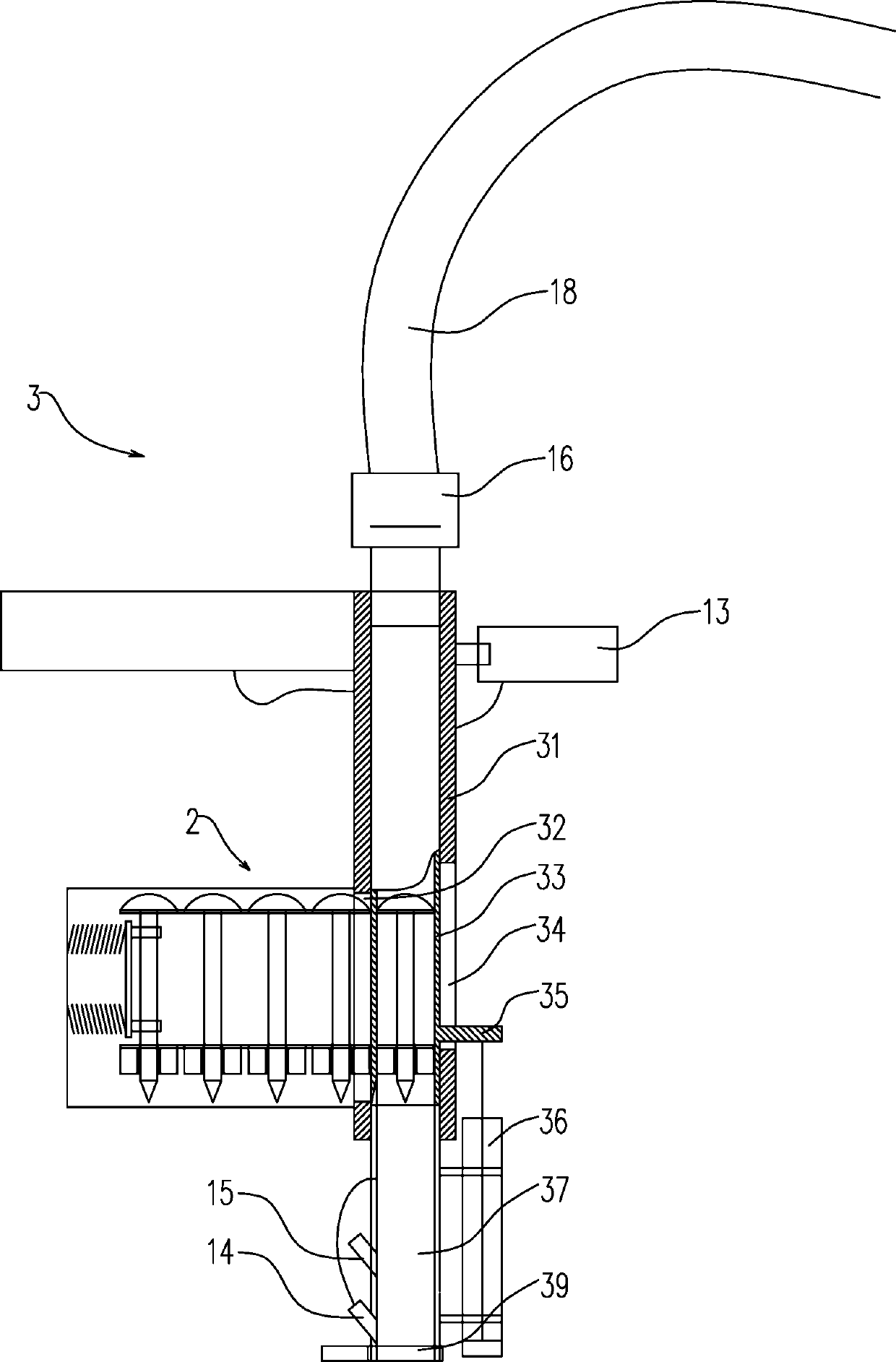

[0036] Such as Figure 1~2 Among them, a fast construction device for wall decorative panels, including nails 2 and nail guns 3;

