Wire saw and method for producing a wire saw

A technology of wire saw and wire frame, which is applied in the field of dividing multiple ceramic components from ceramic component blocks to achieve the effects of small load, small friction and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In all figures, unless otherwise stated, identical or functionally identical elements and devices are identified with the same reference symbols.

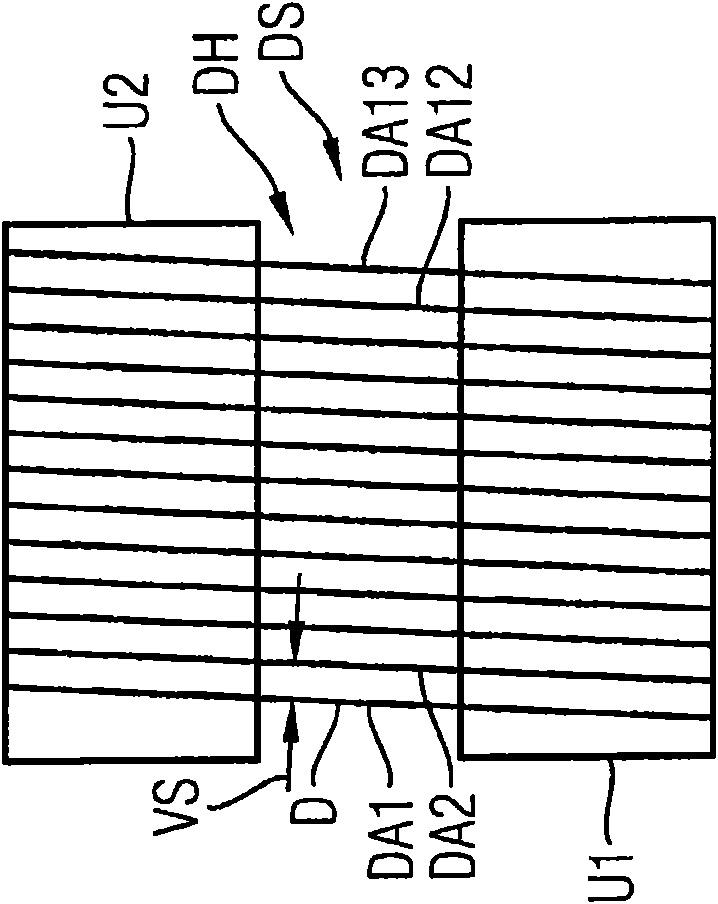

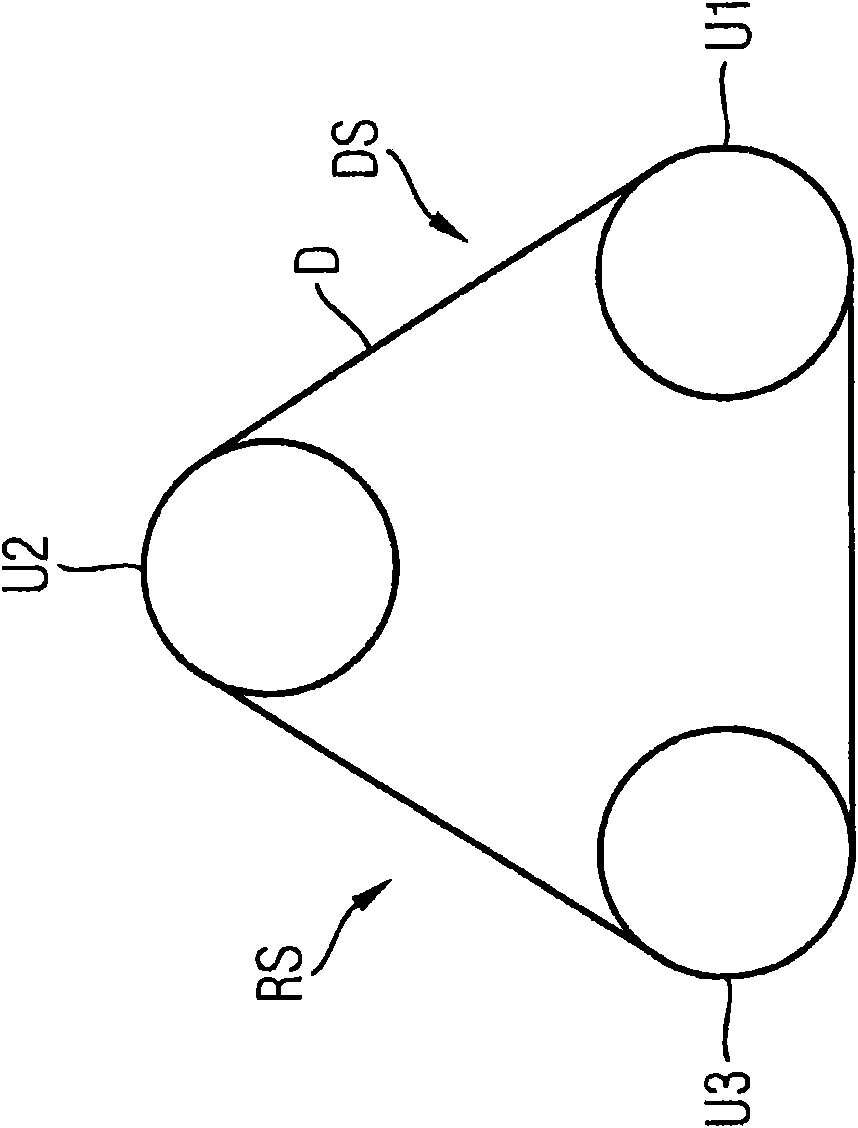

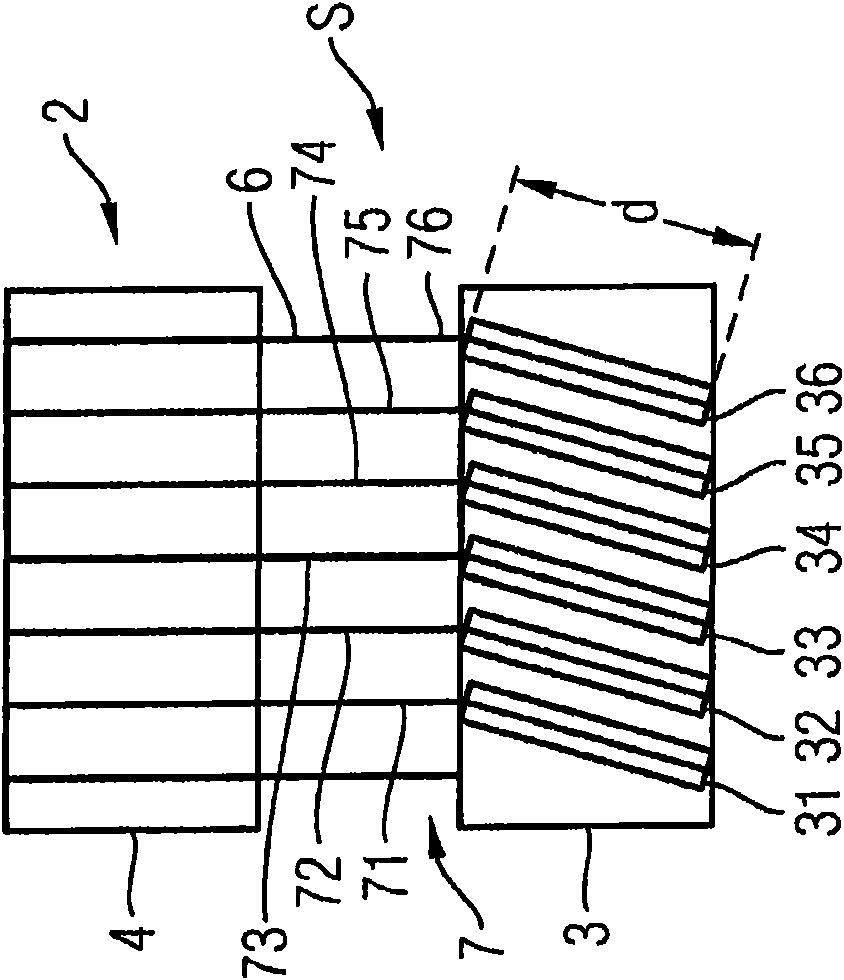

[0042] Figure 2A with 2B A schematic longitudinal section and a schematic transverse section of an exemplary embodiment of a wire saw S according to the invention are shown. pass image 3 This embodiment of the wire saw DS is further illustrated, showing a press Figure 2A A schematic longitudinal sectional view of , with a schematically shown ceramic component block 1 . The wire saw S is suitable for separating a plurality of ceramic components 11 - 16 from the ceramic component block 1 . For this purpose, the wire saw S has a roller system 2 with a plurality of deflection rollers 3 - 5 . exist Figure 2A , 2B Two or three conversion rolls 3-5 are shown in and 3, but not limited thereto. The deflection rollers 3 - 5 guide the wire 6 or the continuous wire so as to form the wire frame 7 . The wire 6 or its coils 61...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com