Patents

Literature

42results about How to "Increase the cutting width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

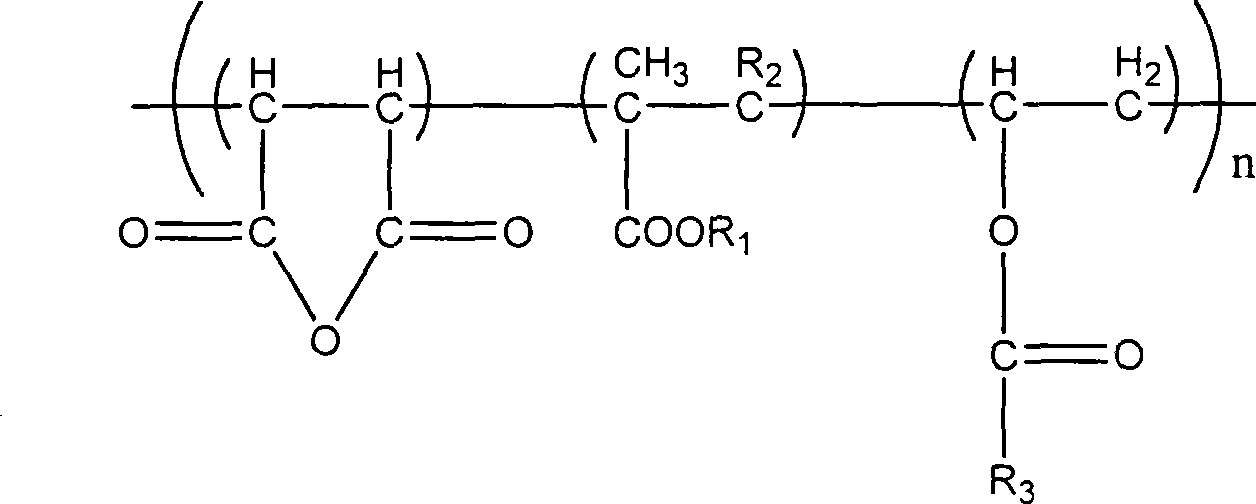

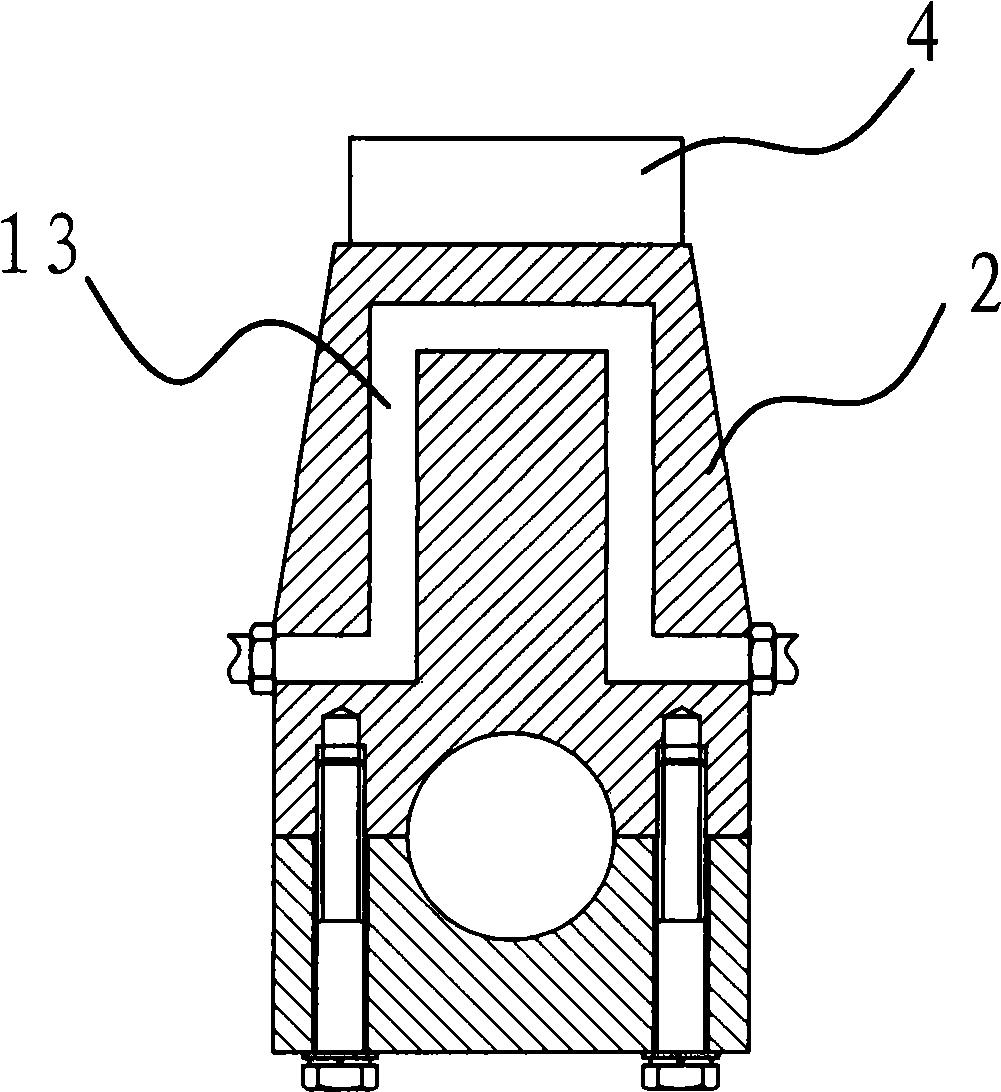

Downhole filter

InactiveUS7188687B2Without complexityWithout expenseDrilling rodsConstructionsParticulatesEngineering

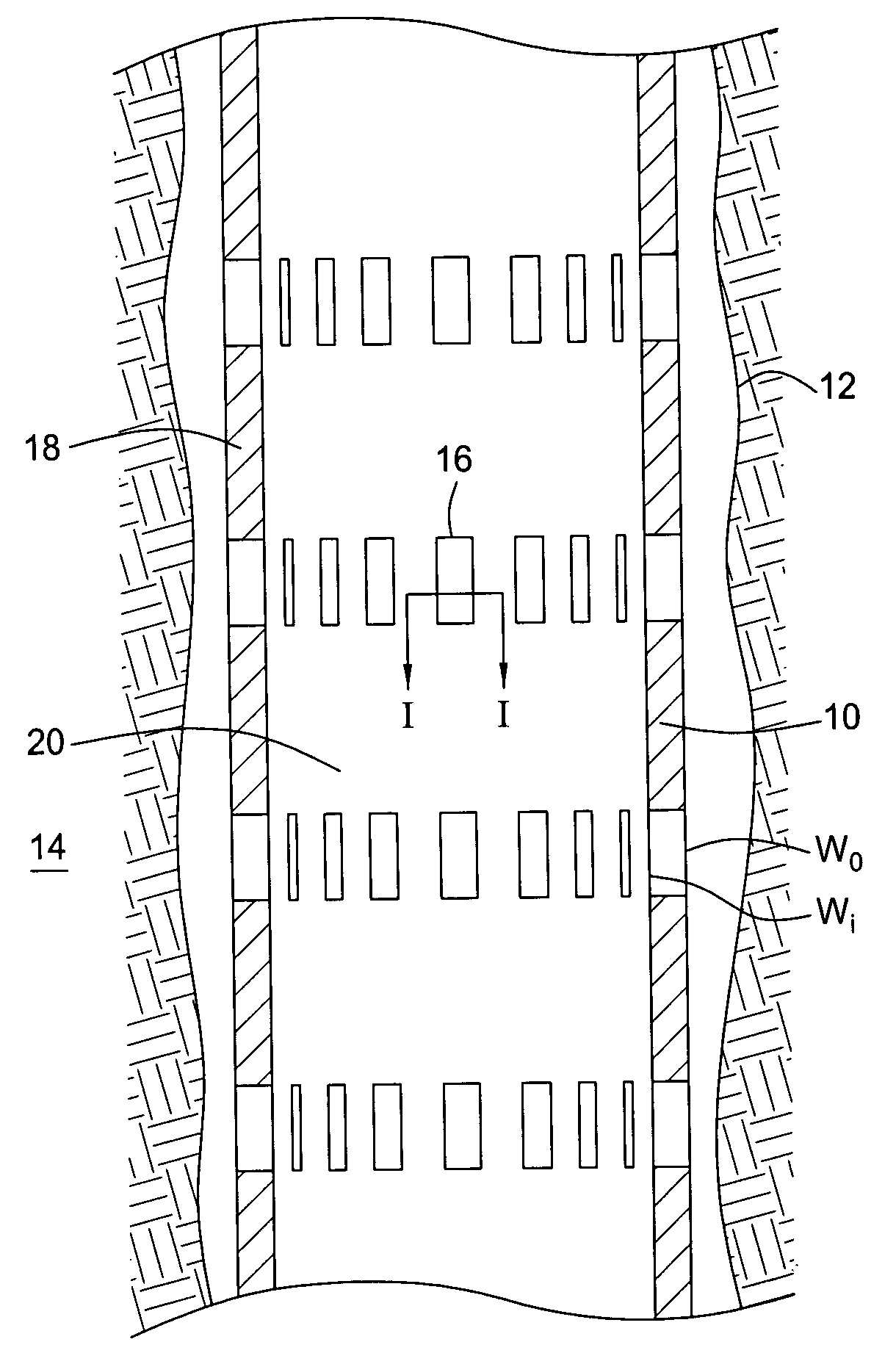

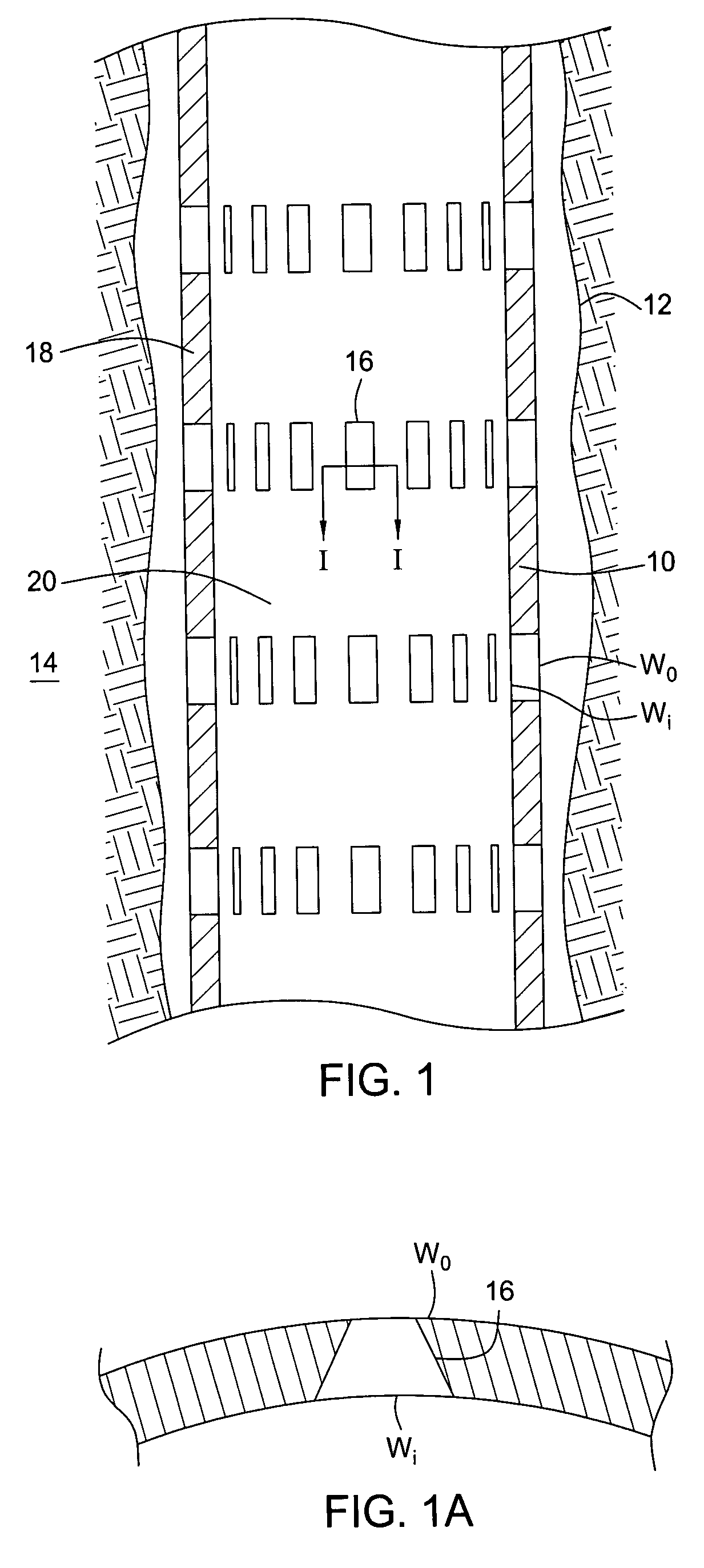

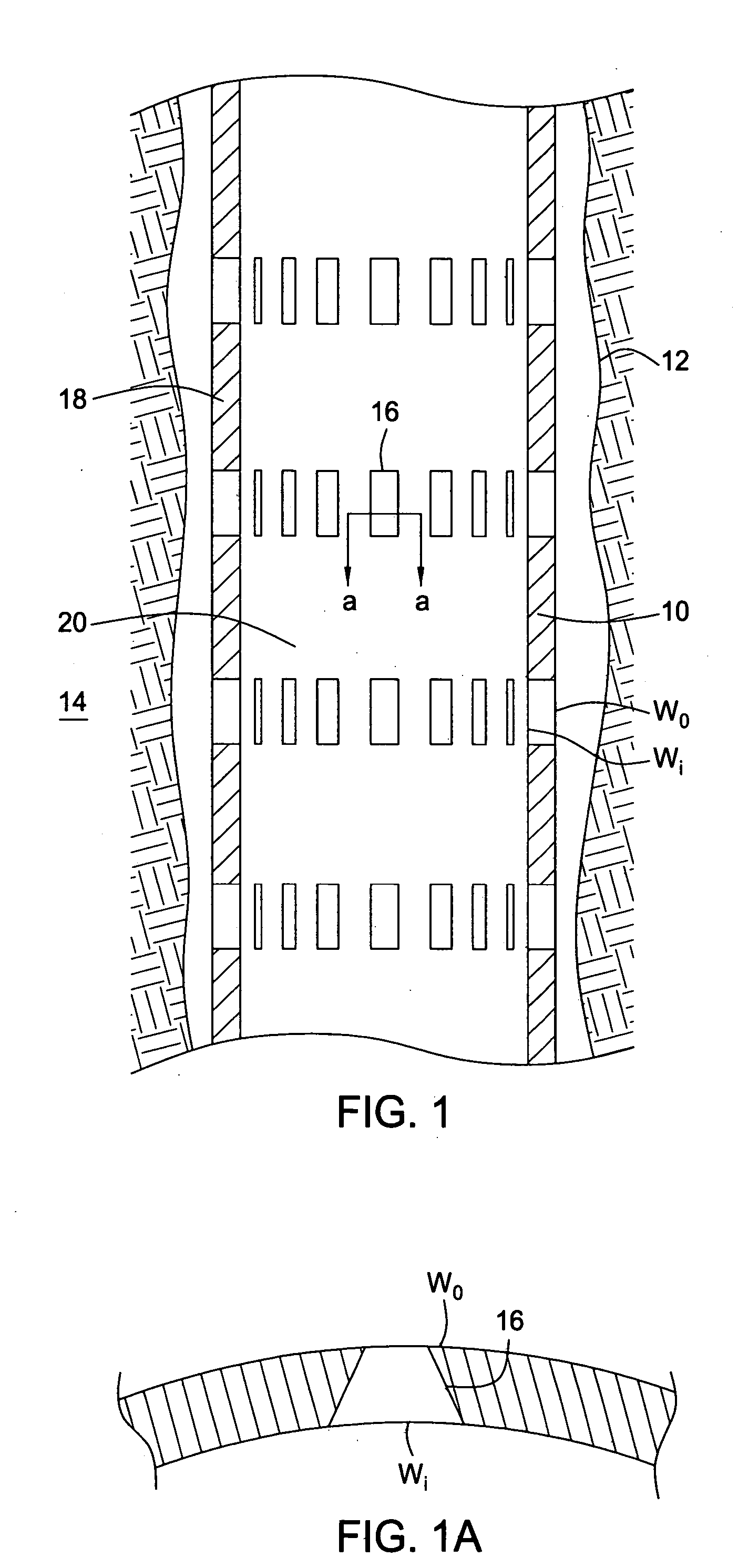

A downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. A method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In another embodiment, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

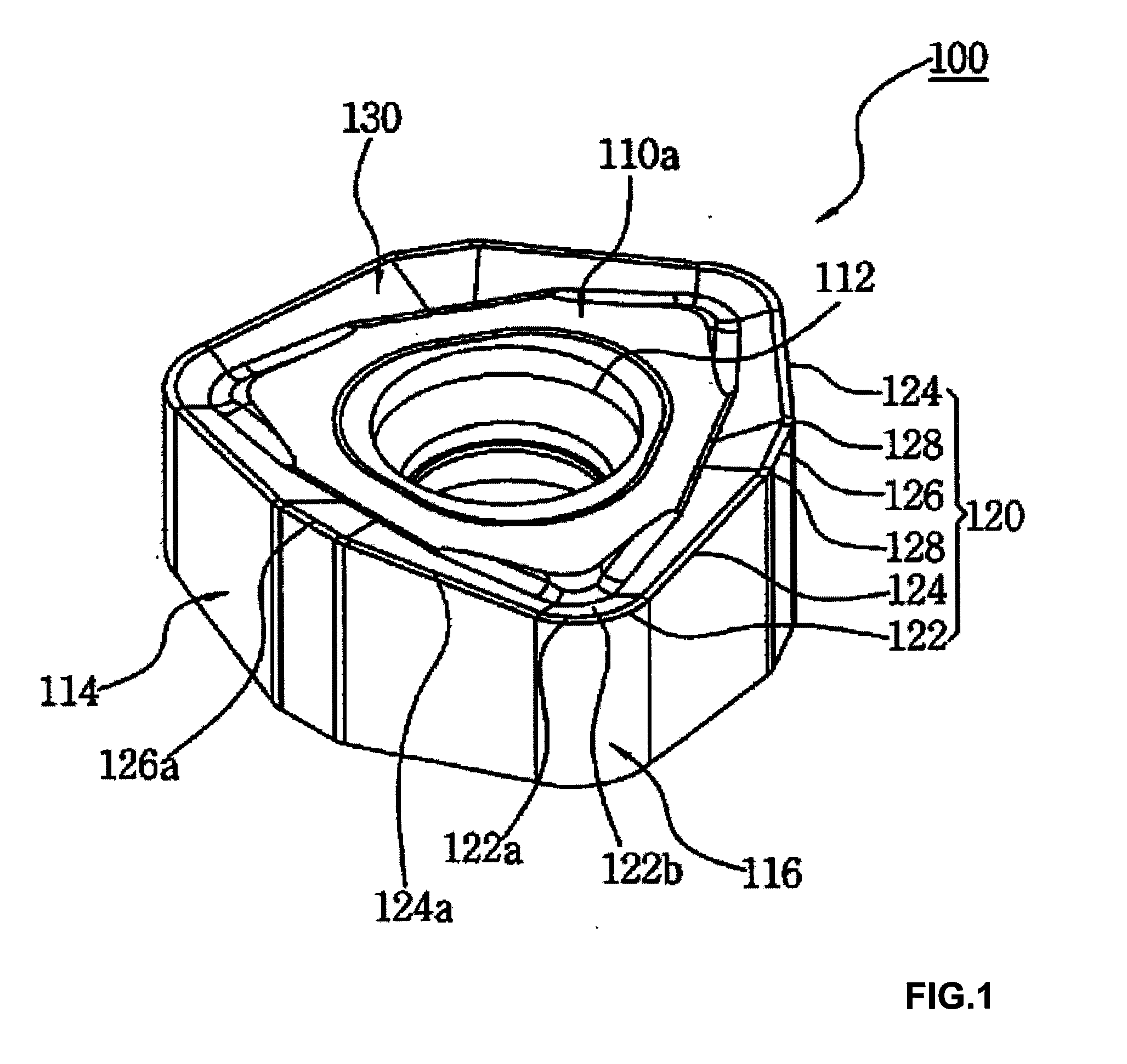

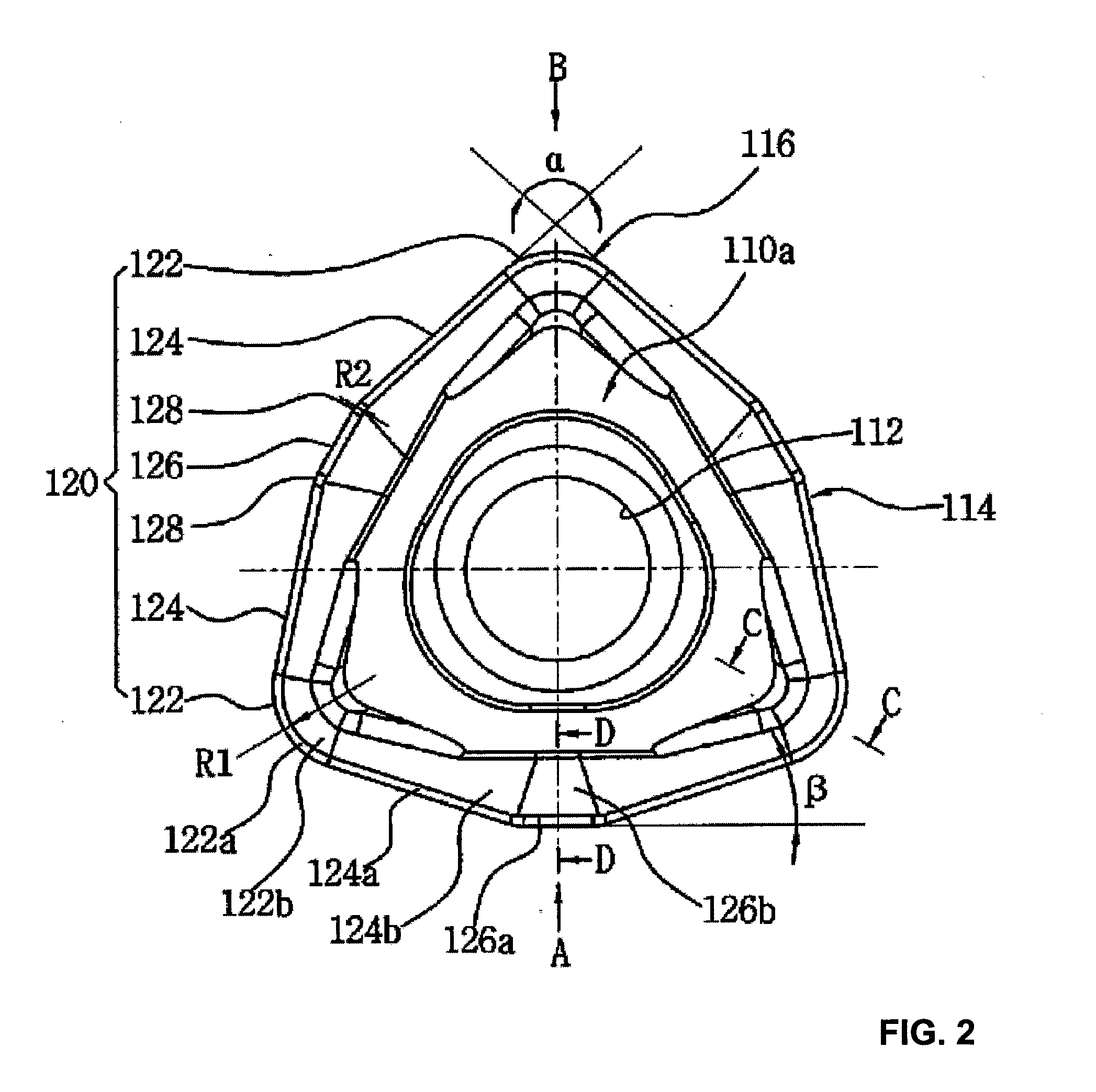

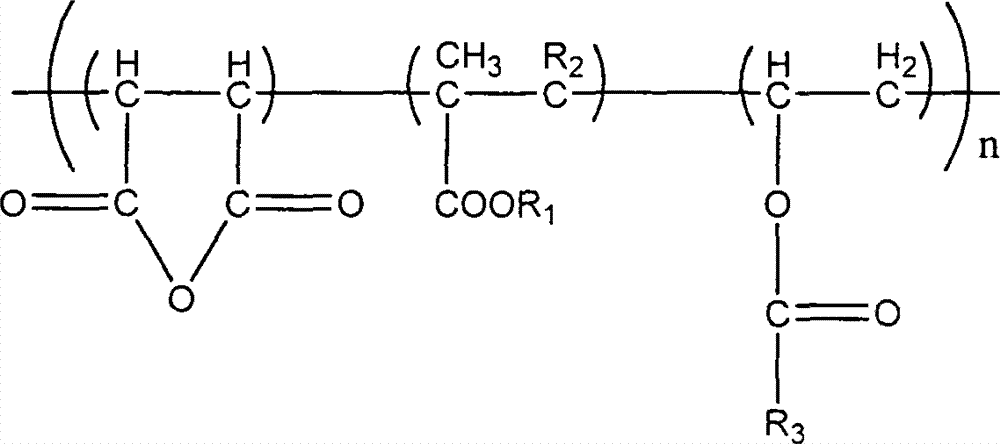

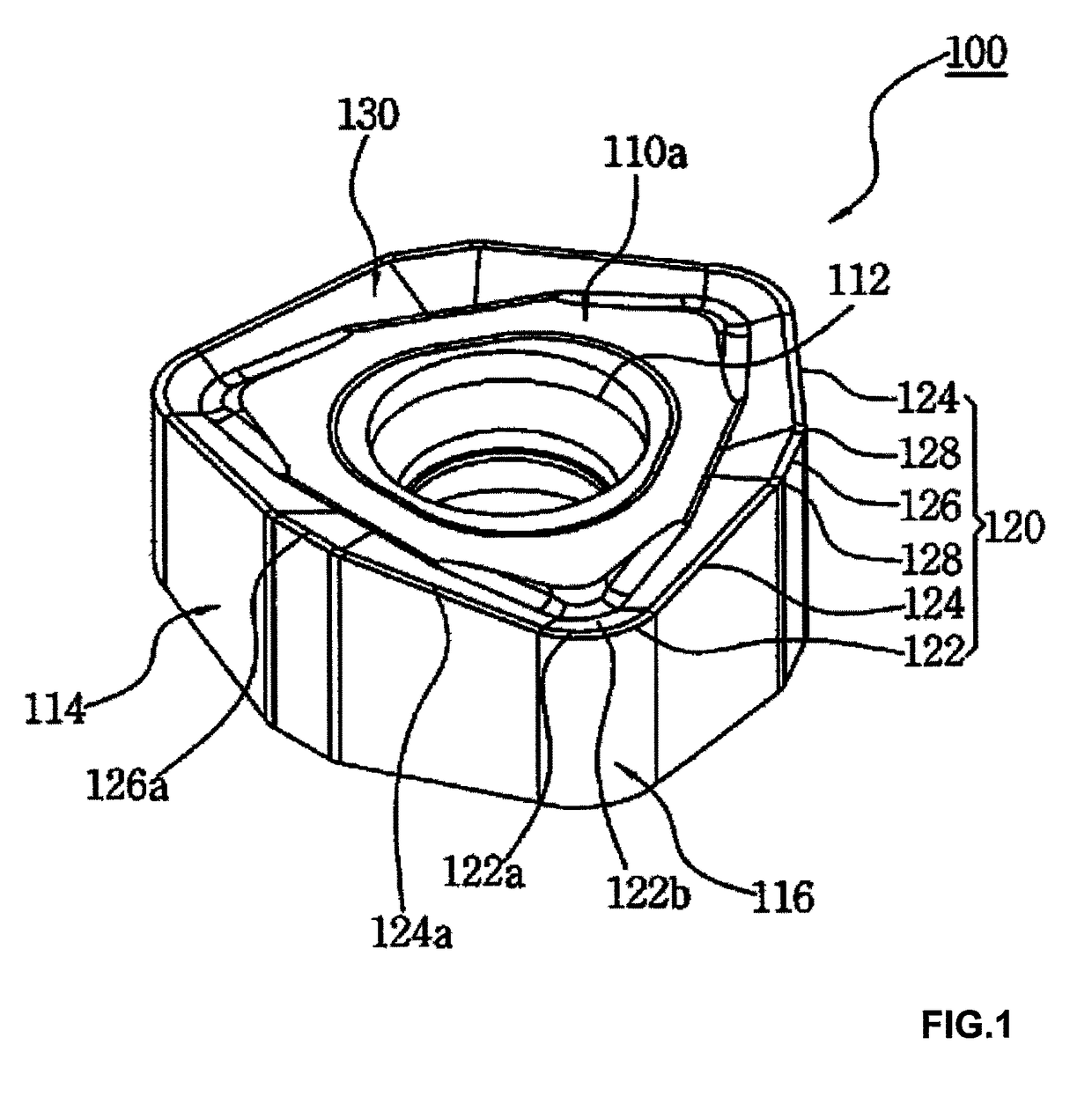

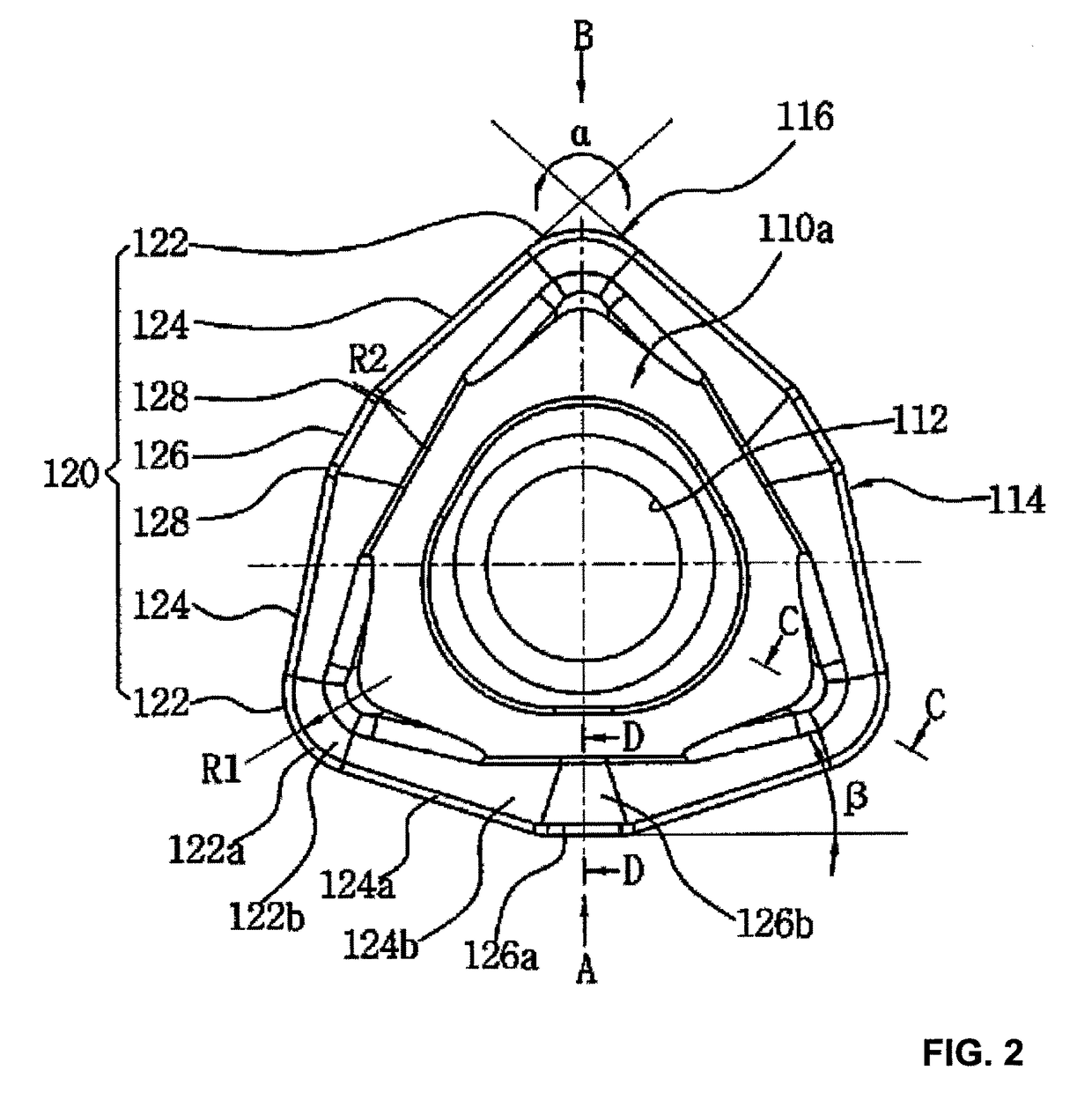

Cutting insert for high-efficient cutting

ActiveUS20100034602A1Increase stiffnessExtended service lifeMilling cuttersCutting insertsEngineeringMechanical engineering

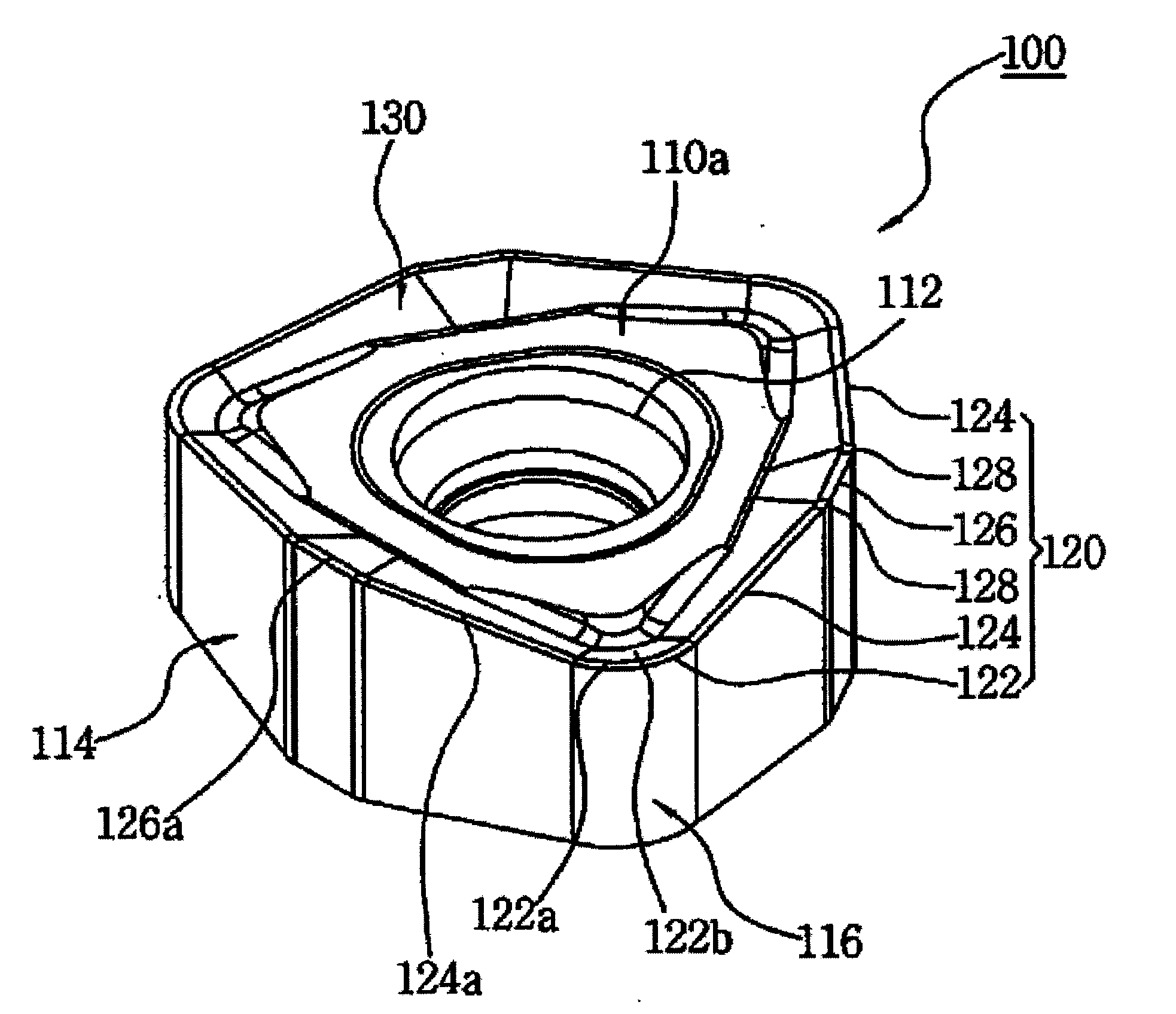

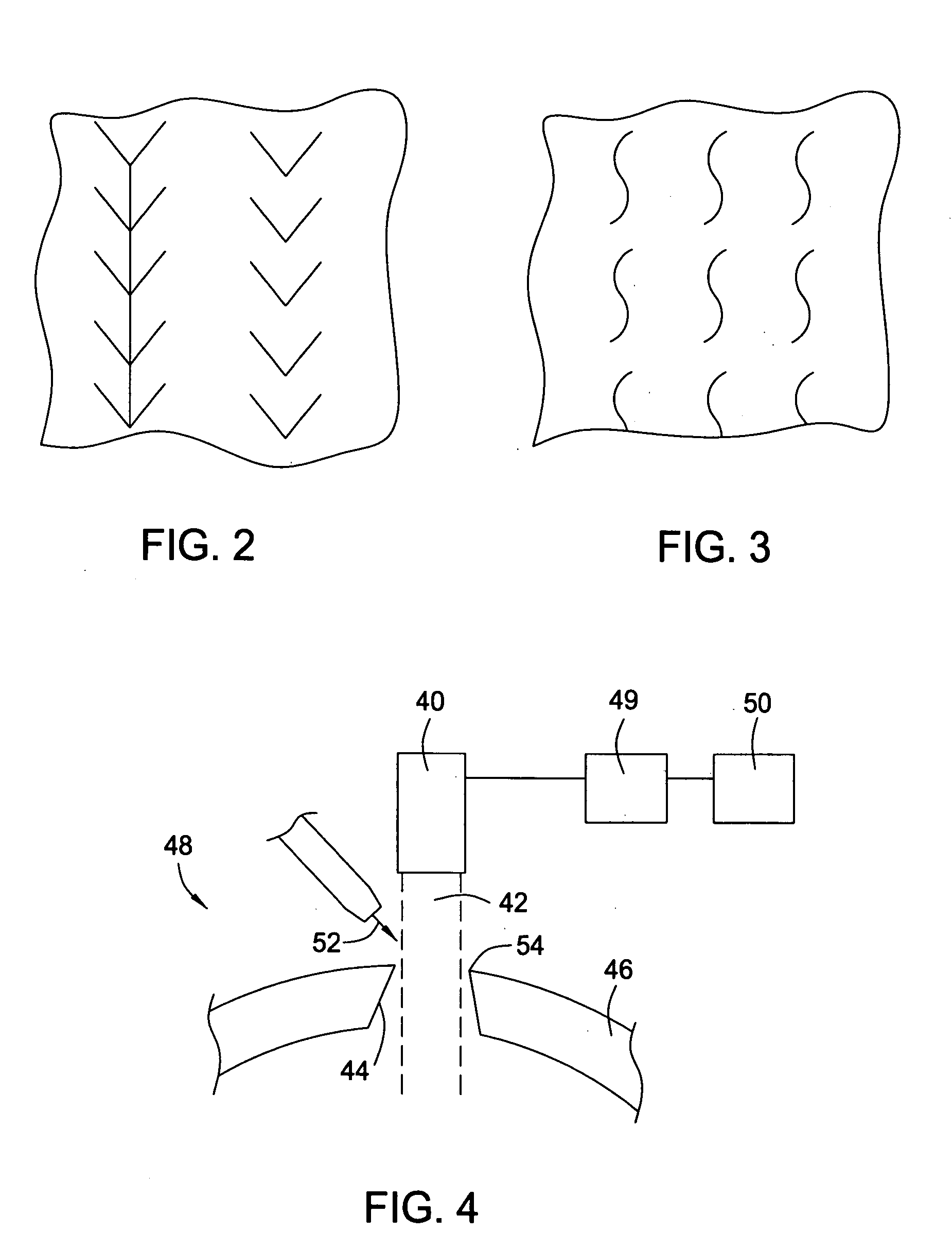

A cutting insert for high-efficiency cutting is disclosed. The cutting insert includes an upper surface (110a), a lower surface (HOb), side surfaces (114) and corner side surfaces (116), which connect the side surfaces to each other. A circular opening is formed through the central portions of the upper and lower surfaces. In the cutting insert, cutting edges are formed by respective junctions between one of the upper and lower surfaces and the side surfaces and between one of the upper and lower surfaces and the corner side surfaces. The cutting edges comprise three corner cutting edges (122), six major cutting edges (124), which extend from opposite ends of the corner cutting edges towards the neighbor corner cutting edges, and three minor cutting edges (126), which are connected between the major cutting edges. Furthermore, the cutting edges may be formed on both the upper surface and the lower surface.

