A joint hinge device suitable for automatic construction of constrained concrete arch frames

A technology of confining concrete and hinged joints, which is applied to shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of inability to carry out automatic construction, high construction cost, and long construction period, so as to realize automatic construction, reduce construction cost, shorten The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

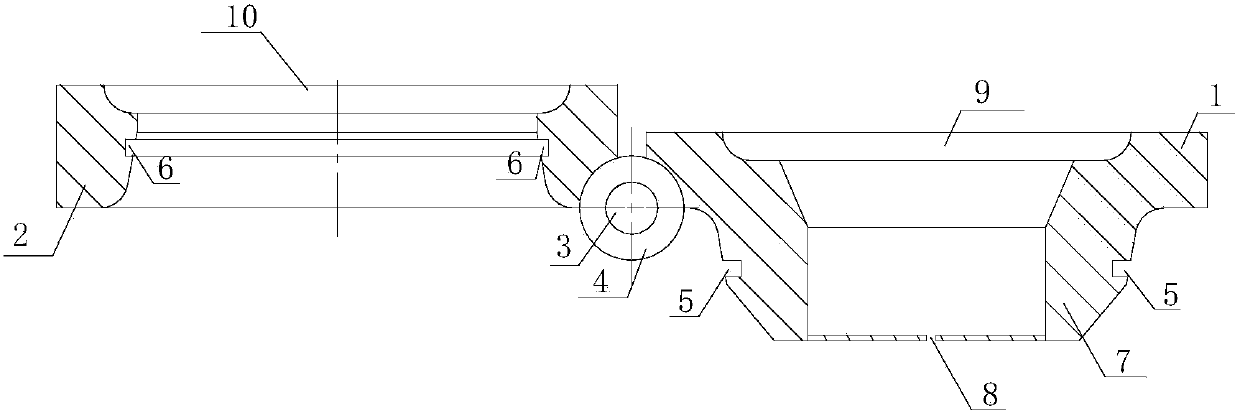

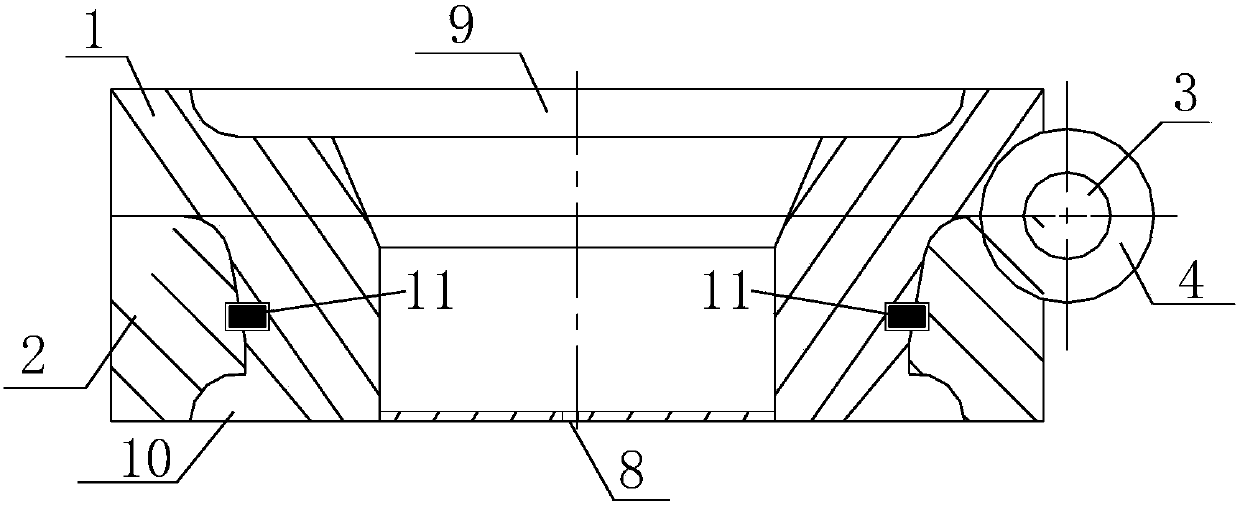

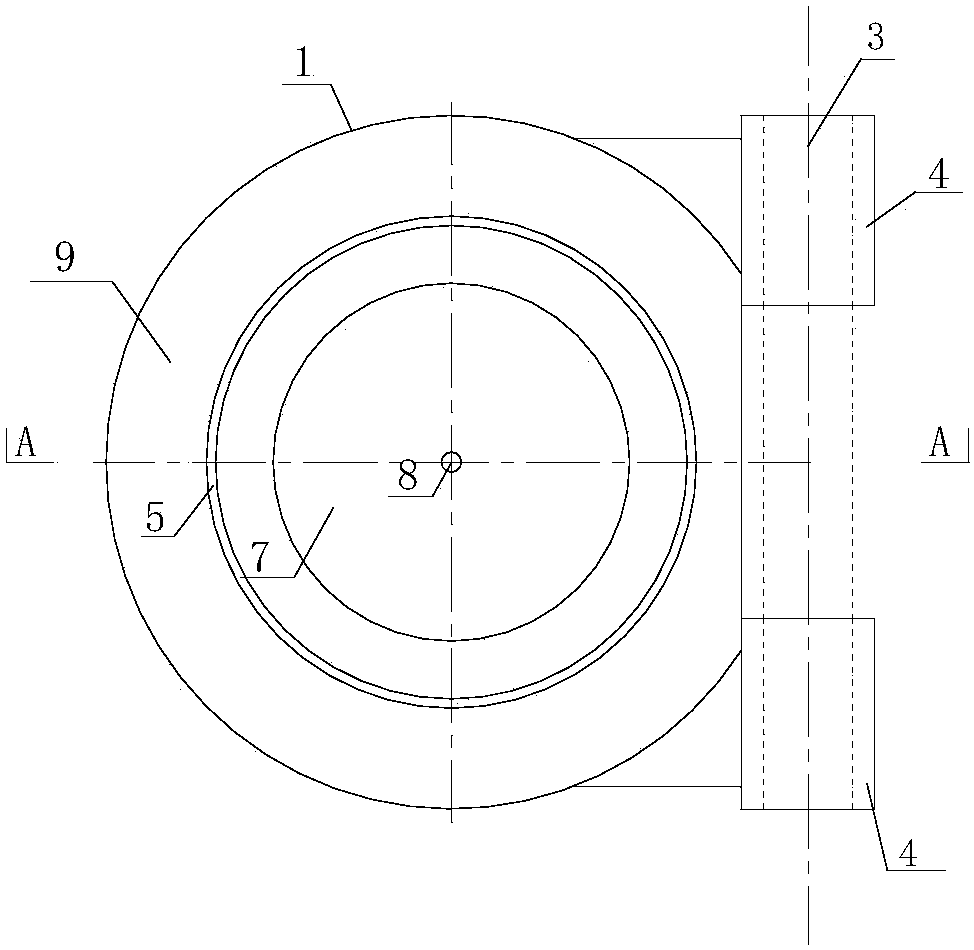

[0036] Such as figure 1 As shown in the figure, it is suitable for the hinge device of restrained concrete automatic construction node, which is composed of hinge buckle 1, hinge groove 2 and hinge shaft 3, and card slots are distributed in hinge buckle 1 and hinge groove 2. Install the circlip 11.

[0037] The hinged buckle 1 is provided with two hinged sleeves 4 , and the hinged slot 2 is provided with a hinged sleeve 4 , and the hinged buckle 1 is connected with the hinged slot 2 via the hinged shaft 3 .

[0038] The hinge buckle 1 and the hinge groove 2 rotate about the hinge axis 3, and the rotation angle is 0-360°.

[0039] The node hinge shaft can be taken out from the hinge sleeve 4.

[0040] The bottom of the hinged buckle 1 is provided with a truncated convex cavity 7 , the upper bottom surface of the truncated convex cavity 7 is closed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com