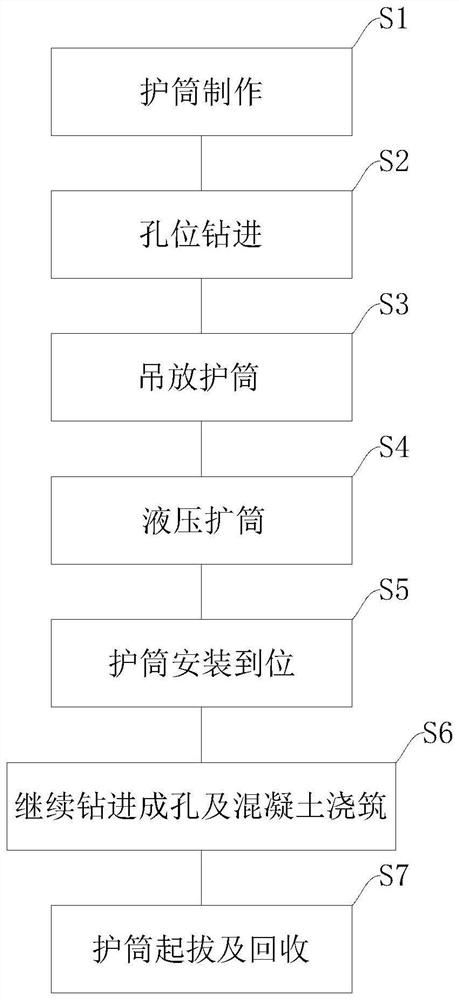

Improvement method for mounting process of long pile casing of cast-in-situ bored pile

A technology of bored piles and installation technology, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of serious noise pollution of vibration equipment, hole collapse in weak ground, disturbance of surrounding ground, etc., to avoid adverse effects, Fast installation, high applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