Owner:KORLOY

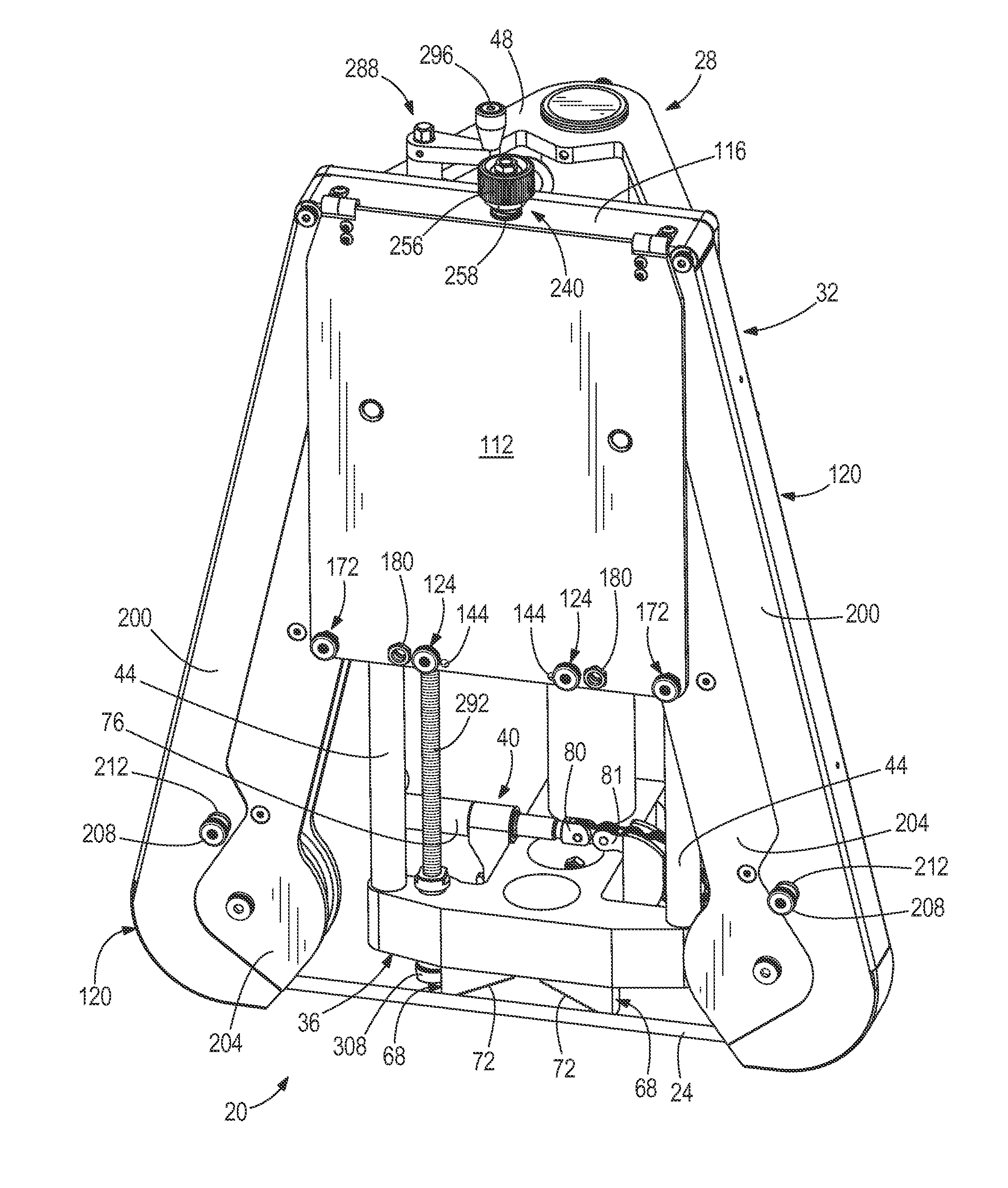

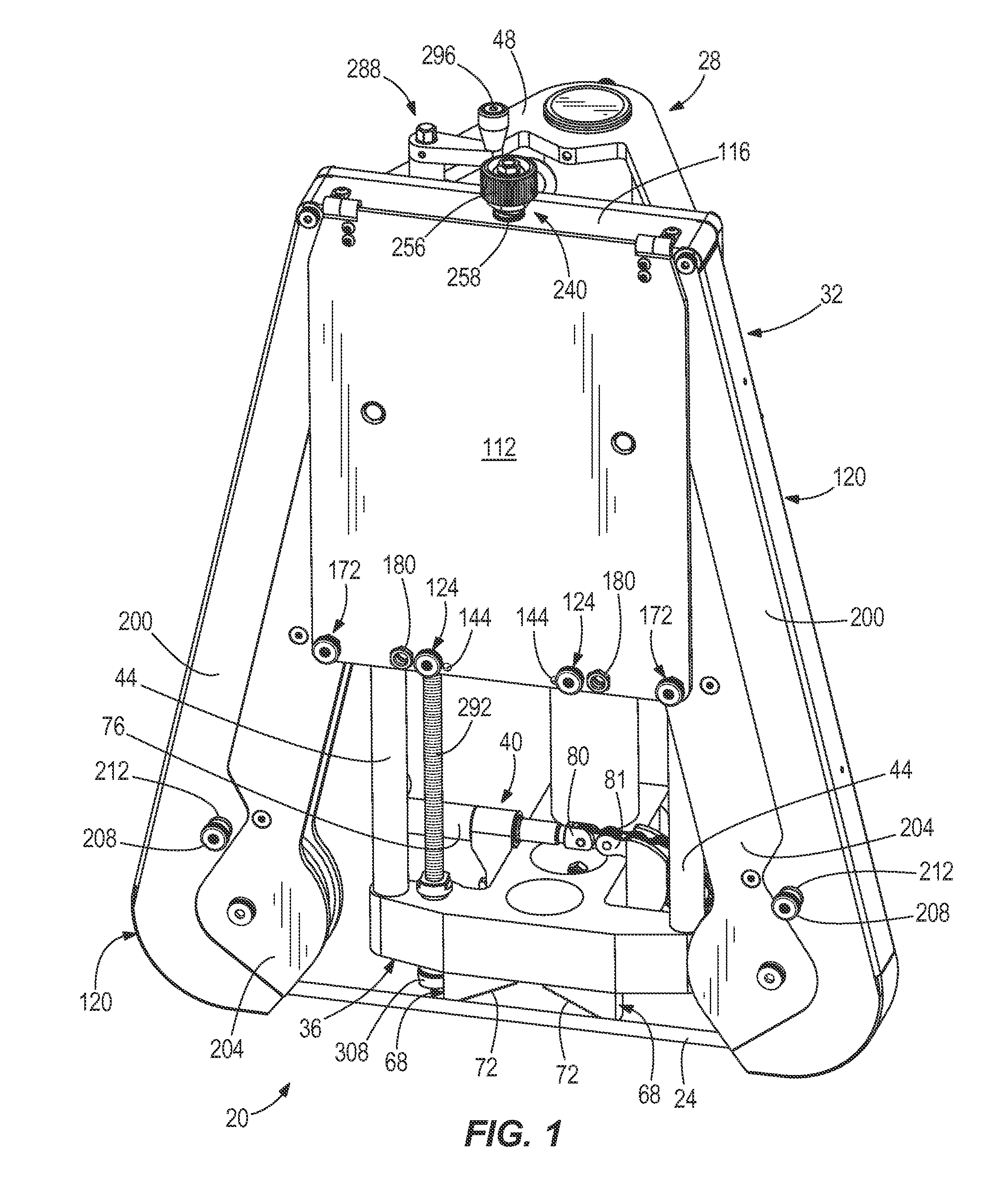

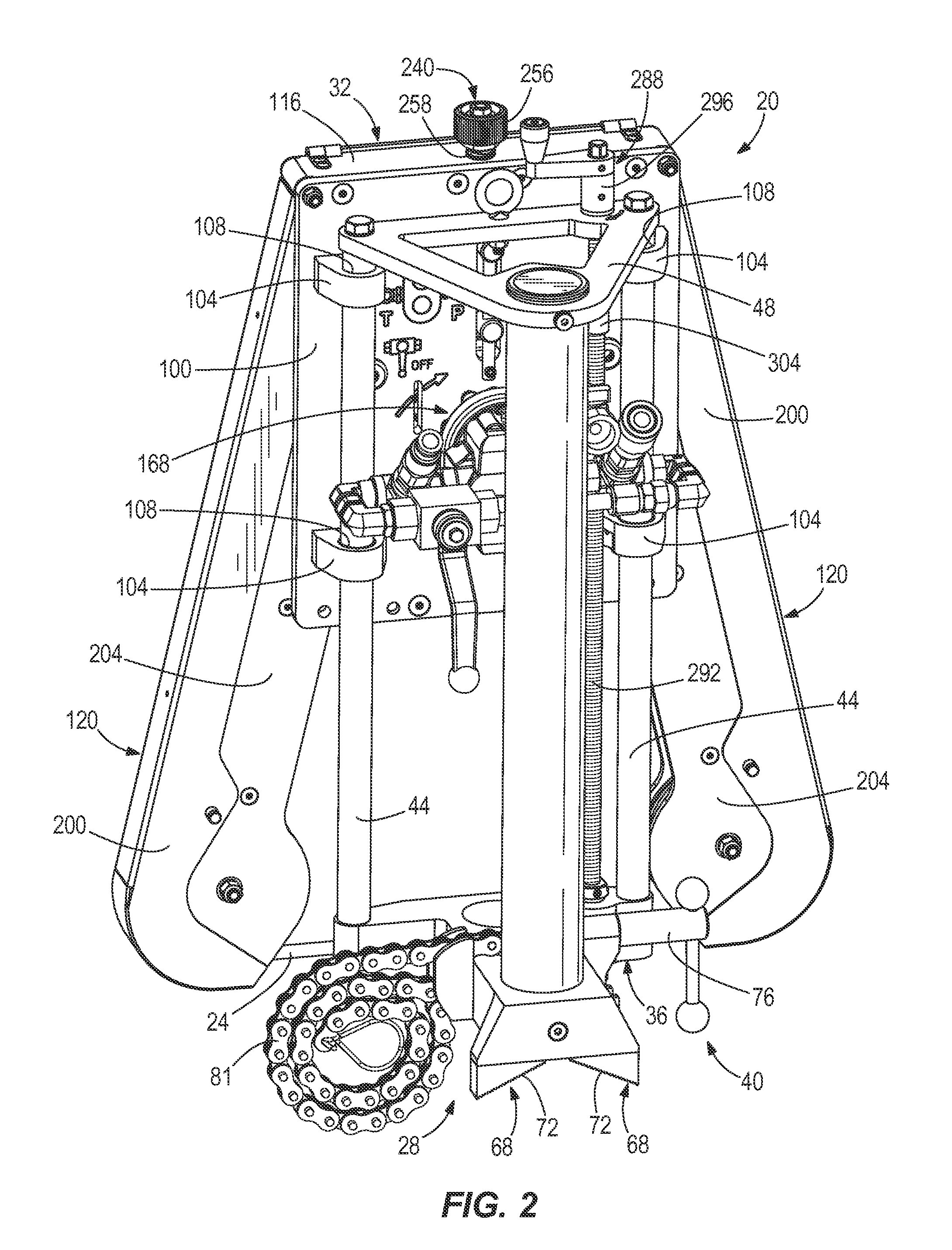

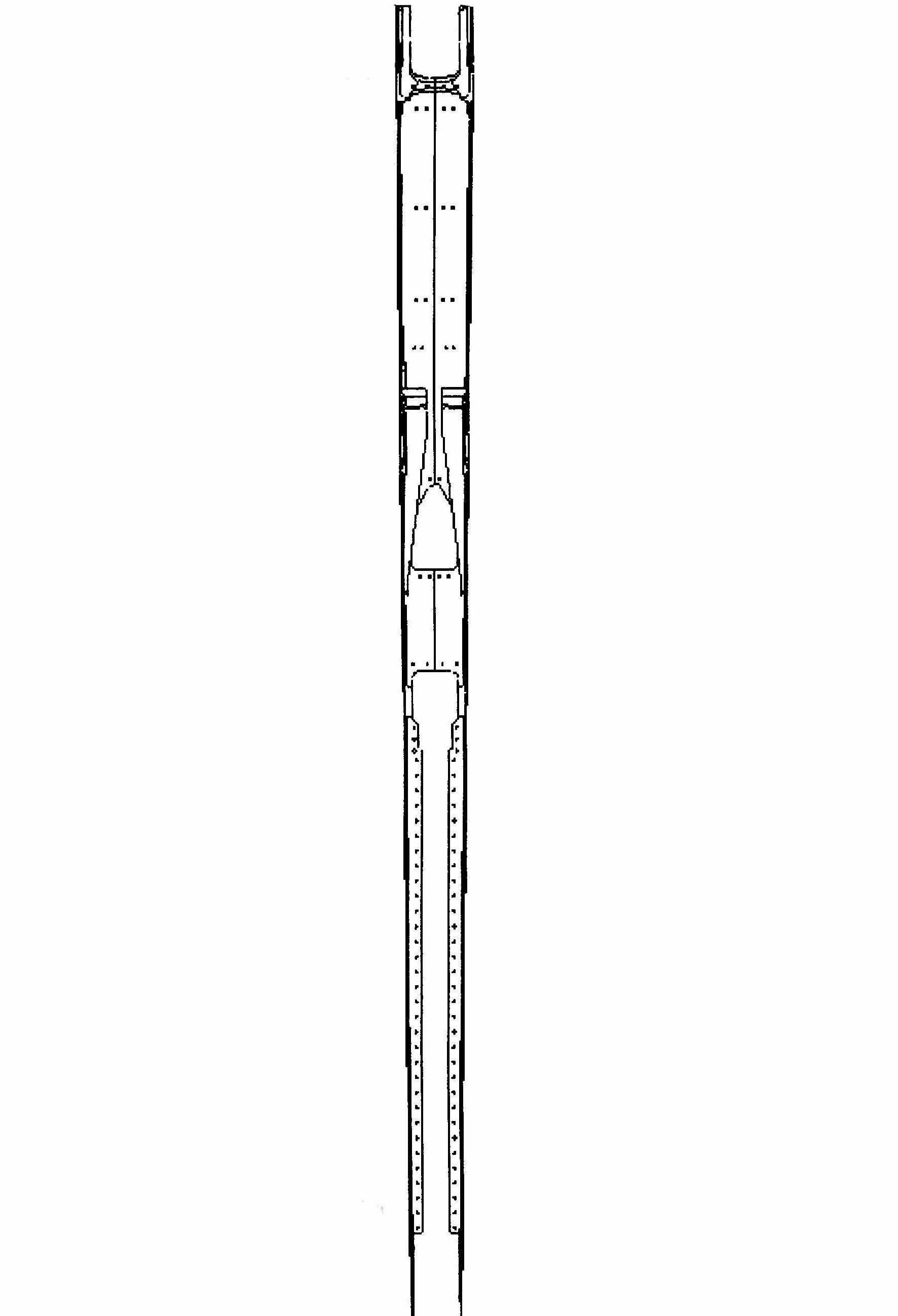

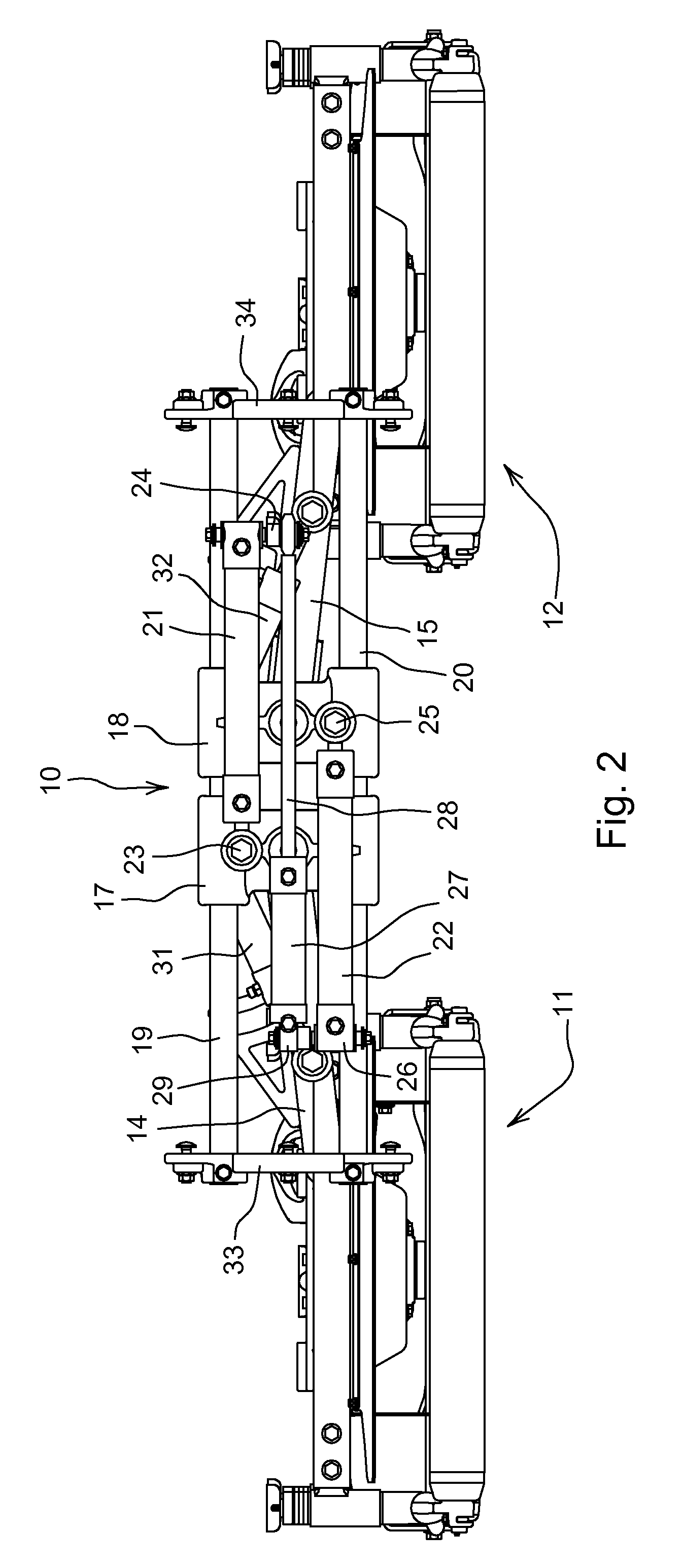

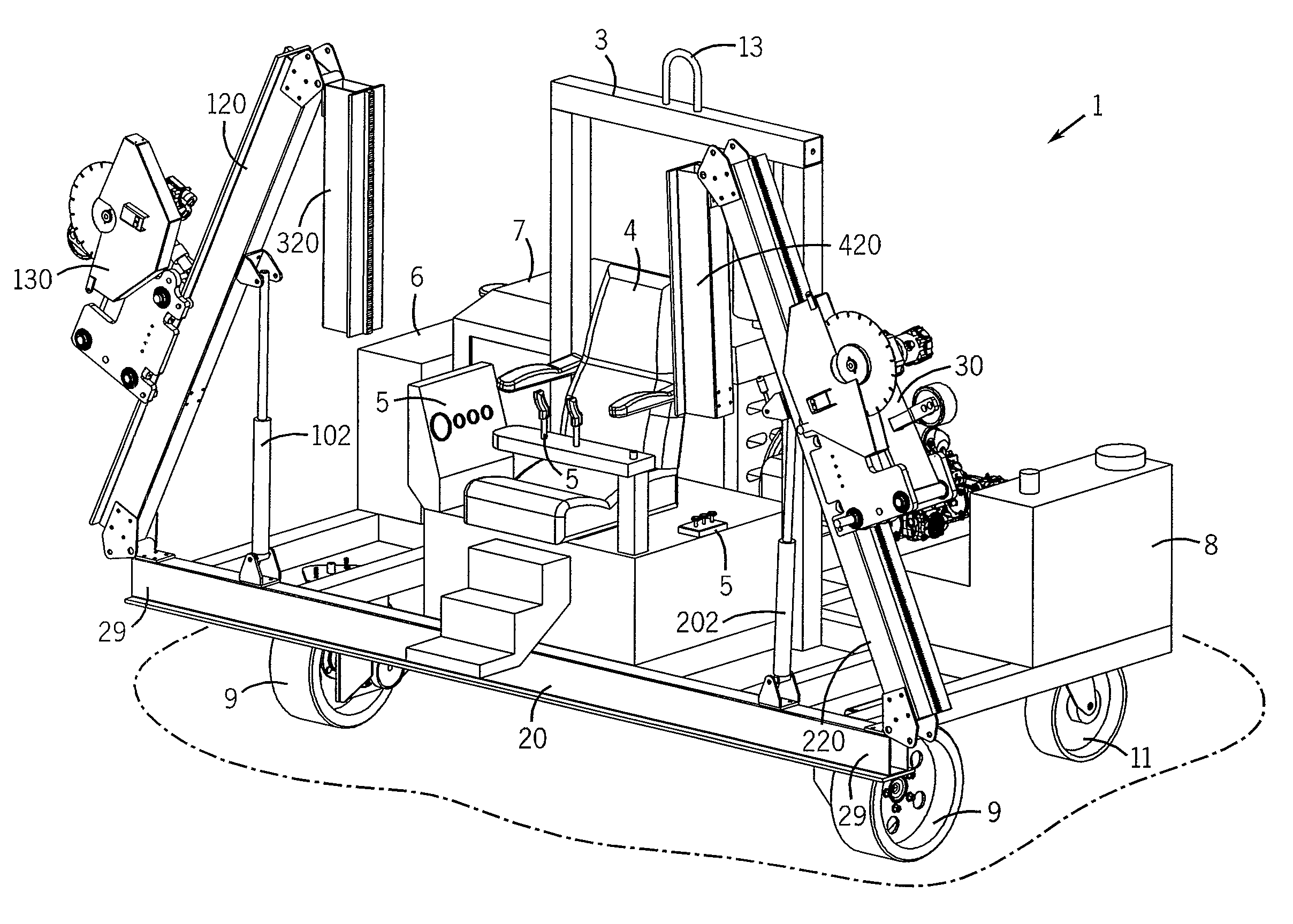

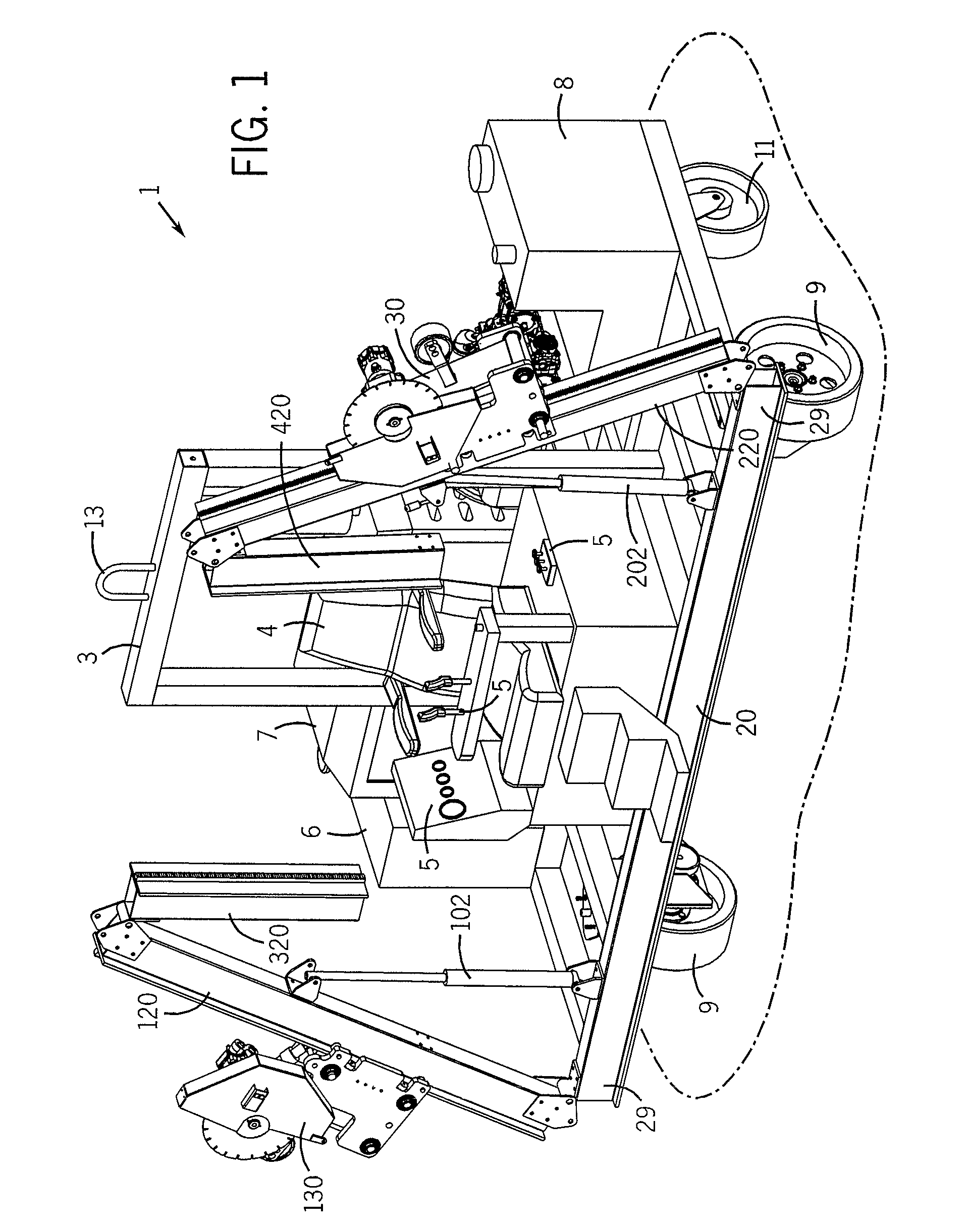

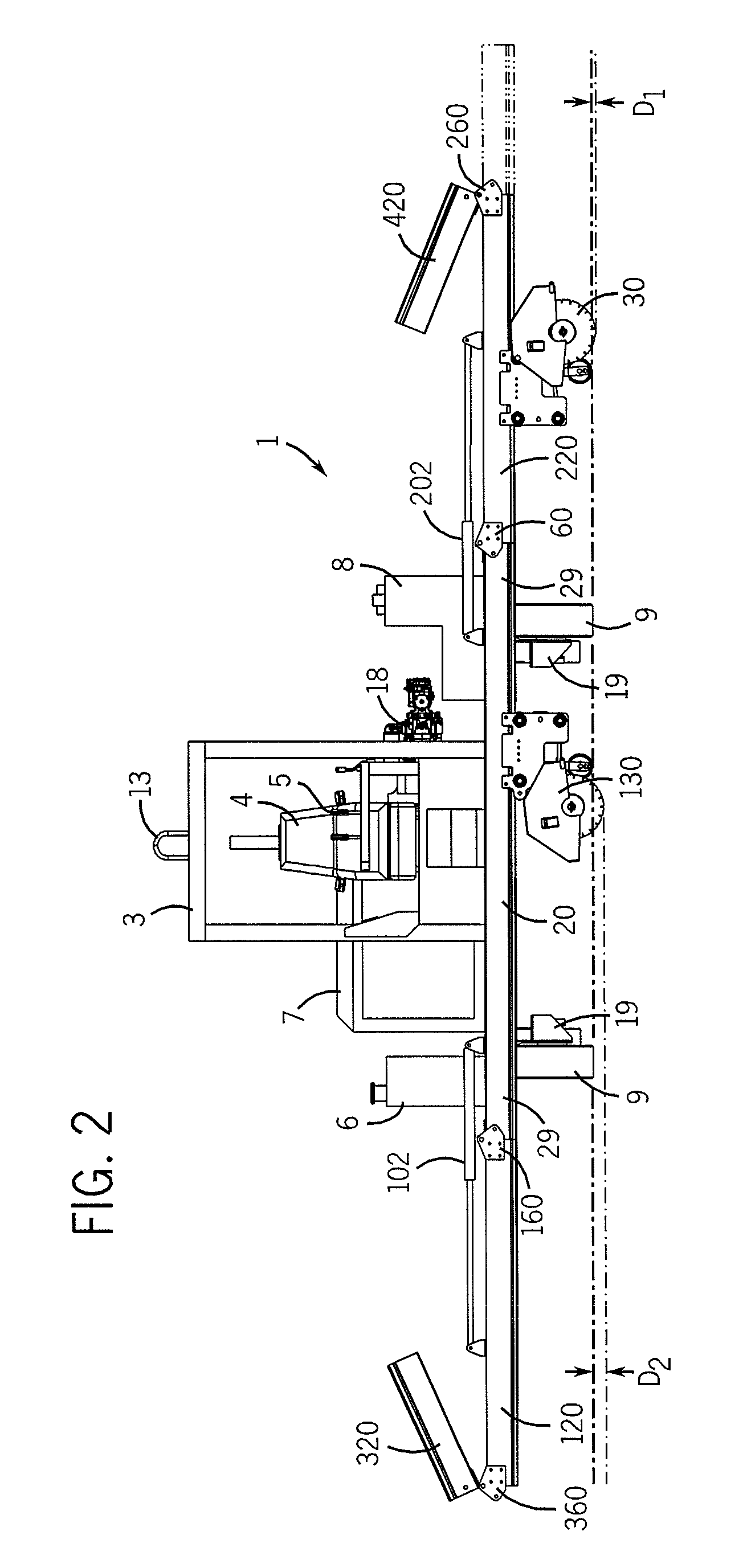

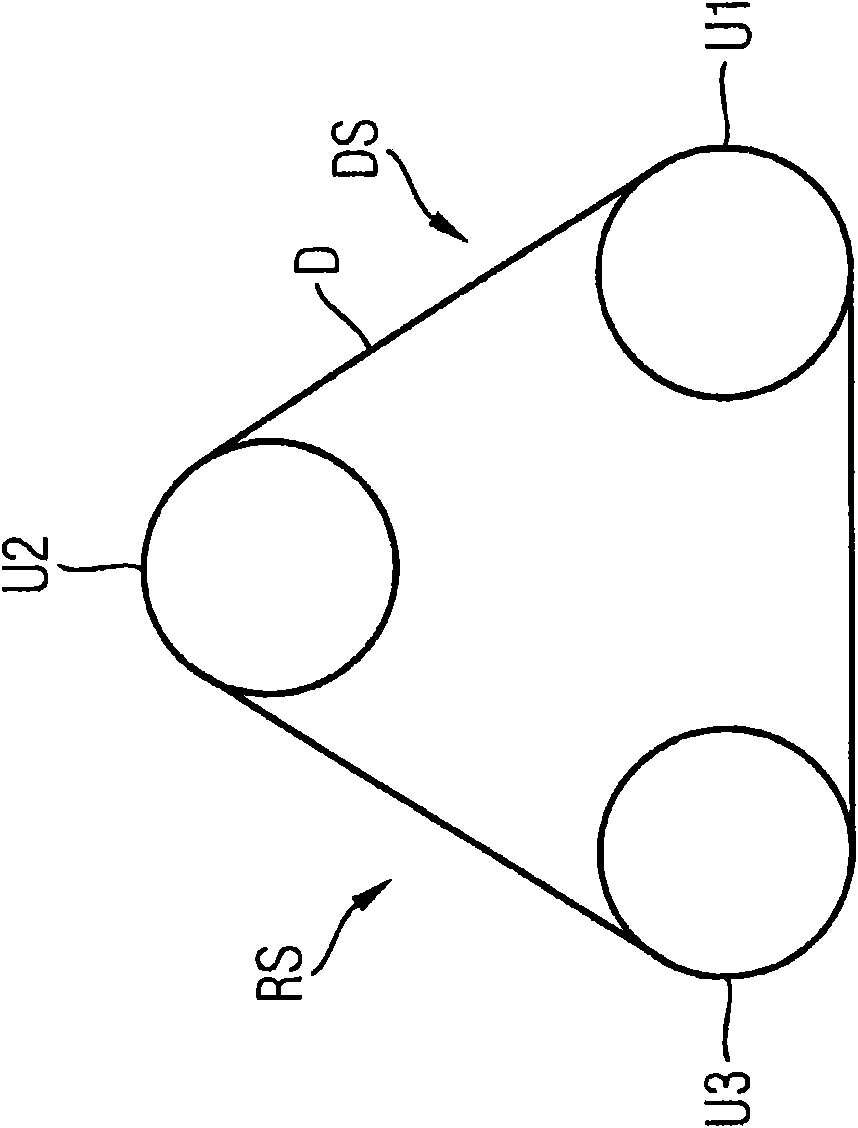

Cutting apparatus including a wire cutting member

ActiveUS20150101471A1Increase the cutting widthIncrease widthMetal sawing devicesMetal working apparatusWire cuttingWire saw

