High-speed vacuum coating online cutting device

A vacuum coating and high-speed technology, which is applied in the field of online slitting devices and high-speed vacuum coating on-line slitting devices, can solve the problems of poor heat dissipation, blunt cutting edge of slitting blades, and inability to dissipate heat, etc., achieving good cooling effect and cooling The effect of fast speed and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

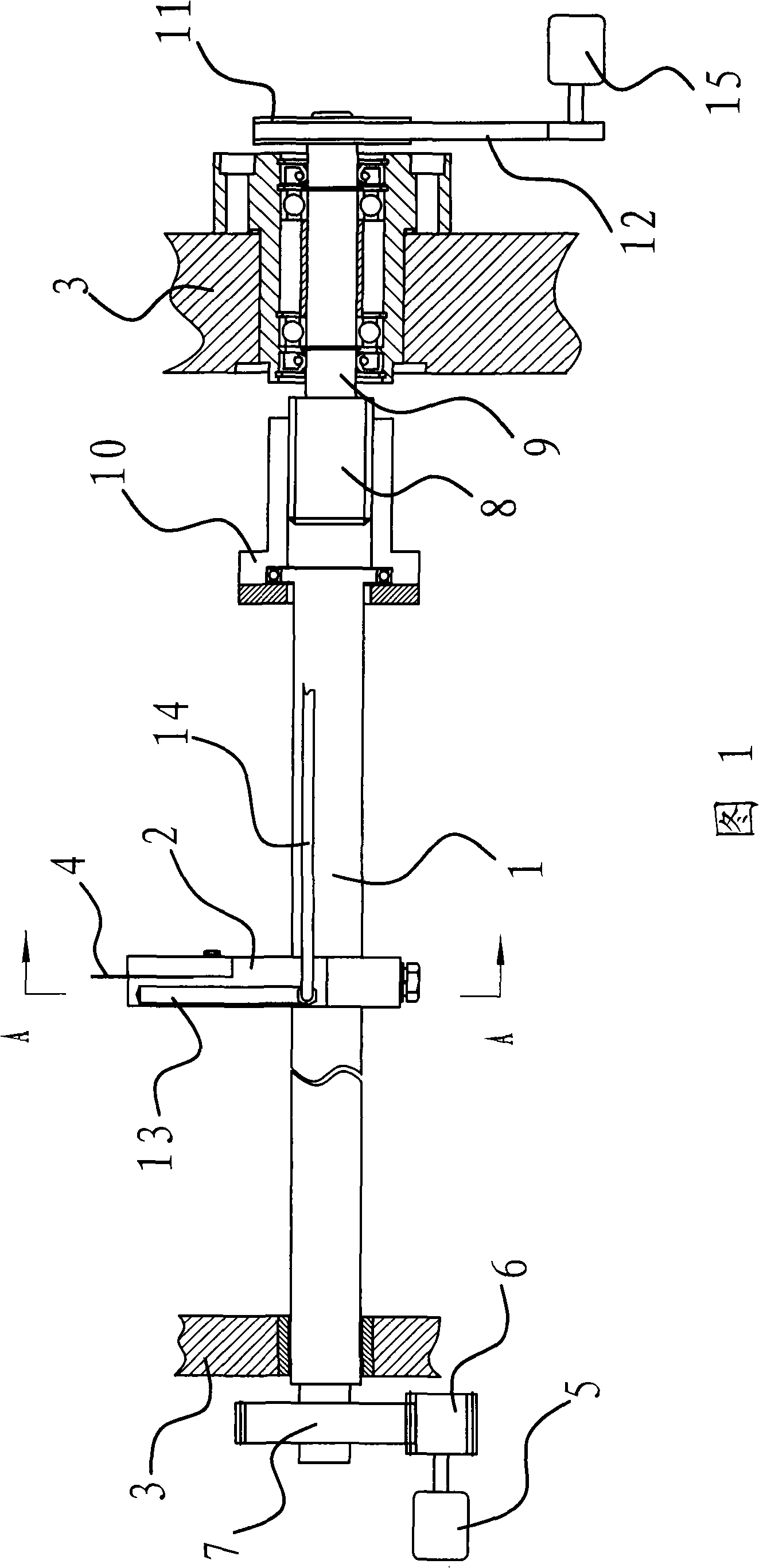

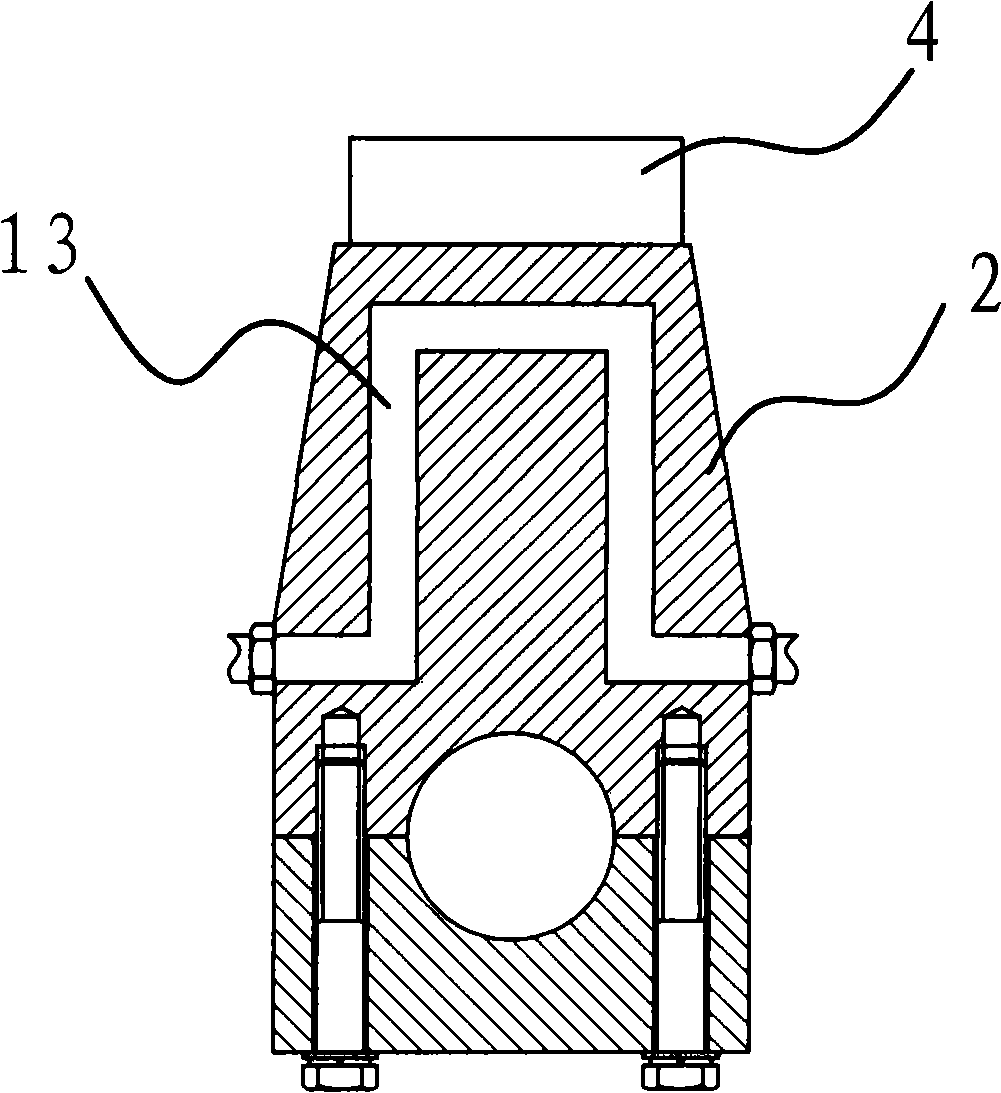

