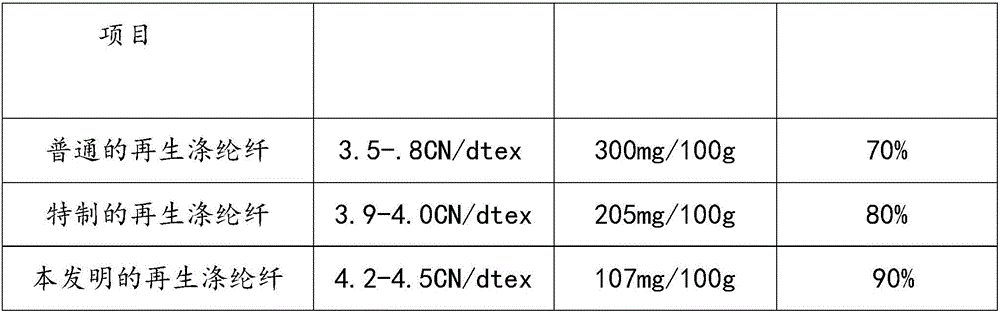

Regenerated polyester fiber spinning process capable of effectively solving yarn breaking phenomenon

A recycled polyester and fiber spinning technology, applied in fiber cutting, fiber treatment, spinning solution degassing, etc., can solve the problems of raw material quality decline, quality decline, tow breakage, etc., and achieve uniform molecular weight and improved melt quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A regenerated polyester fiber spinning process that effectively solves the phenomenon of broken filaments, comprising the following steps:

[0034] 1) Mixing

[0035] 35 parts of bottle flakes and 55 parts of foam materials are mixed in the vacuum drum dryer with 2.2 tons per drum in the feeding workshop;

[0036] 2) dry

[0037] The material obtained in step 1) is in the vacuum drum dryer, and the mixed material is continuously stirred at a speed of 3 revolutions per clock, and is heated to 150 degrees by steam at a heating rate of 30 degrees per hour, and kept for 7 hours; The water ring-Roots vacuum unit maintains a vacuum of 0.01MPa in the vacuum drum dryer; finally, it can be discharged to the silo after the moisture is lower than 150PPM through the inspection room;

[0038] 3) Molten

[0039] The mixture in the silo in step 2) flows into the screw extruder below the silo by gravity, and the screw melts and conveys the material at a speed of 40 revolutions per m...

Embodiment 2

[0059] A regenerated polyester fiber spinning process that effectively solves the phenomenon of broken filaments, comprising the following steps:

[0060] 1) Mixing

[0061] 40 parts of bottle flakes and 60 parts of foam materials are mixed in the vacuum drum dryer with 2.2 tons per drum in the feeding workshop;

[0062] 2) dry

[0063] The material obtained in step 1) is in the vacuum drum dryer, and the mixed material is continuously stirred at a speed of 3 revolutions per clock, and is heated to 150 degrees by steam at a heating rate of 30 degrees per hour, and kept for 7 hours; The water ring-Roots vacuum unit maintains a vacuum of 0.01MPa in the vacuum drum dryer; finally, it can be discharged to the silo after the moisture is lower than 150PPM through the inspection room;

[0064] 3) Molten

[0065] The mixture in the silo in step 2) flows into the screw extruder below the silo by gravity, and the screw melts and conveys the material at a speed of 45 revolutions per min...

Embodiment 3

[0085] A regenerated polyester fiber spinning process that effectively solves the phenomenon of broken filaments, comprising the following steps:

[0086] 1) Mixing

[0087] 45 parts of bottle flakes and 65 parts of foam materials are mixed in the vacuum drum dryer with 2.2 tons per drum in the feeding workshop;

[0088] 2) dry

[0089] The material obtained in step 1) is in the vacuum drum dryer, and the mixed material is continuously stirred at a speed of 3 revolutions per clock, and is heated to 150 degrees by steam at a heating rate of 30 degrees per hour, and kept for 7 hours; The water ring-Roots vacuum unit maintains a vacuum of 0.01MPa in the vacuum drum dryer; finally, it can be discharged to the silo after the moisture is lower than 150PPM through the inspection room;

[0090] 3) Molten

[0091] The mixture in the silo in step 2) flows into the screw extruder below the silo by gravity, and the screw melts and conveys the material at a speed of 50 revolutions per m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com