A cutting apparatus includes a wire cutting member, a plurality of wheels about which the wire cutting member is at least partially wrapped, a first arm member supporting at least one of the plurality of wheels, and a second arm member supporting at least one of the plurality of wheels. The first arm member and the second arm member may be moveable between a first position, in which the cutting apparatus has a first size, and a second position, in which the cutting apparatus has a second size larger than the first size. A wire saw includes an adjustment member coupled to at least one of a plurality of wheels for moving the at least one of the plurality of wheels to adjust a tension of a wire cutting member. A wire saw includes a visual indicator for indicating an amount of tension applied to a wire cutting member

Owner:ILLINOIS TOOL WORKS INC

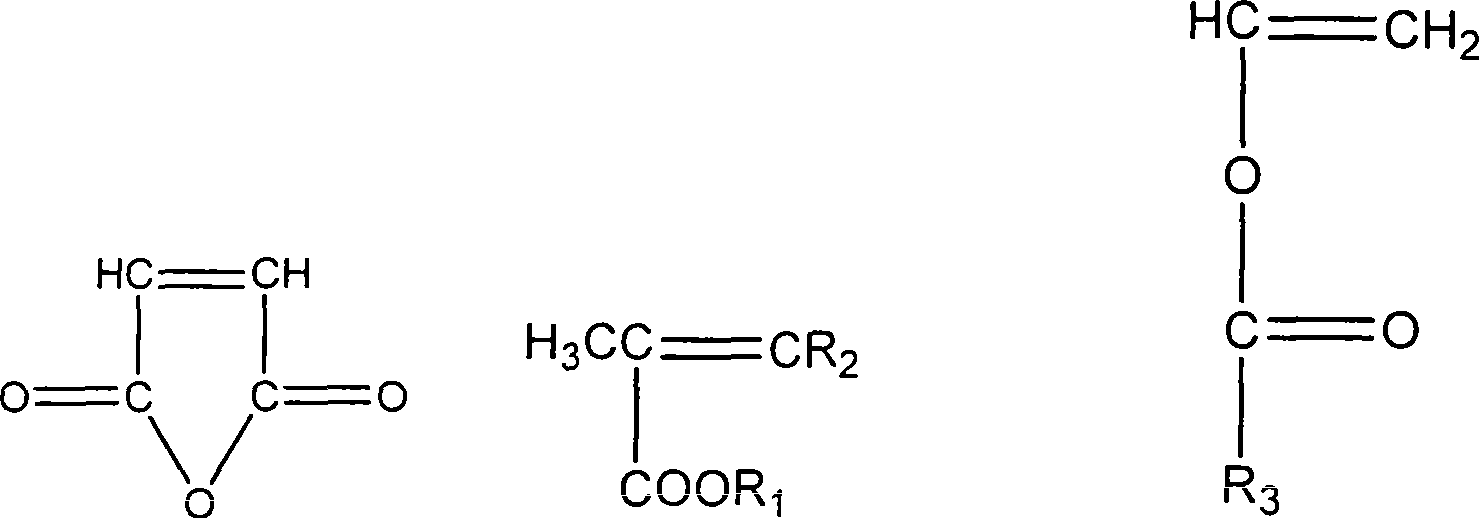

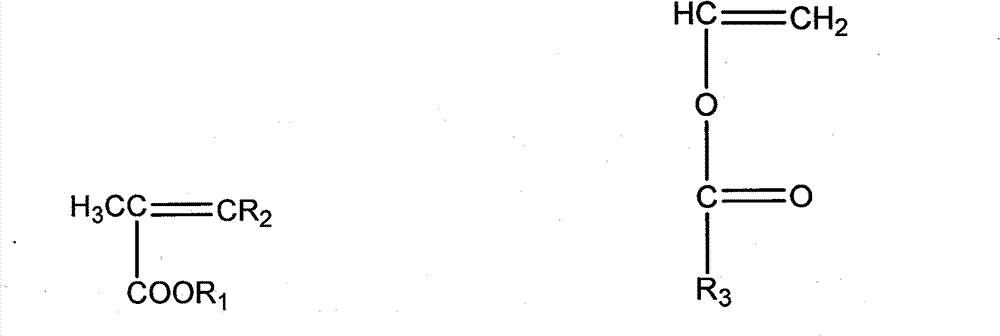

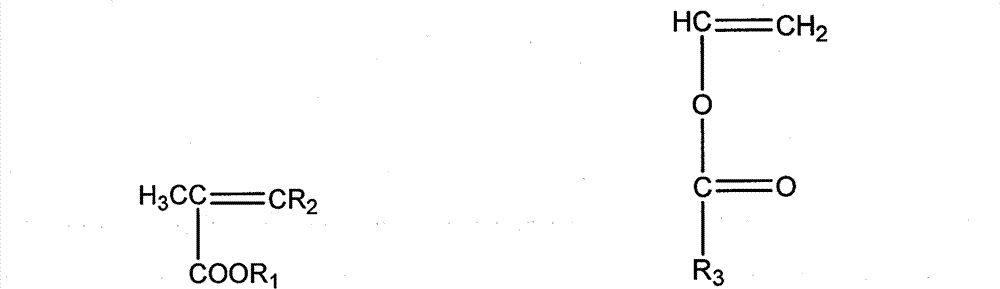

Ternary polymer composite petroleum pour depressant and preparation method thereof

InactiveCN101381640AImprove low temperature rheologyWiden the cutting widthLiquid carbonaceous fuelsFuel additivesMaleic anhydrideChemistry

The invention discloses a terpolymer composite petroleum pour point depressant and a method for preparing the same, wherein the pour point depressant is formed by the random copolymerization of maleic anhydride monomer, 2-methacrylate and carboxylic acid ethylene ester, and the weight average molecular weight is between 10, 000 and 90, 000g / mol. The invention also discloses a terpolymer composite petroleum pour point depressant composite which consists of the following components in weight percentage: 55 t0 92 percent of the terpolymer composite petroleum pour point depressant and 8 to 45 percent of surfactant. The pour point depressant and the pour point depressant composite have the advantages of obviously improving the low-temperature rheological property of crude oil, improving the quality and efficiency of operations such as crude oil exploitation, collection-transfer, storage and the like, widening the cutting width of fraction during the crude oil refining and lowering the energy consumption of pipe transportation.

Owner:NANJING UNIV OF TECH

Downhole filter

InactiveUS20050121232A1Least riskEasy to manufactureDrilling rodsConstructionsParticulatesEngineering

In one aspect, a downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. In another aspect, a method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In yet another aspect, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

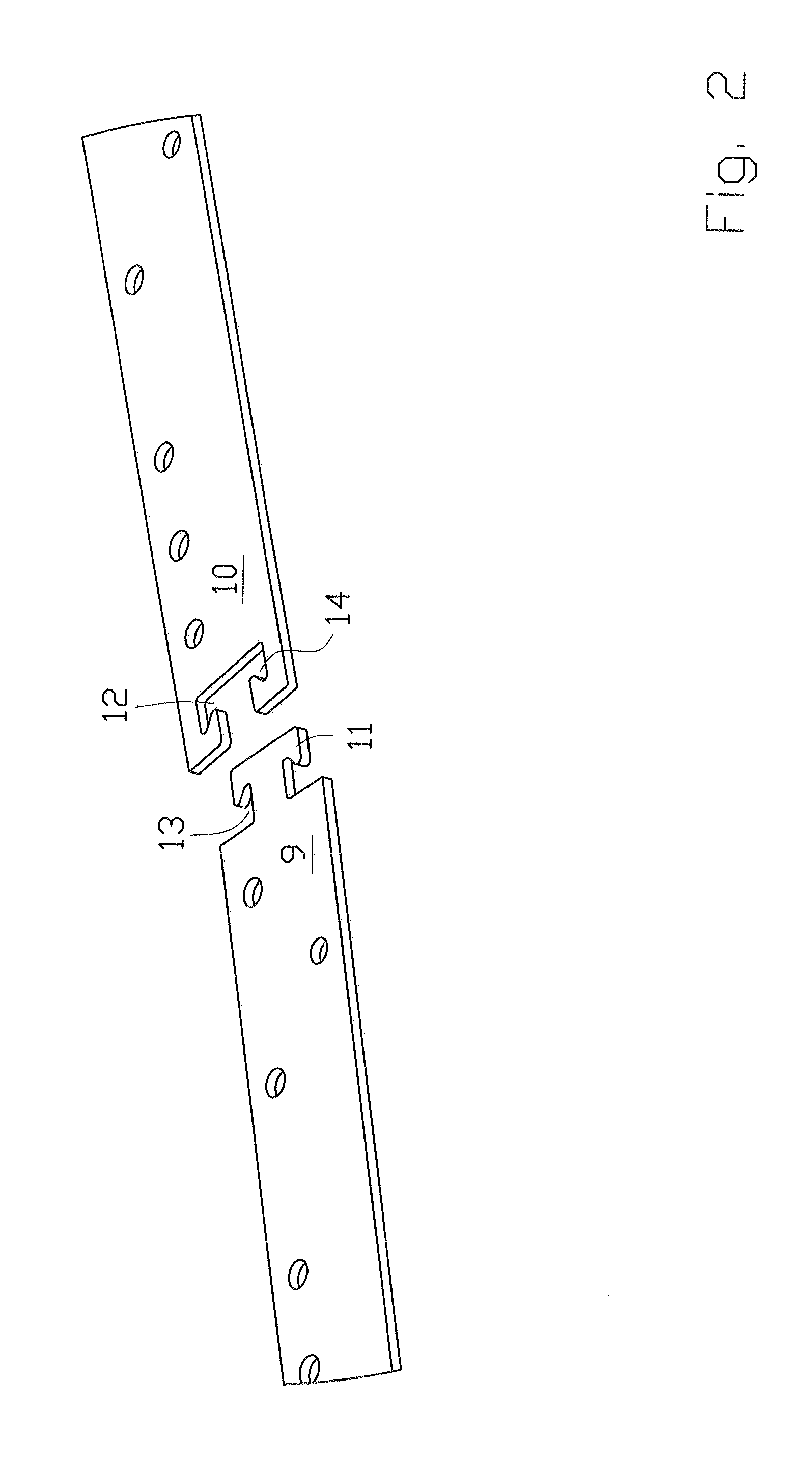

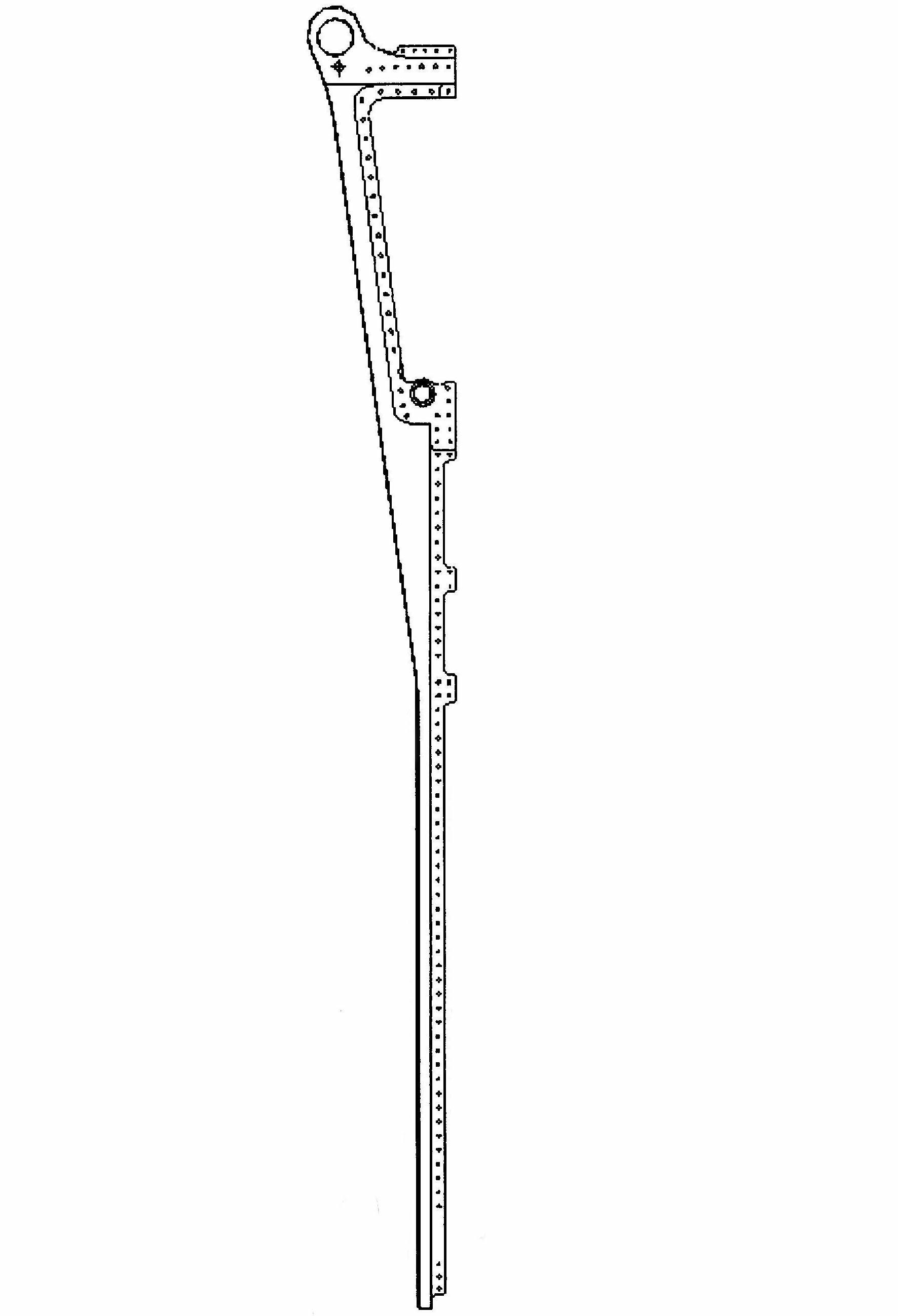

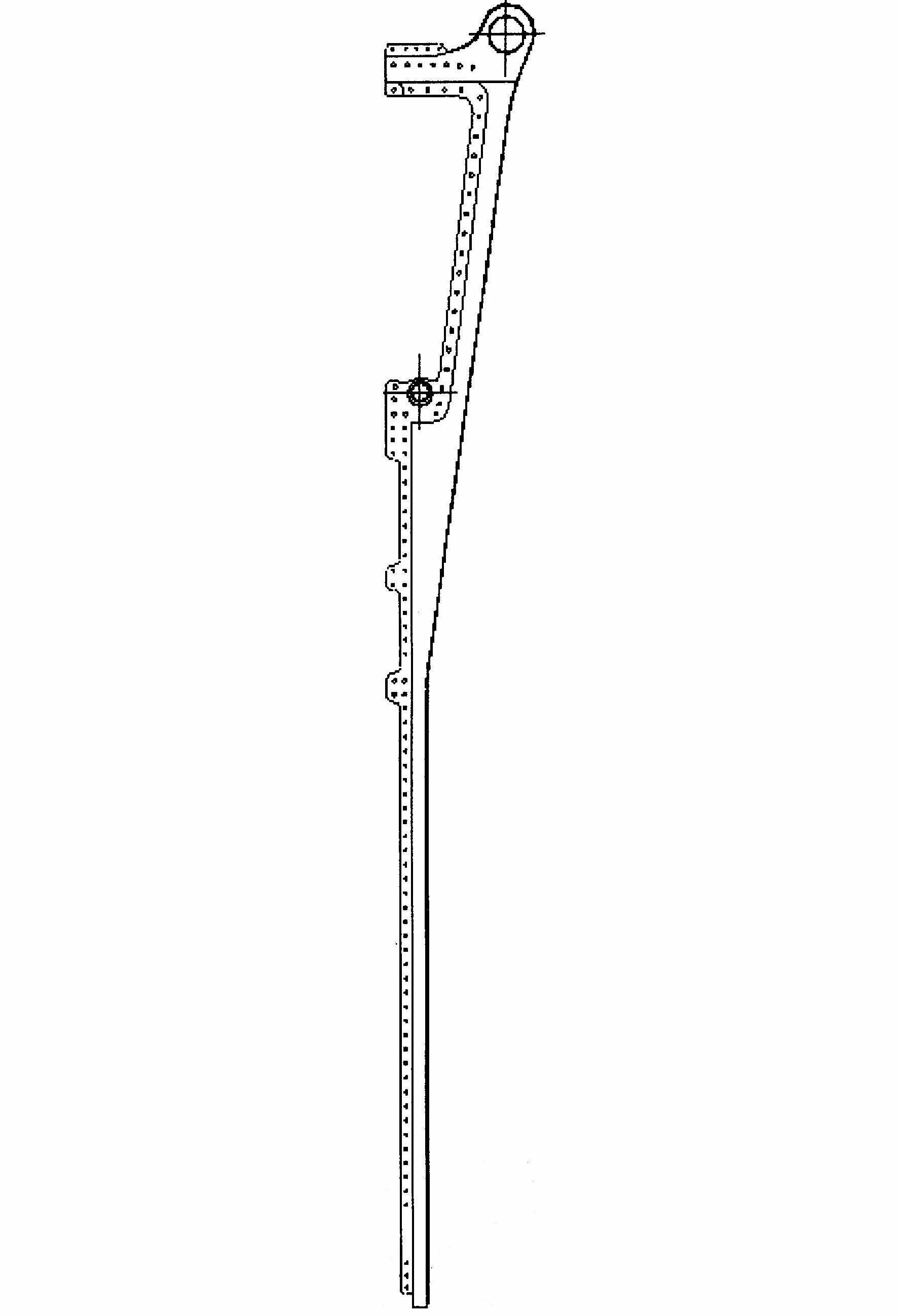

Finger bar

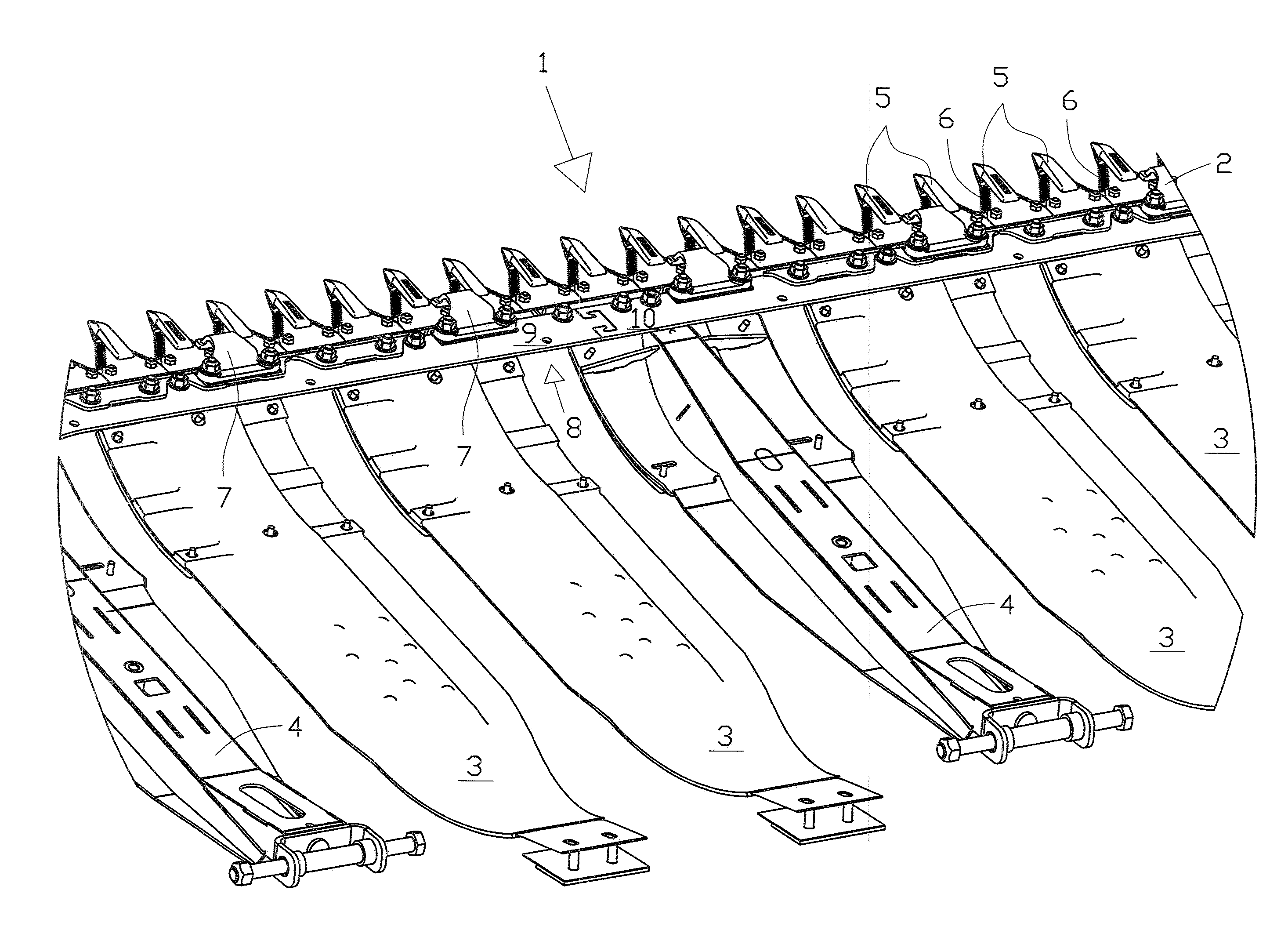

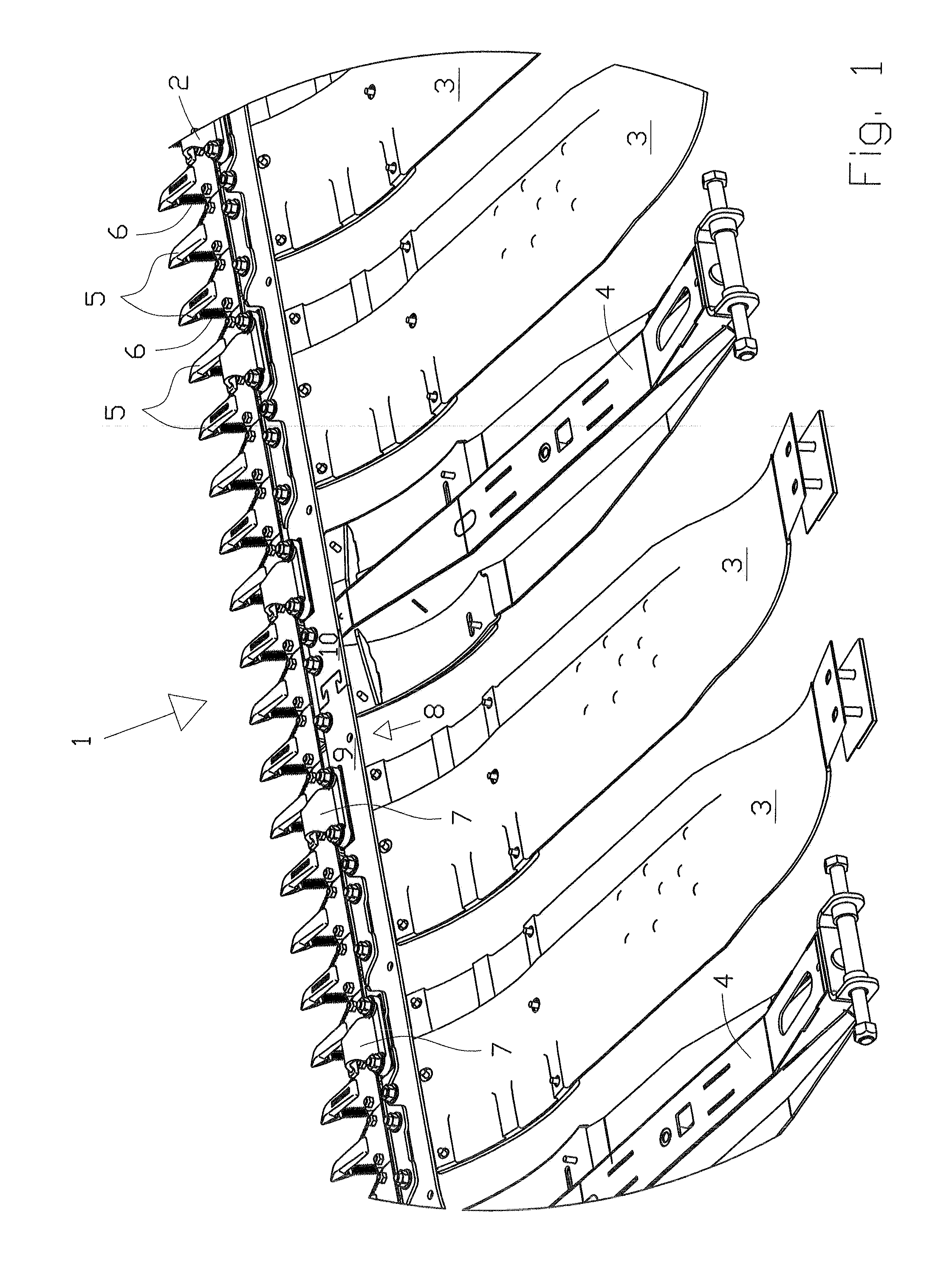

InactiveUS20110308224A1Easy to transportIncrease the cutting widthMowersEngineeringMechanical engineering

A finger bar for a header has a knife bar with at least two partial rails which are interconnectable at the end faces thereof, and a cutting system which can move back and forth in an oscillating manner, is attachable to the knife bar, and is deflectable transversely to the longitudinal axis thereof, in the vertical direction, and the partial rails are interconnectable in a form-locking manner on the end faces thereof that face each other.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

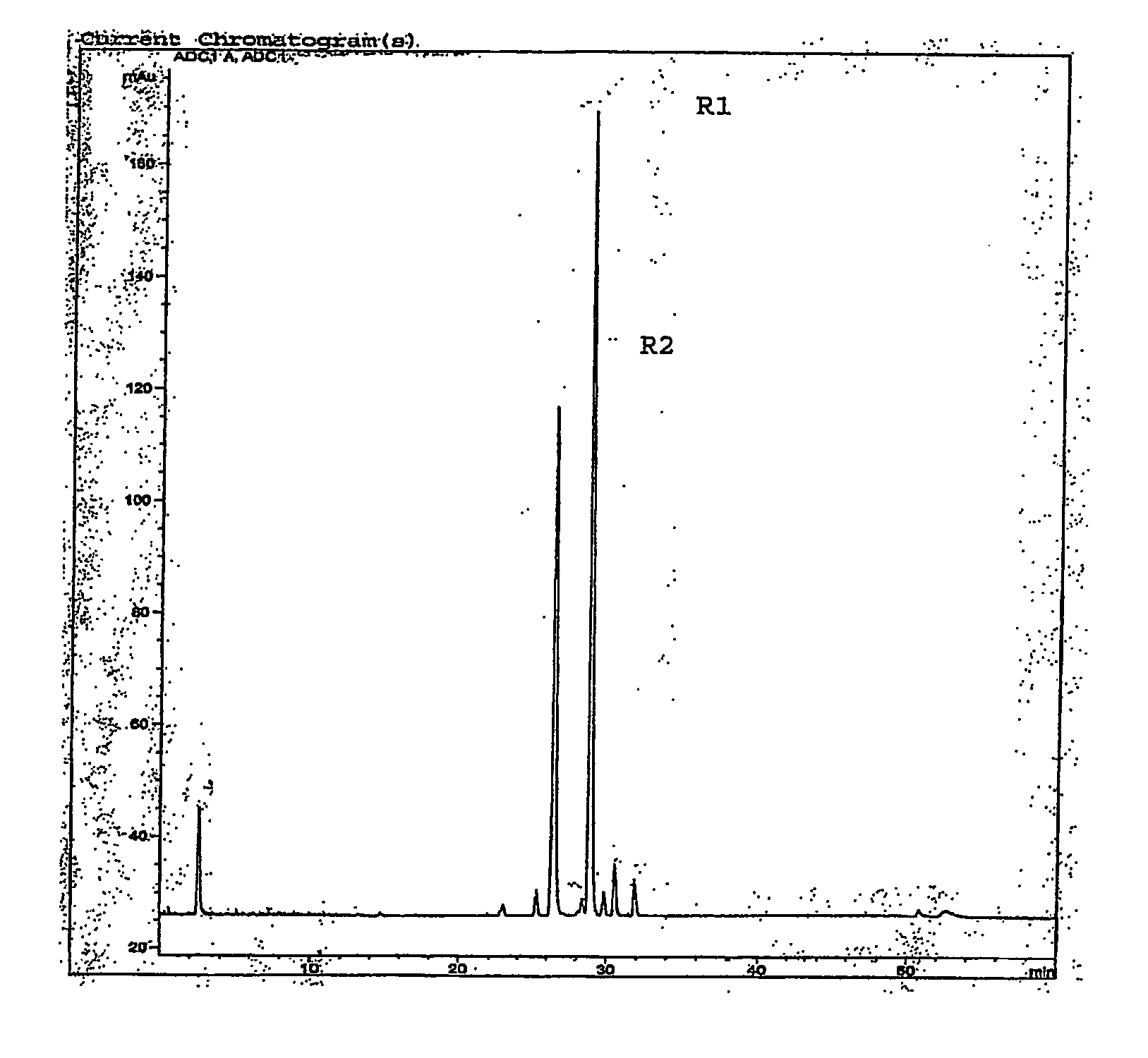

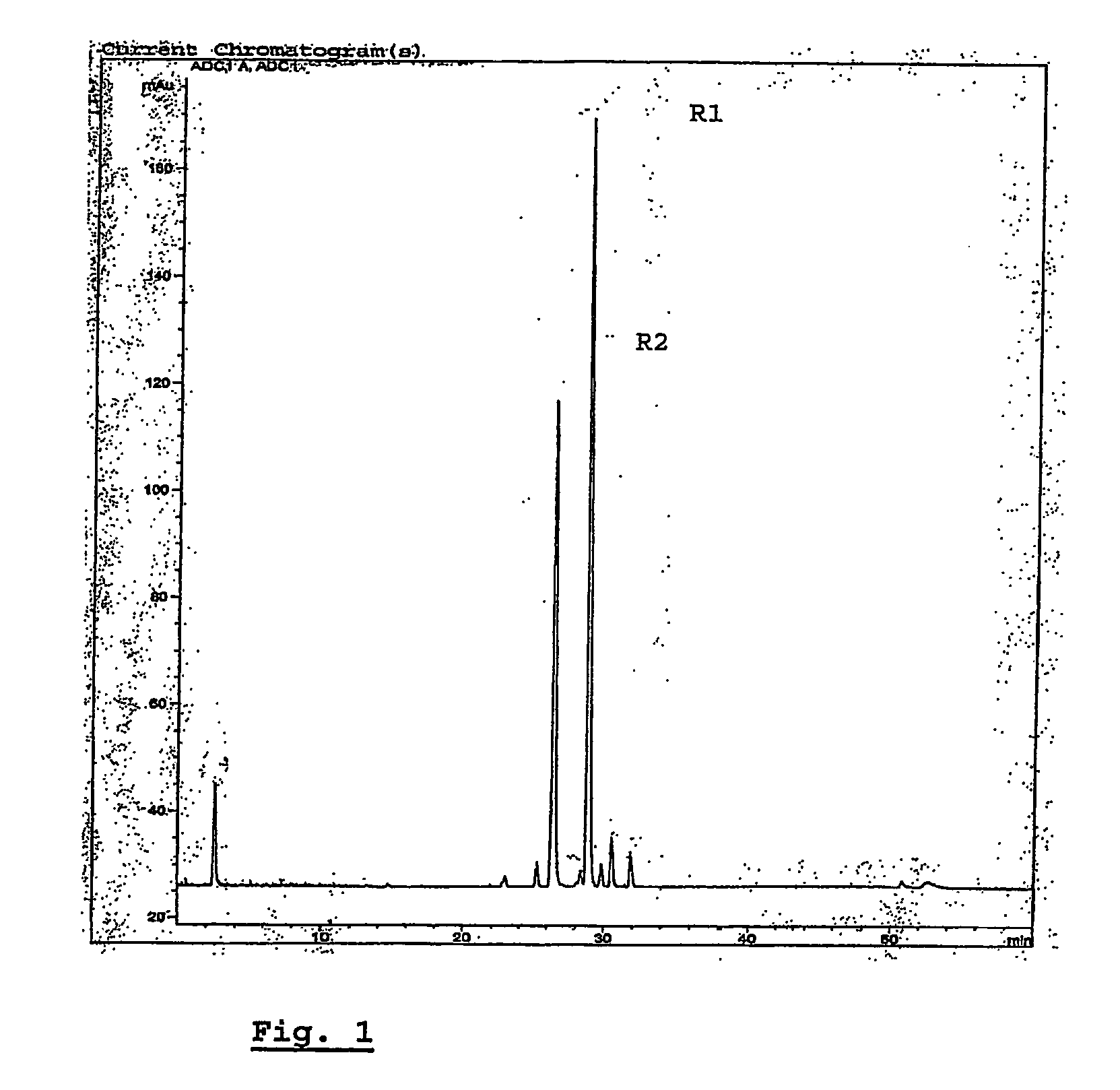

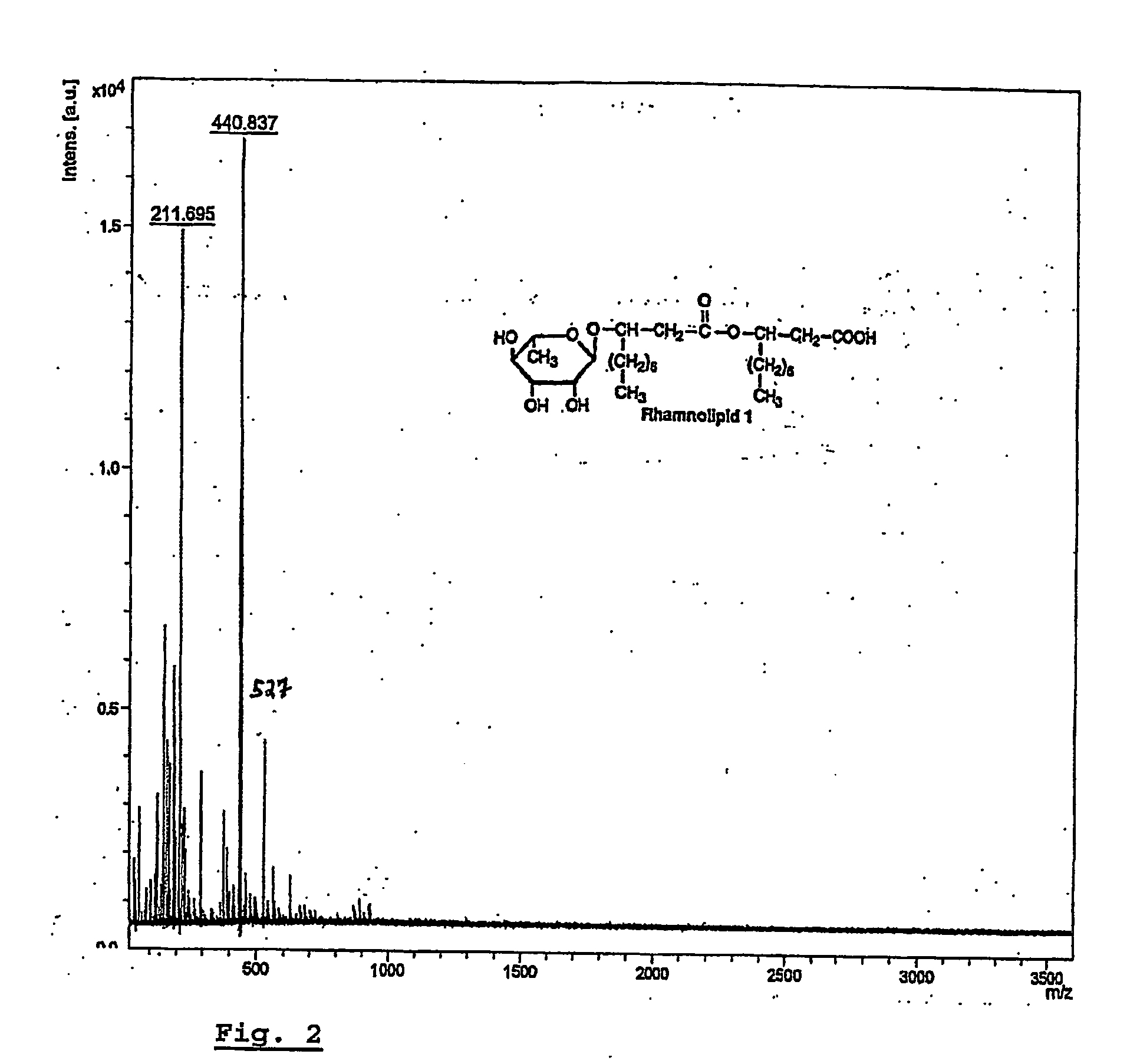

Rhamnolipids in bakery products

InactiveUS20060233935A1Improve structureImprove stabilityDough treatmentPre-baking dough treatmentMicroorganism preservationNon dairy

The present invention is related to a method for the improvement of dough or batter stability, dough texture, volume and shape, width of cut and / or microbial conservation of bakery products which comprises the step of adding a sufficiently effective amount of rhamnolipid(s) to said bakery products. The present invention further relates to an improver for the improvement of dough or batter stability, dough texture, volume and shape, width of cut and / or microbial conservation of bakery products, characterized in that it comprises a sufficiently effective amount of rhamnolipids. The rhamnolipids can further be used to improve the properties of butter cream, decoration cream and / or of non-dairy cream filling for Danish pastries, croissants and other fresh or frozen fine confectionery products.

