A Beam Segment Sliding Device Applicable to Curved Beams

A technology of sliding device and beam section, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems such as oil leakage, single applicable working conditions, and difficult control of pulling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

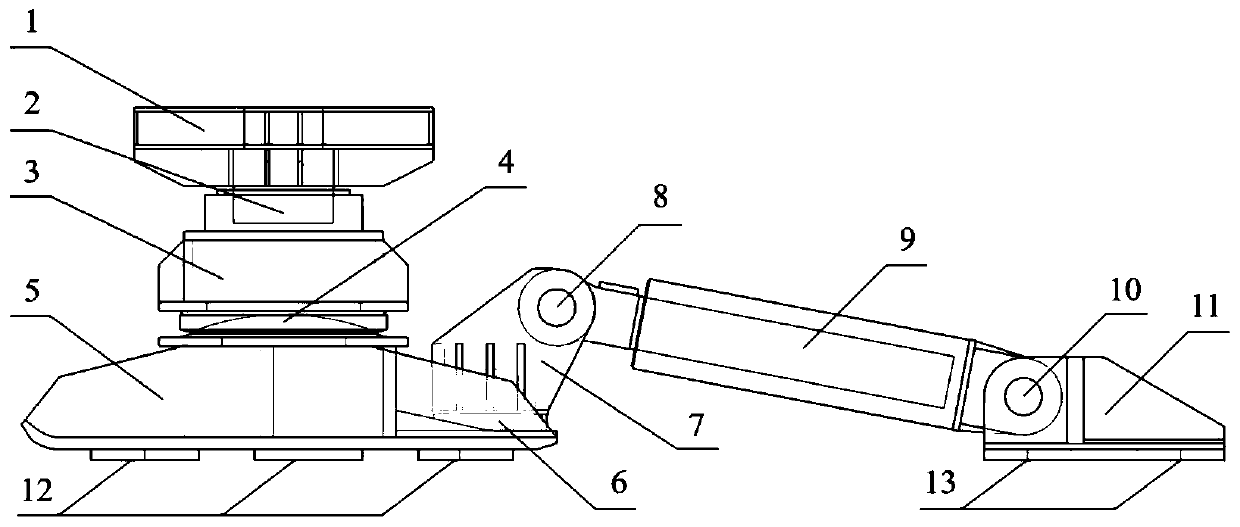

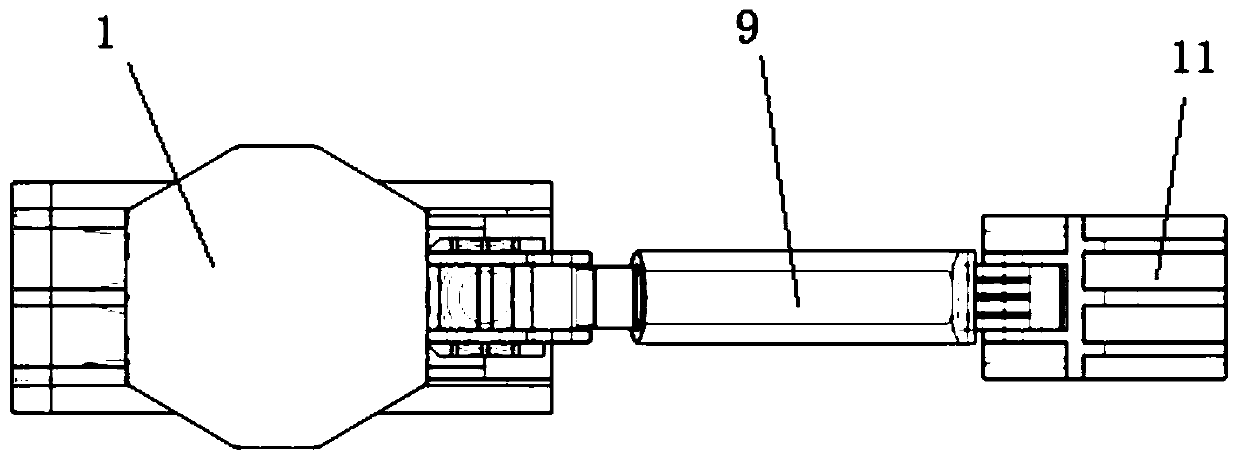

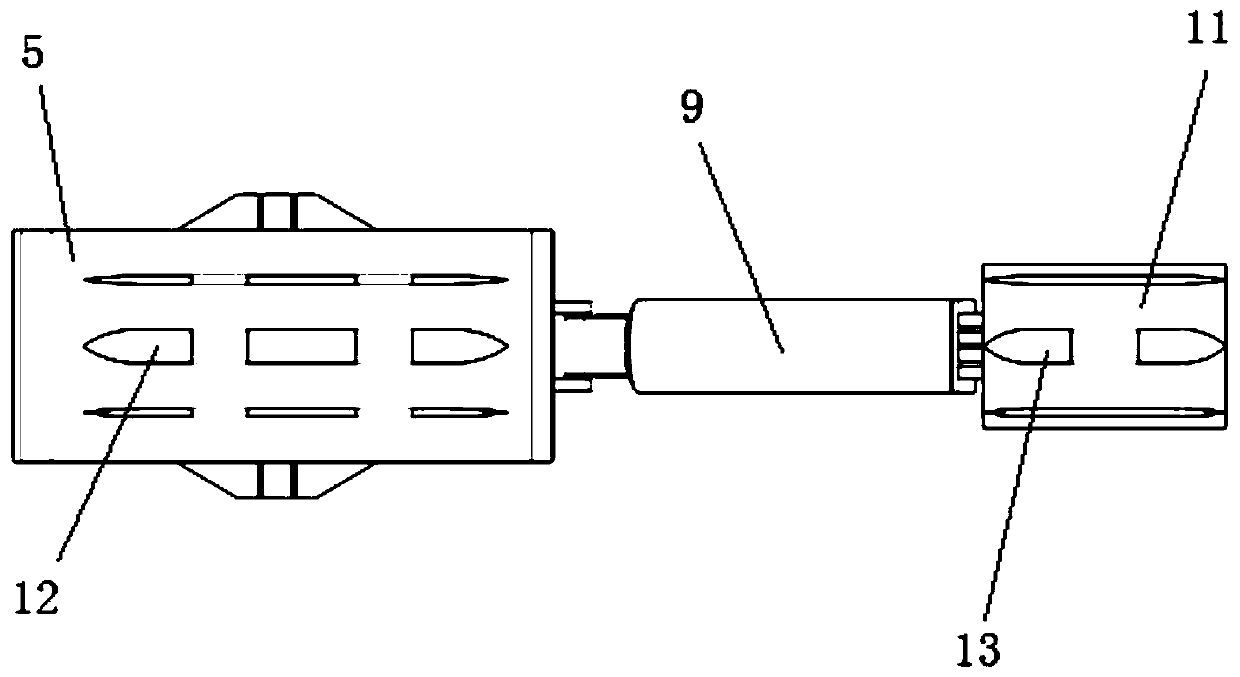

[0035] A beam section sliding device suitable for curved beams, see Figure 1-Figure 6 As shown, it includes the upper bearing platform 1 for supporting the upper bridge segment, the jacking jack 2, the middle support platform 3, the fine-tuning spherical steering wheel 4, the lower sliding shoe 5, the sliding shoe steering wheel 6, the sliding shoe fixing frame 7, Jack front pin shaft 8, promote jack 9, jack tail pin shaft 10, tail slider 11, front slider guide block 12, tail slider guide block 13.

[0036] Among them, the front sliding shoe guide block 12 is welded directly below the lower sliding shoe 5, and the fine-tuning spherical steering wheel 4 is arranged directly above the lower sliding shoe 5; type groove, and buckle on the top of the fine-tuning spherical steering wheel 4, the fine-tuning spherical steering wheel 4 and the middle support platform 3 can cooperate to form a steering structure, which can be adapted to steering in various directions, see Figure 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com