Automatic TIG (Tungsten Inert Gas) welding method for liner-free single-side welding and double-side forming of aluminum alloy butted circular seam

A single-sided welding double-sided, welding method technology, applied in the field of aluminum alloy welding, can solve the problems of unsightly welding seam formation, girth welding seam edge collapse, easy generation of pores, etc., to enhance the degree of welding automation, welding heat affected zone Small, consistent ripple spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] An automatic TIG welding method for single-side welding and double-side forming of aluminum alloy butt joint without liner, including the following steps:

[0014] The first step is to use acetone to clean the oil around the butt joint of the cylinder before welding, and use a stainless steel wire wheel to remove the 50mm inner oxide film around the butt joint of the cylinder. The thickness of the cylinder is 8mm and the diameter is 200mm.

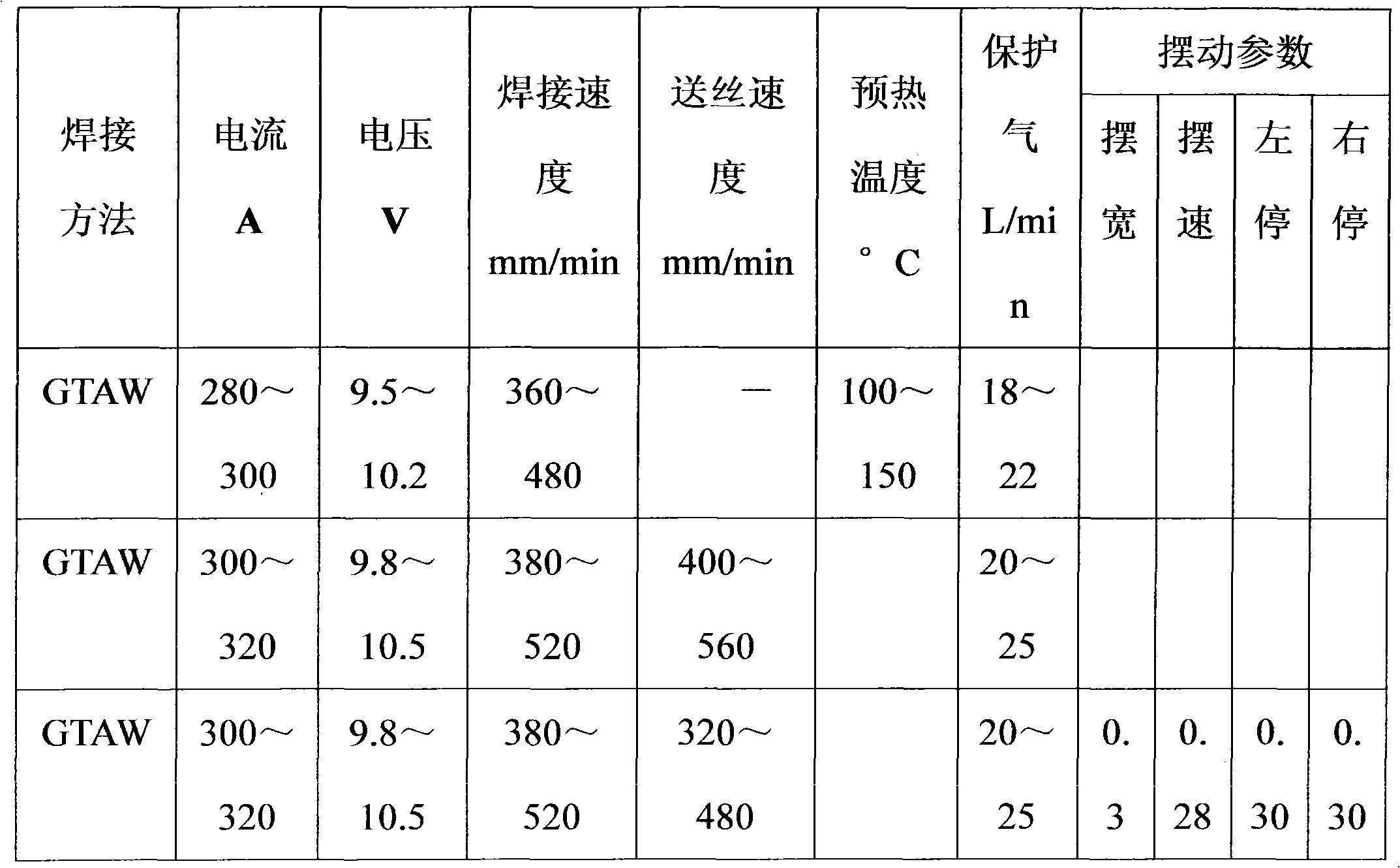

[0015] The second step is to preheat before welding, the temperature is 110°C, and the debugging control panel controls the welding current, voltage, welding speed, and wire feeding speed in real time. The specific parameters are as follows:

[0016]

[0017] The third step is to use an automatic argon tungsten arc welding machine for welding. The first layer is welded without adding welding wire to form the back, the second layer is filled with welding wire, the third layer is added with welding wire, and the welding torch swings...