Owner:PURATOS NV

Method for controlling numeric control machining deformation of slender and complicated T-shaped component

ActiveCN102689145AReduce distortionShorten the manufacturing cycleMilling equipment detailsMachining deformationEngineering

The invention provides a method for controlling numeric control machining deformation of a slender and complicated T-shaped component, which comprises the following steps of: 1), dividing the machined slender and complicated T-shaped component into a left subpackage member and a right subpackage member, i.e. a subpackage member I and a subpackage member II; 2) performing coarse machining on the subpackage member I and the subpackage member II and manufacturing a positioning reference plane and a positioning hole; 3) fixing the subpackage member I and the subpackage member II on a numerically-controlled milling machine machining table board through a fixed tool; 4) performing equal-height drop layer ring cutting on components in a shallow-cutting machining way; 5) reserving machining allowance to an assembling part; 6) welding the subpackage member I and the subpackage member II into a whole and carrying out thermal treatment; and 7) completing the machining process of the slender and complicated T-shaped component. By adopting the method, the deformation of the tail part of the assembly before the welding of the component can be eliminated in the numeric control machining process, and the deformation amount is removed.

Owner:SHENYANG AIRCRAFT CORP

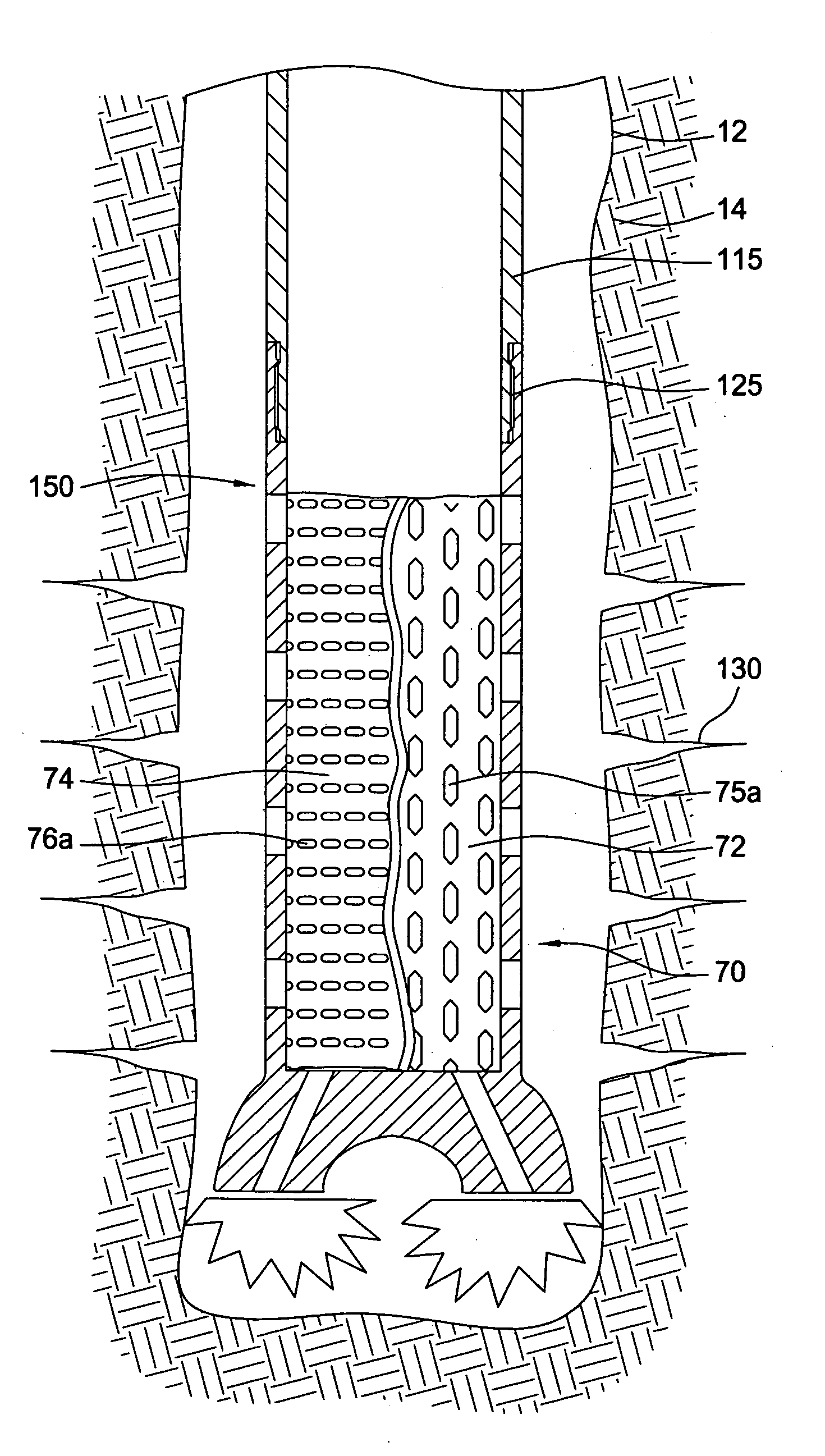

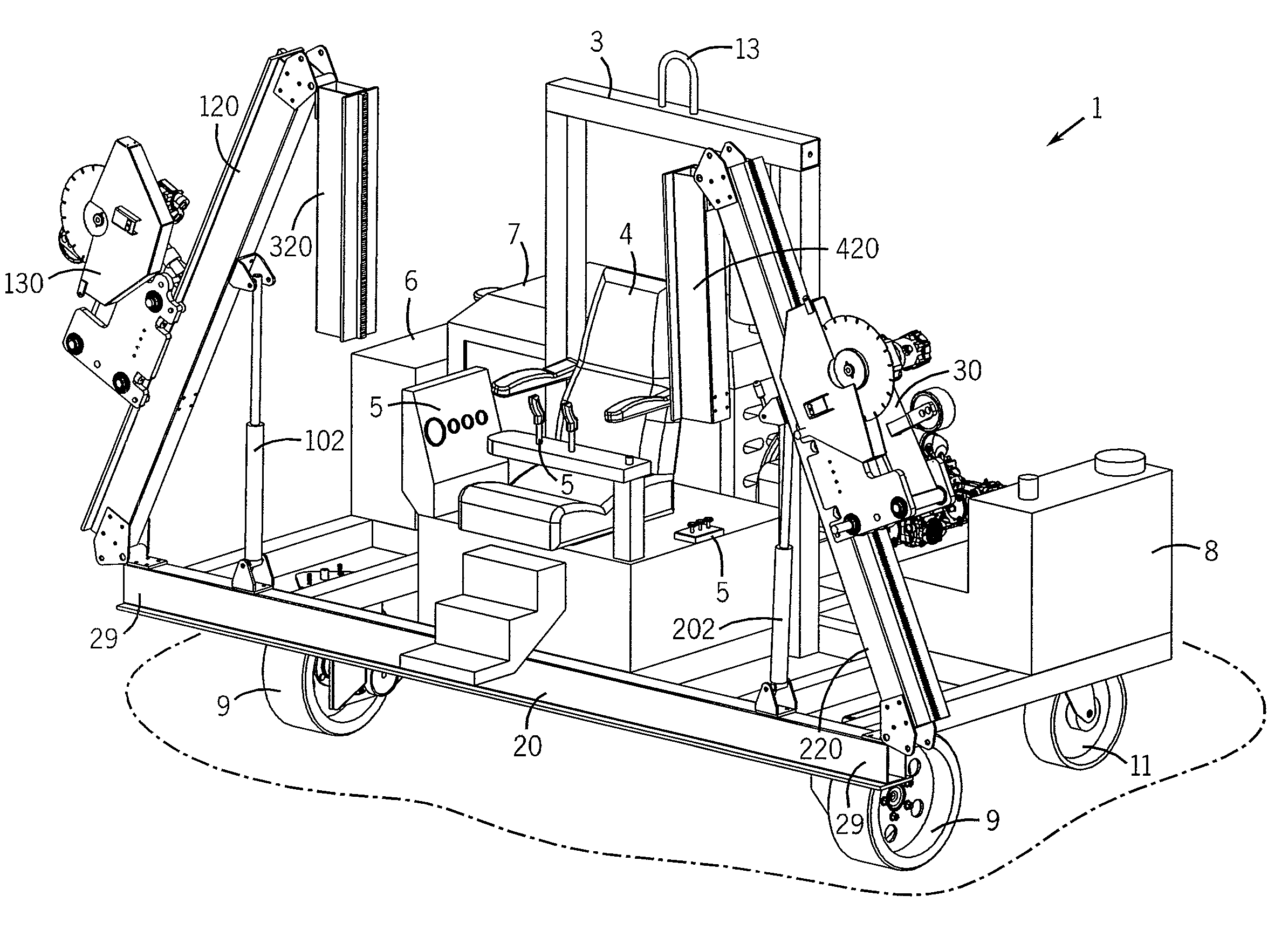

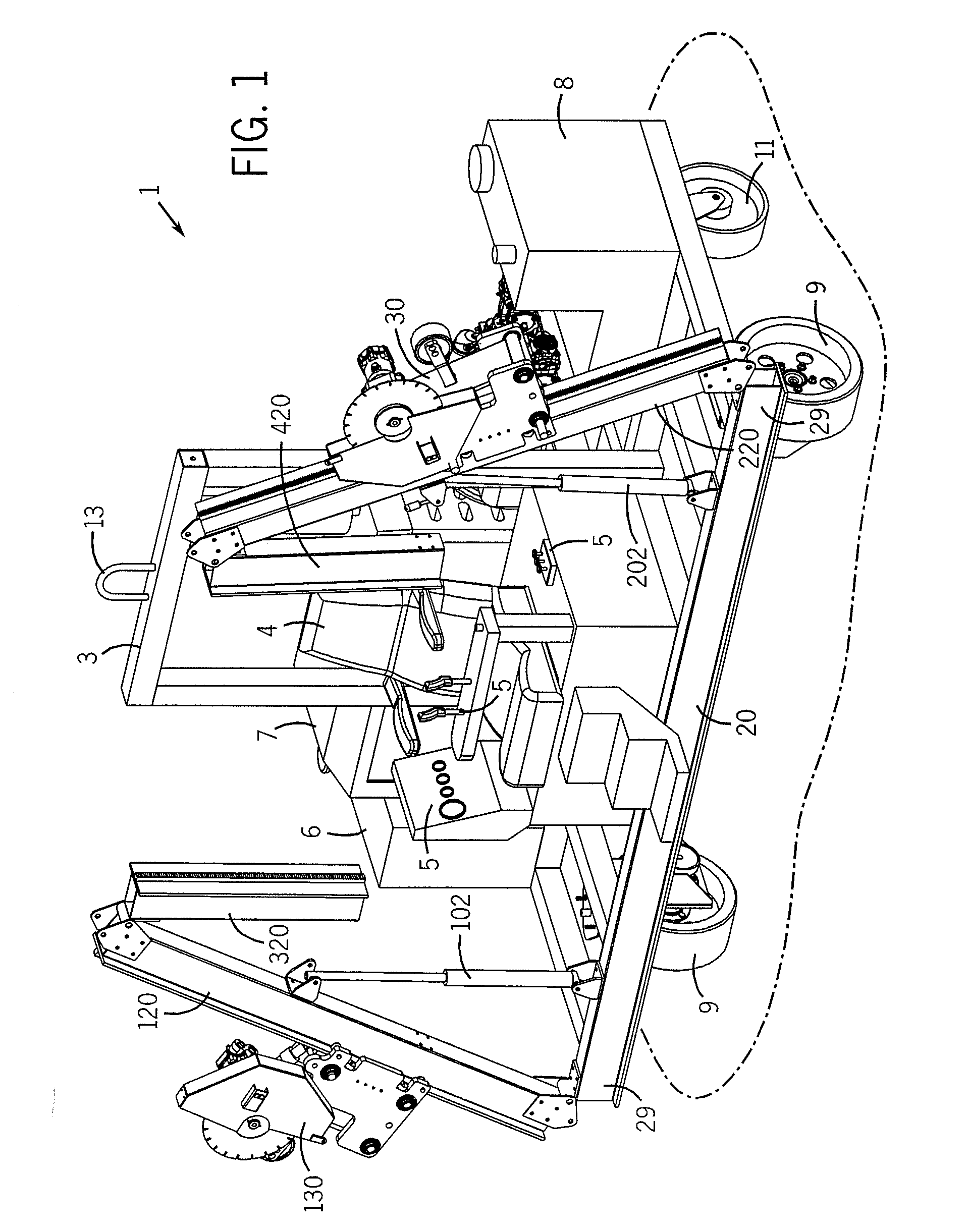

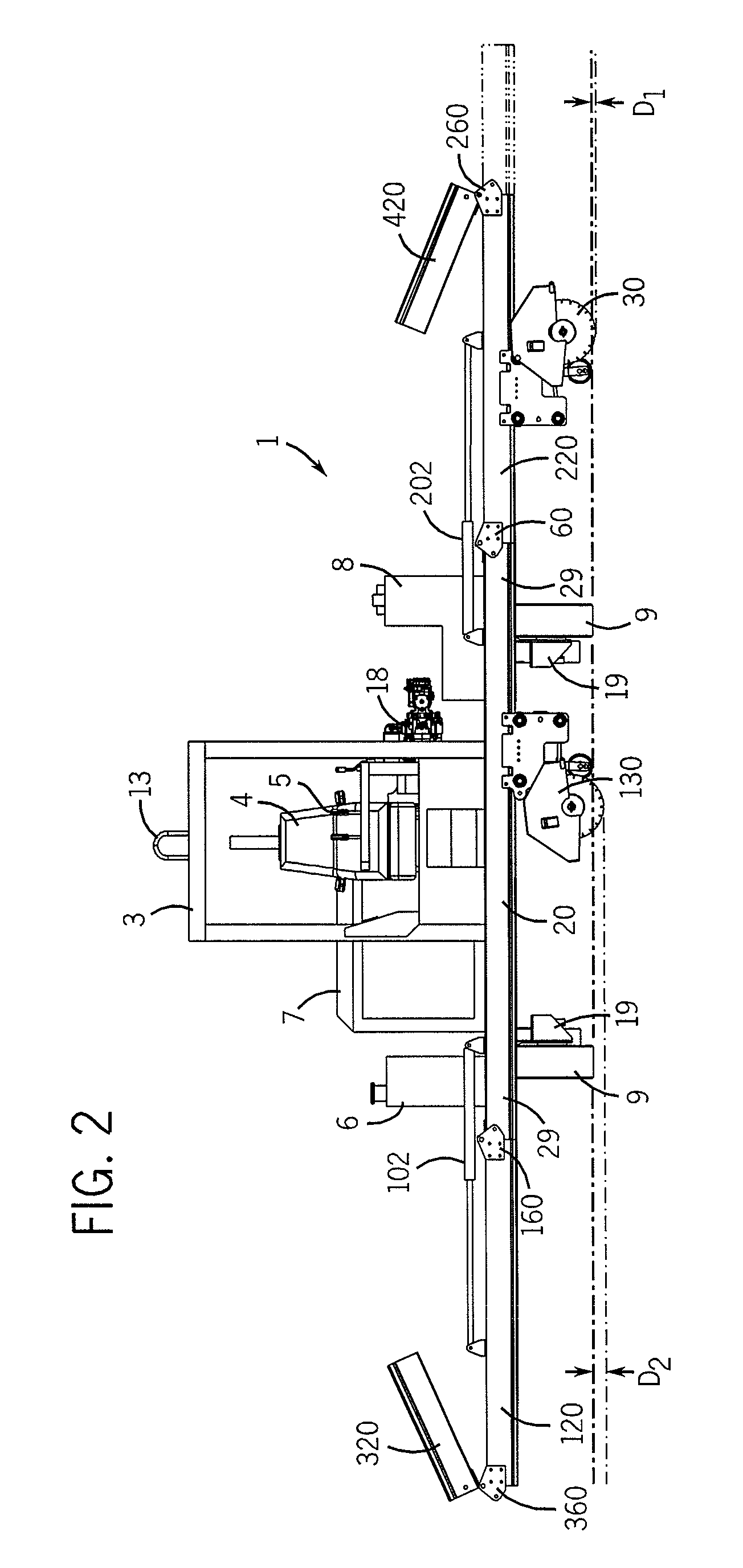

Concrete cutter

ActiveUS20070209651A1Easy and reliable positioningIncrease the cutting widthStone-like material working toolsCutting machinesEngineeringCantilever

An improved concrete cutter has a longitudinally-extending primary boom and one or more saw carriage sub-assemblies that move along the length of the boom. “Wing-like” boom extensions are hingedly secured at each end of the primary boom. The boom extensions can be easily positioned at each end of the primary boom to extend the cutting width of the concrete cutter and without requiring removal of the boom extensions from the concrete cutter. The saw carriage sub-assemblies are independently movable along the boom extensions. Carriage spacing is variably-adjustable along the boom such that each saw carriage can move toward or away from the other saw carriage. Each saw carriage sub-assembly is height-variable and is self-adjusting to contours in the profile of the concrete surface being cut.

Owner:SPIDER CUT IP

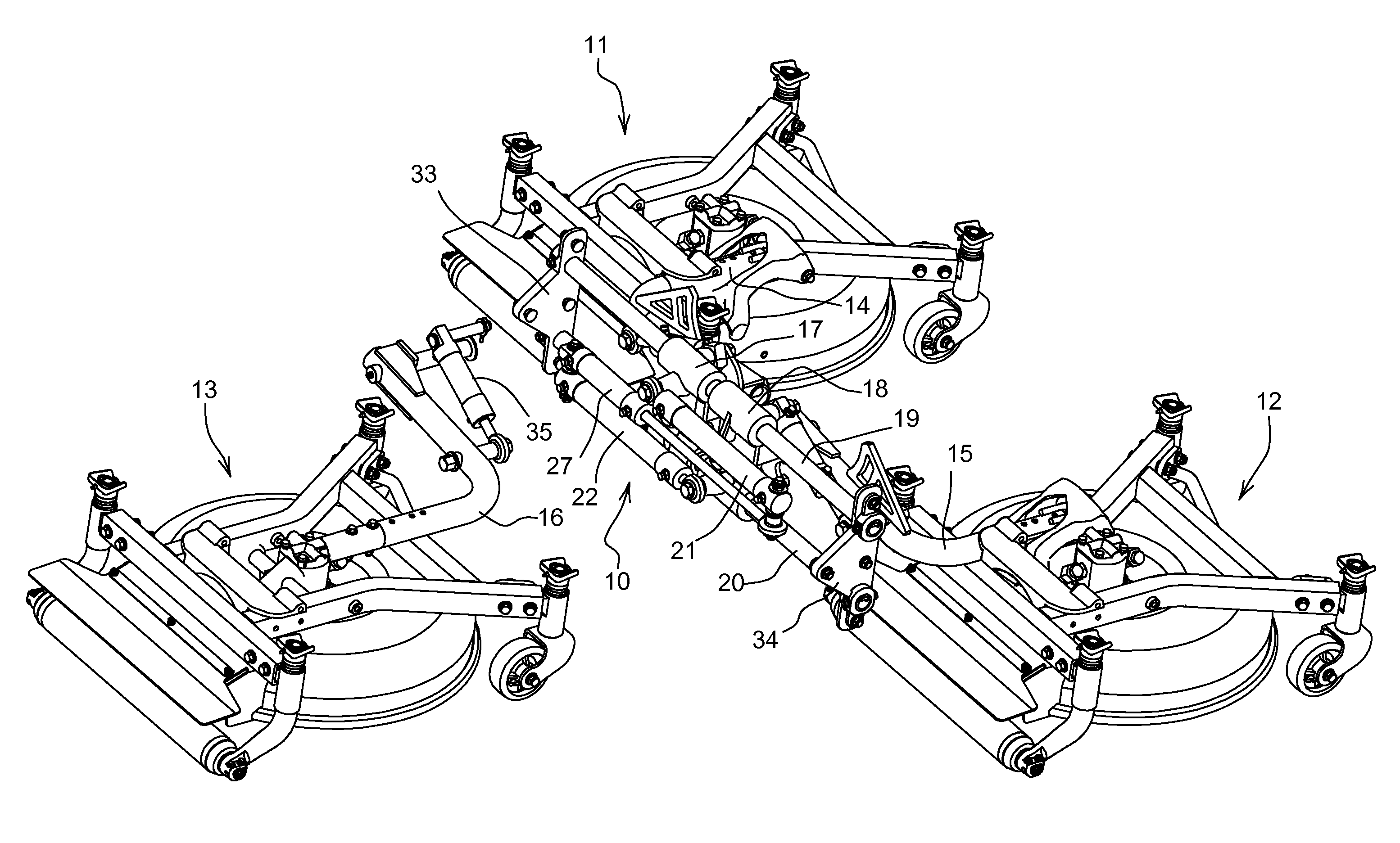

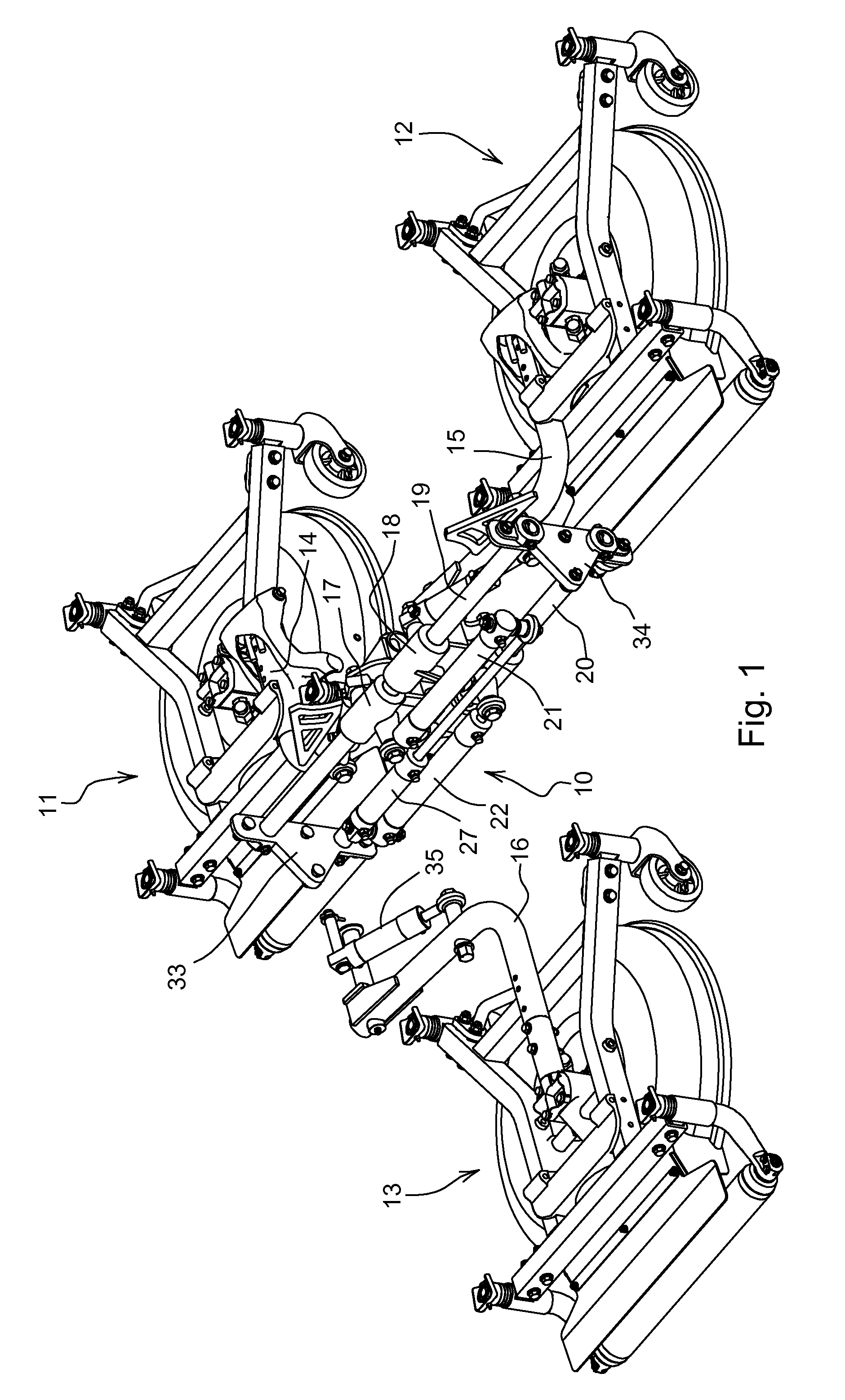

Shift mechanism for trim mower cutting units

ActiveUS7437864B2Not sacrifice productivityIncrease the cutting widthMowersAgricultural undercarriagesMowerEngineering

