Three-phase transformer iron core silicon steel sheet stacking equipment

A technology of three-phase transformers and silicon steel sheets, which is applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problem of inability to ensure the uniformity of transformer iron core silicon steel sheets, and the inability to compress and enlarge transformer iron core silicon steel sheets. Problems such as the labor force of the staff, to avoid increasing the labor force, avoiding direct stacking, and increasing the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention is further elaborated.

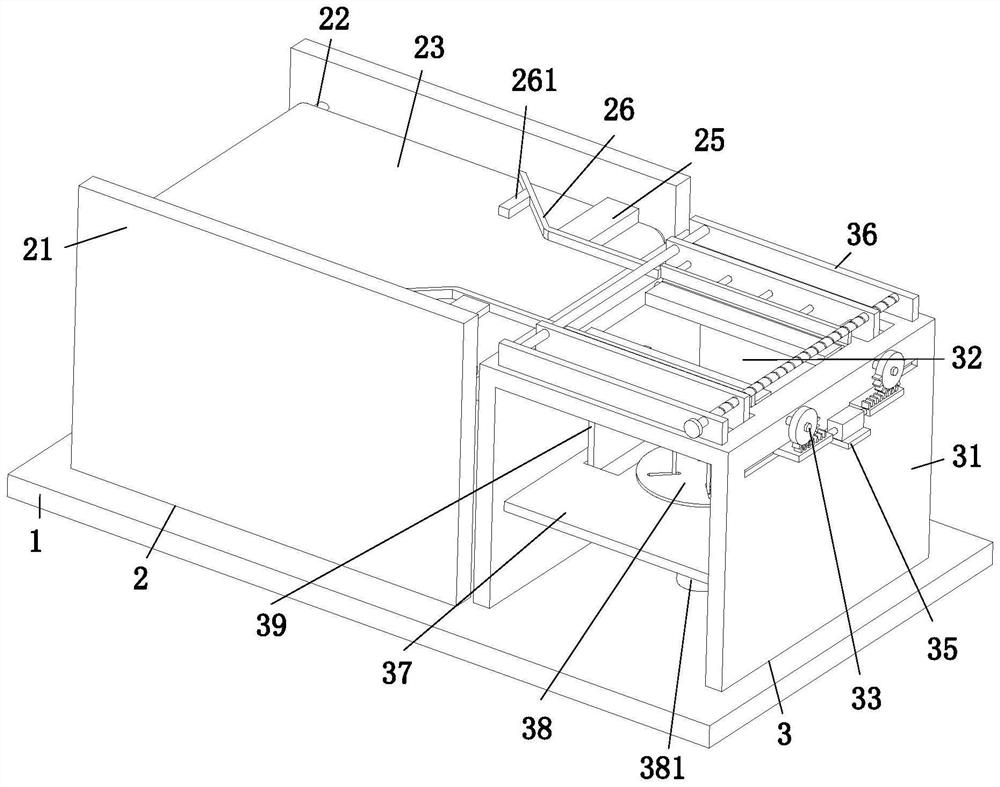

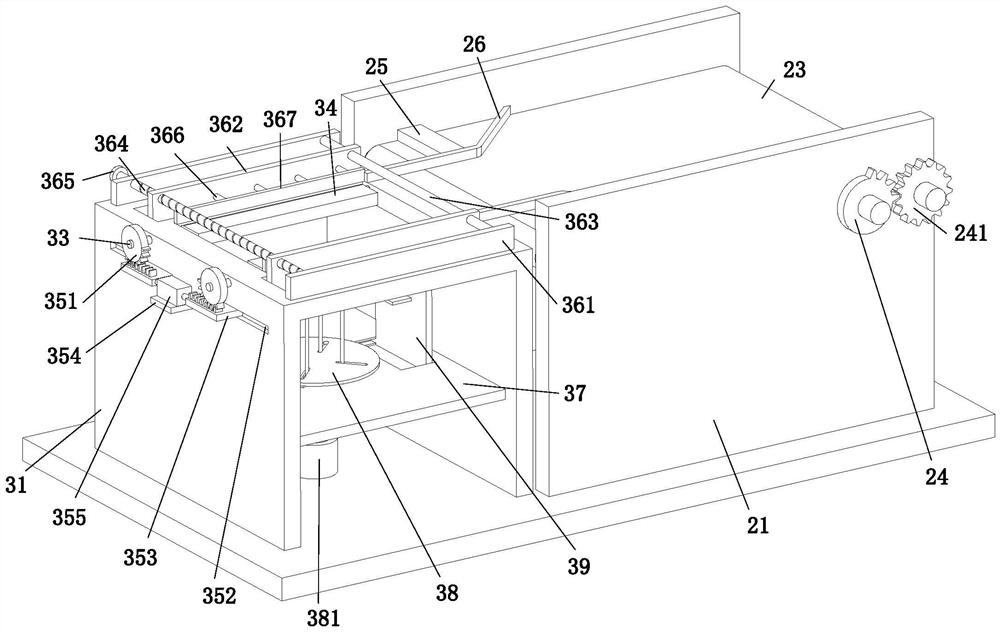

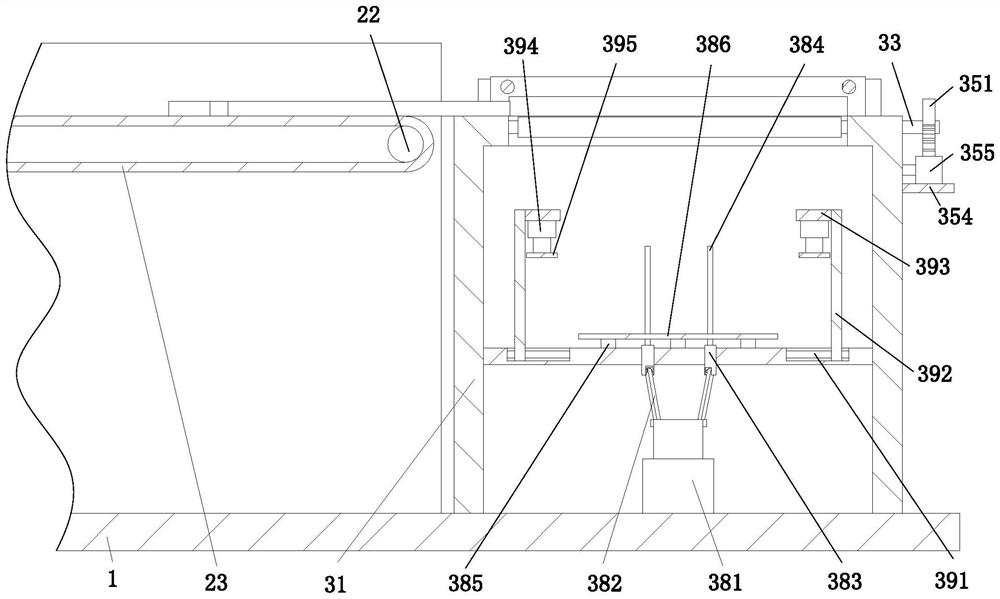

[0031] refer to figure 1 with figure 2 , a three-phase transformer iron core silicon steel sheet stacking equipment, including a workbench 1, a transmission device 2 and a moving device 3, the upper end of the workbench 1 is provided with a transmission device 2 and a moving device 3 in sequence from left to right ;

[0032] refer to figure 1 , figure 2 with image 3 , the transmission device 2 includes a fixed structure plate 21, a rotating shaft 22, a transmission belt 23, a turret 24, a support plate 25 and an inclined plate 26, and the upper end surface of the workbench 1 is close to the left side of the front and rear sides A fixed structure plate 21 is installed symmetrically and fixedly, and a rotating shaft 22 is arranged between the two fixed structural plates 21 from left to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com