Rapid construction system and method for anchor rod holes on side wall of tunneling working face and advance borehole

A technology of excavating working face and advanced drilling, which is applied to drilling equipment and methods, automatic control system of drilling, installation of anchor rods, etc. Pole hole etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

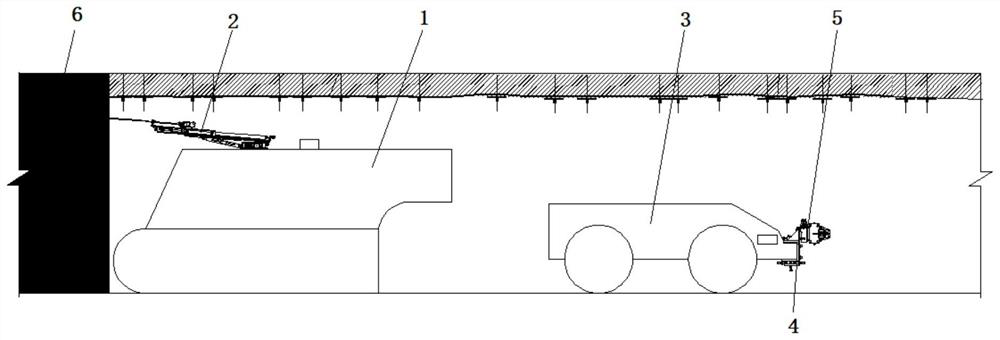

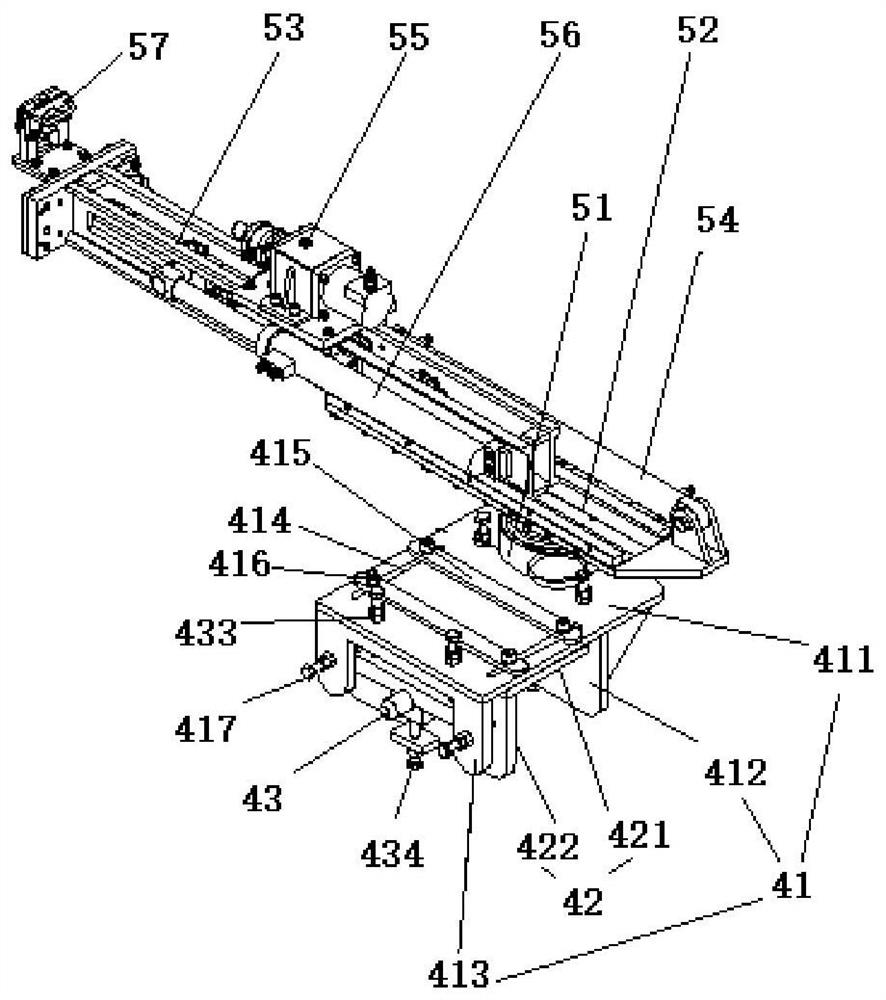

[0082] Such as Figure 1 to Figure 9 As shown, the present embodiment provides a rapid construction system for side rock bolt holes and advanced drilling in the excavation working face, including a bolter 1, an onboard drilling rig 2 arranged on the top platform of the bolter 1, a shuttle car 3, The lower airborne drilling rig 5 and the control system are arranged at the tail of the shuttle car 3 through the limit adjustment device 4; wherein, the upper airborne drilling rig 2 is used for the construction of the upper row of bolt holes and advanced drilling in the roadway of the excavation working face, and the lower machine The drilling rig 5 is used for the construction of the lower row of bolt holes in the two sides of the roadway, and the control system is used for the automatic control of the drilling construction of the drilling rig.

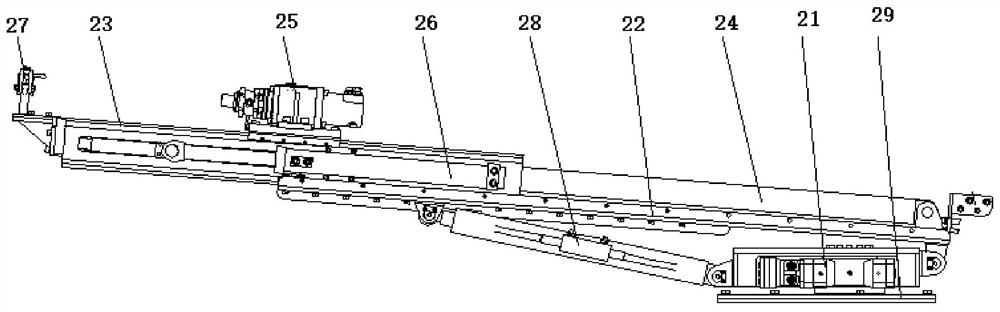

[0083] Such as figure 2 As shown, the upper airborne drilling rig 2 includes: a rotary mechanism A21, a secondary feeding device A22 ar...

Embodiment 2

[0102] This embodiment provides a method for rapid construction of the side rock bolt holes on the excavation working face, the method includes the rapid construction of the upper row of bolt holes on the side of the excavation face by the upper airborne drilling rig and the lower row of anchor rods by the lower airborne drilling rig Hole rapid construction;

