Advanced supporting structure spliced by adopting corrugated steel pipe sheets and advanced supporting method

A technology of corrugated steel pipe and advanced support, which is applied in mining equipment, shaft equipment, earthwork drilling and mining, etc., can solve the problems of inability to realize assembly construction, low construction efficiency, and complicated construction, and achieve high construction efficiency, fast construction, and The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

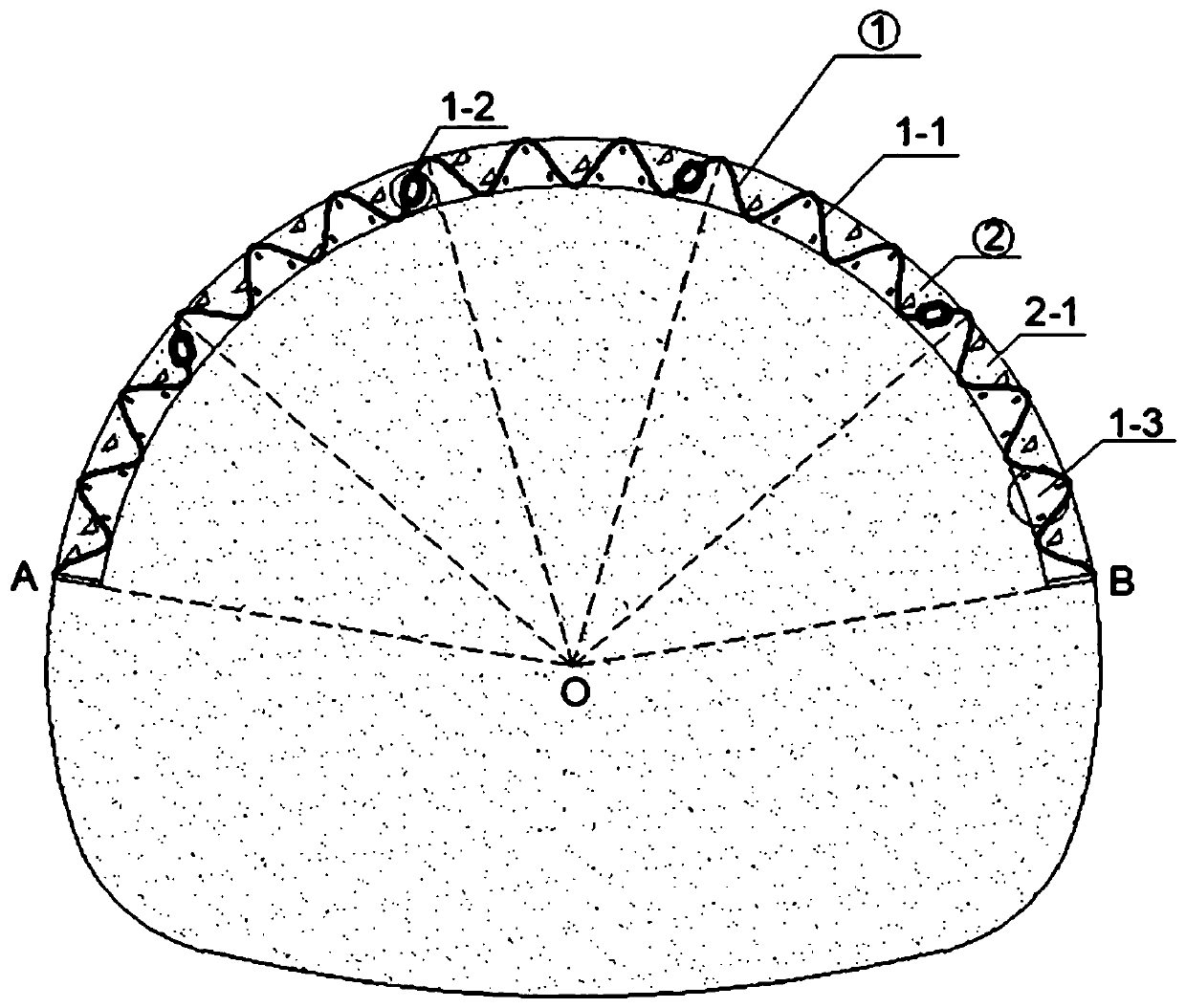

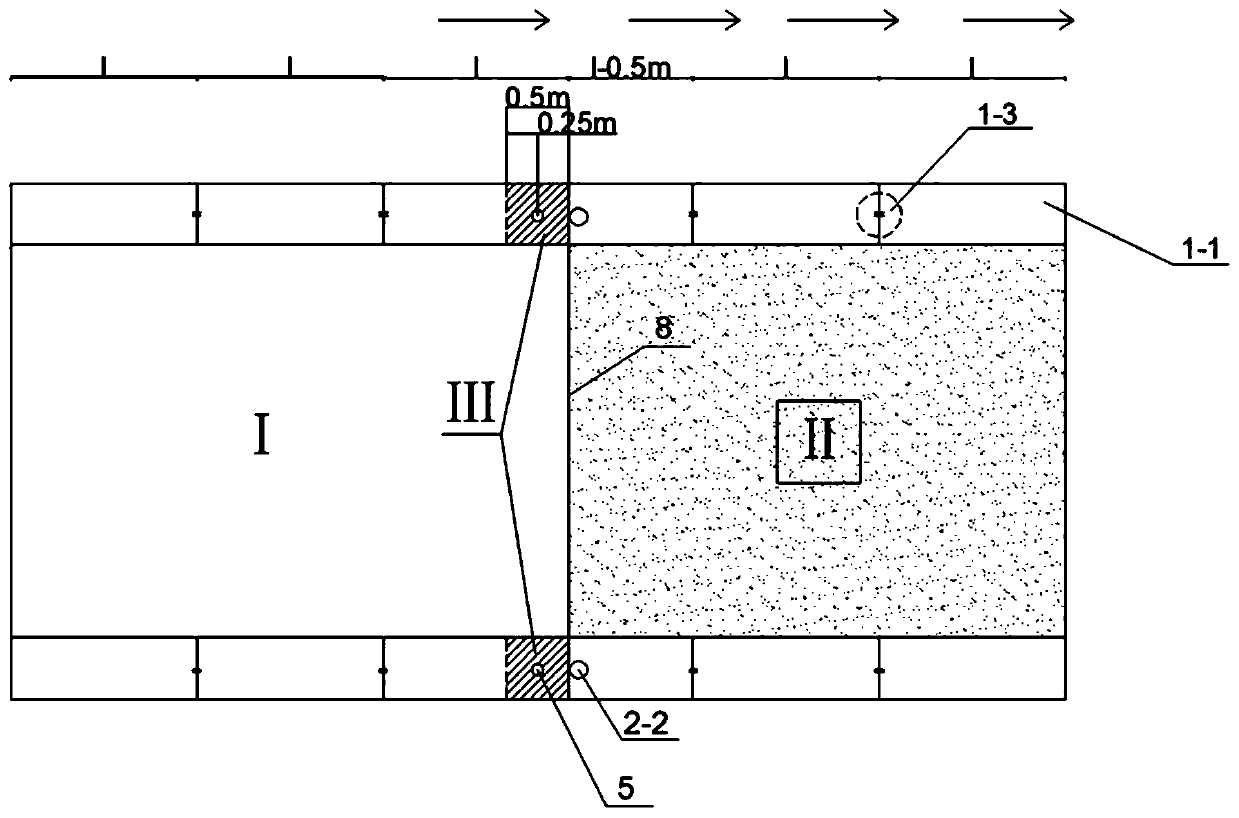

[0044] Such as figure 1 As shown, in this implementation case, an advanced support structure assembled by corrugated steel pipe sheets is used. Through the composite structure composed of corrugated steel pipe sheets and grouting body, the high strength of corrugated steel corrugated structure support is fully utilized. The method makes the corrugated steel and the surrounding rock form a continuous whole. Through assembly construction, the construction efficiency is greatly improved, thereby controlling the deformation of surrounding rock caused by tunnel excavation, and ensuring the stability of the excavation surface during tunnel excavation.

[0045] The composite structure mainly includes: a corrugated steel assembly module 1 and a grouting body 2 .

