Method for controlling numeric control machining deformation of slender and complicated T-shaped component

A technology of processing deformation and control method, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment details, etc., to achieve the effect of increasing cutting width, improving processing efficiency and reducing cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

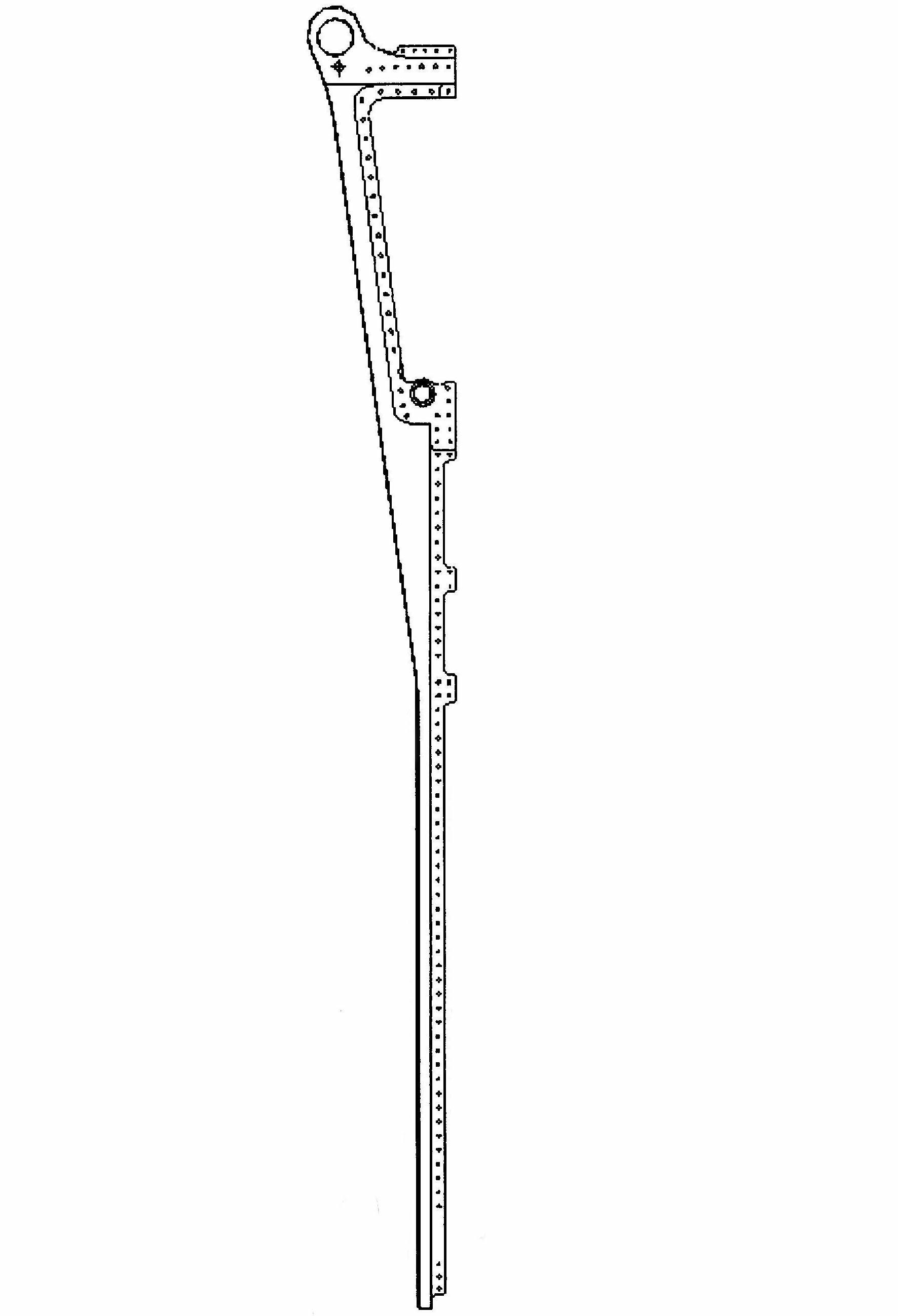

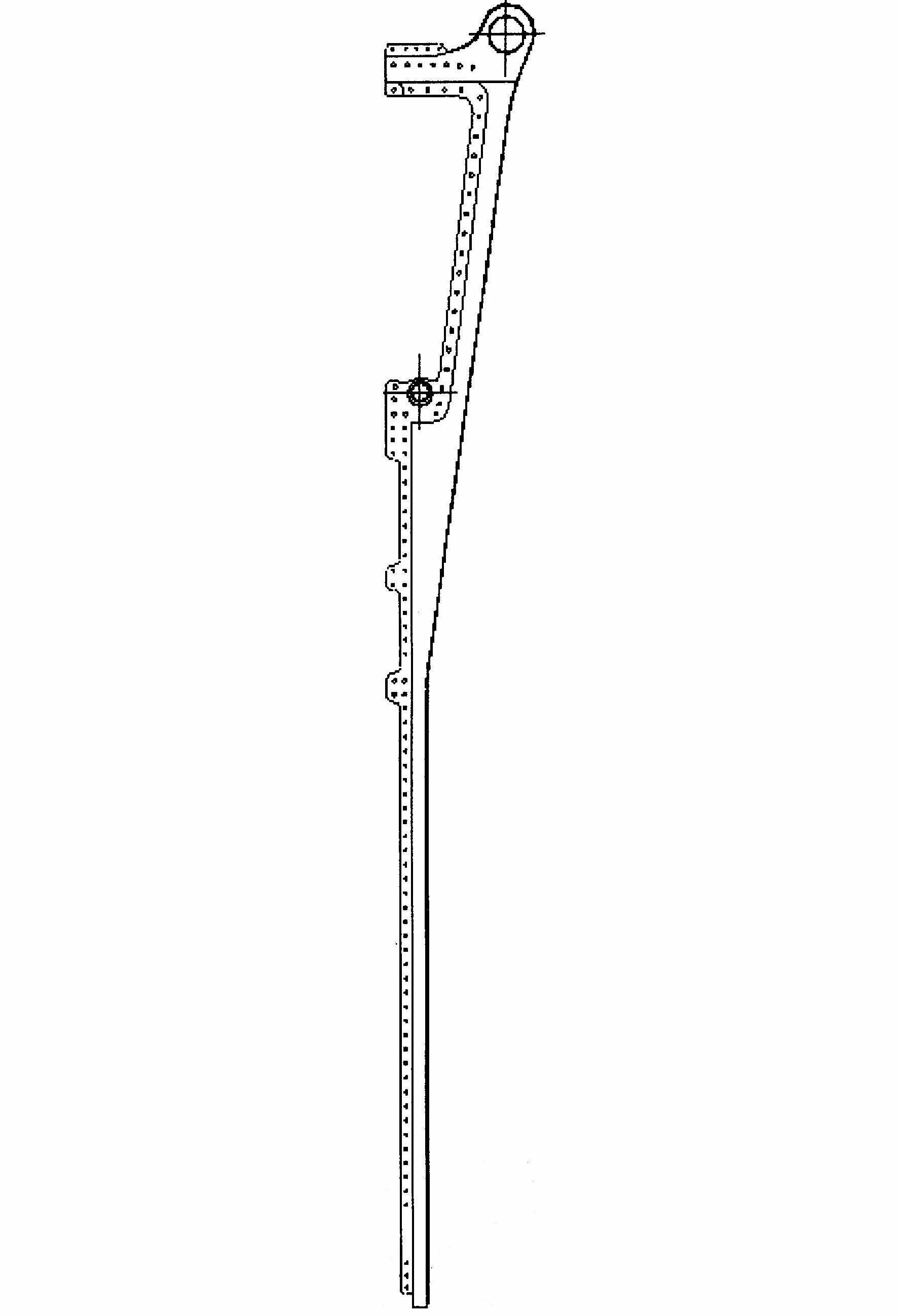

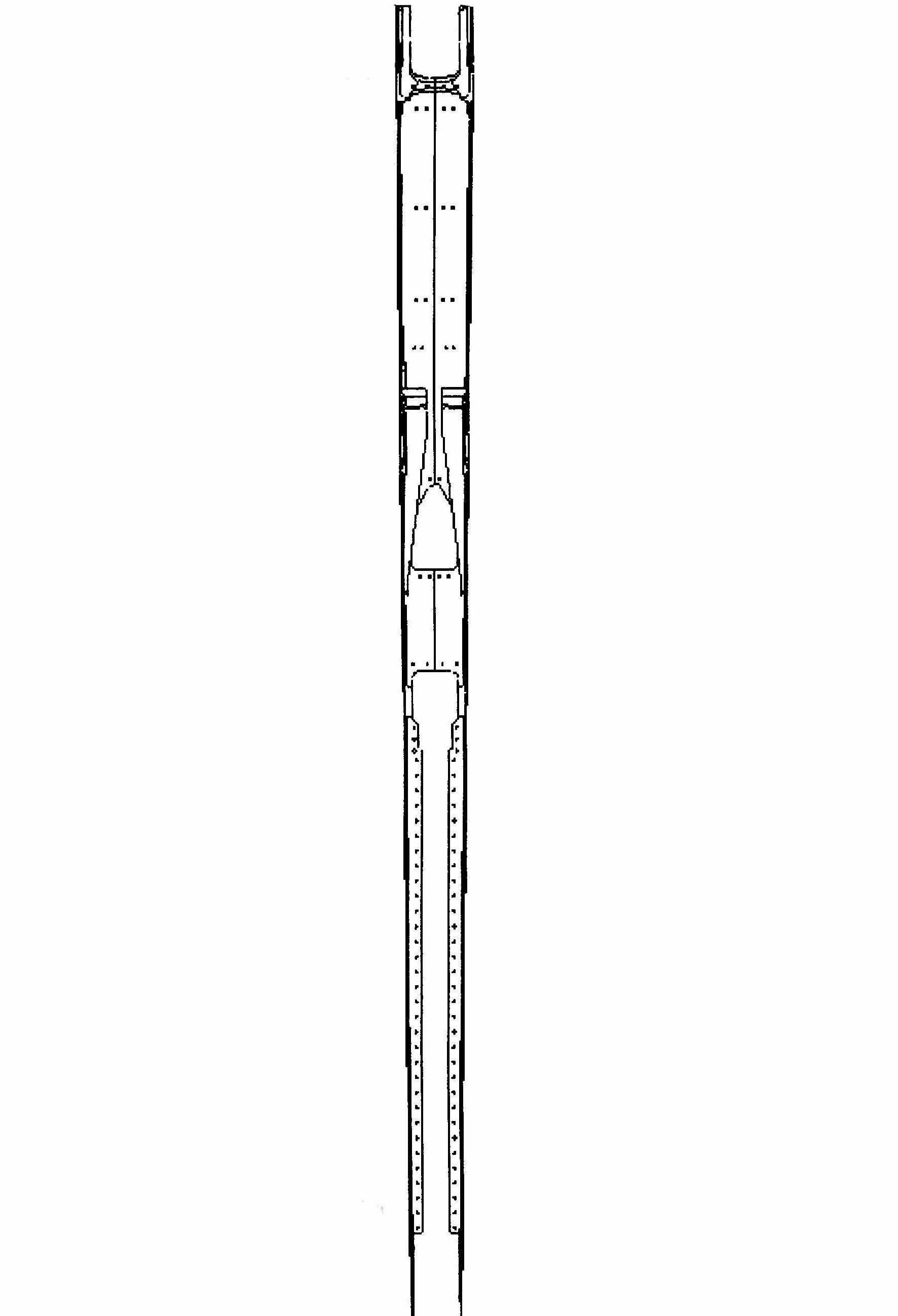

[0018] Deformation control method for NC machining of slender and complex T-shaped parts, such as Figure 1 to Figure 4 shown, including the following steps:

[0019] 1) Divide the processed slender and complex T-shaped parts into two left and right sub-packages, namely sub-package I and sub-package II;

[0020] 2) Carry out rough machining of sub-package part I and sub-package part II and make positioning datum plane and positioning hole;

[0021] 3) Subassembly Ⅰ and subassembly Ⅱ are fixed on the processing table of CNC milling machine through fixed tooling;

[0022] 4) Use the shallow cutting processing method to perform contour cutting on the parts;

[0023] 5) Reserve machining allowance for assembly parts;

[0024] 6) Weld subassembly I and subassembly II into a whole and perform heat treatment;

[0025] 7) Complete the machining process of slender and complex T-shaped parts.

[0026] The specific method of the step 4) is: adopt the cutting method of equal height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com