Owner:DEERE & CO

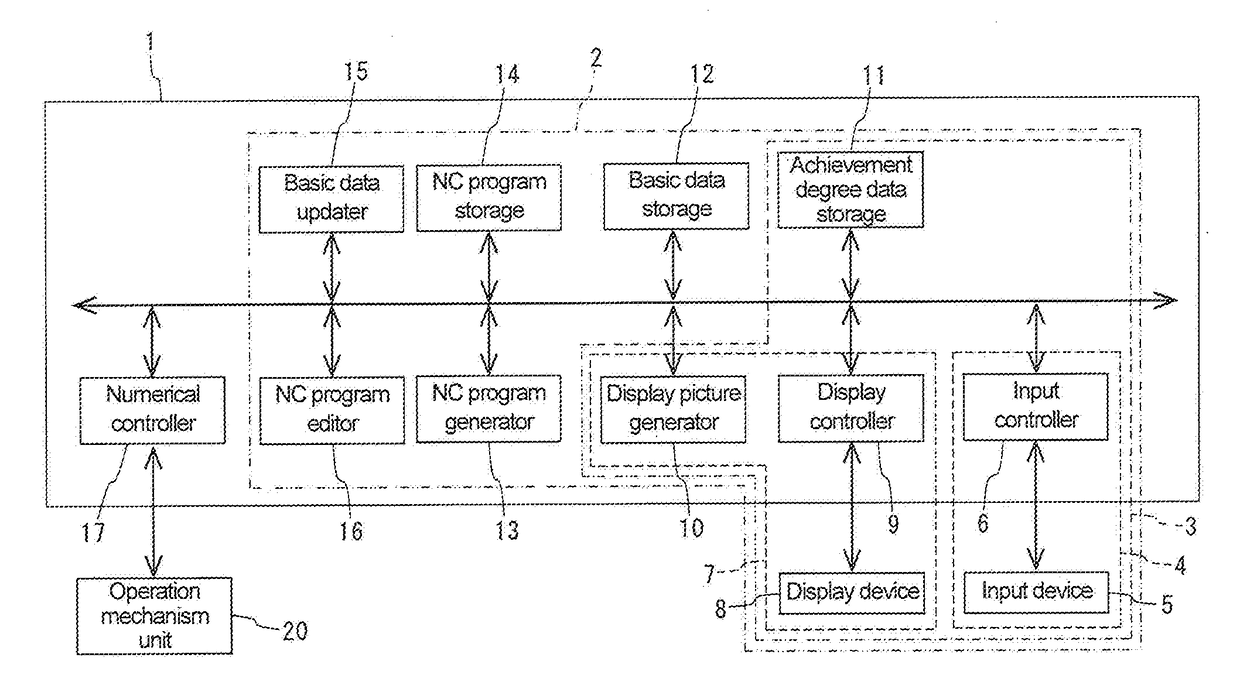

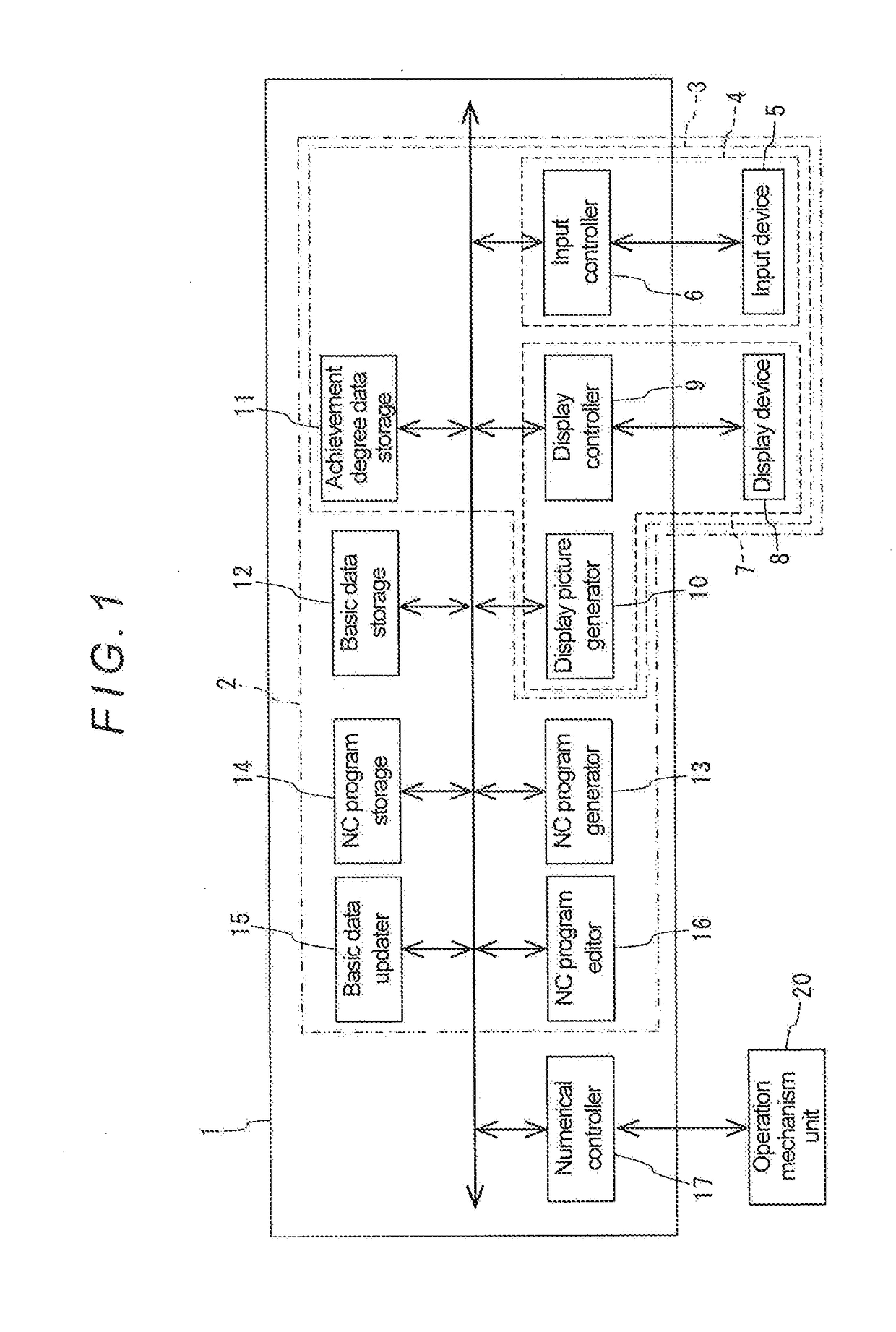

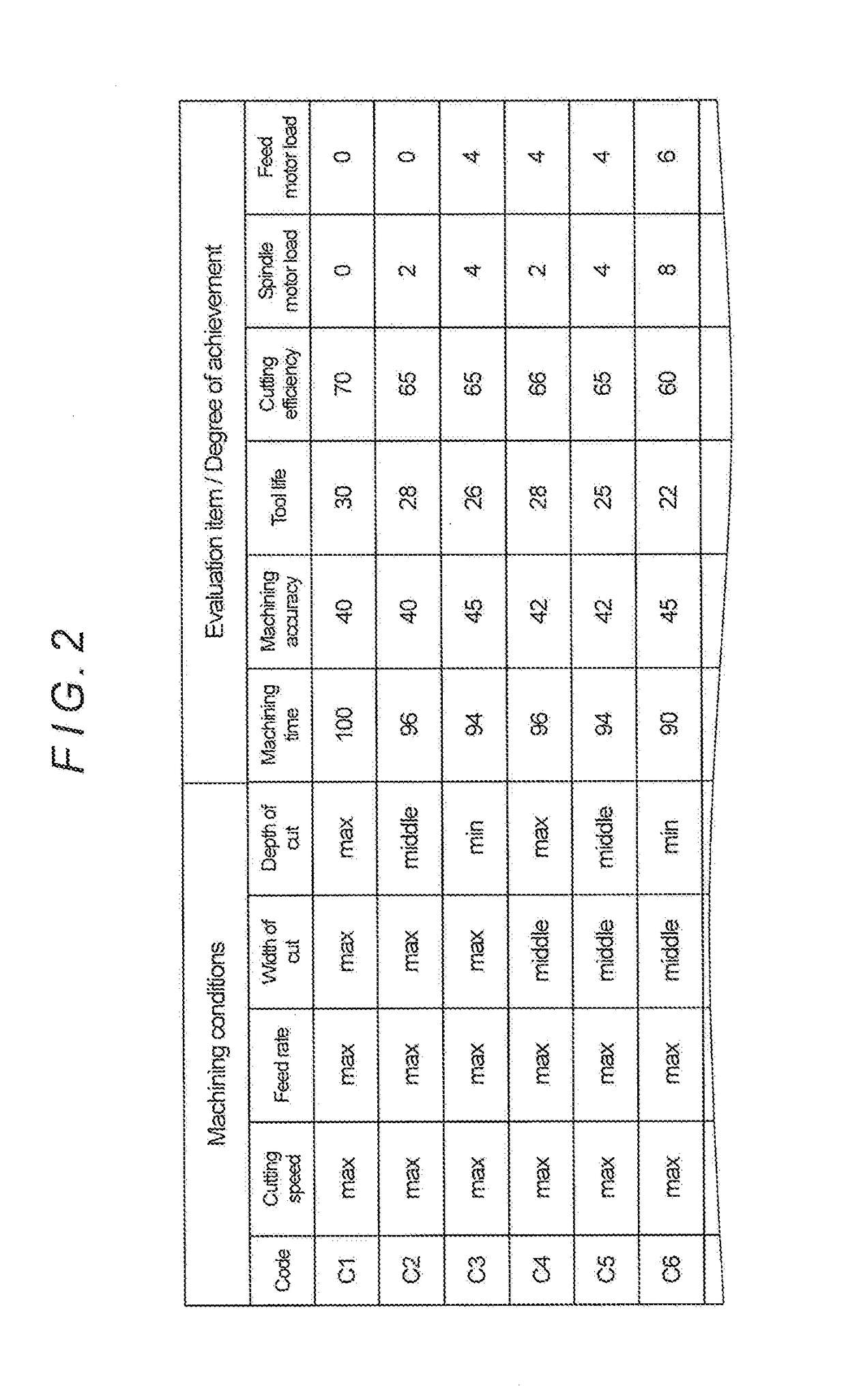

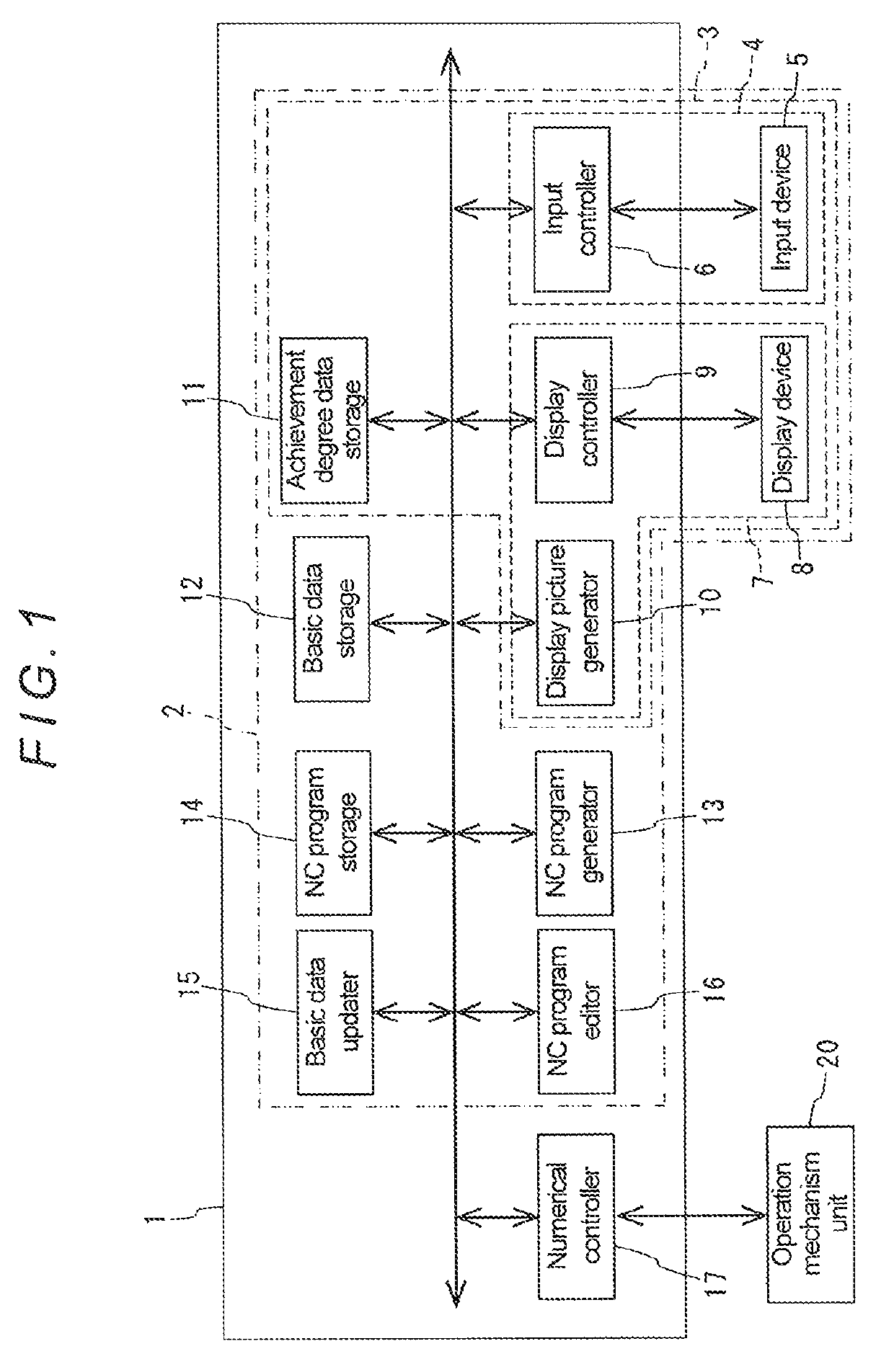

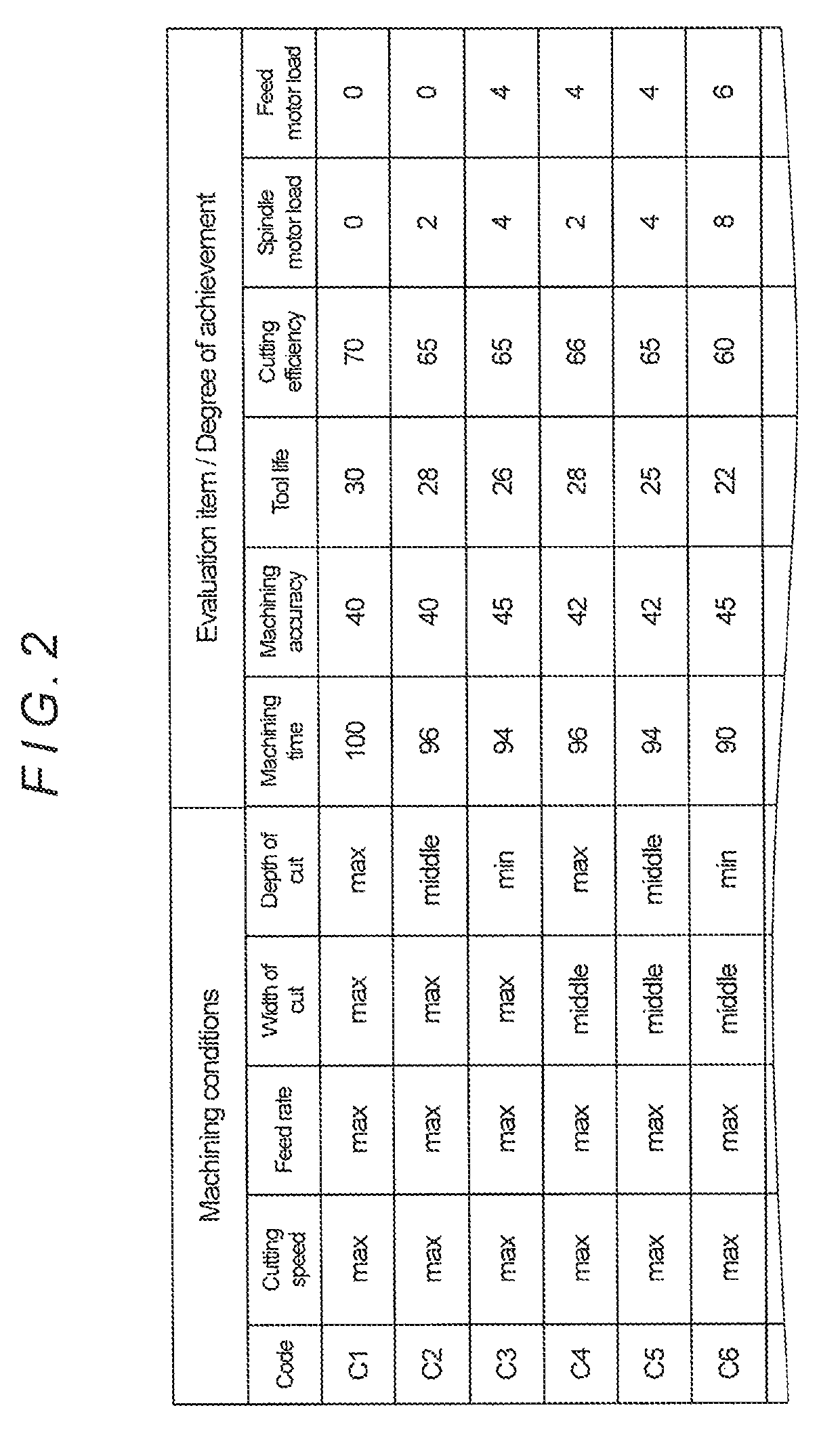

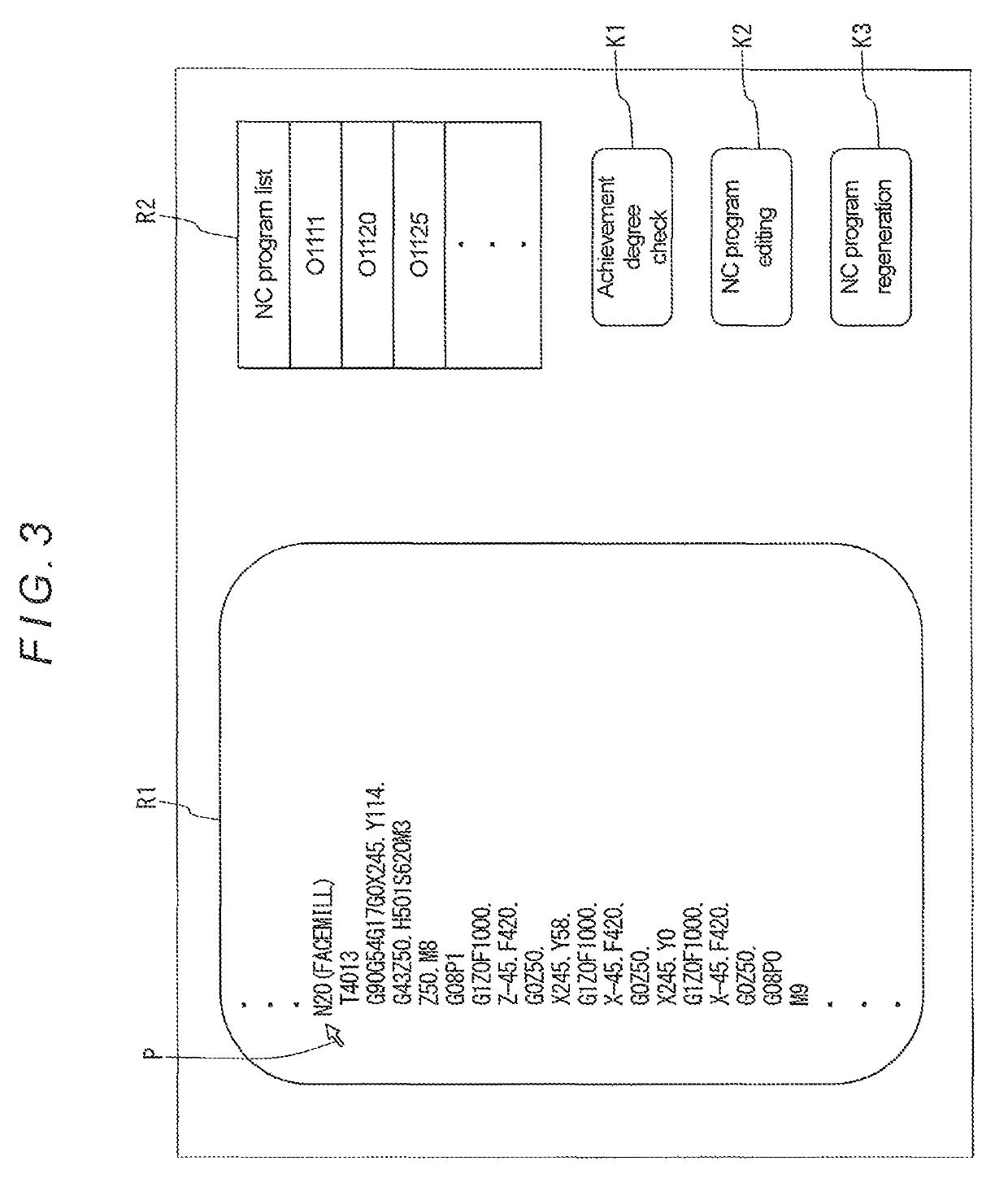

Machining Status Display Apparatus, and NC Program Generating Apparatus and NC Program Editing Apparatus Provided with the Same

ActiveUS20180032054A1Improve machining accuracyLow costComputer controlSimulator controlData memoryComputer science

A machining status display apparatus includes an achievement degree data storage storing achievement degree data relating to a degree of achievement of each of predetermined machining-related evaluation items within a range determined by attainable maximum and minimum values of the evaluation item and storing the degrees of achievement of the evaluation items obtained under each of predetermined sets of machining conditions in association with the set of machining conditions, a display part displaying the degrees of achievement of the evaluation items corresponding to a selected set of machining conditions by referring to the data in the achievement degree data storage, and an input part inputting a selection signal for selecting a set of machining conditions. The display part displays the degrees of achievement of the evaluation items obtained under the set of machining conditions corresponding to the selection signal by referring to the data in the achievement degree data storage.

Owner:DMG MORI SEIKI CO LTD

Concrete cutter

ActiveUS7451757B2Easy and reliable positioningIncrease the cutting widthStone-like material working toolsCutting machinesEngineeringCantilever

An improved concrete cutter has a longitudinally-extending primary boom and one or more saw carriage sub-assemblies that move along the length of the boom. “Wing-like” boom extensions are hingedly secured at each end of the primary boom. The boom extensions can be easily positioned at each end of the primary boom to extend the cutting width of the concrete cutter and without requiring removal of the boom extensions from the concrete cutter. The saw carriage sub-assemblies are independently movable along the boom extensions. Carriage spacing is variably-adjustable along the boom such that each saw carriage can move toward or away from the other saw carriage. Each saw carriage sub-assembly is height-variable and is self-adjusting to contours in the profile of the concrete surface being cut.

Owner:SPIDER CUT IP

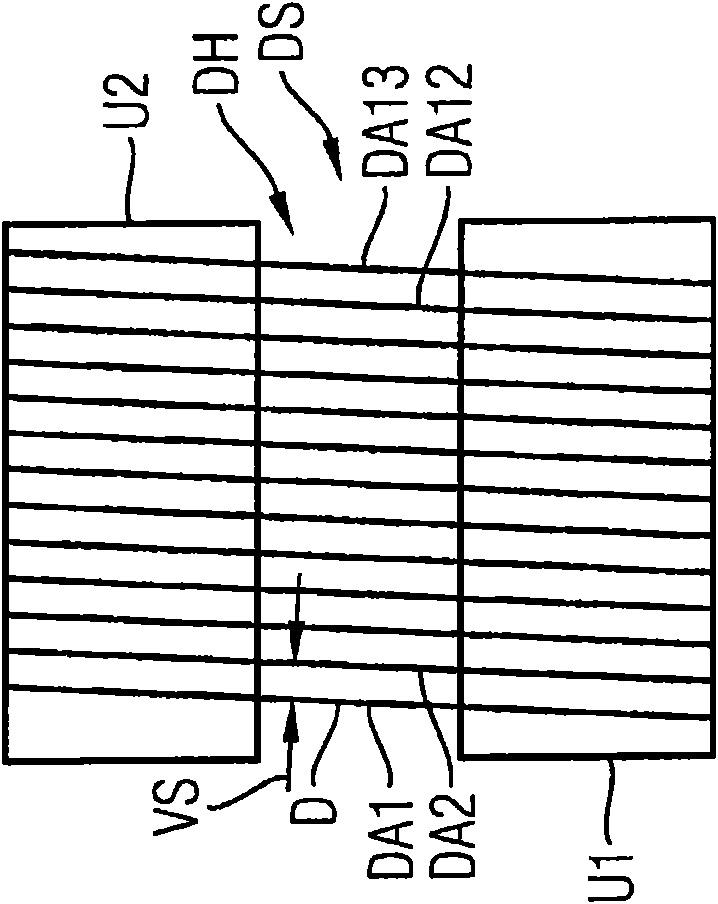

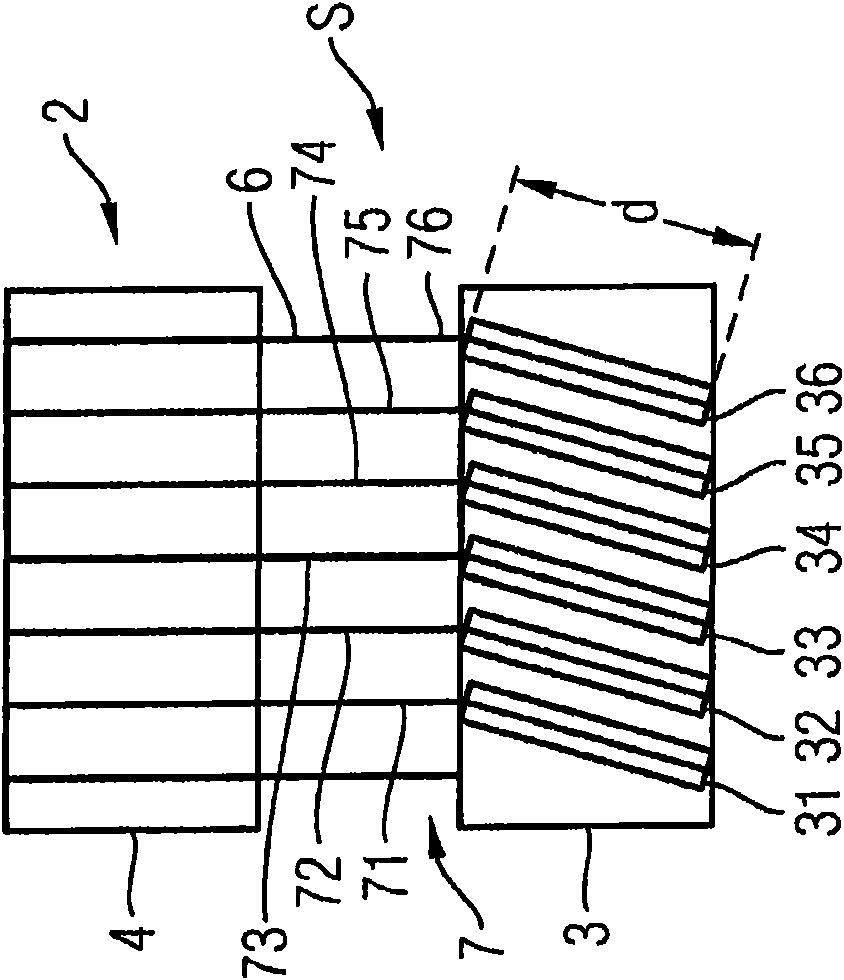

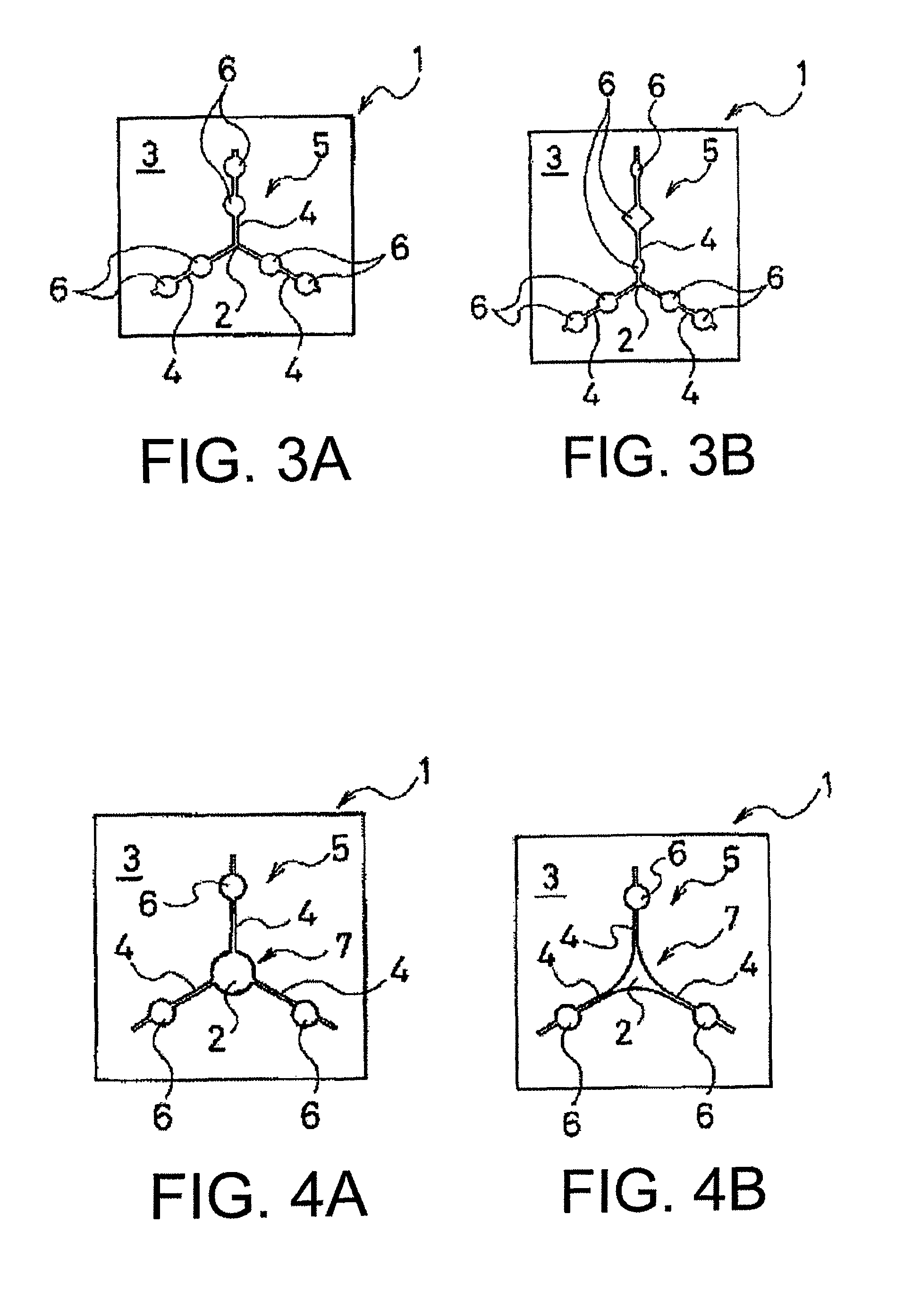

Wire saw and method for producing a wire saw

The invention relates to a wire saw (S) for separating a plurality of ceramic components (11-16) from a ceramic component block (1), comprising a roller system (2), said roller system comprising a plurality of deflecting rollers (3-5) guiding a wire (6) to form a wire harp (7), wherein at least one of the deflecting rollers (3) is divided into separate discs (31-36) guiding a single wire winding (61-66) of the wire (6) and being inclined at an adjustable angle (a) of less than 90 DEG to an axle (A) connecting the centers (M1-M6) of the discs (31-36).

Owner:SIEMENS AG

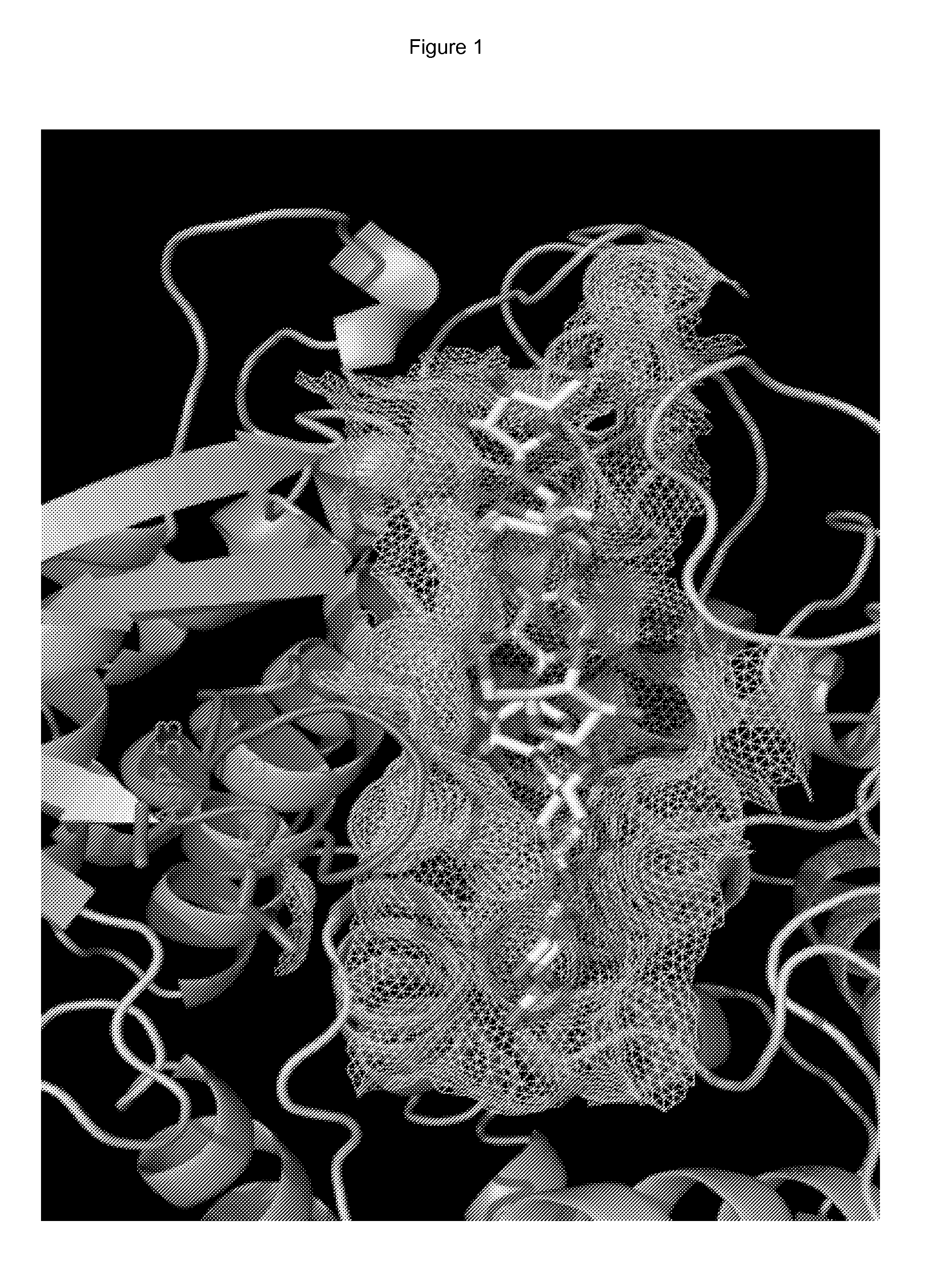

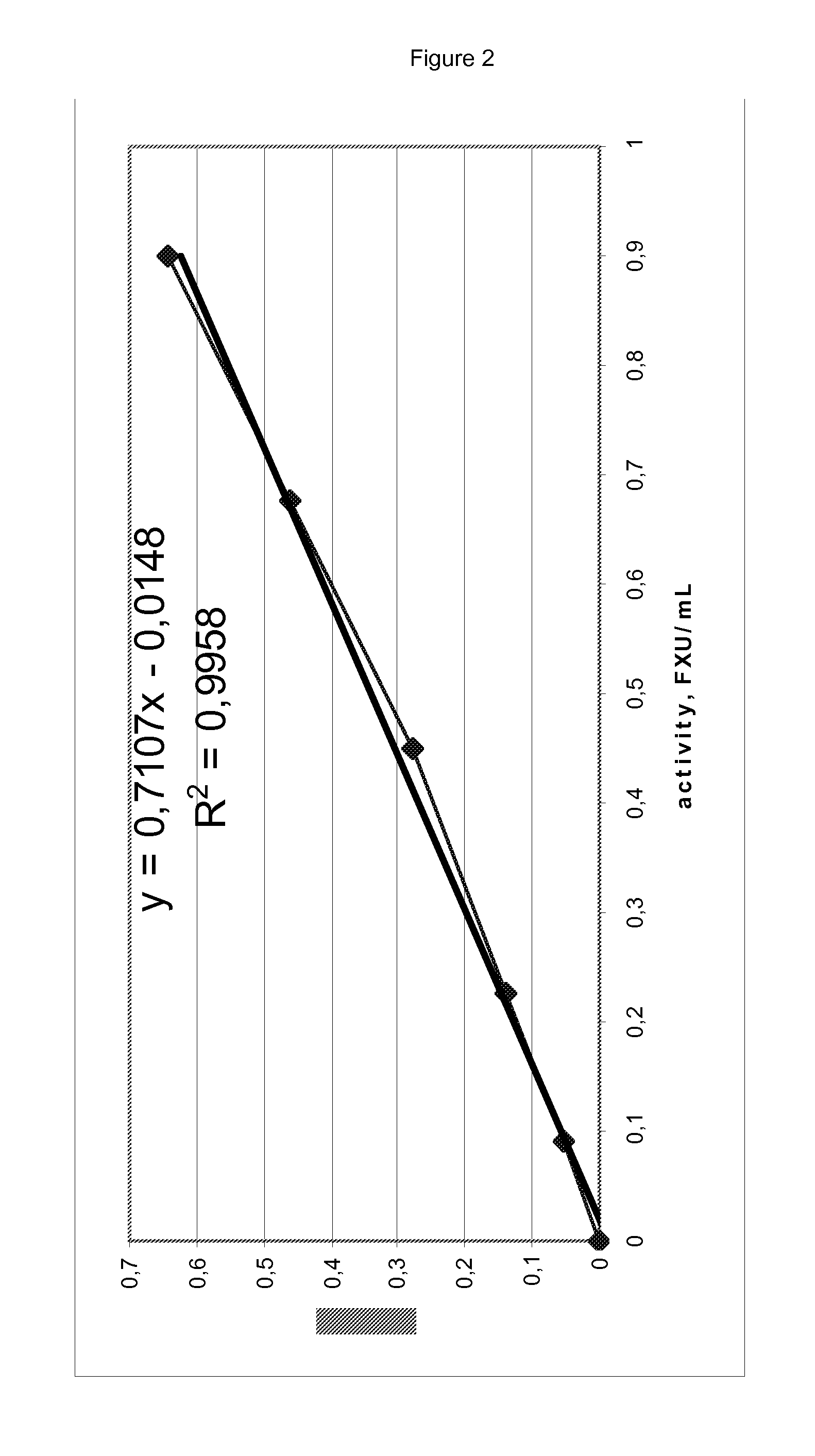

Methods of Producing GH8 Xylanase Variants

ActiveUS20120288585A1Increase volumeIncrease the cutting widthFungiDough treatmentBiotechnologyNucleotide

The present invention relates to isolated polypeptides having xylanase activity and isolated polynucleotides encoding the polypeptides. The invention also relates to nucleic acid constructs, vectors, and host cells comprising the polynucleotides as well as methods of producing and using the polypeptides.