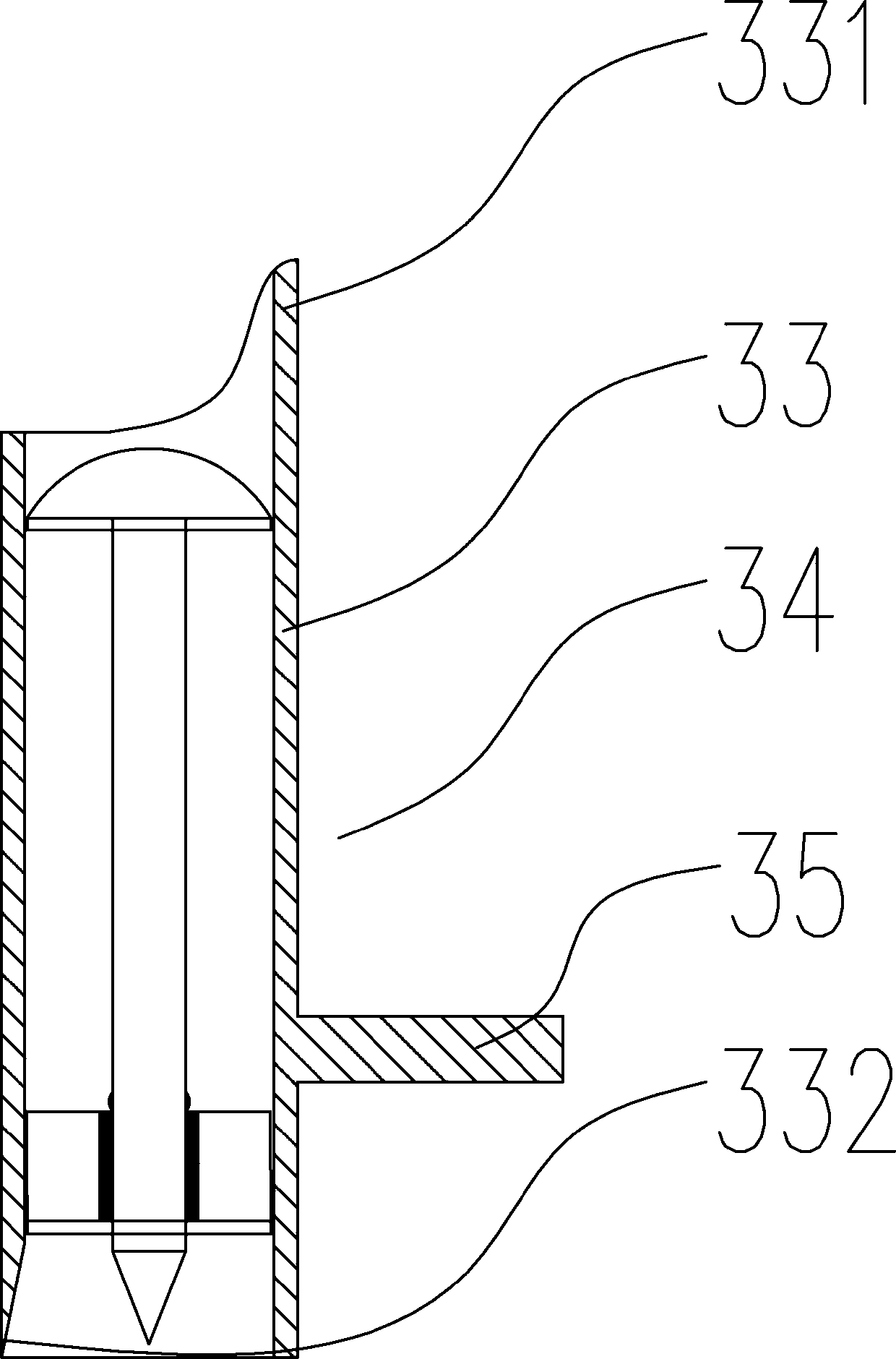

[0037] Among the described nails 2 , one end of the nail post 22 of the nail 2 is provided with a nail cap 21 , and the end away from the nail cap 21 is provided with a slidable sleeve 101 . Corresponding wing plate 102; in the initial state, the wing plate 102 and the nail cap 21 are used as a guiding structure, when the nail 2 is driven into the wall 5, the sleeve 101 is close to the nail cap 21, the end surface of the nail cap 21 and the wing plate 102 constitutes a structure for limiting the corners of the decorative board 6 , thereby fixing the decorative board 6 .

[0038] In the described nail gun 3, the outer sleeve 31 is fixedly connected to the inner sleeve 37, a nail inlet 32 is provided on one side of the outer sleeve 31, and a chute 34 is also provided on the outer wall of the outer sleeve 31;

[0039] The sliding sleeve 33 is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com