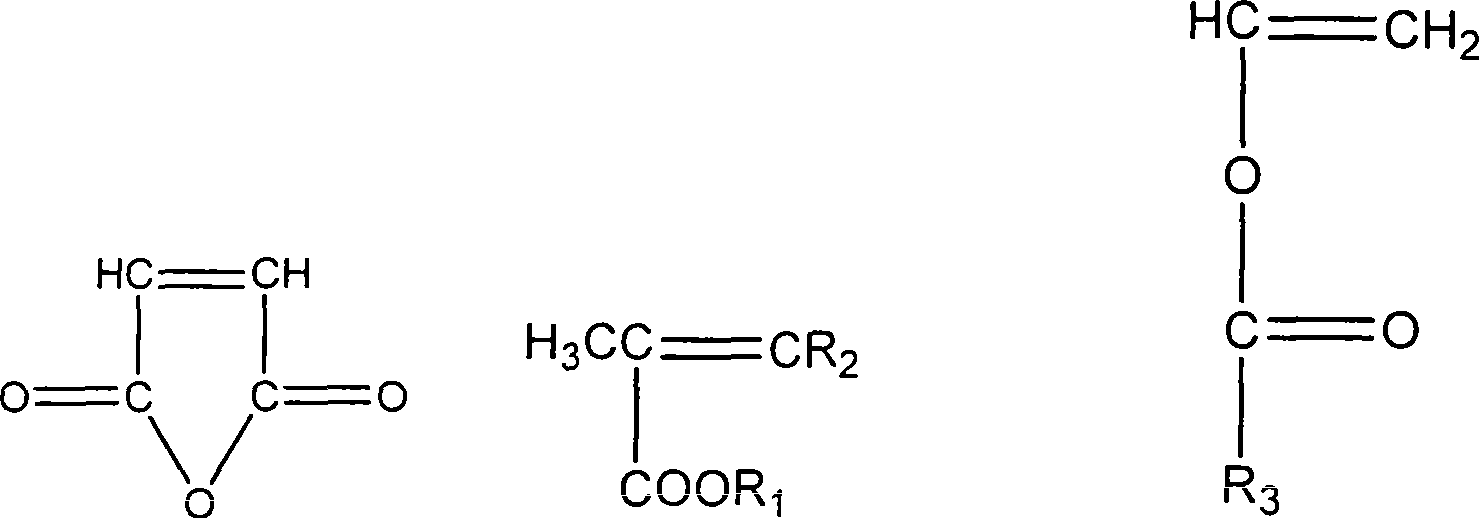

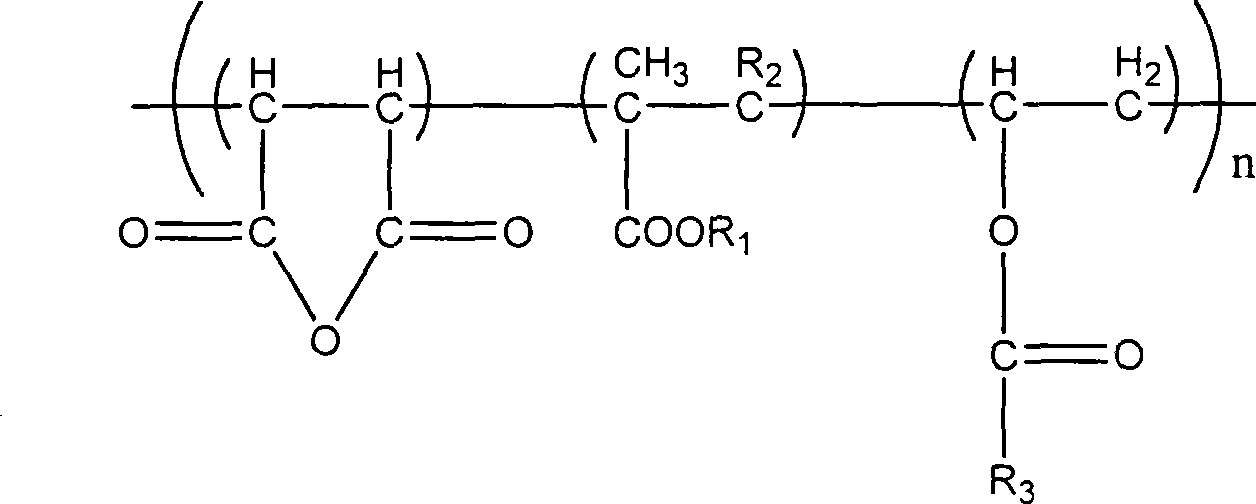

Ternary polymer composite petroleum pour depressant and preparation method thereof

A ternary polymer and pour point depressant technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of freezing point viscosity, high yield value, crude oil decline, high energy consumption, etc., to improve low temperature rheology , reduce the energy consumption of pipeline transportation, and widen the effect of cutting width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 0.5g (0.005mol) of maleic anhydride and 10g of toluene in a reactor equipped with an electric stirrer, a thermometer, and a reflux condenser, heat up to 40-70°C and stir for 30 minutes, then heat up to 50-90°C, and then add 17.41g (0.045mol) 2-methacrylic acid mixed ester (by 2-methacrylic acid and C 20 ~C 24 Mixed alcohol is made, wherein the ratio of alcohol is eicosanol 70%, behenyl alcohol 20%, tetracosyl alcohol 10%), 0.43g (0.005mol) vinyl acetate, 0.37g benzoyl peroxide, temperature After automatically rising to 100°C, the external temperature is removed, and when the temperature drops to 60-85°C, it is reacted at a constant temperature for 1 hour to obtain a 2-methacrylic acid derivative polymer, that is, a ternary polymer composite petroleum pour point depressant. Add 7.3g of Span-85 and stir for half an hour to obtain a light yellow viscous liquid crude oil pour point depressant composition. Weight average molecular weight It is 23152g / mol. 2-methacry...

Embodiment 2