Embodiment 2

[0020] The first step is to use acetone to clean the oil around the butt joint of the cylinder before welding, and use a stainless steel wire wheel to remove the 50mm inner oxide film around the butt joint of the cylinder. The thickness of the cylinder is 10mm and the diameter is 800mm.

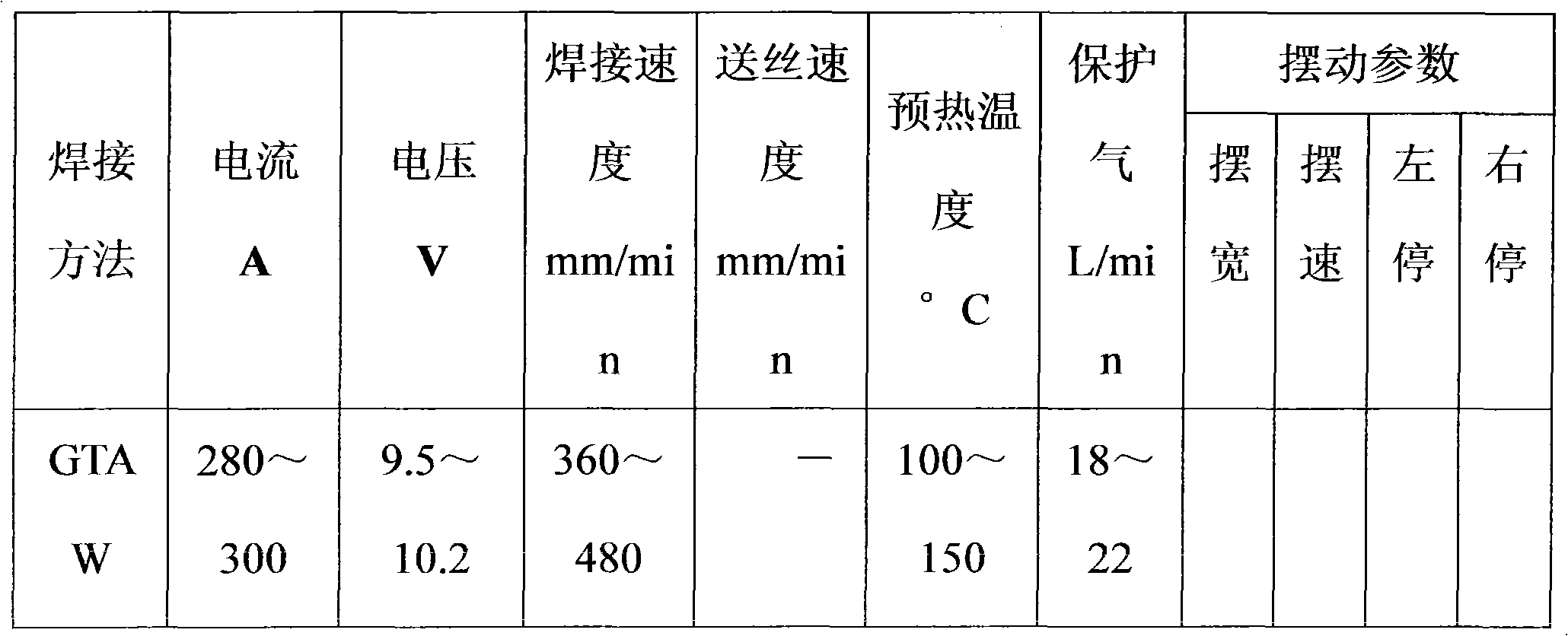

[0021] The second step is to preheat before welding. The temperature is 130°C. The debugging control panel controls the welding current, voltage, welding speed and wire feeding speed in real time. The specific parameters are as follows:

[0022]

[0023] The third step is to use an automatic argon tungsten arc welding machine for welding. The first layer is welded without adding welding wire to form the back, the second layer is filled with welding wire, the third layer is added with welding wire, and the welding torch swings to form the cover.

