A double-arc turning blade

A double arc and blade technology, applied in cutting blades, tools for lathes, turning equipment, etc., can solve the problems of affecting the service life of tools, reducing processing efficiency, easy to generate vibration, etc., so as to improve processing efficiency and increase cutting tools. Durability, the effect of increasing the cutting width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

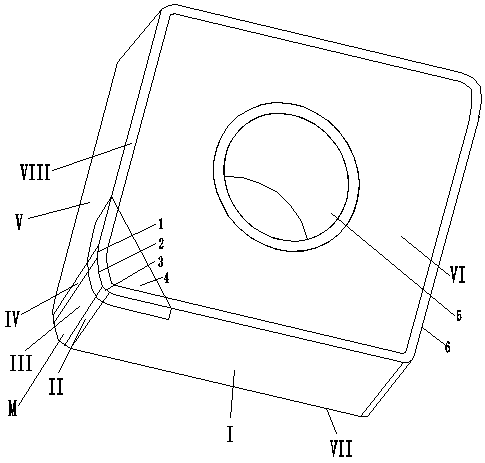

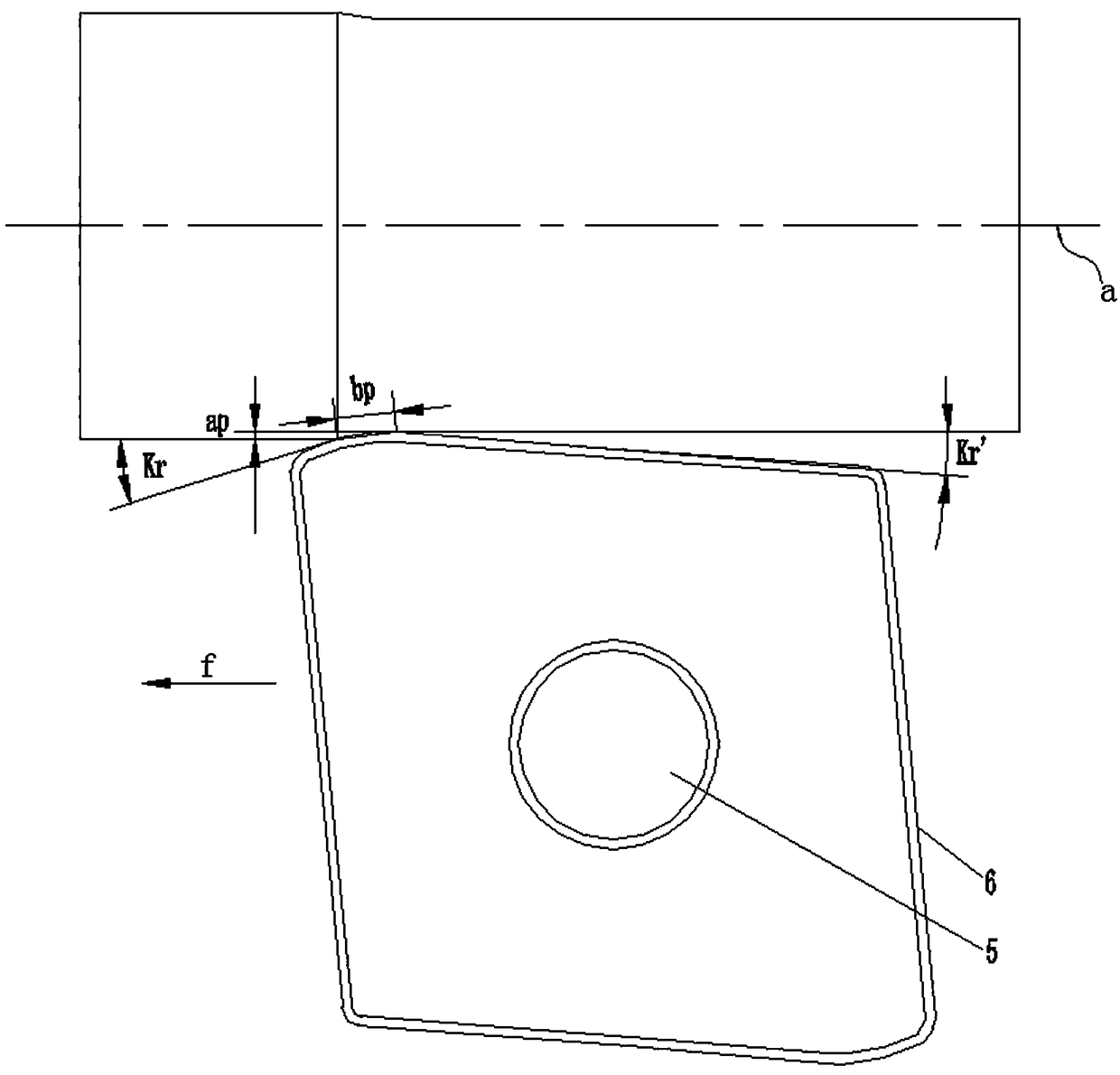

[0018] Specific implementation mode one: as figure 1 and figure 2 As shown, a double-arc turning blade is composed of a cutter body 6 and a knife tip insert 4. The middle part of the cutter body 6 is provided with a tool holder mounting hole 5, and the horizontal section of the cutter body 6 is The shape is polygonal, and any corner of the upper surface VI of the cutter body 6 is provided with an embedding groove that matches the blade tip insert 4, and the blade tip insert 4 is tightly embedded in the embedding groove of the cutter body 6, so The side of the turning insert includes a side I, a side two V and a cutting corner M, the side I and the side two V are located on both sides of the cutting corner M, and the cutting edge insert 4 has a cutting edge A cutting section, the cutting section of the knife edge is processed with a negative chamfer VIII;

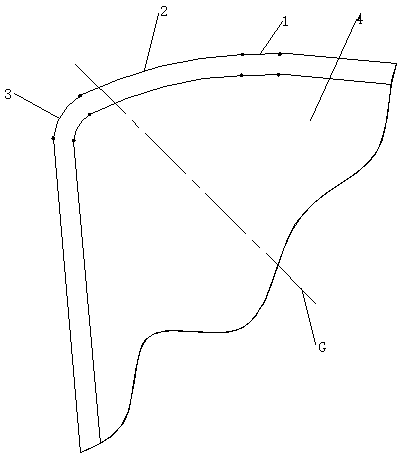

[0019] The cutting corner M includes a curved surface II, a curved surface III, a smoothing surface IV and three cuttin...

specific Embodiment approach 2

[0022] Specific implementation mode two: as figure 1 and figure 2 As shown, for the double-arc cutting insert described in Embodiment 1, the point where the arc cutting edge 1 2 and the arc cutting edge 2 3 intersect is the highest point, and the arc cutting edge 2 3 intersects with the center line G of the cutting corner M, and the arc cutting edge 2 3 is asymmetrically arranged on the center line of the cutting corner M, and the highest point is set near the center line of the cutting corner M (two arcs The point on the cutting edge cannot exceed the highest point).

specific Embodiment approach 3

[0023] Specific implementation mode three: as figure 1 As shown, for the double-arc turning blade described in Embodiment 1, the width of the negative chamfer VIII is in the range of 0.15-0.24mm, and the range of the angle of the negative chamfer VIII is -5°~-25° °. The effect is: If the chamfer width and chamfer angle are too large, the cutting force generated during the cutting process will be too large, and the vibration generated during machining will also increase, which will affect the quality of the processed surface. If the value is too small, the effect of chamfering is not obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com