[0028] Put 0.5g (0.005mol) of maleic anhydride and 10g of toluene in a reactor equipped with an electric stirrer, a thermometer, and a reflux condenser, heat up to 40-70°C and stir for 30 minutes, then heat up to 50-90°C, and then add 13.49g (0.035mol) 2-methacrylic acid mixed ester (the proportion of alcohol is eicosanol 80%, behenyl alcohol 10%, tetracosyl alcohol 10%), 0.43g (0.005mol) vinyl acetate , 0.29g benzoyl peroxide, the temperature automatically rises to 100°C and then the external temperature is removed, and when the temperature drops to 60-85°C, the reaction is constant for 2 hours. Add 7.1 g of Span-83 and stir for half an hour to obtain a light yellow viscous liquid crude oil pour point depressant composition. Weight average molecular weight It is 46989g / mol. 2-methacrylic acid derivative polymer infrared data: 1729.56cm -1 It is the stretching vibration absorption peak of the -C=O group in the ester group; 1782.32cm -1 It is the stretching vibration absor...

Embodiment 3

[0030] Put 0.5g (0.005mol) of maleic anhydride and 10g of toluene in a reactor equipped with an electric stirrer, a thermometer, and a reflux condenser, heat up to 40-70°C and stir for 30 minutes, then heat up to 50-90°C, and then add 17.47g (0.045mol) 2-methacrylic acid mixed ester (wherein the ratio of alcohol is eicosanol 60%, behenyl alcohol 30%, tetracosyl alcohol 10%), 0.43g (0.005mol) vinyl acetate , 0.37g benzoyl peroxide, the temperature automatically rises to 100°C and then the external temperature is removed, and when the temperature drops to 60-85°C, the temperature is reacted for 1h. Add 7.27g of Span-80 and stir for half an hour to obtain a light yellow viscous liquid crude oil pour point depressant composition. Weight average molecular weight It is 29868g / mol. 2-methacrylic acid derivative polymer infrared data: 1732.23cm -1 It is the stretching vibration absorption peak of the -C=O group in the ester group; 1783.78cm -1 It is the stretching vibration absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com