High-speed stretch yarn machine length control system with yarn-cutting control function

A high-speed elastic and shredding technology, which is applied in the direction of comprehensive factory control, fiber cutting, textiles and papermaking, etc., can solve the problems of increasing the production cost of the enterprise, the fixed length value exceeding the predetermined value, and the waste of production materials, so as to improve production efficiency, The effect of precision production process and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

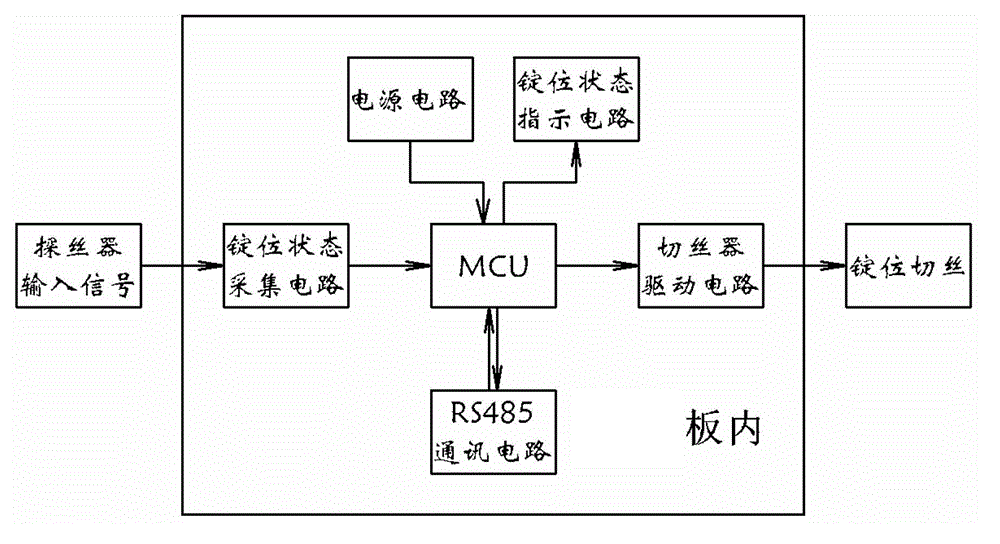

[0034] Such as figure 1 As shown, the length-fixing system of high-speed elastic yarn machine with wire cutting control in the present invention is composed of MCU, spindle position state acquisition circuit, RS485 communication circuit, shredder drive circuit, spindle position state indication circuit, and power supply circuit. The input end of the spindle position state acquisition circuit is connected with the input signal of the wire detector, and the output end is connected with the MCU. The MCU separately controls the driving circuit of the cutter to cut the silk at the spindle position, and the indicating circuit of the spindle position status gives a prompt. The RS485 communication circuit is connected with the MCU, and is responsible for the communication between the fixed-length system of the present invention and the man-machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com