[0103] Such as Figure 5 and Figure 6 , the steps of construction of the upper row of bolt holes by the upper airborne drilling rig include:

[0104] A1: Adjust the angle adjustment cylinder group to complete the opening angle positioning of the upper row of bolt holes on the left side of the roadway;

[0105] A2: When the onboard drilling rig is constructing the upper row of bolt holes, the bolt drilling rig that comes with the bolter is also constructing the bolt holes, so select the power control mode of mode 1 for the onboard drilling rig to ensure that the upper The construction of the airborne drilling rig does...

Embodiment 3

[0120] This embodiment provides a rapid construction method for advanced drilling in the excavation working face. The advanced drilling includes a water exploration hole, a regional verification hole and a coal seam water injection hole;

[0121] On C, the airborne drilling rig constructs the excavation work face and explores the water hole and includes the following steps:

[0122] C1: Adjust the angle adjustment oil cylinder group and the slewing mechanism A to complete the positioning of the opening angle of the water hole on the excavation face;

[0123] C2: Since the bolter miner stops construction when the onboard drilling rig is carrying out the construction of the water hole, the efficiency priority mode of mode 2 is selected for the onboard drilling rig to realize the rapid construction of the water hole;

[0124] C3: through mode 2 to control the primary feed cylinder A and the secondary feed cylinder A to realize the two-stage rod drilling of the power head;

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com