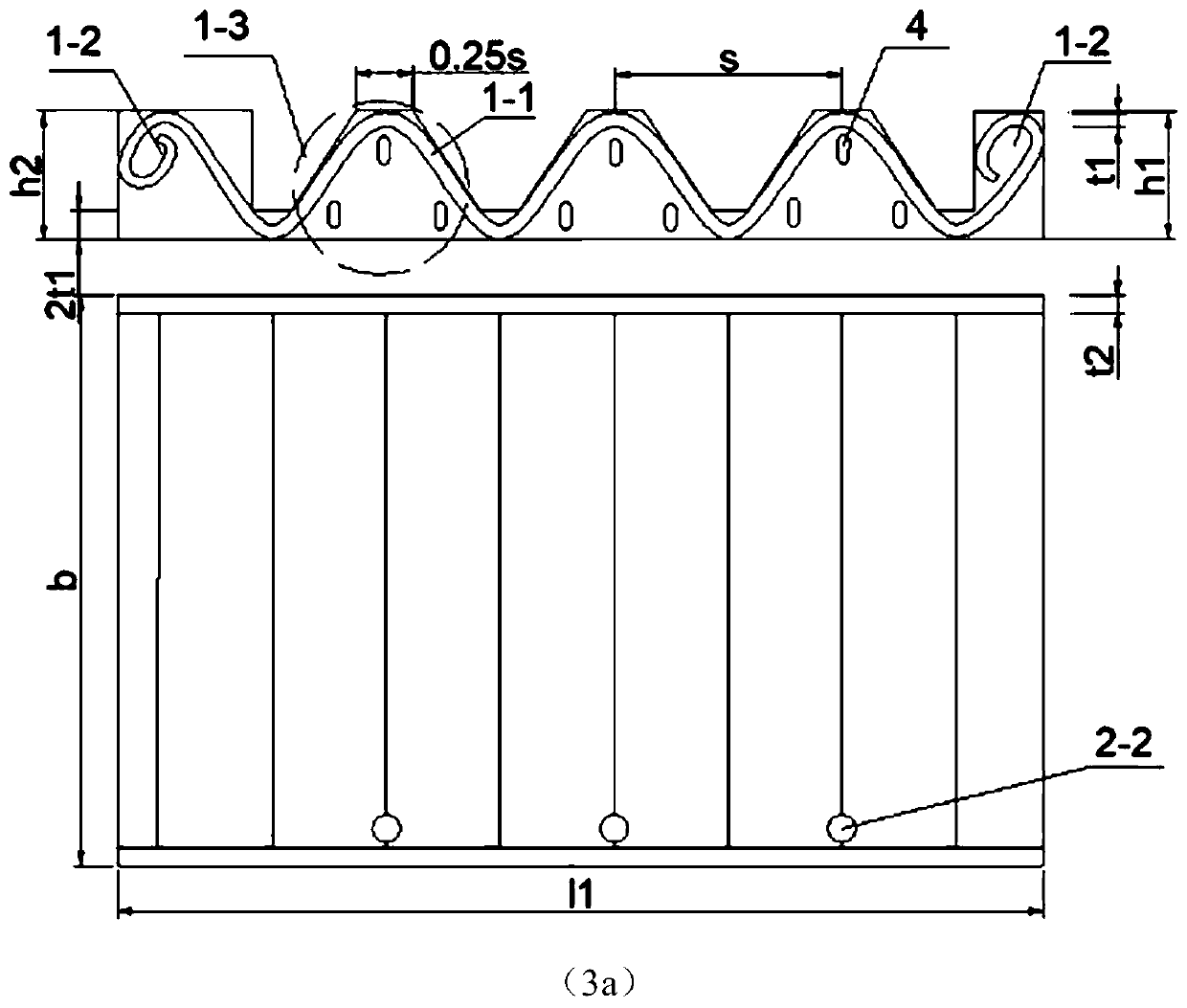

[0046] The corrugated steel assembly module 1 is formed by assembling and connecting prefabricated corrugated steel pipe sheets 1-1 through circumferential joints 1-2 and longitudinal joints 1-3. The advance support struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com