Light concrete cast-in-place robot

A light-weight concrete and robot technology, applied in construction, building structure, and building material processing, can solve problems such as low technical content, large machinery, and limited precision, and achieve high flexibility and precision, and construction rhythm Compact, highly mechanized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

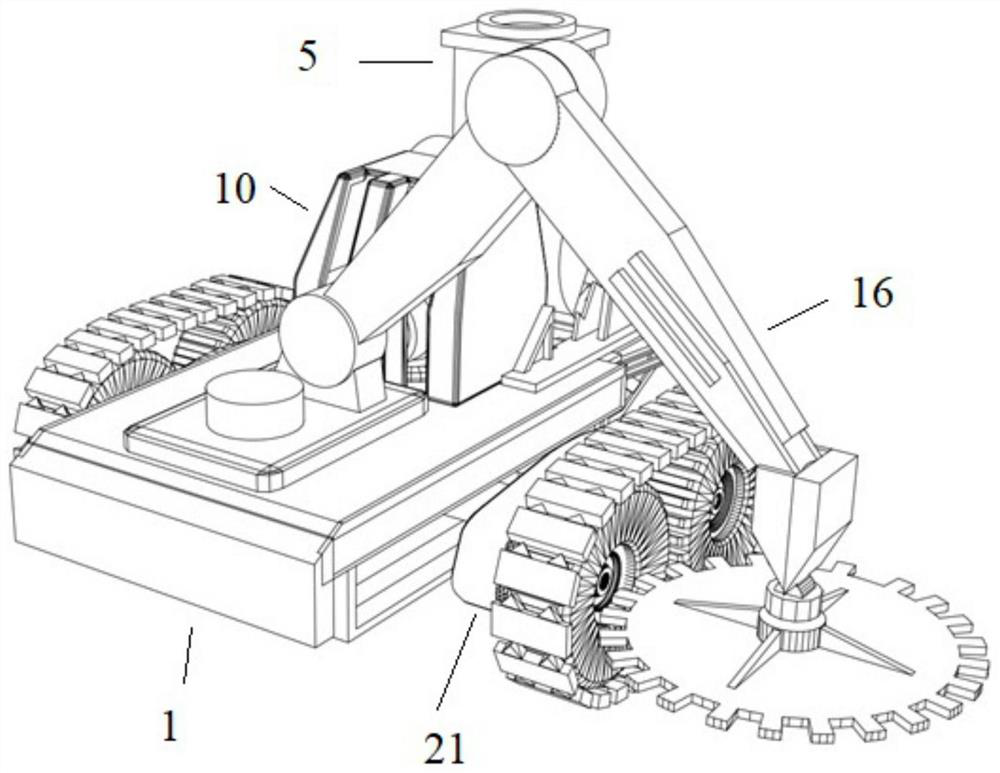

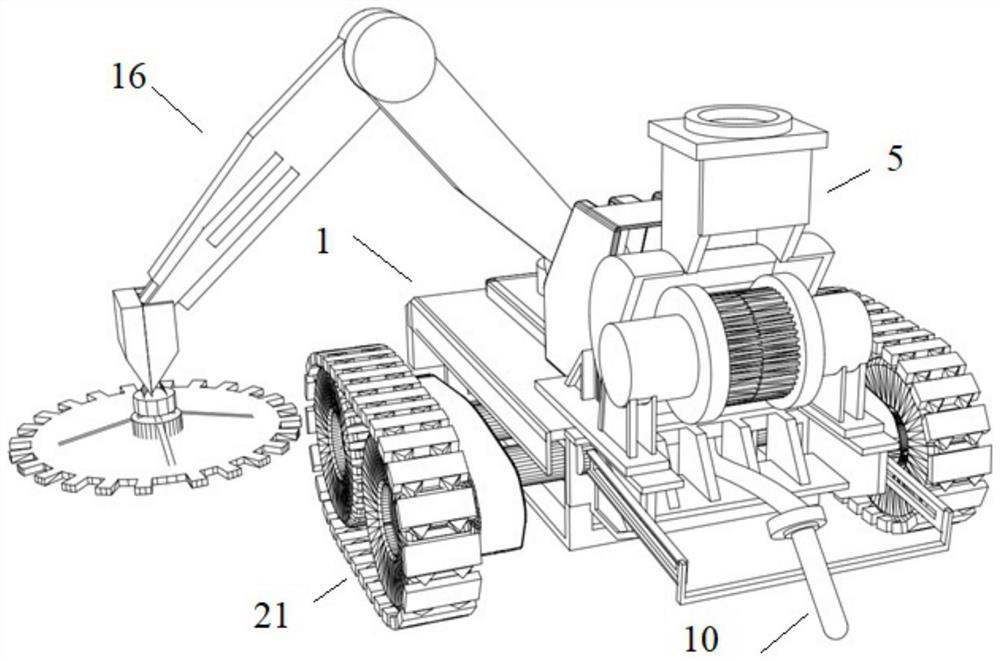

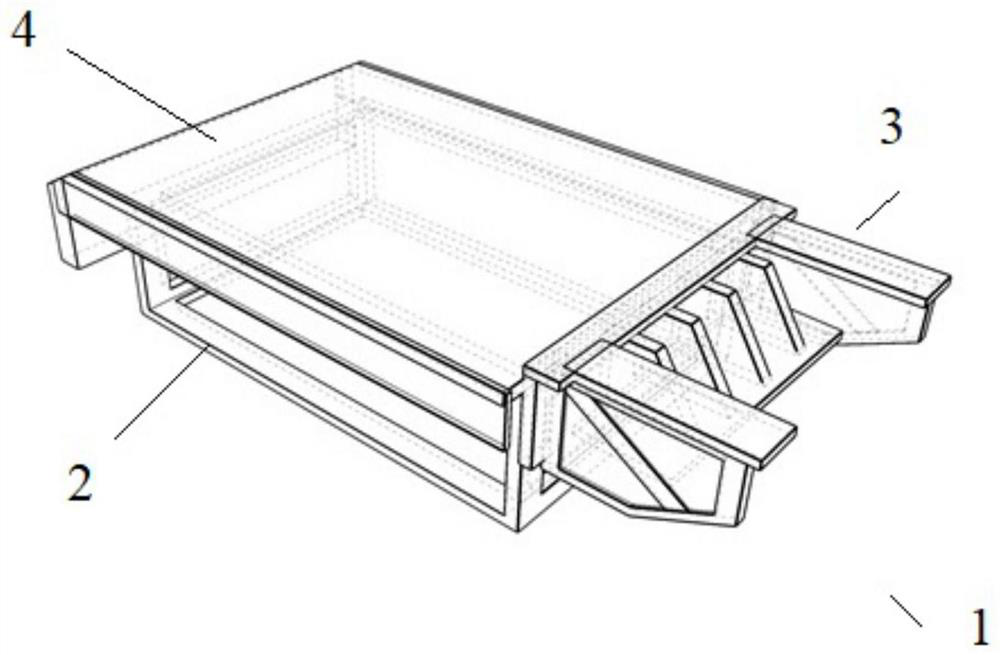

[0047] like figure 1 , 2 As shown, a light-duty concrete cast-in-place robot, the cast-in-place robot includes a vehicle body 1, a motion system 21, a blanking system 5, a vibrating system 10, a plastering system 16 and a motor system 21, a blanking system 5, and a vibrating system respectively. 10 and the plastering system 16 are electrically connected to the control system, the motion system 21 is arranged at the bottom of the vehicle body 1, the unloading system 5, the vibrating system 10 and the plastering system 16 are all arranged on the vehicle body 1, and the unloading system 5 includes a concrete The lower material cylinder 6 of the channel, the bottom of the lower material cylinder 6 is provided with a concrete discharge port 601 opening to the rear of the vehicle body 1, the vibrating system 10 includes a vibrating rod 11 that can be lifted and positioned at the rear of the vehicle body 1, and the plastering system 16 includes a The multi-degree-of-freedom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com