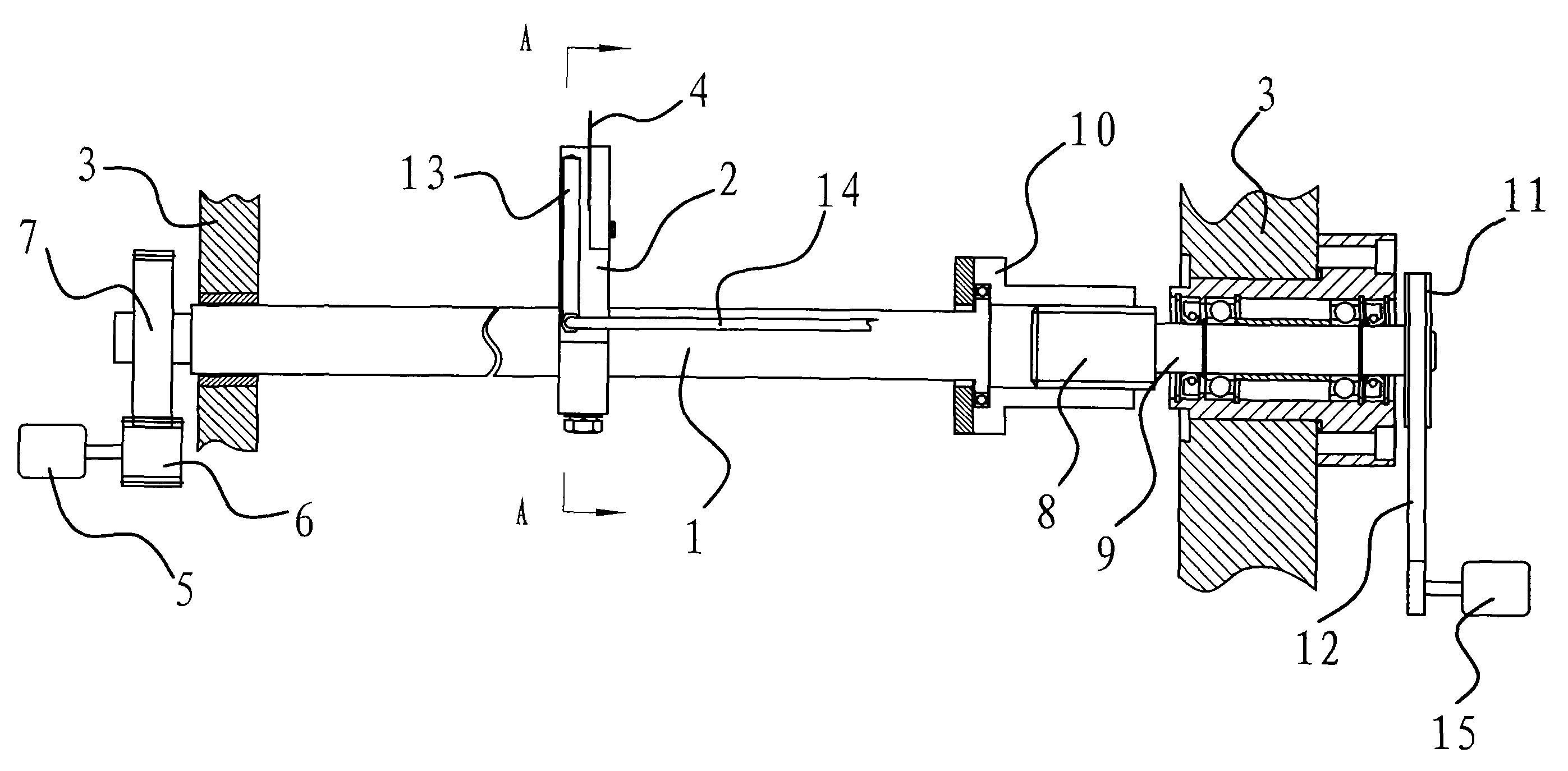

[0016] Such as figure 1 As shown, the high-speed vacuum coating on-line slitting device includes a rotating shaft 1 and a tool holder 2. The two ends of the rotating shaft 1 are respectively connected with a power mechanism and a blade adjusting device, and are supported by a wall 3 . The knife rest 2 is vertically fixed on the rotating shaft 1, and the outer end of the knife rest 2 is provided with a blade 4 . In this embodiment, the knife holder 2 is made of red copper.

[0017] The power mechanism comprises a reduction motor one 5, a main gear 6 and an auxiliary gear 7 interlocked with the rotating shaft 1, and the reduction motor one 5 drives the rotating shaft 1 to rotate through the transmission of the main gear 6 and the auxiliary gear 7 successively. In this embodiment, the total reduction ratio reaches 400, so that the blade 4 can stably cut into the film or sheet at a very slow speed, so as to ensure that the film or sheet can be cut smoothly. At the same time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com