[0024] After the first layer of welding, the back of the weld has the same height and width, and a 5mm deep groove is formed on the front of the w...

Embodiment 3

[0026] The first step is to use acetone to clean the oil around the butt joint of the cylinder before welding, and use a stainless steel wire wheel to remove the 50mm inner oxide film around the butt joint of the cylinder. The thickness of the cylinder is 11mm and the diameter is 1400mm.

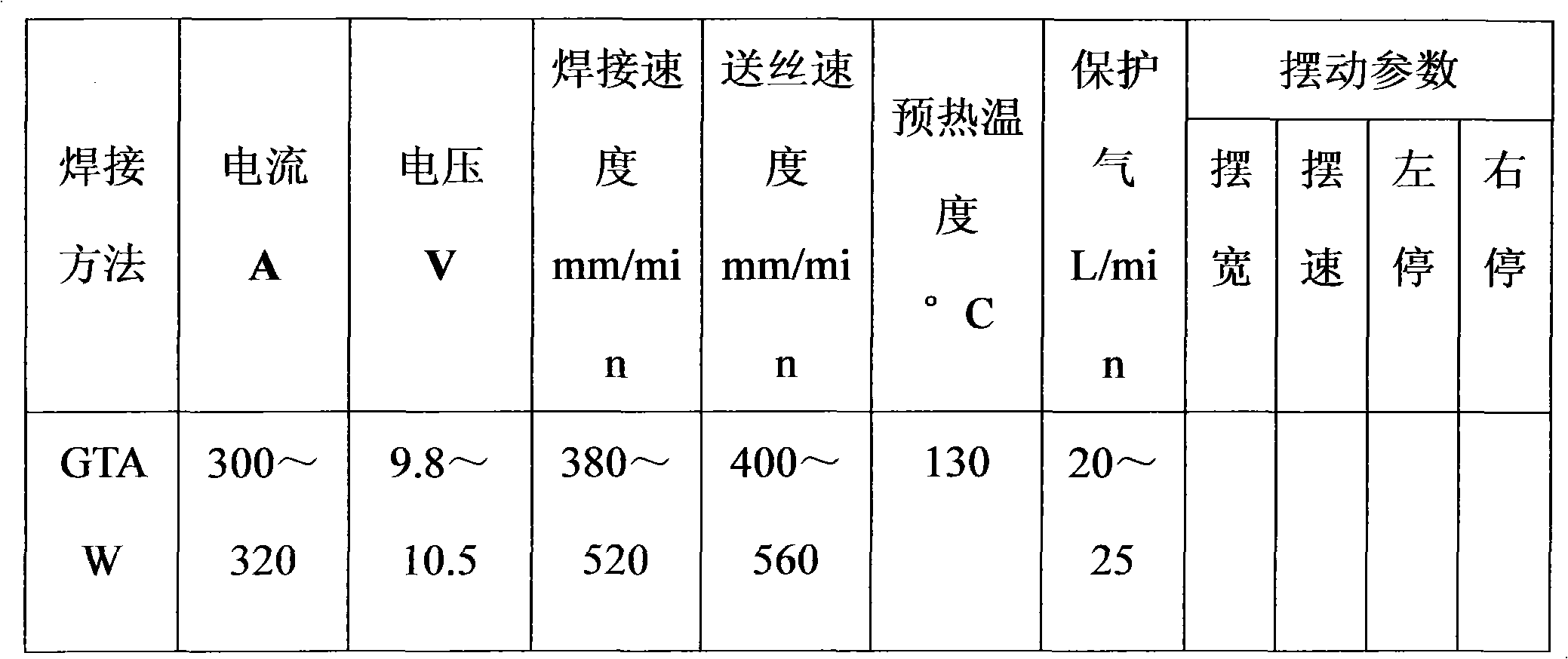

[0027] The second step is to preheat before welding. The temperature is 140°C. The debugging control panel controls the welding current, voltage, welding speed and wire feeding speed in real time. The specific parameters are as follows:

[0028]

[0029] The third step is to use an automatic argon tungsten arc welding machine for welding. The first layer is welded without adding welding wire to form the back, the second layer is filled with welding wire, the third layer is added with welding wire, and the welding torch swings to form the cover.

[0030] After the first layer of welding, the back of the weld has the same height and width, and a 6mm deep groove is formed on the front of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com