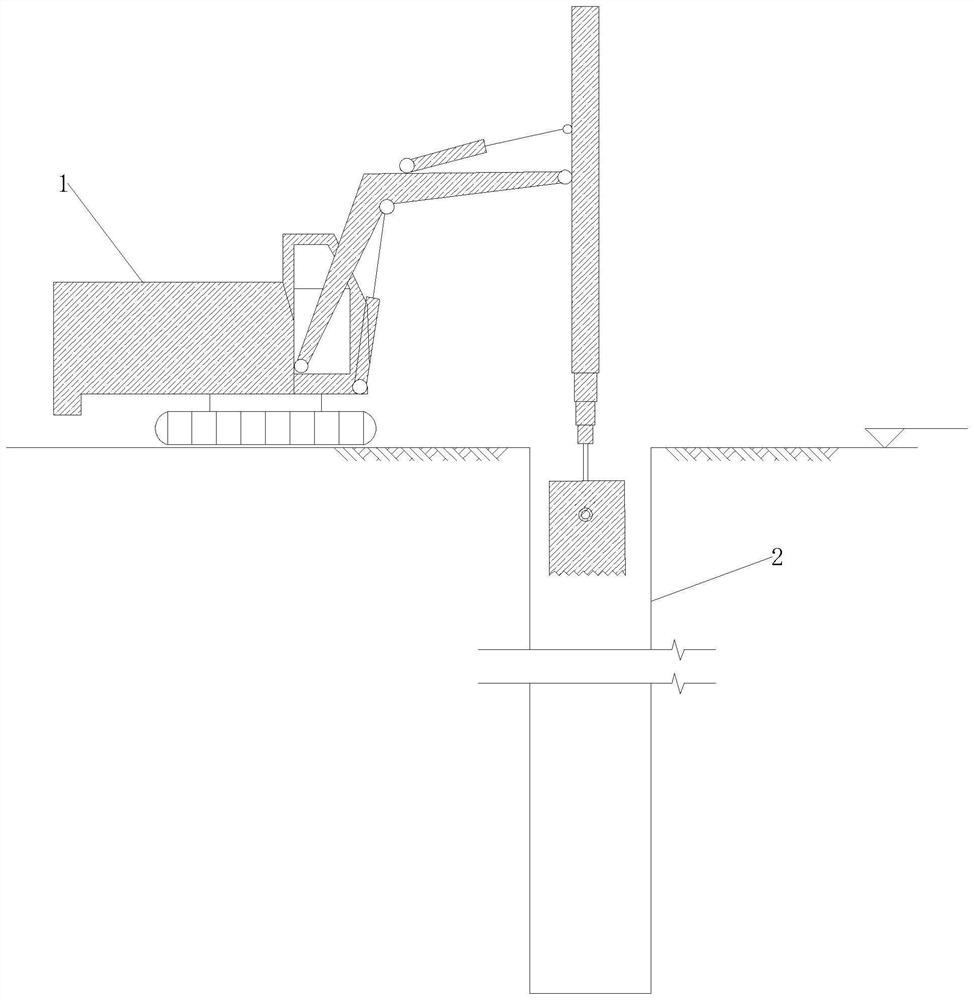

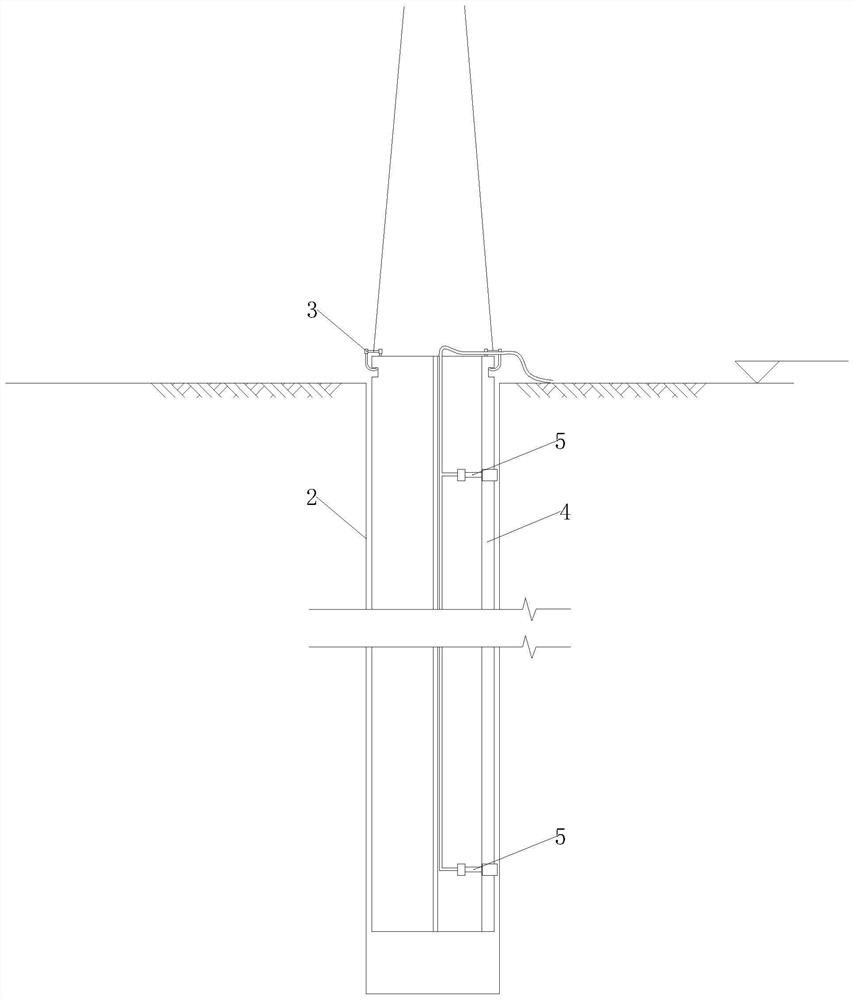

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0041] It should be noted that the terms "comprising" and "having" and any variations thereof in the description and claims of the present invention are intended to cover non-exclusive inclusion. For example, a process, method, system, product or device comprising a series of steps or units is not limited to the listed steps or units, but optionally also includes unlisted steps or units, or optionally also includes For other steps or units inherent to these processes, methods, products or devices. Terms such as "arrangement", "connection" and "installation" should be understood in a broad sense, for example, it may be a fixed connection, a detachable connection, or an integral body; it may be a mechanical connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com