Owner:NOVOZYMES AS

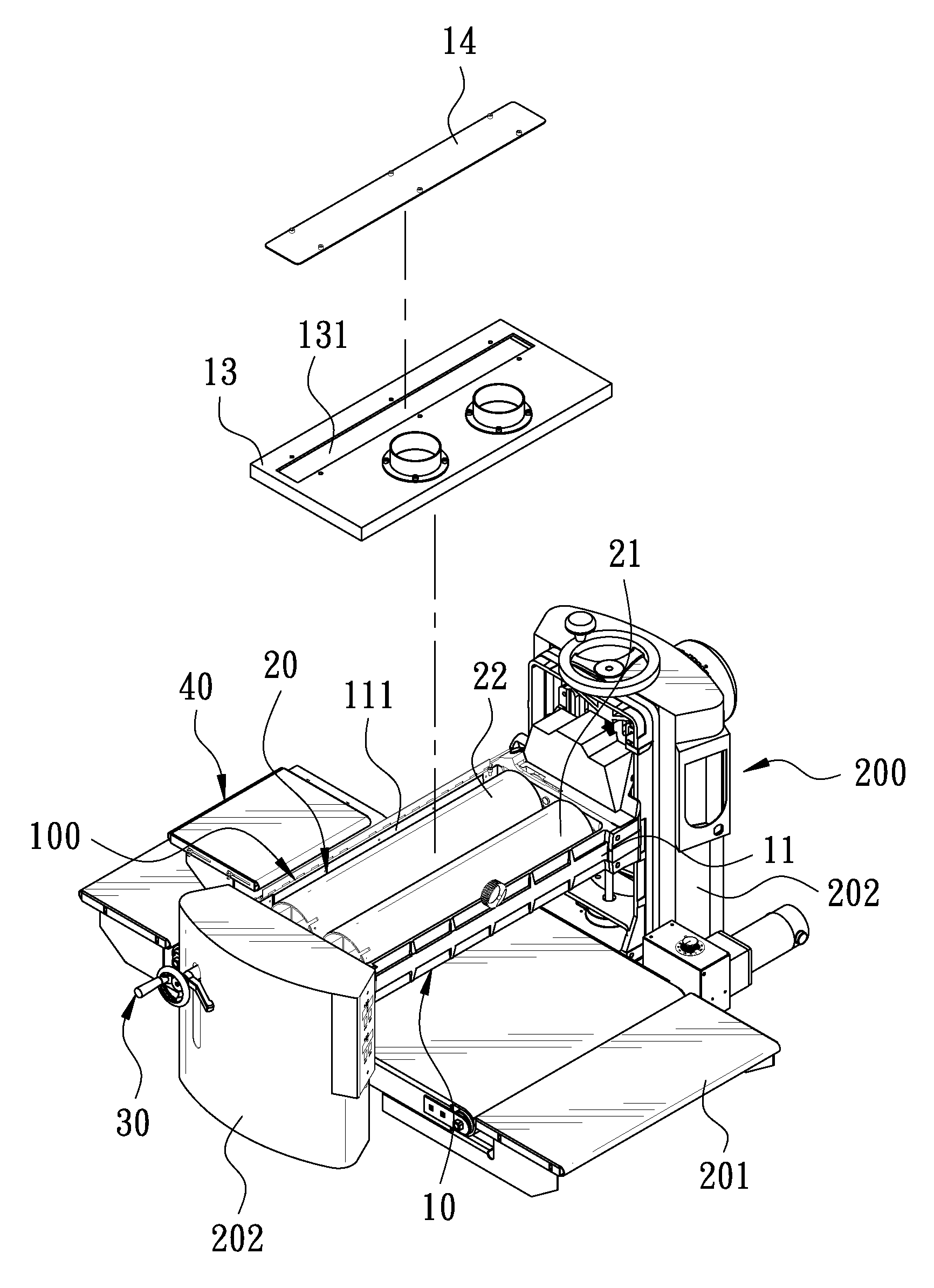

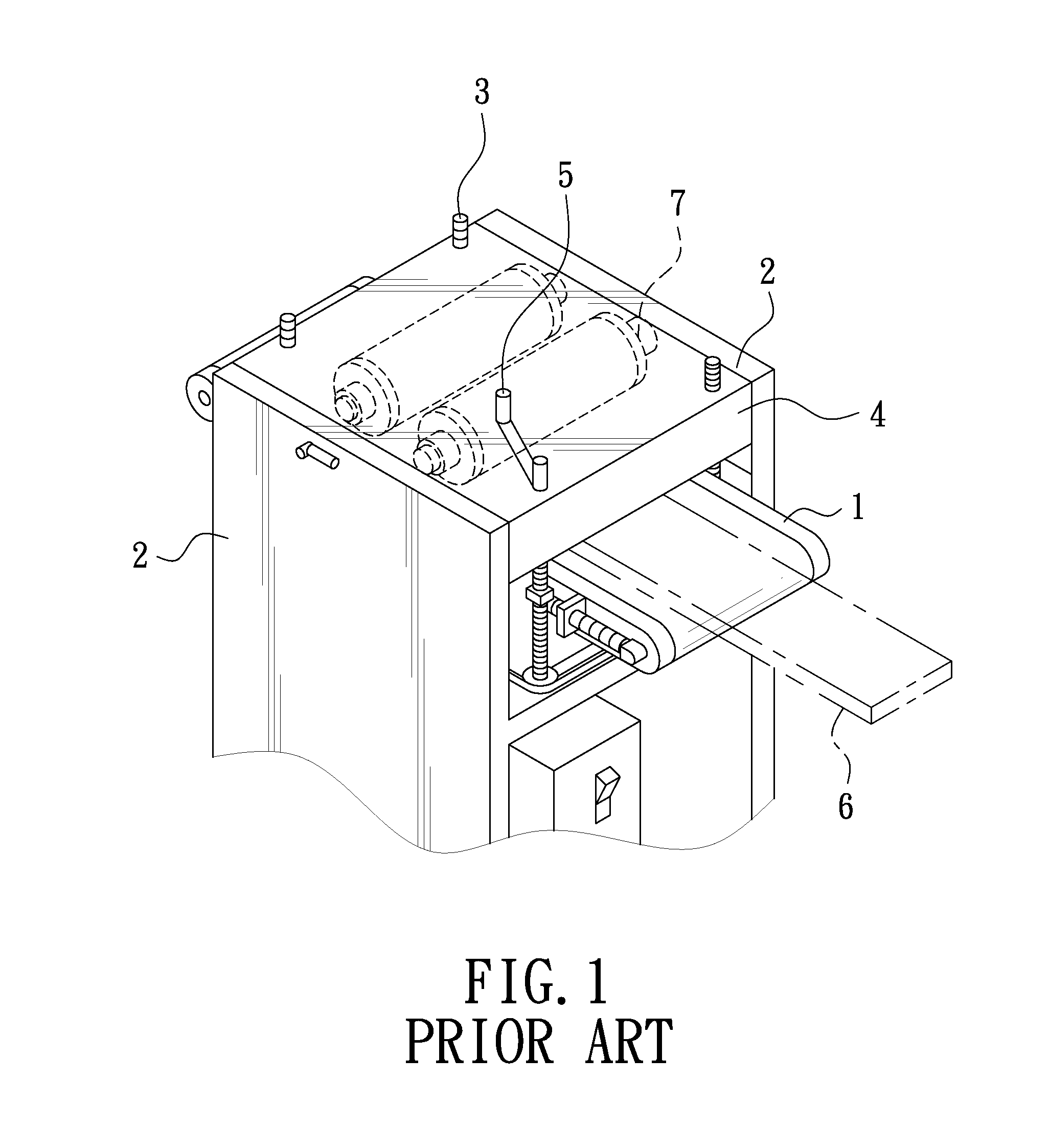

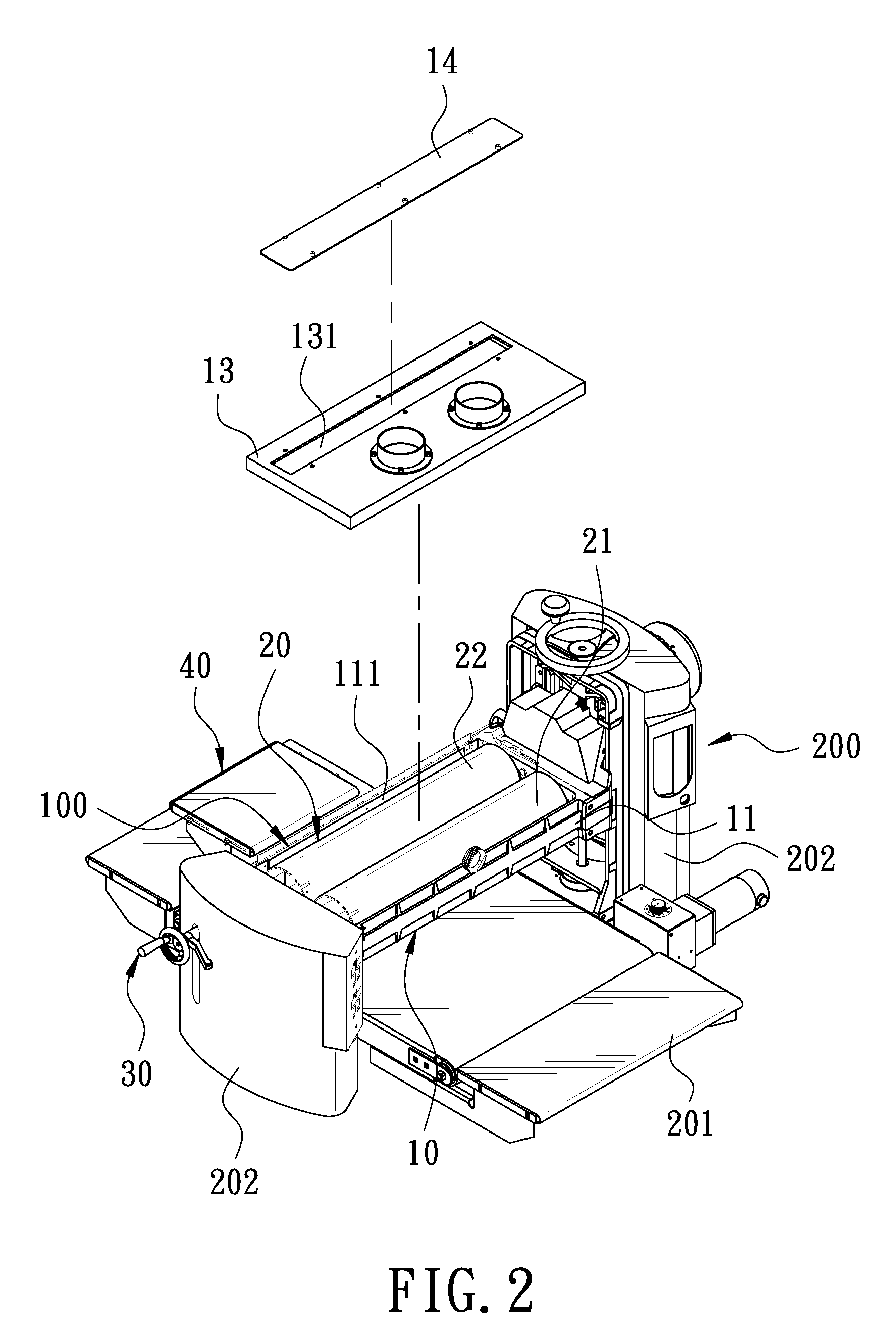

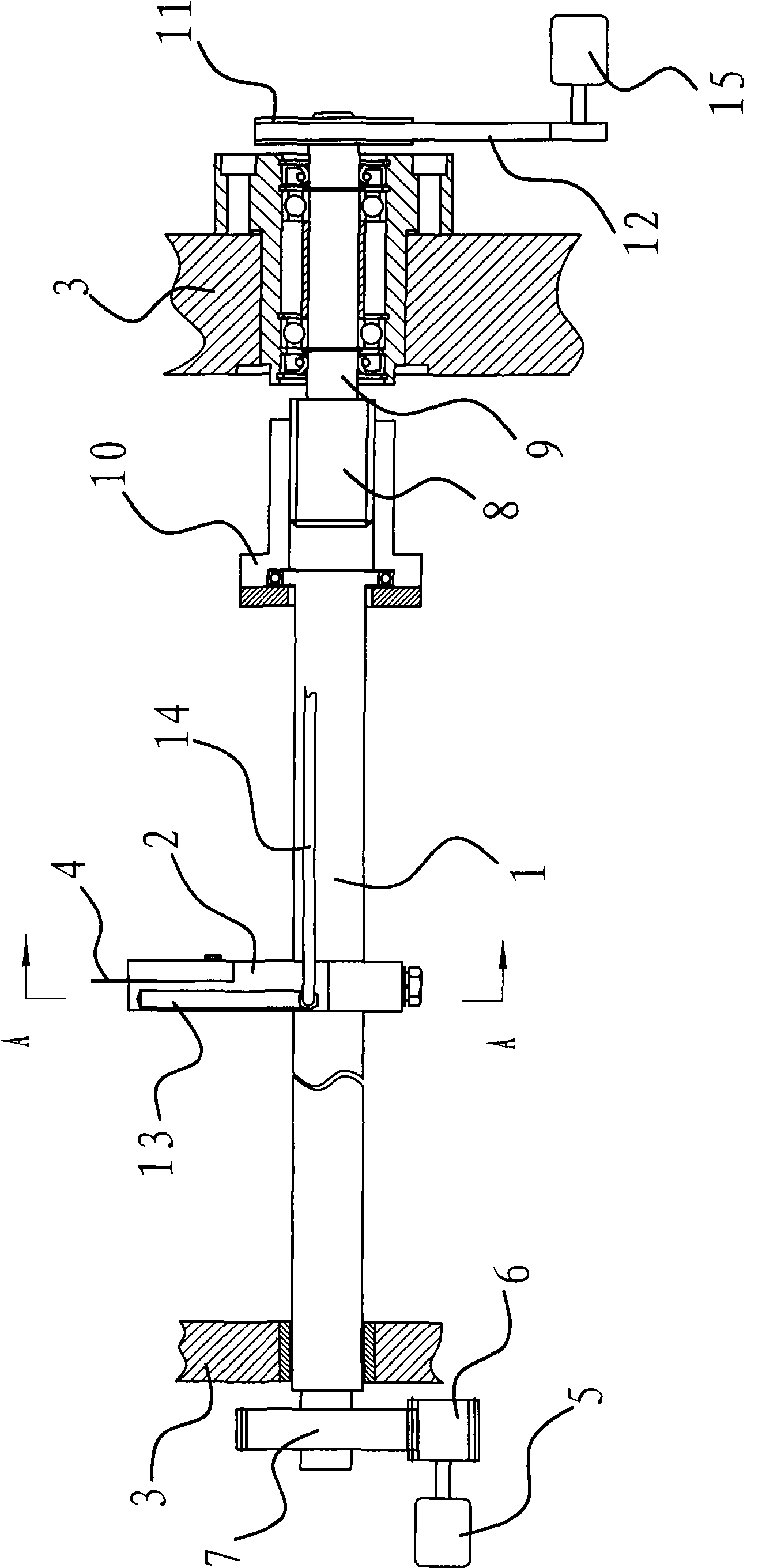

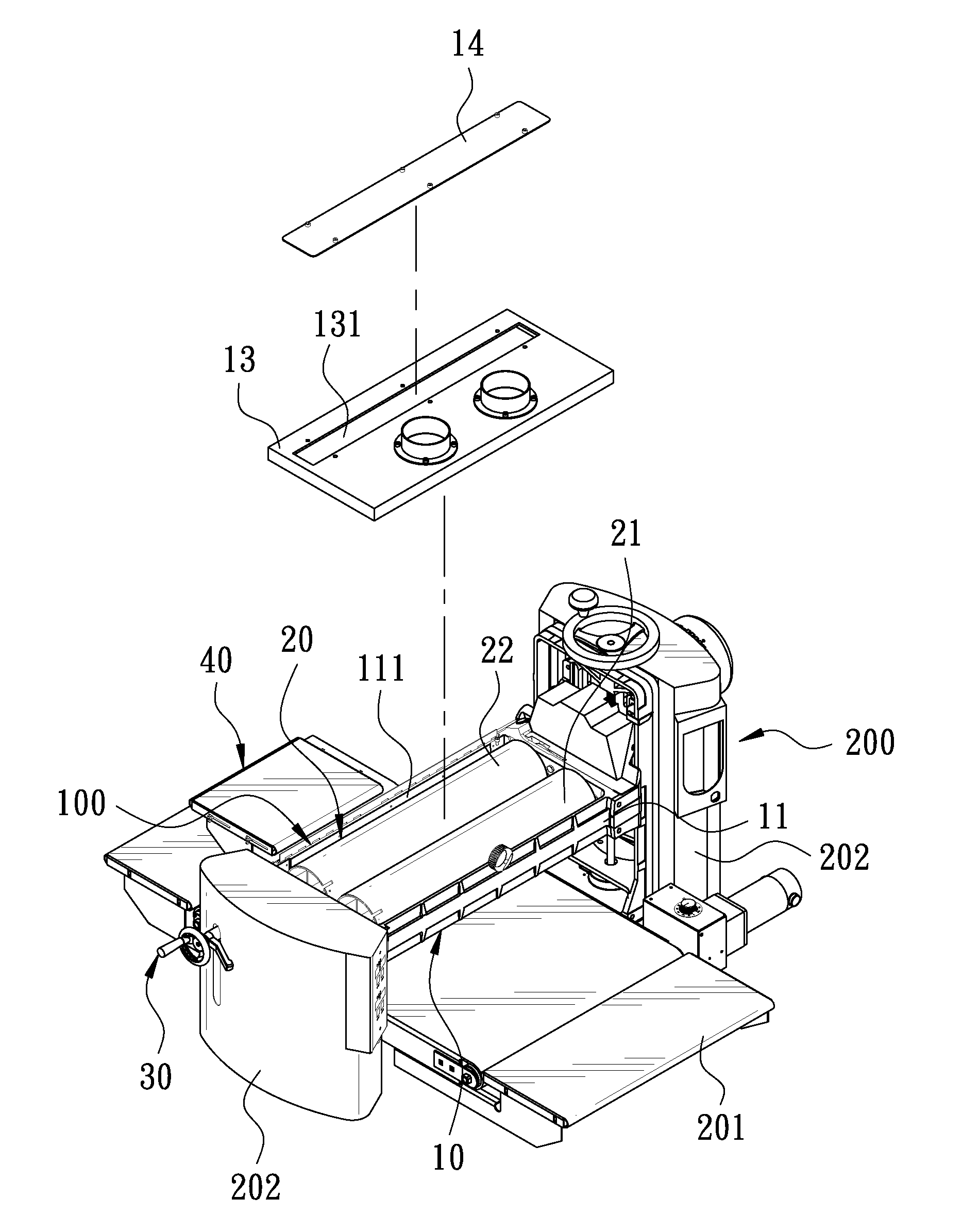

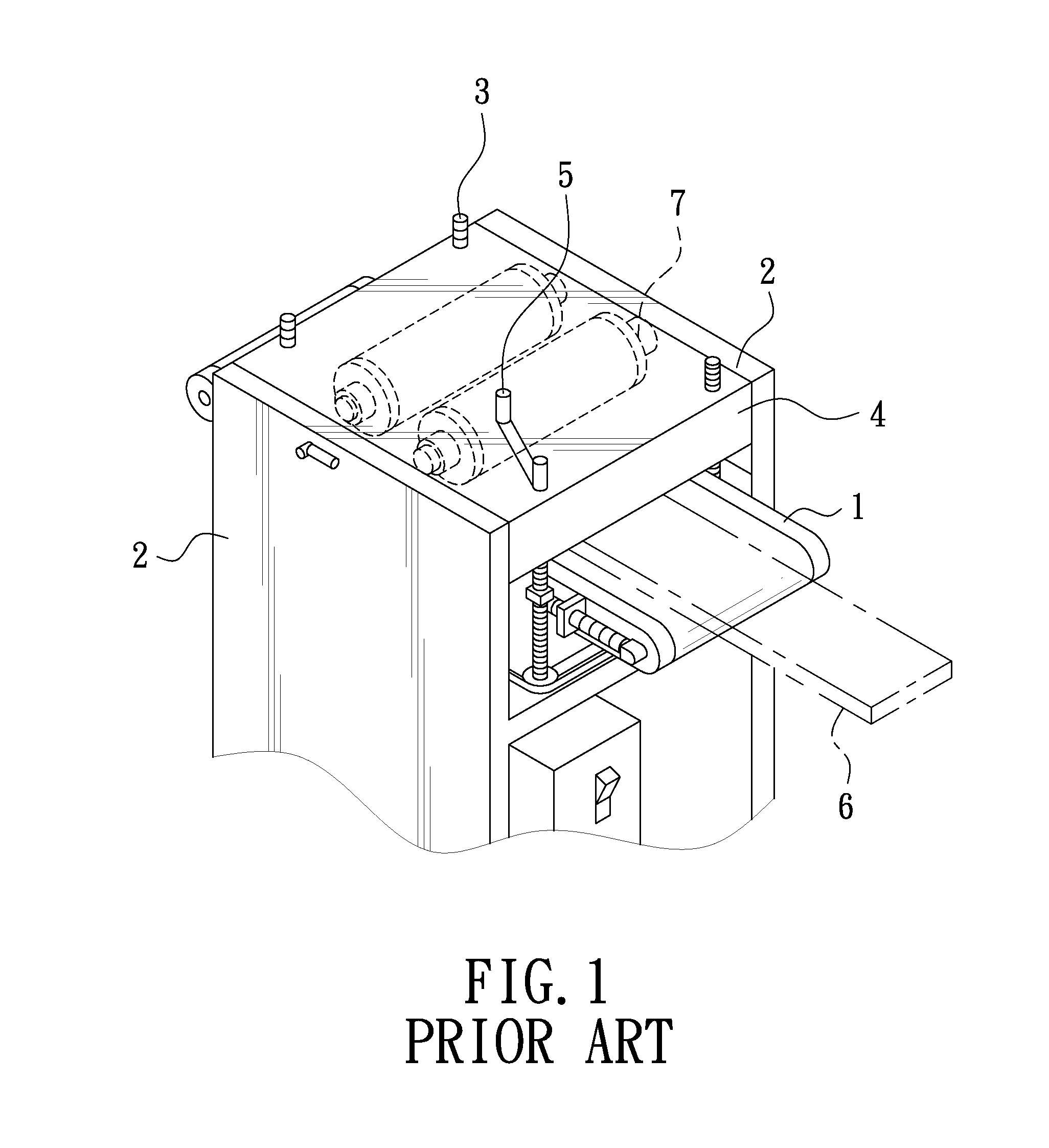

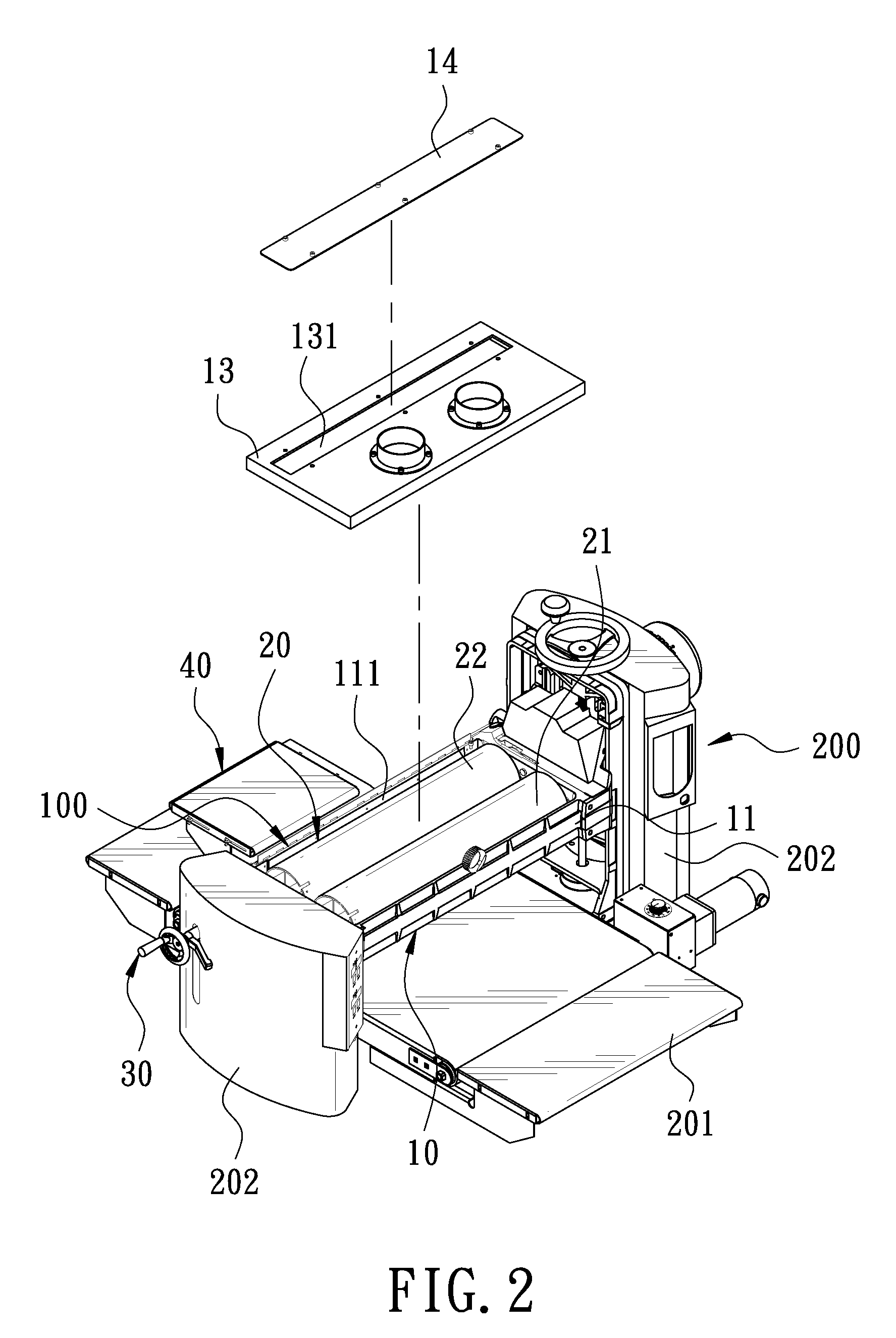

Abrasive apparatus of a sander

ActiveUS8287335B2Easy to useLow costGrinding feed controlAutomatic grinding controlSanderEngineering

An abrasive apparatus of a sander is provided. The abrasive apparatus is disposed above a worktable of the sander and includes a base and a lift unit. At least one abrasive wheel is provided in the base. The base has a top formed with at least one slot. The lift unit is disposed on the abrasive wheel to bring the abrasive wheel to move up so that an abrasive surface of the abrasive wheel passes through the slot of the base and protrudes from the base for the top of the base to sand the side of a workpiece. The cutting width of the sander can be extended to enhance the use of the sander, so the manufacturing process can be shortened to increase the production efficiency.

Owner:KINGSAND MACHINERY

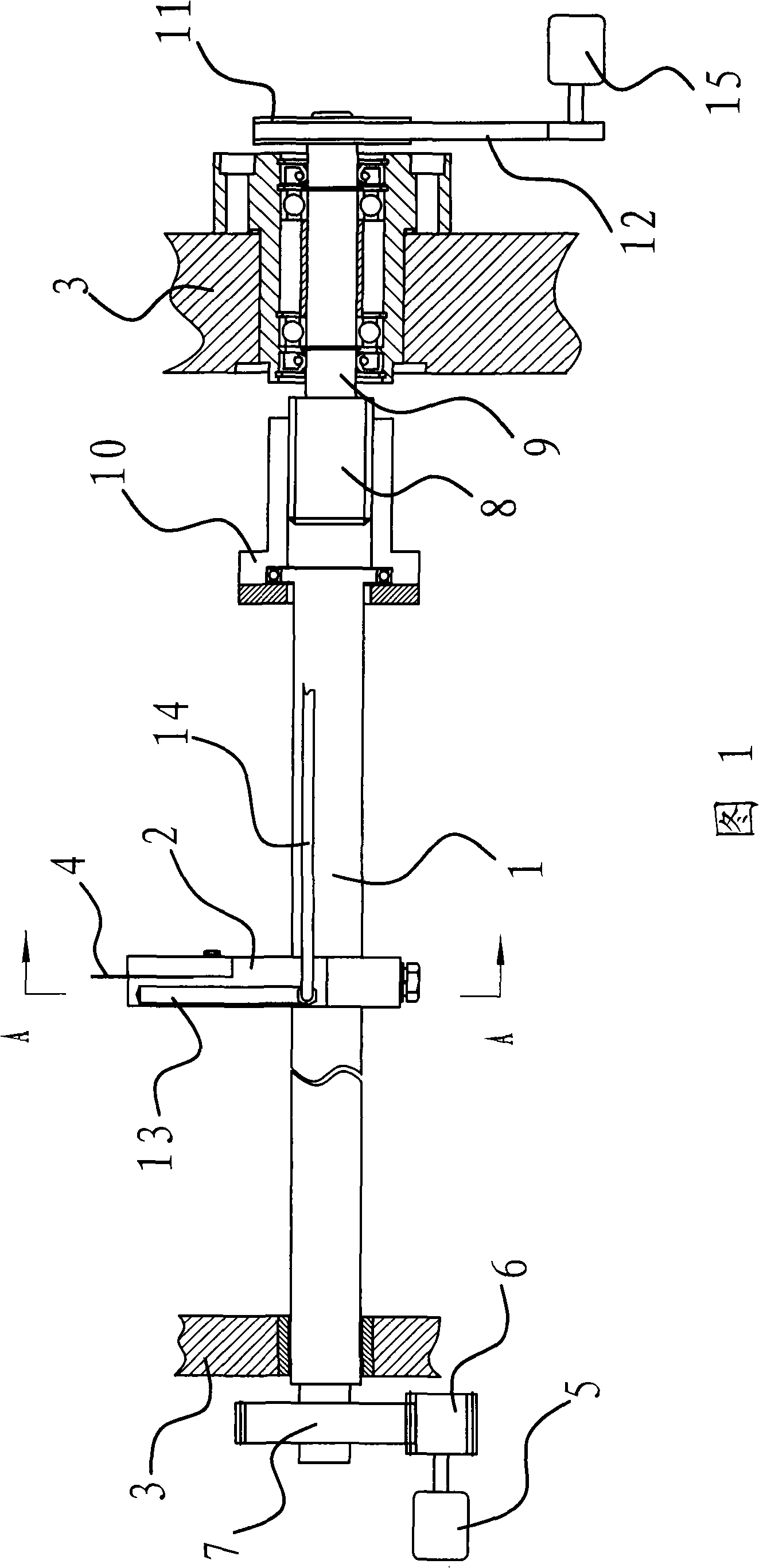

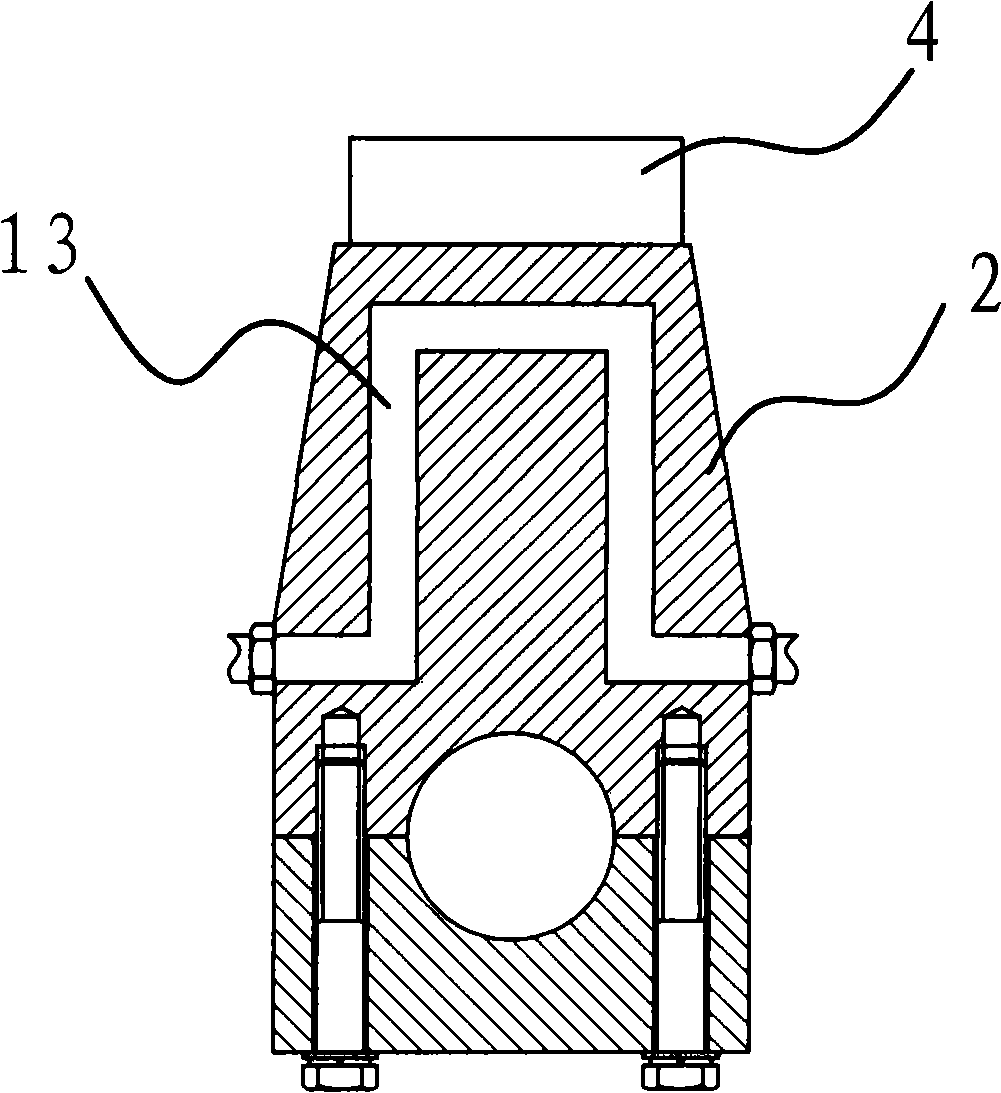

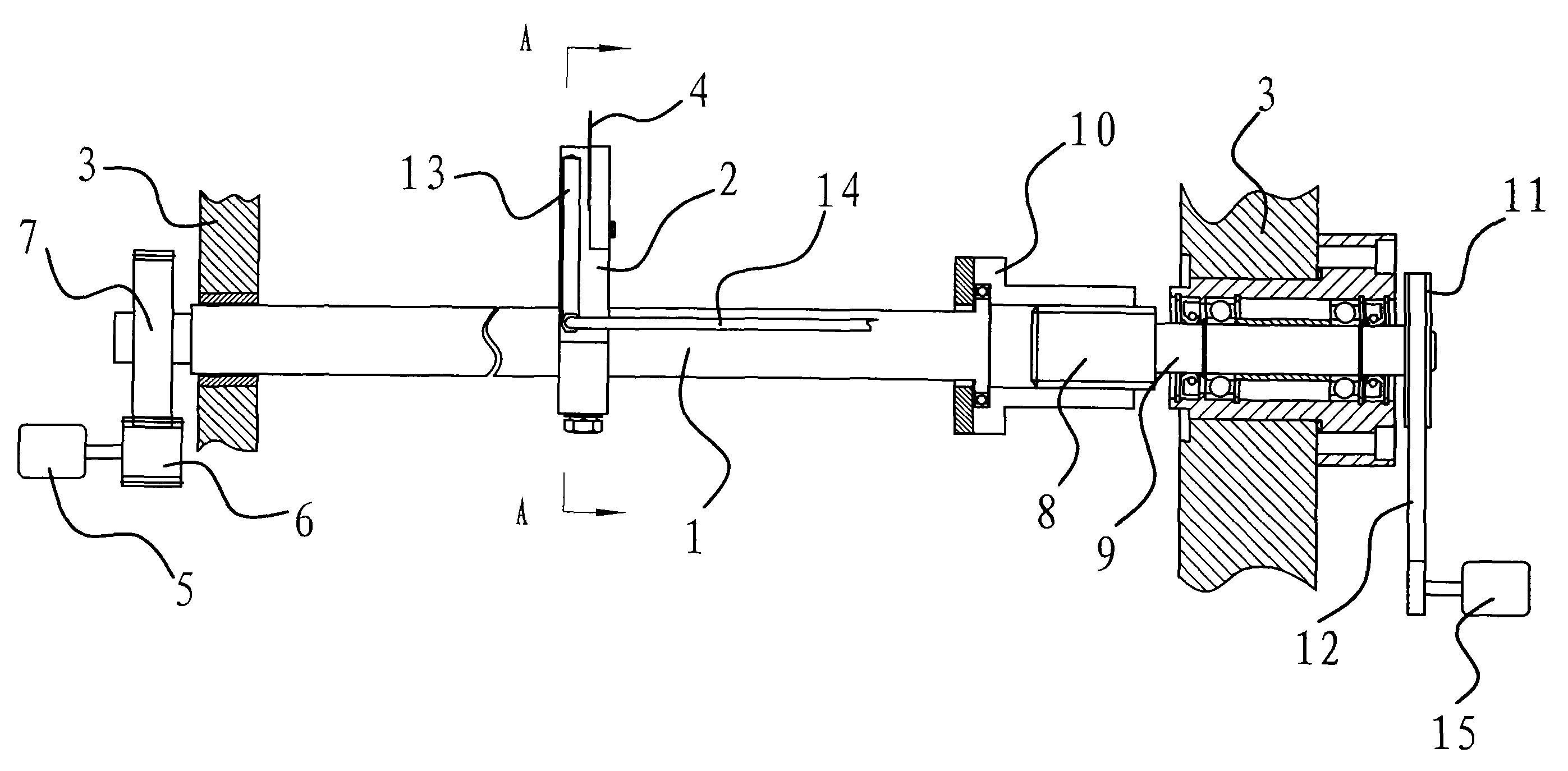

High-speed vacuum coating online cutting device

ActiveCN101545098AExtended service lifeIncrease the cutting widthVacuum evaporation coatingSputtering coatingEngineeringCooling pipe

The invention provides a high-speed vacuum coating online cutting device, which belongs to the technical field of coating processing. The high-speed vacuum coating online cutting device solves the problem that the prior cutter has poor cooling effect when cutting coated films and sheets. The high-speed vacuum coating online cutting device comprises a rotating shaft, a tool rest and a power mechanism connected with the rotating shaft, wherein the tool rest is fixedly arranged on the rotating shaft, the outer end part of the tool rest is provided with a cutting blade, the power mechanism drives the rotating shaft to rotate radially so as to control the cut-in of the cutting blade, the tool rest is made from a heat conduction material and is internally provided with a cooling passage, the rotating shaft is provided with a cooling device for providing cooling liquid, and two ends of the cooling passage are connected with the cooling device through a cooling pipe so as to form a closed circulation path. The cutting device is provided with a cooling structure to cool the cutting blade, and the cooling effect is good so that the service life of the cutting blade is prolonged. Simultaneously, a cutting blade adjusting device is arranged on the cutting device for adjusting the position of the cutting blade so as to adjust the cutting width of the films or the sheets.

