Cutting machine

A cutting machine and cutting edge technology, which is applied to sawing equipment, metal sawing equipment, sawing machine devices, etc., can solve the problems of larger size of the cutting machine, increased cost, complex structure, etc., so as to suppress the increase in cost and expand cutting. Width, the effect of ensuring cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

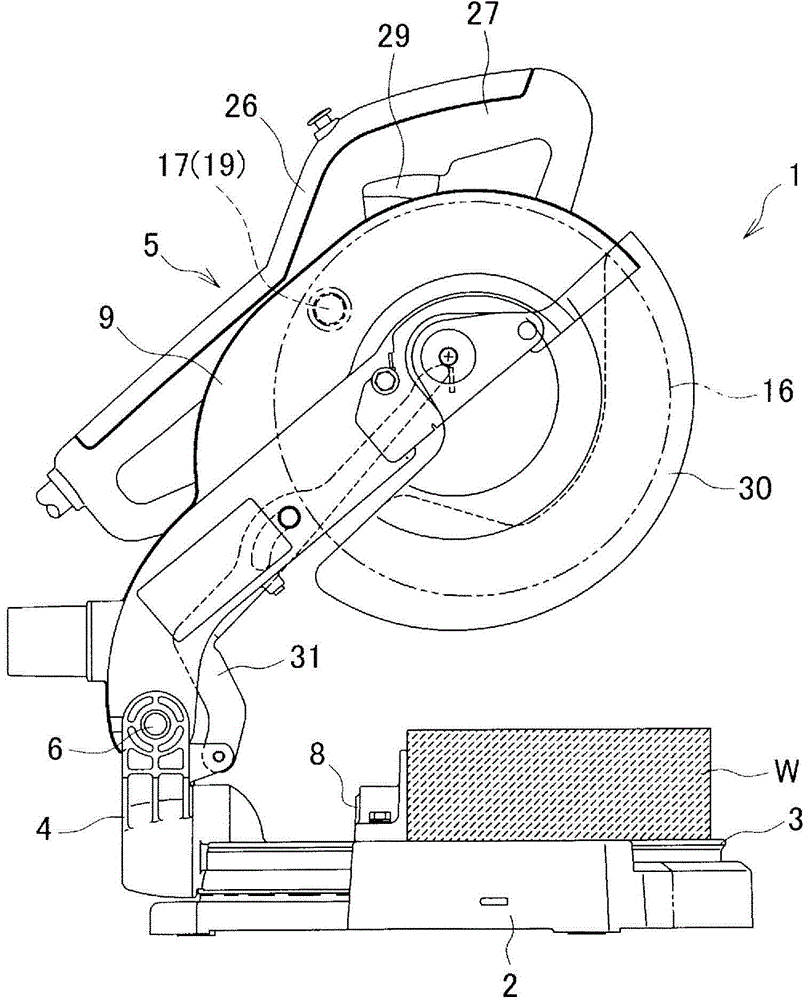

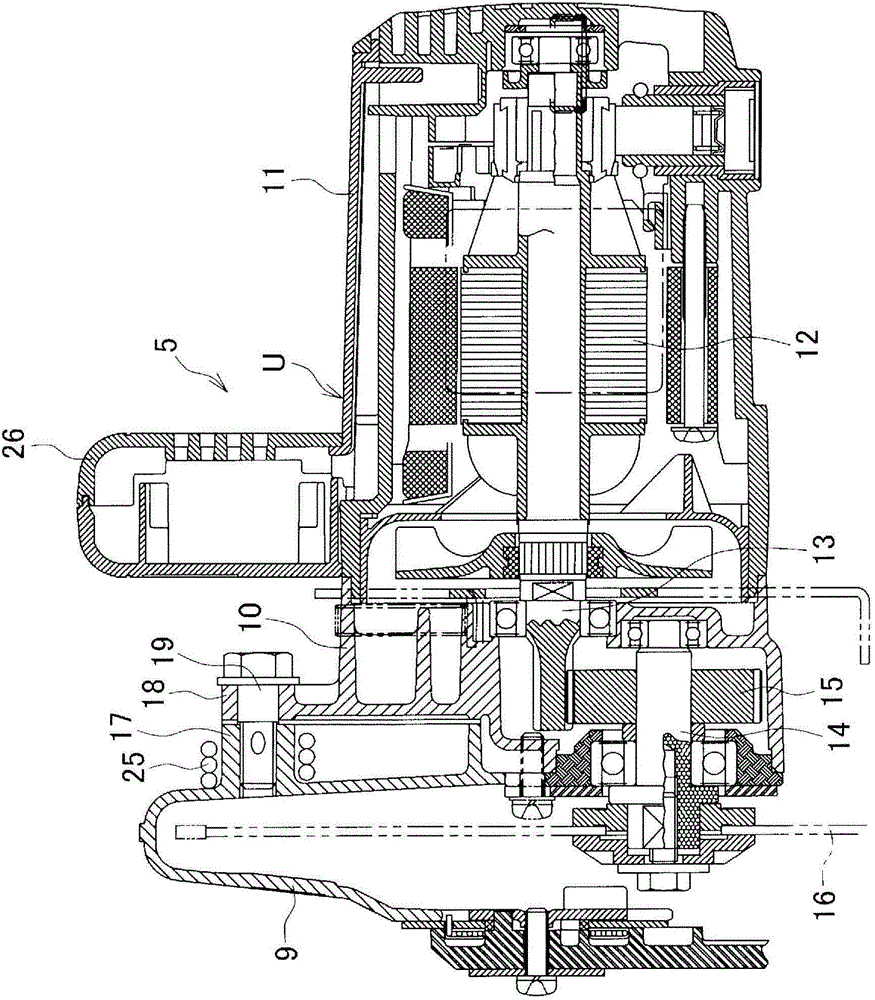

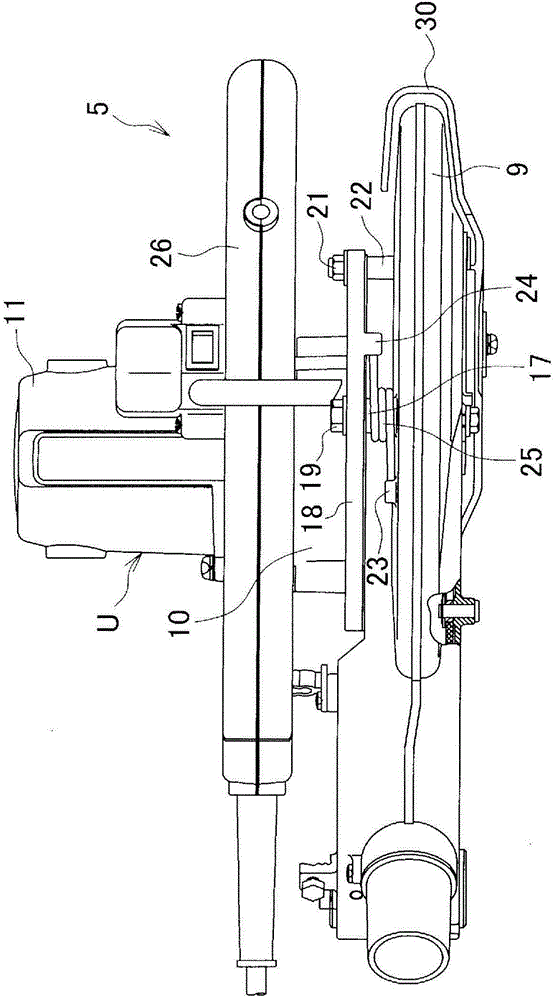

[0028] Next, specific embodiments of the present invention will be described with reference to the drawings.

[0029] figure 1 It is a left side view of a desktop circular saw as an example of a cutting machine. In the desktop circular saw 1, a turntable 3 capable of horizontal rotation is placed on a base 2. The height of the upper surface of the turntable 3 is the same as that of the base 2. The same height of the upper surface, at the rear end of turntable 3 (with figure 1 The right side of the paper in the middle is the front) erectly provided with a support arm 4 that can rotate around the axis in the front-rear direction, and at the upper end of the support arm 4, a rotatable main body 5 is installed through a fulcrum 6 in the left-right direction. However, in the normal state due to being arranged on the torsion spring 7 on the fulcrum 6 (refer to Figure 4 ) of the force, the main body 5 is in the figure 1 upper limit position shown. 8 denotes a guide baffle, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com