Laser cutting and ring removing method for wafer

A laser cutting and wafer technology, applied in laser welding equipment, circuits, manufacturing tools, etc., can solve the problems of splashing ablation, micro-cracks in the effective area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

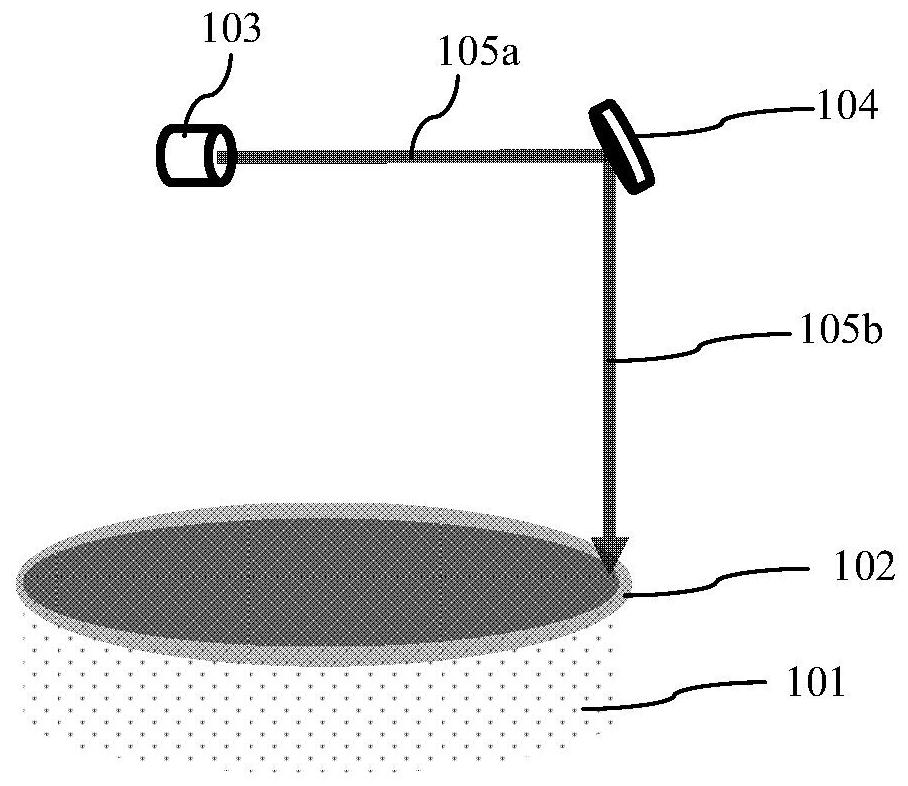

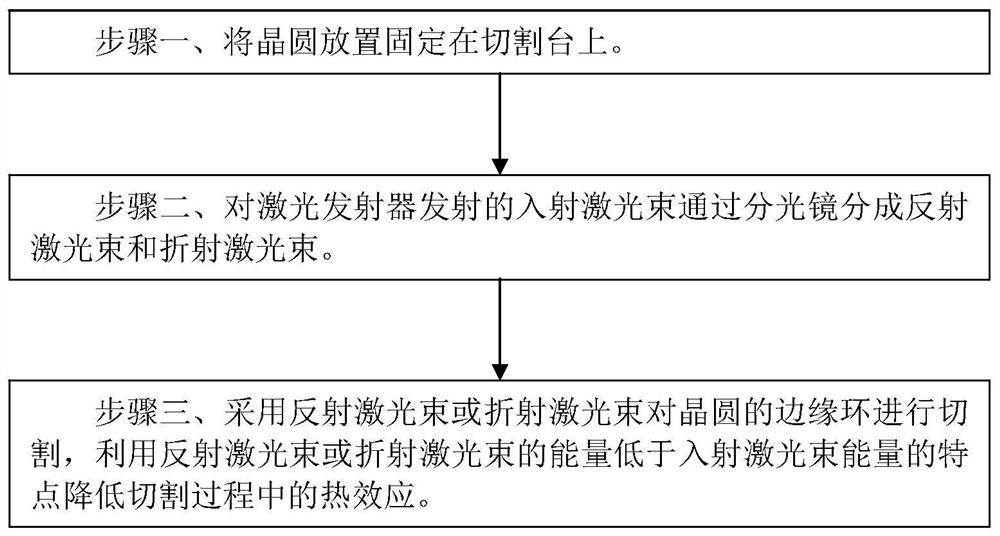

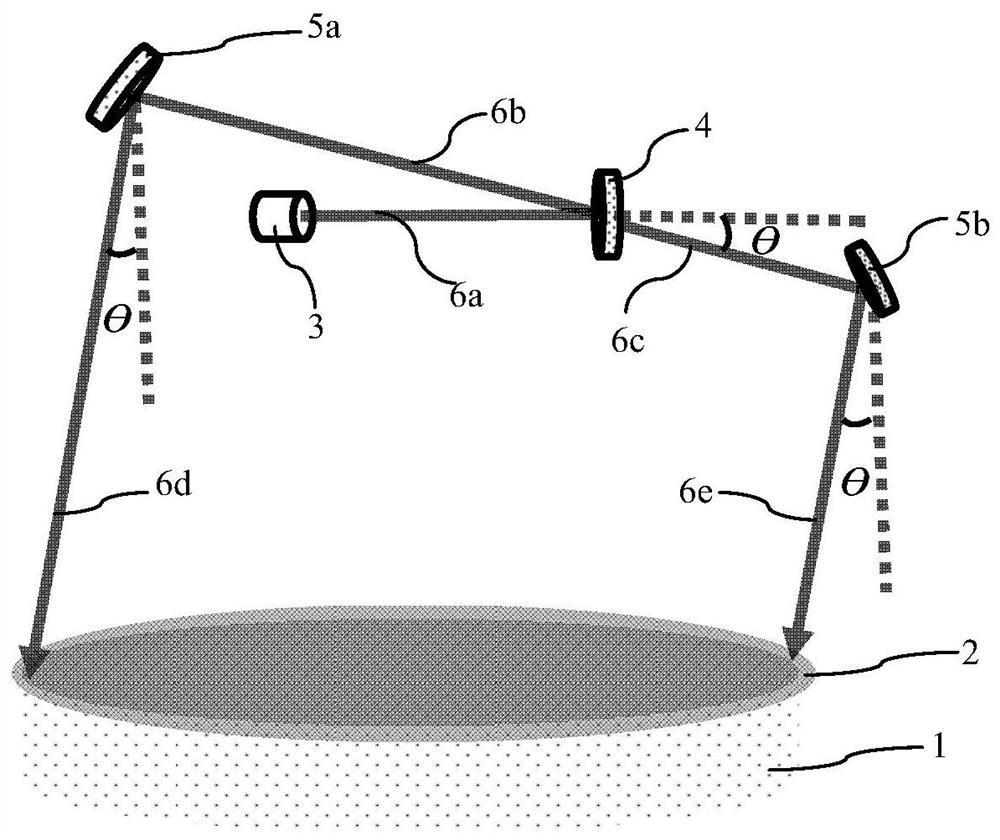

[0037] Such as figure 2 Shown is the flow chart of the laser cutting ring removal method of wafer 2 in the embodiment of the present invention; as image 3 As shown, it is a schematic diagram of laser dicing in the laser dicing and ring removal method of wafer 2 in the embodiment of the present invention. The laser cutting and deringing method of wafer 2 in the embodiment of the present invention comprises the following steps:

[0038] Step 1, placing and fixing the wafer 2 on the cutting table 1 .

[0039] The wafer 2 has been thinned.

[0040] The thinning process of the wafer 2 includes Taiko thinning.

[0041] The thinned wafer 2 has a thickness ranging from tens of microns to hundreds of microns.

[0042] The width of the edge ring to be cut on the wafer 2 is less than several millimeters.

[0043] Step 2: The incident laser beam 6a emitted by the laser emitter 3 is divided into a reflected laser beam 6b and a refracted laser beam 6c by a beam splitter 4, and the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com