Owner:WENLING HUAHANG ELECTRONICS TECH CO LTD

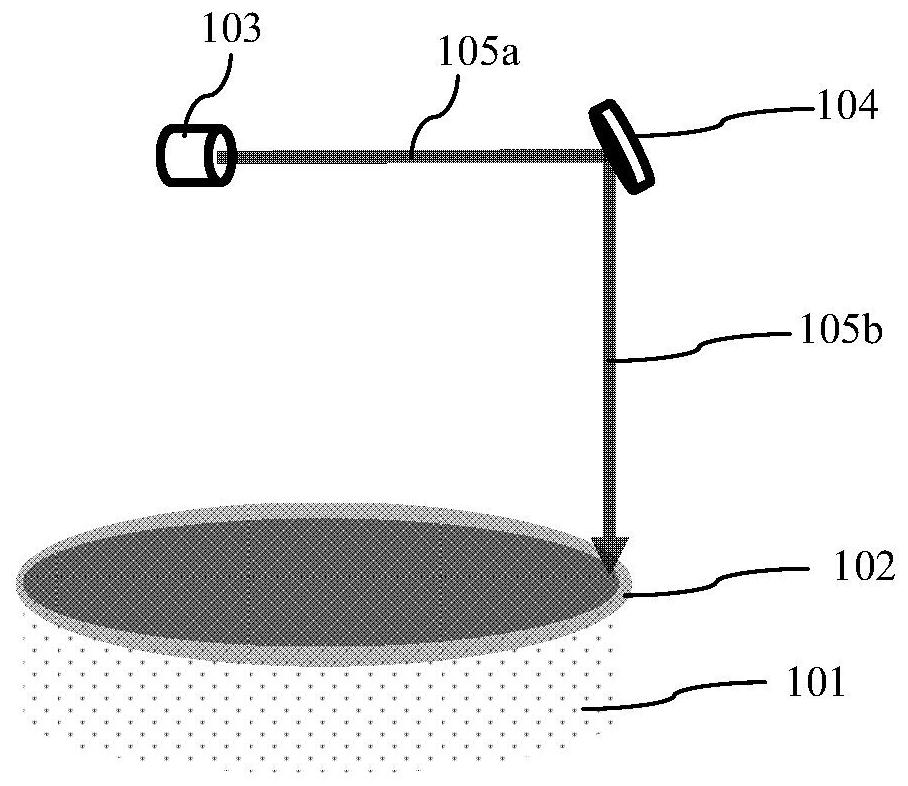

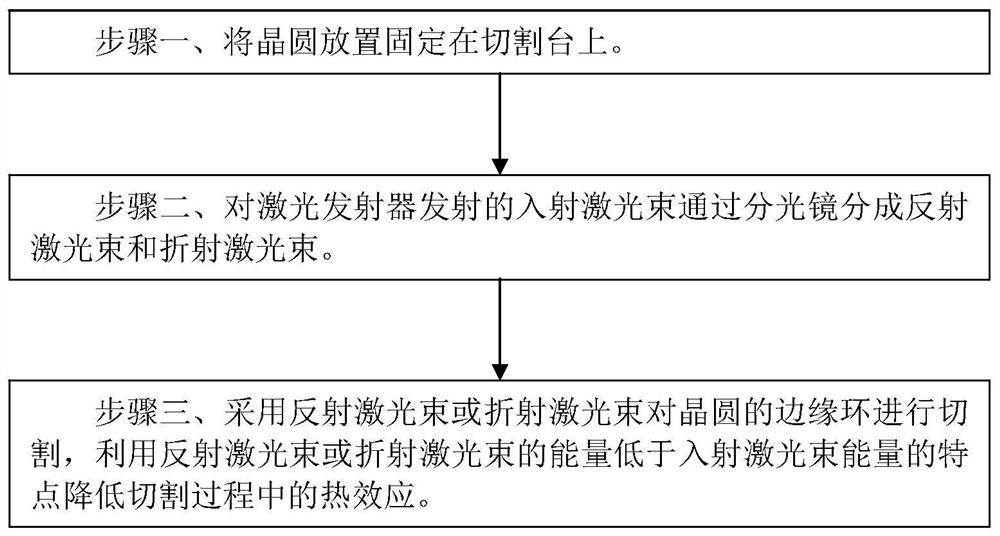

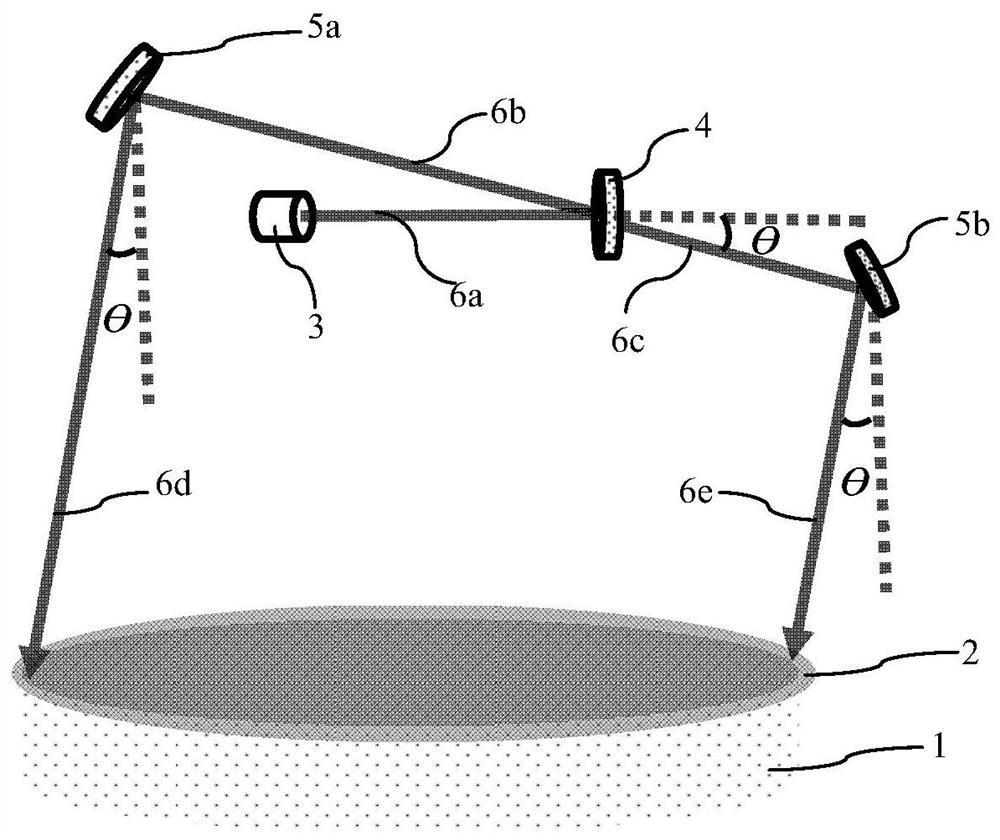

Laser cutting and ring removing method for wafer

PendingCN112705859ASave energyReduce widthMetal working apparatusLaser beam welding apparatusLaser transmitterBeam splitter

The invention discloses a laser cutting and ring removing method for a wafer. The laser cutting and ring removing method comprises the following steps that 1, the wafer is placed and fixed to a cutting table; 2, an incident laser beam emitted by a laser emitter is divided into a reflected laser beam and a refracted laser beam through a spectroscope; and 3, the edge ring of the wafer is cut and removed by adopting the reflected laser beam or the refracted laser beam, and the heat effect in the cutting process is reduced by utilizing the characteristic that the energy of the reflected laser beam or the refracted laser beam is lower than that of the incident laser beam. According to the laser cutting and ring removing method, the width of the laser cutting light beam can be increased, the laser cutting light beam is ensured to have lower energy so that the heat effect in the cutting process can be reduced, ablative substances are prevented from splashing to the surface of the wafer on the inner side of the edge ring, adverse effects on effective chip crystal grains of the wafer can be prevented, and meanwhile, the wider laser cutting light beam is beneficial to cutting of the thinner wafer without generating micro cracks.

Owner:HUA HONG SEMICON WUXI LTD

Ternary polymer composite petroleum pour depressant and preparation method thereof

InactiveCN101381640BImprove low temperature rheologyQuality improvementLiquid carbonaceous fuelsFuel additivesMethacrylate2-methylpropene

The invention discloses a terpolymer composite petroleum pour point depressant and a method for preparing the same, wherein the pour point depressant is formed by the random copolymerization of maleic anhydride monomer, 2-methacrylate and carboxylic acid ethylene ester, and the weight average molecular weight is between 10, 000 and 90, 000g / mol. The invention also discloses a terpolymer compositepetroleum pour point depressant composite which consists of the following components in weight percentage: 55 t0 92 percent of the terpolymer composite petroleum pour point depressant and 8 to 45 percent of surfactant. The pour point depressant and the pour point depressant composite have the advantages of obviously improving the low-temperature rheological property of crude oil, improving the quality and efficiency of operations such as crude oil exploitation, collection-transfer, storage and the like, widening the cutting width of fraction during the crude oil refining and lowering the energy consumption of pipe transportation.

Owner:NANJING TECH UNIV

Ternary polymer composite petroleum pour-point depressant and preparation method thereof

InactiveCN104693344AImprove low temperature rheologyQuality improvementLiquid carbonaceous fuelsDrilling compositionMethacrylateTransportation energy

The invention discloses a ternary polymer composite petroleum pour-point depressant and a preparation method thereof. The ternary polymer composite petroleum pour-point depressant is prepared from monomer maleic anhydride, 2-methacrylate and vinyl carboxylate by random copolymerization and has weight average molecular weight of 10000-90000g / mol. The invention also discloses a biopolymer composite petroleum pour-point depressant composition comprising 55-92wt% of the ternary polymer composite petroleum pour-point depressant and 8-45wt% of a surfactant. The ternary polymer composite petroleum pour-point depressant and its composition can obviously improve crude oil low temperature rheological properties, improve quality and efficiency of crude oil exploitation, gathering and transportation, and storage, widens cutting width of a fraction in crude oil melting and reduces pipe transportation energy consumption.

Owner:QINGDAO HUICHENG PETROCHEM TECH

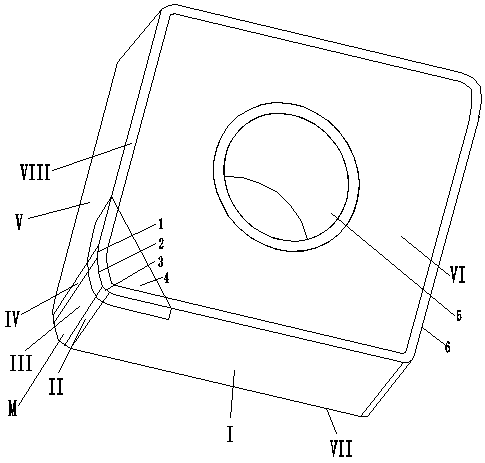

Cutting insert for high-efficient cutting

ActiveUS10086435B2Increase stiffnessExtended service lifeMilling cuttersCutting insertsMechanical engineering

A cutting insert for high-efficiency cutting is disclosed. The cutting insert includes an upper surface (110a), a lower surface (HOb), side surfaces (114) and corner side surfaces (116), which connect the side surfaces to each other. A circular opening is formed through the central portions of the upper and lower surfaces. In the cutting insert, cutting edges are formed by respective junctions between one of the upper and lower surfaces and the side surfaces and between one of the upper and lower surfaces and the corner side surfaces. The cutting edges comprise three corner cutting edges (122), six major cutting edges (124), which extend from opposite ends of the corner cutting edges towards the neighbor corner cutting edges, and three minor cutting edges (126), which are connected between the major cutting edges. Furthermore, the cutting edges may be formed on both the upper surface and the lower surface.

Owner:KORLOY

Abrasive apparatus of a sander

ActiveUS20110256816A1Cut width of be extendEnhances useGrinding feed controlAutomatic grinding controlEngineeringSander

An abrasive apparatus of a sander is provided. The abrasive apparatus is disposed above a worktable of the sander and includes a base and a lift unit. At least one abrasive wheel is provided in the base. The base has a top formed with at least one slot. The lift unit is disposed on the abrasive wheel to bring the abrasive wheel to move up so that an abrasive surface of the abrasive wheel passes through the slot of the base and protrudes from the base for the top of the base to sand the side of a workpiece. The cutting width of the sander can be extended to enhance the use of the sander, so the manufacturing process can be shortened to increase the production efficiency.

Owner:KINGSAND MACHINERY

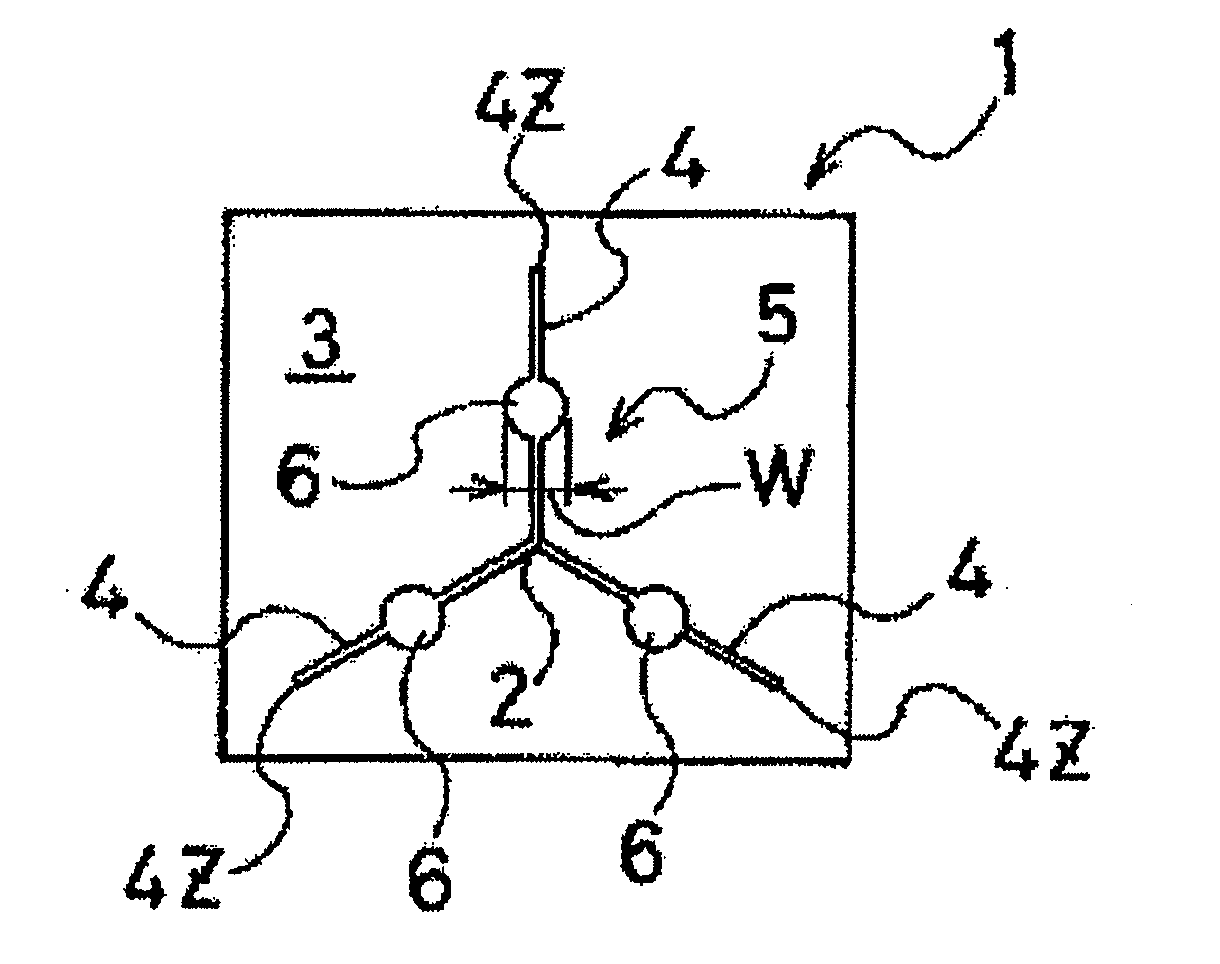

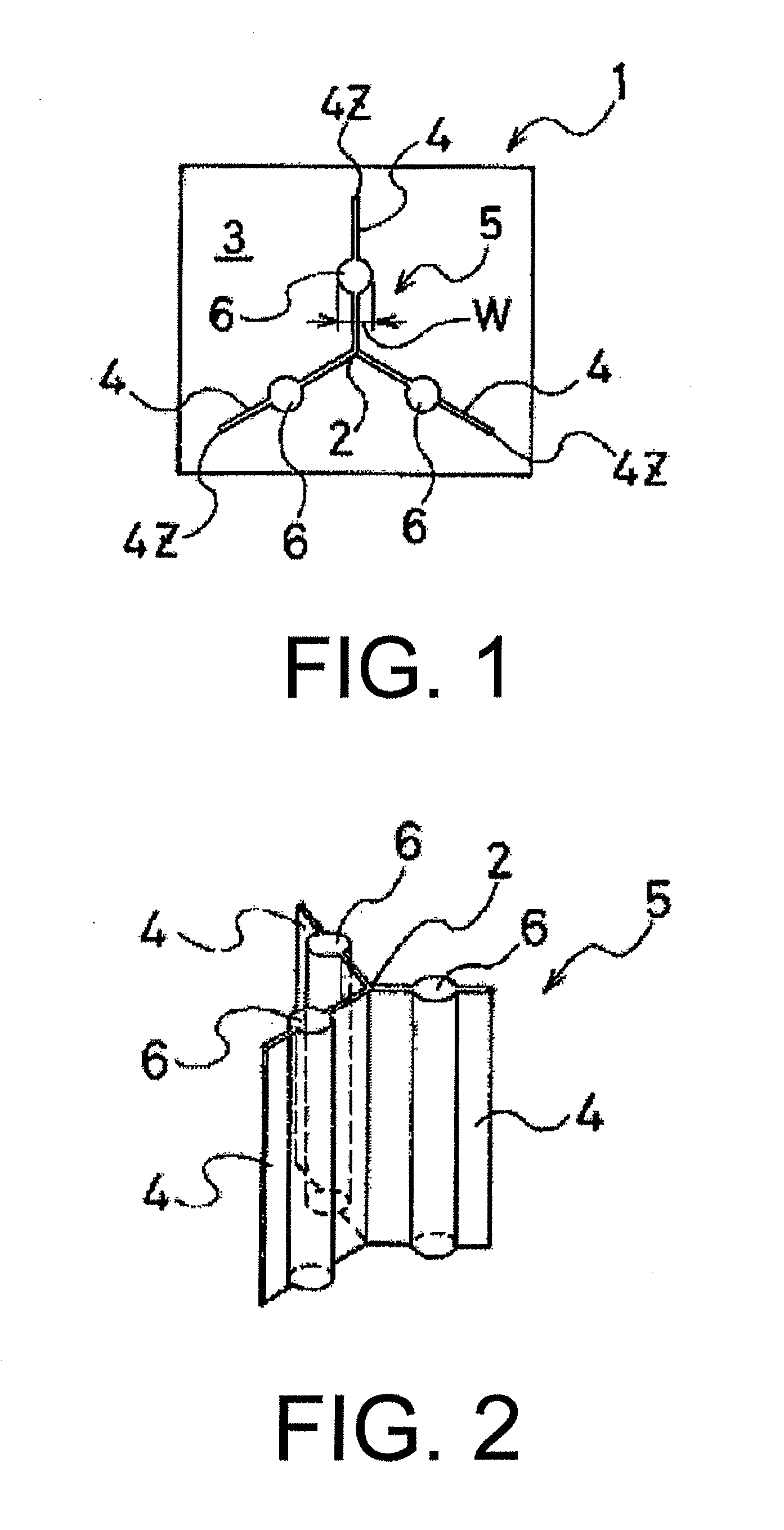

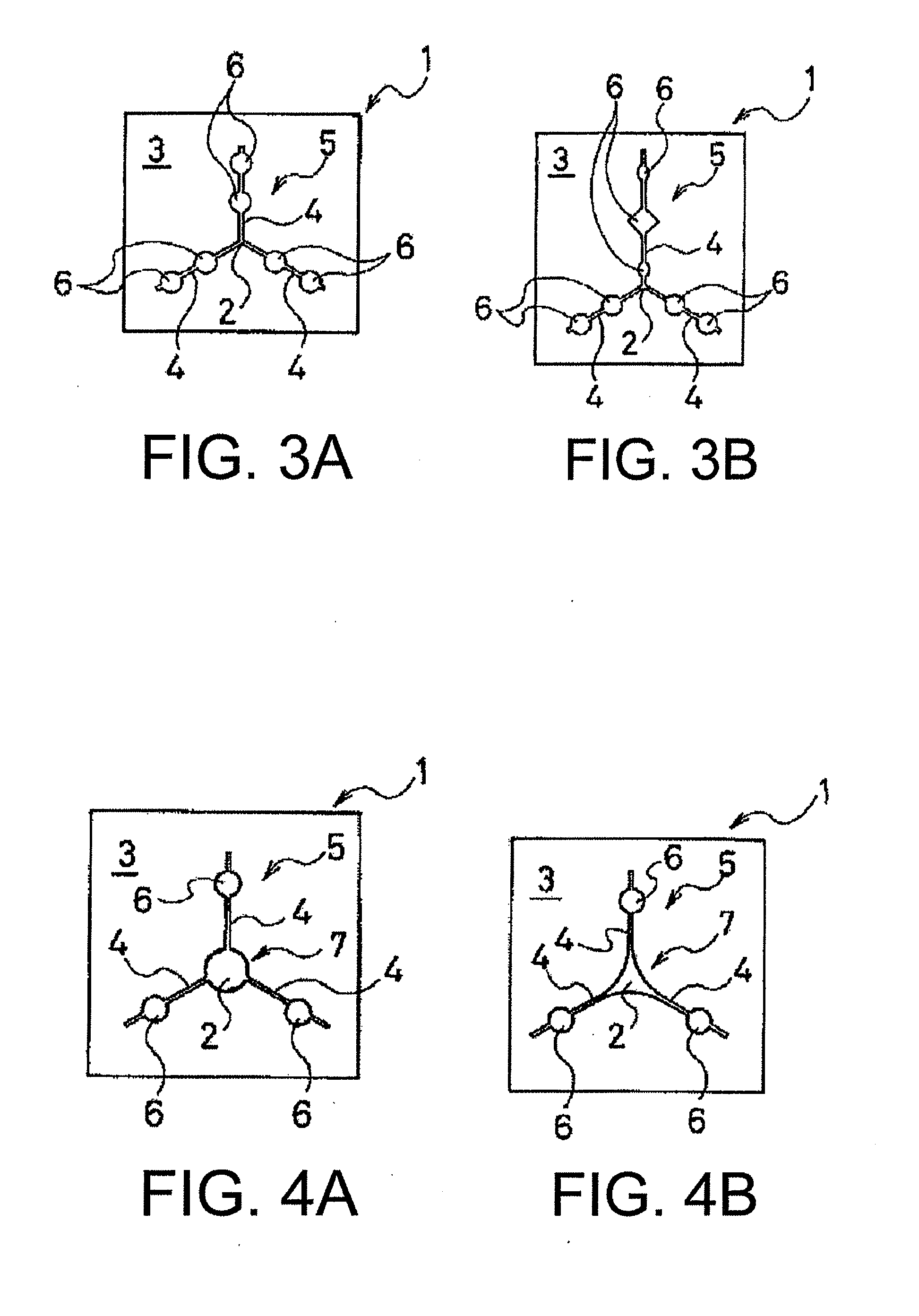

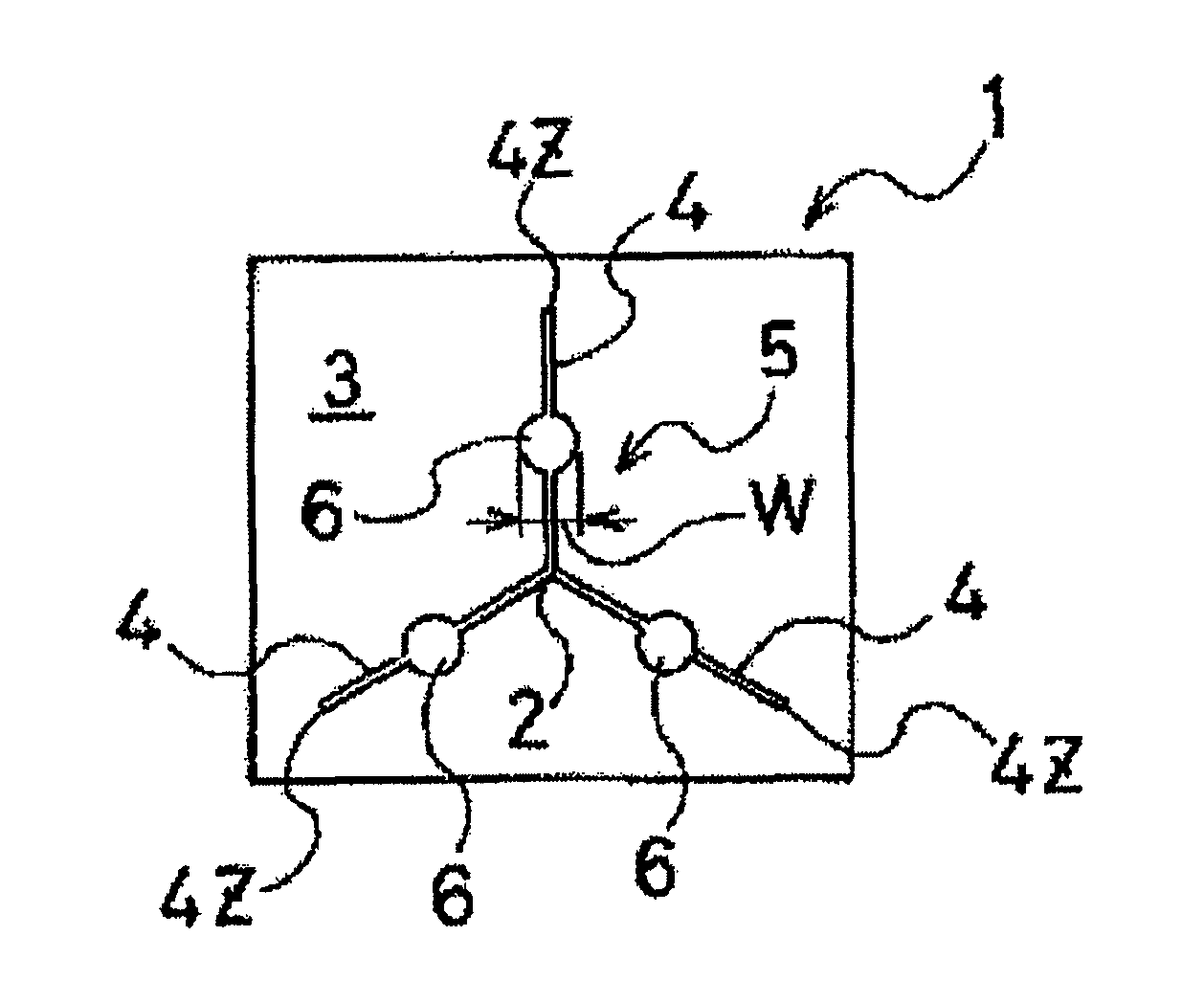

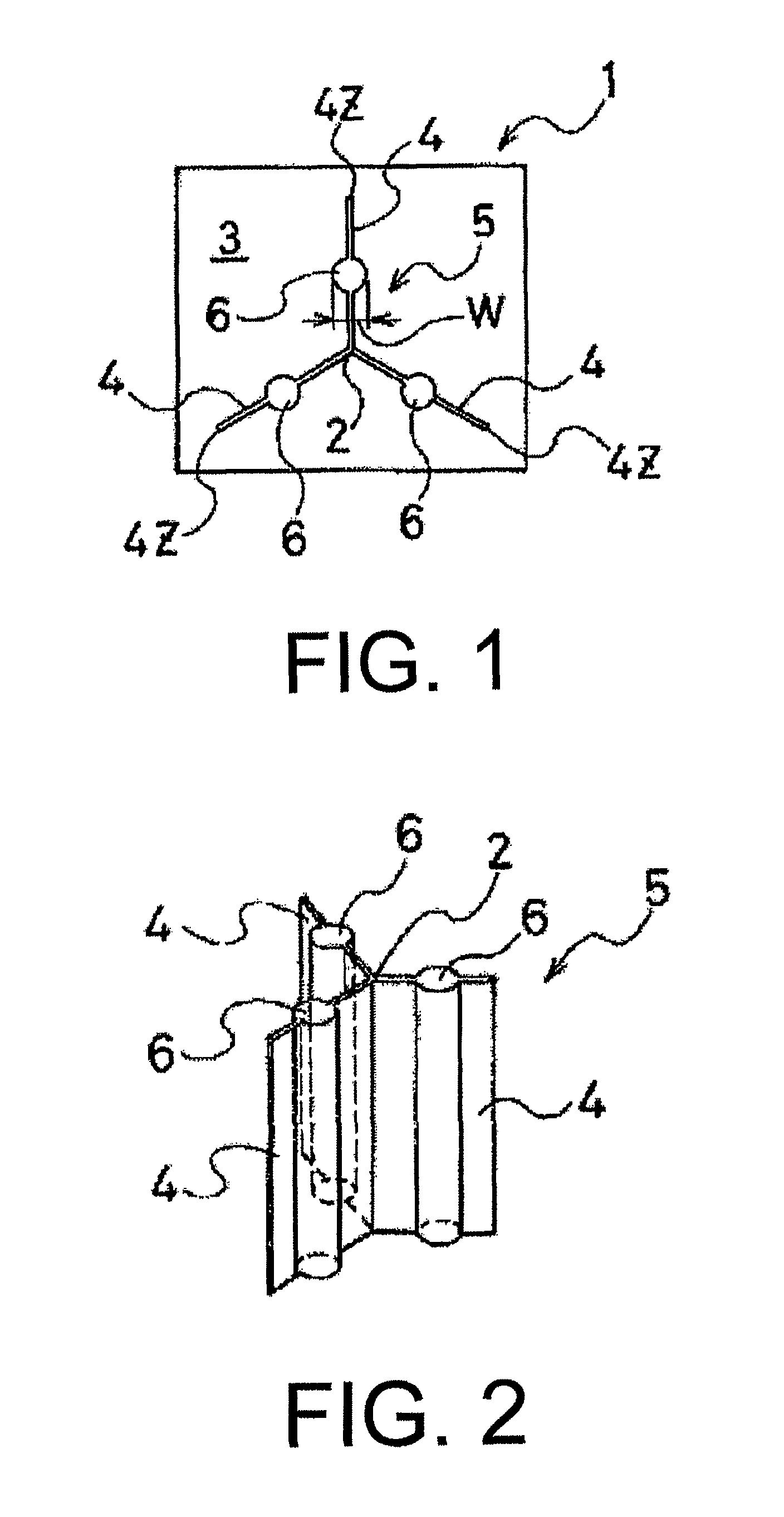

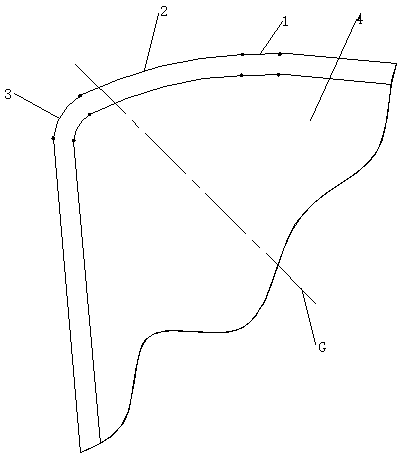

Pneumatic tire

ActiveUS20120103490A1Improve braking effectIncrease the cutting widthTyre tread bands/patternsNon-skid devicesEngineeringDepth direction

A pneumatic tire including a closed sipe 5 in a land portion 3 formed in a tread surface 1, provided with at least three cuts 4 extending in a radiation direction from an imaginary axis 2 that extends in a depth direction of the land portion 3, and that terminate in the land portion 3. A widened portion 6 where a width of a cut is locally increased is formed at least one position of an intermediate region from the imaginary axis 2 to a terminating portion 4z of the cuts 4.

Owner:THE YOKOHAMA RUBBER CO LTD

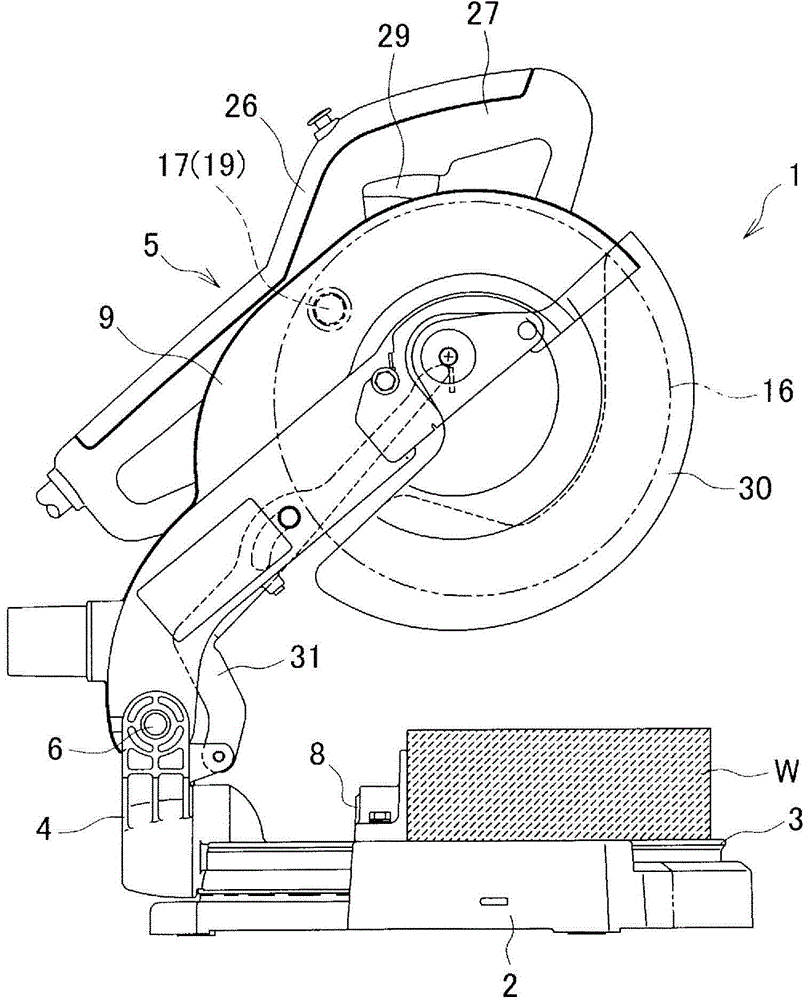

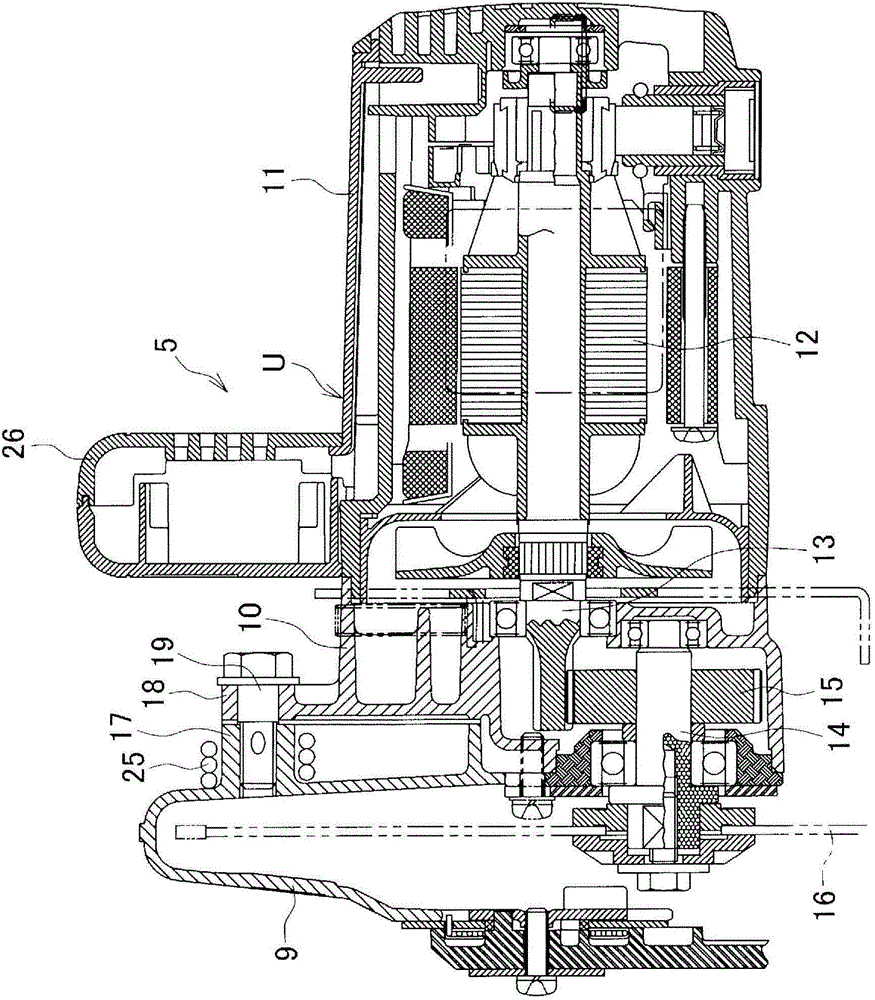

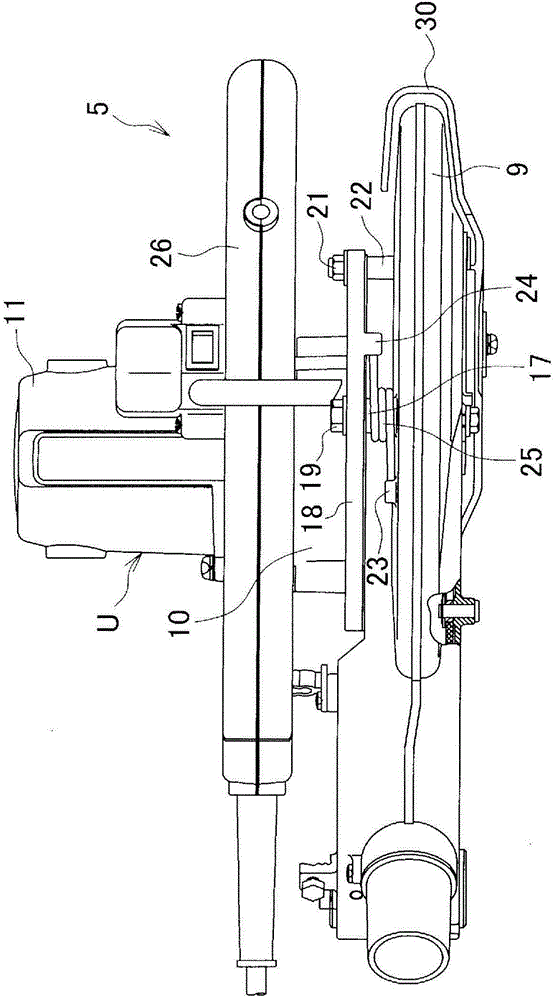

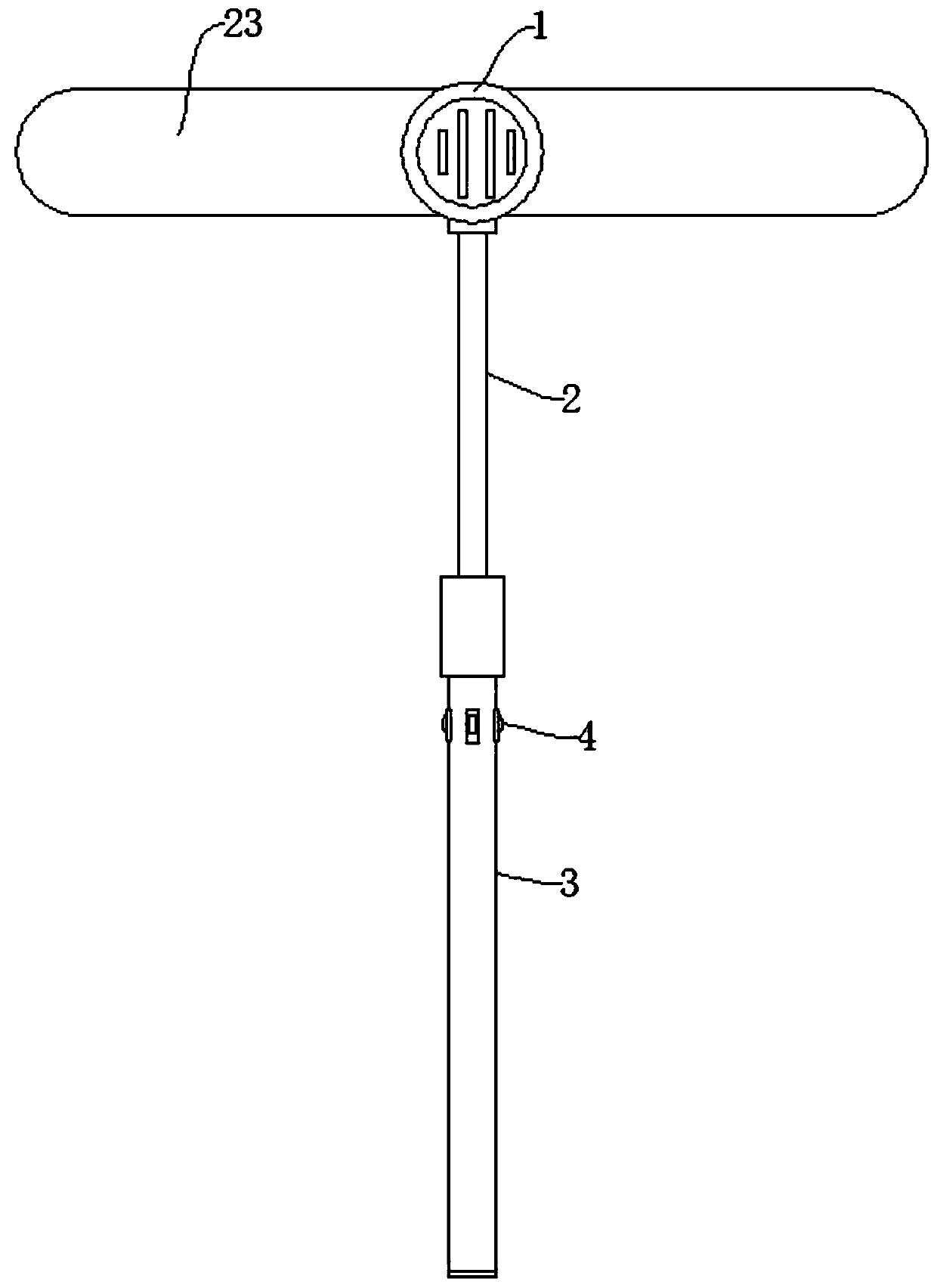

Cutting machine

To obtain high cutting ability, using a simple configuration capable of maintaining increased compactness and low cost. [Solution] A bench circular saw, wherein a unit (U) extending from a motor (12) to a saw blade (16) is separated, as a separate body, inside a main body (5), and the unit (U) is held inside the main body (5) so as to be swingable in the front-rear direction at the lower limit position of the main body (5). As a result, a wide cutting width can be obtained using a simple configuration whereby only the unit (U) is swung, without sliding the whole main body (5) in the front-rear direction.

