Method for improving low-temperature rheological property of oil-based drilling fluid

A technology of oil-based drilling fluid and rheology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve good economy, improve low-temperature rheology, and stabilize rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The main purpose of the invention is to reduce the viscosity and shear force increase of oil-based drilling fluid at low temperature, keep its rheological properties relatively stable, prevent downhole complexity caused by excessively high equivalent circulation density, and prevent pipeline blockage under low temperature conditions. Reduce the dependence on heating facilities when drilling with oil-based drilling fluid in cold regions, and achieve the effect of energy saving and emission reduction.

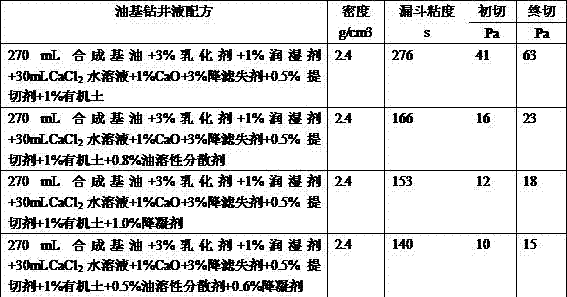

[0018] On the basis of the existing oil-based drilling fluid formula, add 0.4% to 1.2% of oil-soluble dispersant and 0.6% to 2.5% of pour point depressant to improve the low temperature rheology of oil-based drilling fluid. Oil-soluble dispersant and pour point depressant can be added at the same time, or only one kind can be added. Oil-soluble dispersant and pour point depressant can be added when preparing oil-based drilling fluid, and can also be added during maintenanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com