Owner:MAKITA CORP

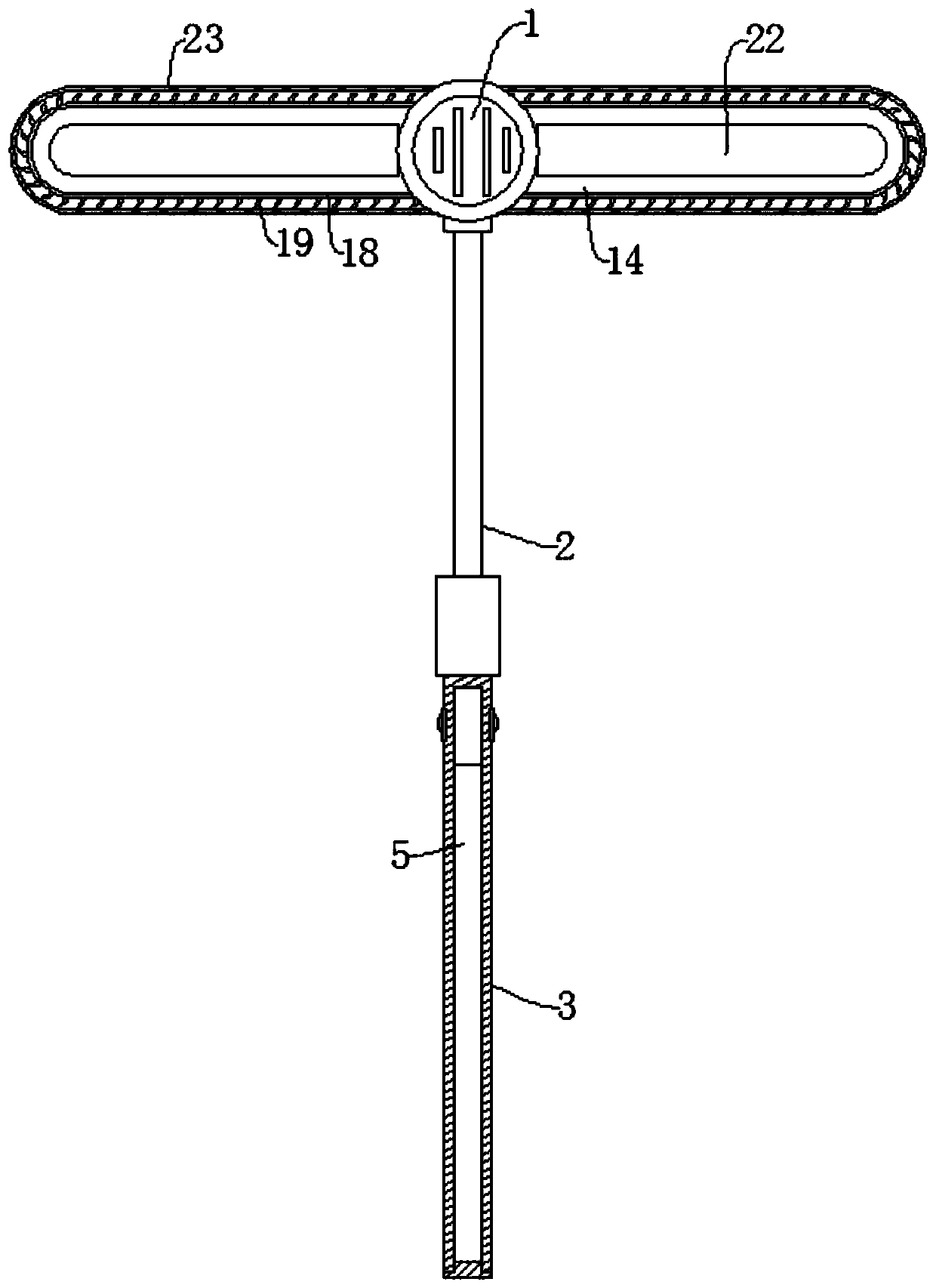

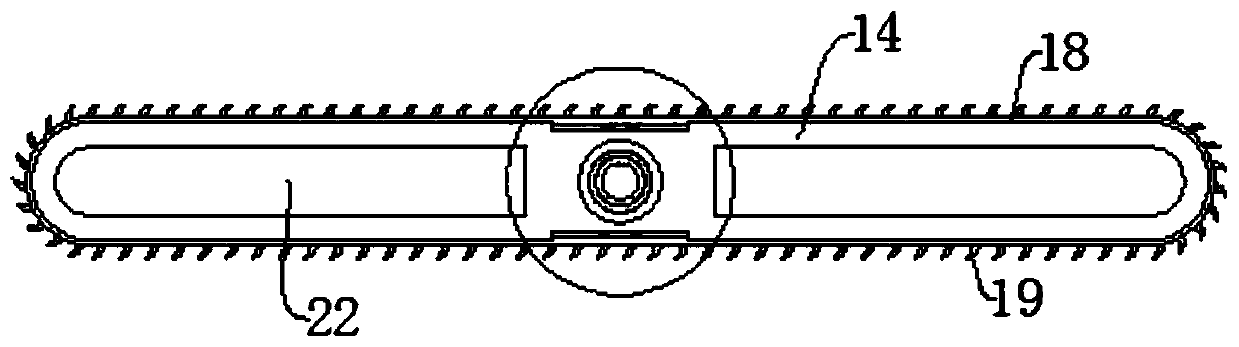

Rotary chain saw lawnmower

ActiveCN110447375AHigh cutting efficiency and speedIncrease the cutting widthMowersDrive motorEngineering

The invention discloses a rotary chain saw lawnmower which comprises a driving motor and an output shaft fixedly installed on the driving motor. A spline is arranged on the output shaft and provided with a driving gear. A sleeve is arranged on the side face of the driving gear. A sleeve ring is arranged on the sleeve in a rolling mode. A small electric hydraulic push rod is arranged on the side face of the sleeve ring. A large electric hydraulic push rod is arranged on the side face of the small electric hydraulic push rod. An antiskid block is arranged on the large electric hydraulic push rod. The rotary chain saw lawnmower has the advantages that a chain saw guide plate and a chain are added, the chain is driven to rotate so as to cut weeds, and the chain saw guide plate is high in length, so the rotary chain saw lawnmower is higher in cutting width, cutting efficiency and cutting speed in movement process compared with a traditional lawnmower with a circular saw web and is particularly suitable for large-area weeding.

Owner:泰兴市康森爱特传动设备科技有限公司

Pneumatic tire

ActiveUS8844591B2Improve braking effectIncrease the cutting widthTyre tread bands/patternsNon-skid devicesDepth directionMechanical engineering

Owner:THE YOKOHAMA RUBBER CO LTD

High-speed vacuum coating online cutting device

ActiveCN101545098BExtended service lifeIncrease the cutting widthVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention provides a high-speed vacuum coating online cutting device, which belongs to the technical field of coating processing. The high-speed vacuum coating online cutting device solves the problem that the prior cutter has poor cooling effect when cutting coated films and sheets. The high-speed vacuum coating online cutting device comprises a rotating shaft, a tool rest and a power mechanism connected with the rotating shaft, wherein the tool rest is fixedly arranged on the rotating shaft, the outer end part of the tool rest is provided with a cutting blade, the power mechanism drivesthe rotating shaft to rotate radially so as to control the cut-in of the cutting blade, the tool rest is made from a heat conduction material and is internally provided with a cooling passage, the rotating shaft is provided with a cooling device for providing cooling liquid, and two ends of the cooling passage are connected with the cooling device through a cooling pipe so as to form a closed circulation path. The cutting device is provided with a cooling structure to cool the cutting blade, and the cooling effect is good so that the service life of the cutting blade is prolonged. Simultaneously, a cutting blade adjusting device is arranged on the cutting device for adjusting the position of the cutting blade so as to adjust the cutting width of the films or the sheets.

Owner:WENLING HUAHANG ELECTRONICS TECH CO LTD

Machining status display apparatus, and NC program generating apparatus and NC program editing apparatus provided with the same

ActiveUS10386814B2Efficient machining of a workpieceLow costComputer controlSimulator controlData memoryComputer science

A machining status display apparatus includes an achievement degree data storage storing achievement degree data relating to a degree of achievement of each of predetermined machining-related evaluation items within a range determined by attainable maximum and minimum values of the evaluation item and storing the degrees of achievement of the evaluation items obtained under each of predetermined sets of machining conditions in association with the set of machining conditions, a display part displaying the degrees of achievement of the evaluation items corresponding to a selected set of machining conditions by referring to the data in the achievement degree data storage, and an input part inputting a selection signal for selecting a set of machining conditions. The display part displays the degrees of achievement of the evaluation items obtained under the set of machining conditions corresponding to the selection signal by referring to the data in the achievement degree data storage.

Owner:DMG MORI CO LTD

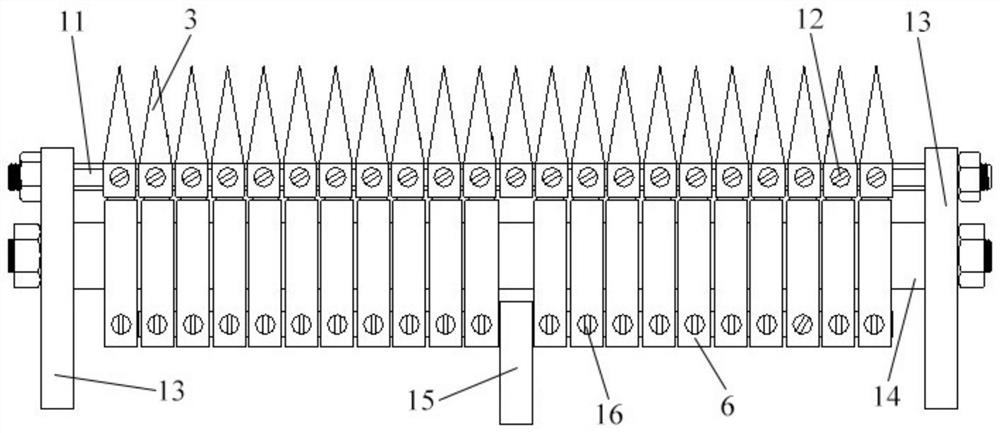

A split type reciprocating cutter

The invention provides a split-type reciprocating cutter, which comprises a sawtooth shaft, a slide rail, a side, sawtooth, a sawtooth screw, a knife holder, a knife holder shaft, a knife holder screw and a cutting knife. Both the sawtooth shaft and the slide rail are fixed and installed on the side with nuts; several of the sawtooths are arranged neatly on the sawtooth shaft and fastened by sawtooth screws; several of the knife holders are neatly arranged on the knife on the frame shaft, fastened by serrated screws, and can slide freely on the slide rail; the cutting knife is installed on the knife frame; The knife reciprocates along the slide rail. Both the sawtooth and the knife rest of the present invention are split, can be processed and produced separately, and the gap between the sawtooth and the knife rest can be adjusted arbitrarily as required.

Owner:JIANGSU UNIV

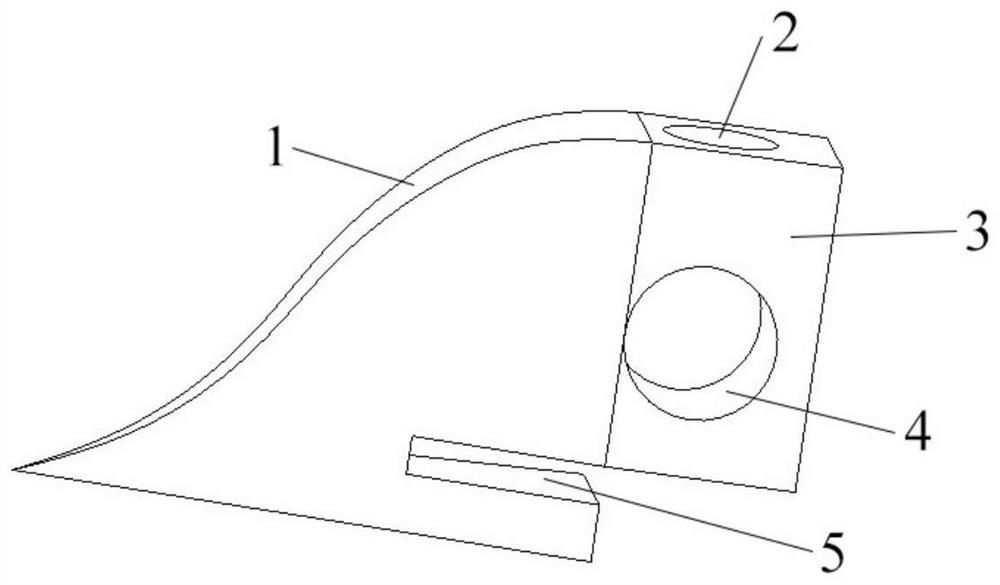

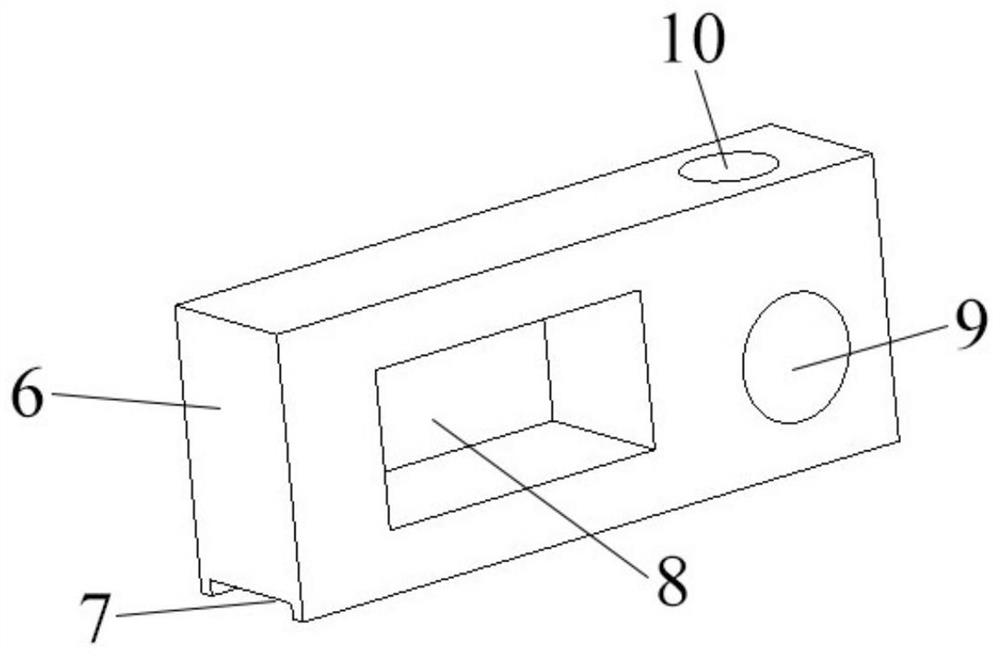

A double-arc turning blade

ActiveCN106346030BIncreased durabilityIncrease the cutting widthCutting insertsTurning toolsSurface finishMachining

The invention provides a double-circular-arc turning tool blade and belongs to the technical field of turning tools. The invention aims at providing the double-circular-arc turning tool blade which can improve the machining efficiency and the surface finish degree and can prolong the service life. An embedding groove matched with a tool nose embedding sheet is arranged at any one vertex angle of an upper surface of a tool body; the tool nose embedding sheet is tightly embedded into an embedding groove of the tool body; a side face I and a side face II are of the turning tool blade are located at two sides of a cutting corner part; the tool nose embedding sheet is provided with a tool nose cutting section and a negative chamfered edge is machined on the tool nose cutting section; the cutting corner part comprises a curved surface I, a curved surface II, a smoothening surface and three cutting edges; the three cutting edges are arranged at a lower edge of the negative chamfered edge of the tool nose embedding sheet; the three cutting edges comprises a linear cutting edge, a circular-arc cutting edge I and a circular-arc cutting edge II respectively; the side face I is tangent to the curved surface I and the curved surface I is tangent to the curved surface II; the curved surface II and the smoothening surface are connected through a smooth transition surface and an included angle is formed between the smoothening surface and the side face II. The double-circular-arc turning tool blade is applicable to finish turning machining.

Owner:HARBIN UNIV OF SCI & TECH

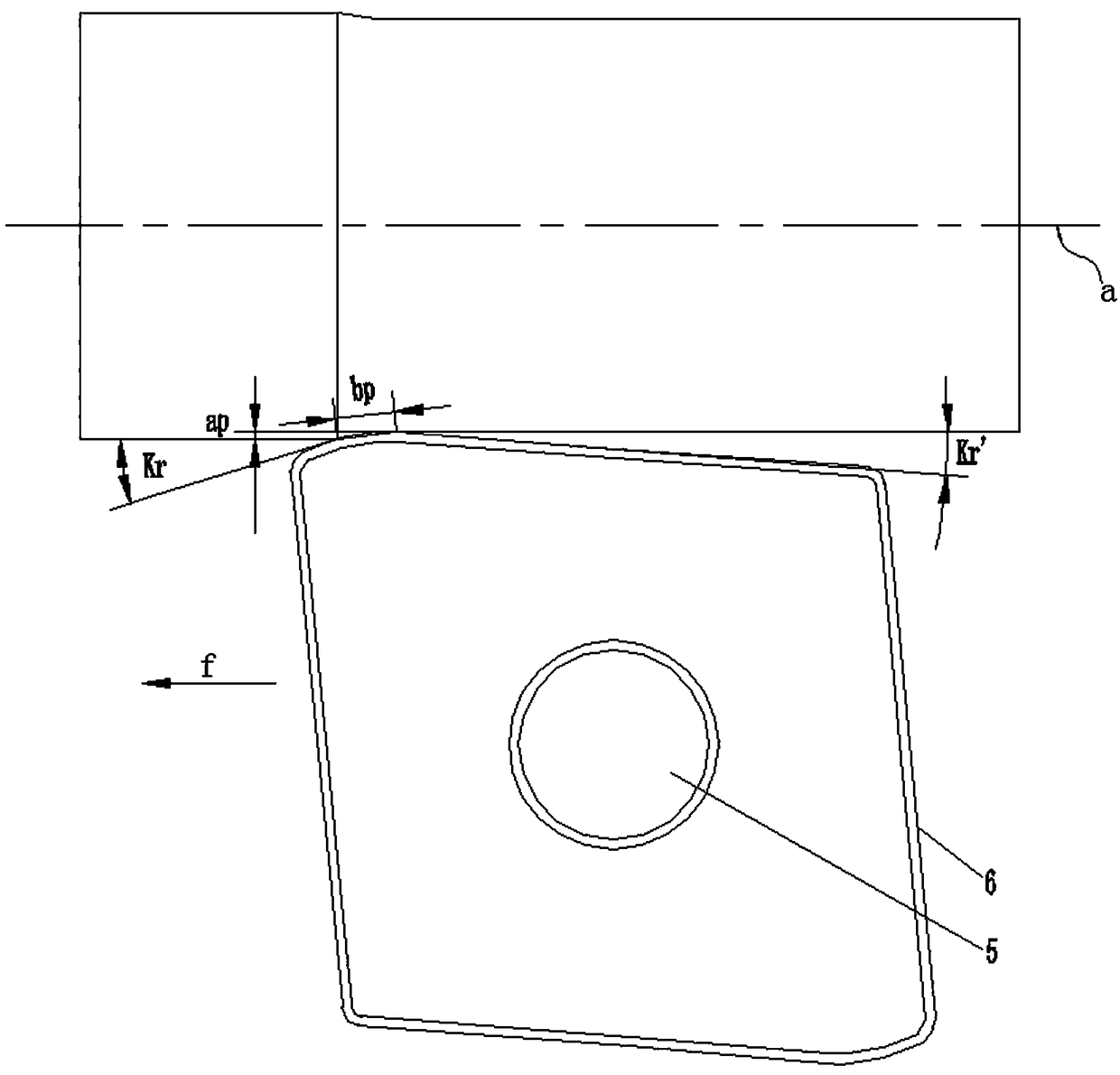

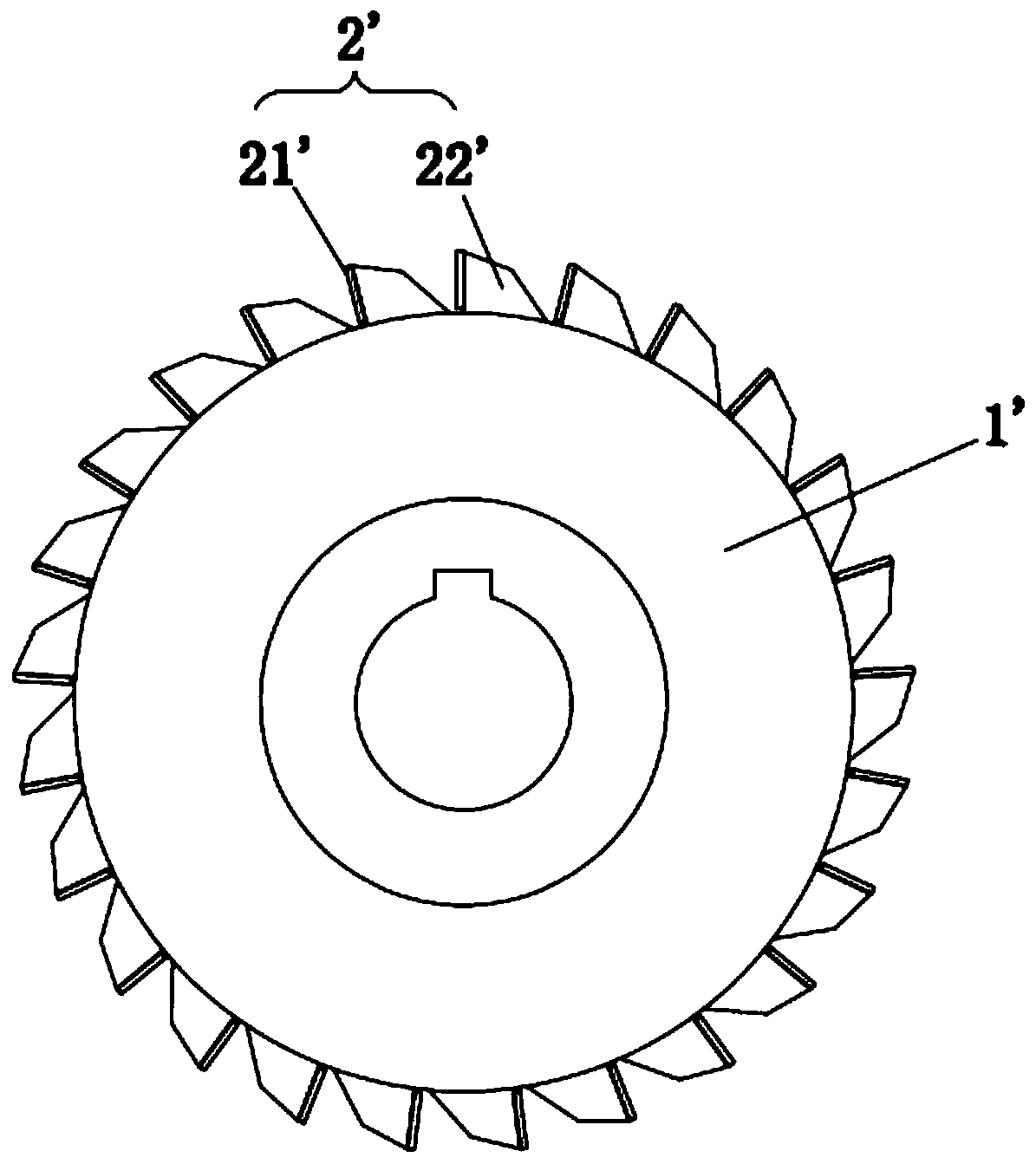

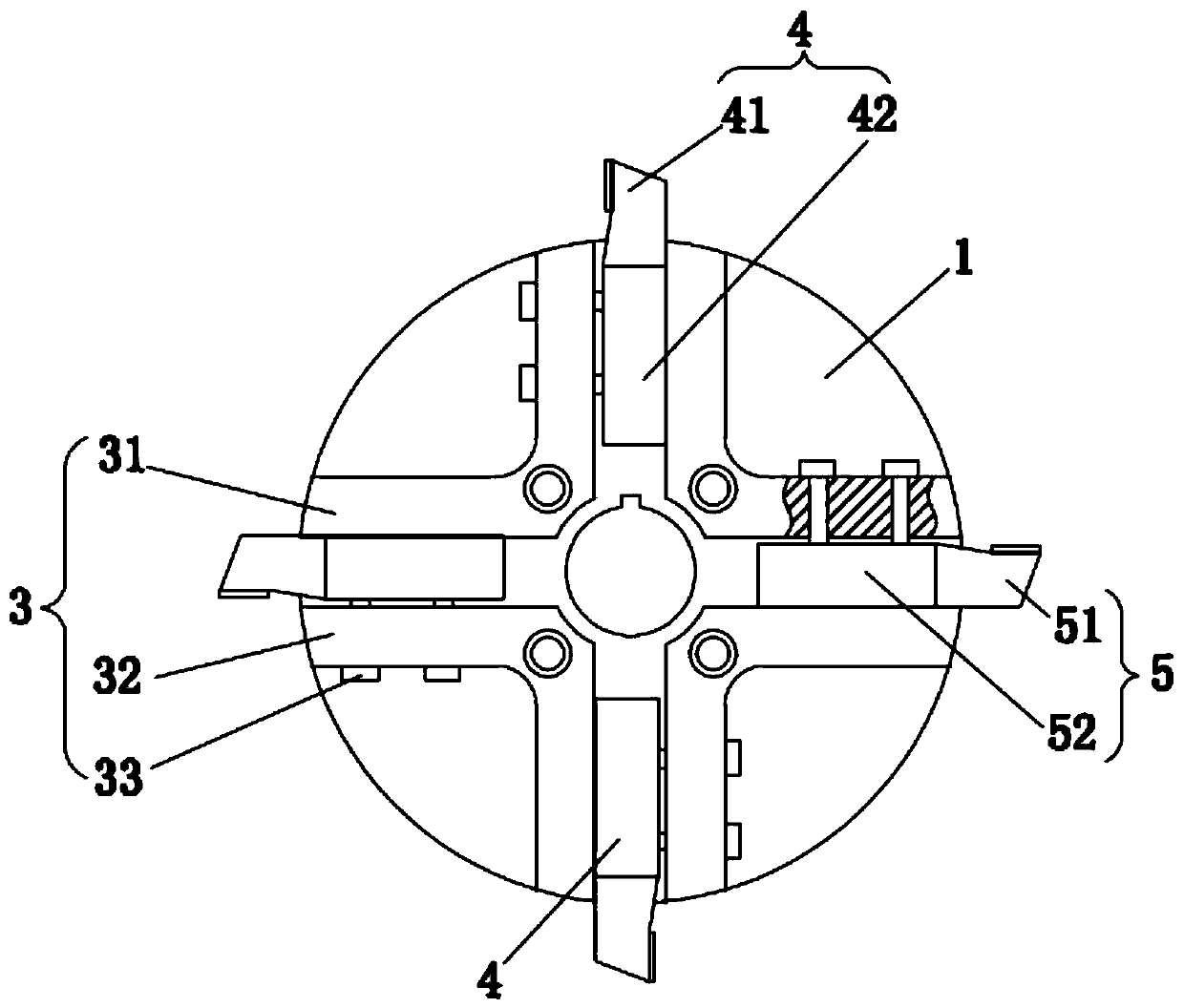

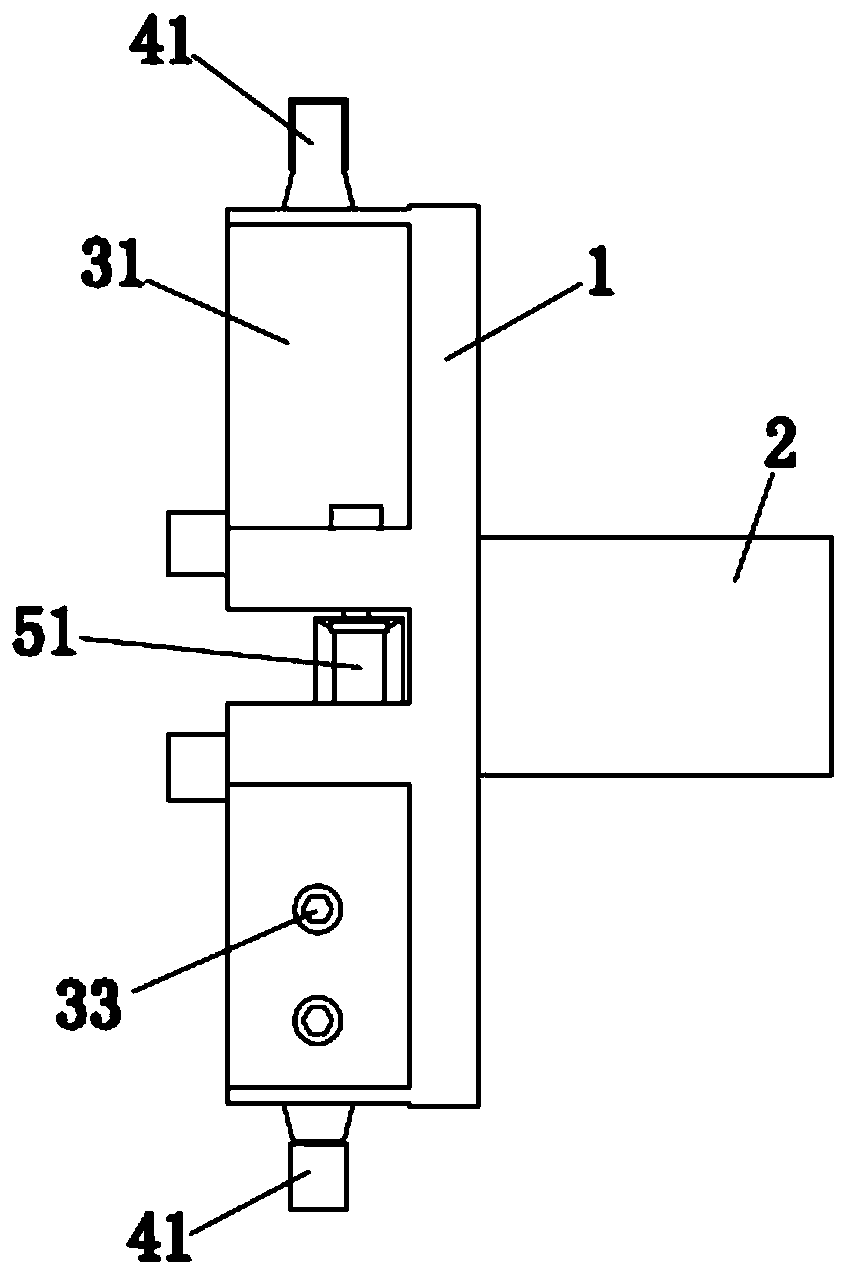

Groove milling method and high-speed milling cutter device

PendingCN110216317AWill not increase the loadLarge feedMilling cuttersMilling equipment detailsMilling cutterEngineering

The invention discloses a groove milling method and a high-speed milling cutter device. The groove milling method comprises the steps that at least two cutters in a cutter set on a milling cutter turntable rotate along with the turntable, and the workpieces are sequentially cut; and in the same cutter set, the cutting ranges of every two adjacent cutters in front and back are staggered in the width direction of the groove milling and partially overlapped. The high-speed milling cutter device comprises the turntable, at least one cutter set is arranged on the turntable, and one cutter set comprises at least two cutters arranged around a rotation axis of the turntable; in every two adjacent cutters in the cutter set, a cutting edge on one side of the front cutter protrudes out of the cuttingedge on the same side of the a back cutter; the cutting edge of the other side of the front cutter is positioned between the cutting edges on the two sides of the back cutter; and the cutting edge onthe other side of the back cutter protrudes out of the cutting edge at the same side of the front cutter. According to the groove milling method and the high-speed milling cutter device, the cuttingwidth of one-circle rotation of the milling cutter is large, the service life of the cutter can be ensured to be long enough, and the groove milling efficiency is high.

Owner:颜亚秀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com