Cutting device of phloem fiber

A cutting device, bast fiber technology, applied in fiber cutting, fiber processing, textiles and papermaking, etc., can solve the problems of unsafe use, high labor intensity, inconvenient operation, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

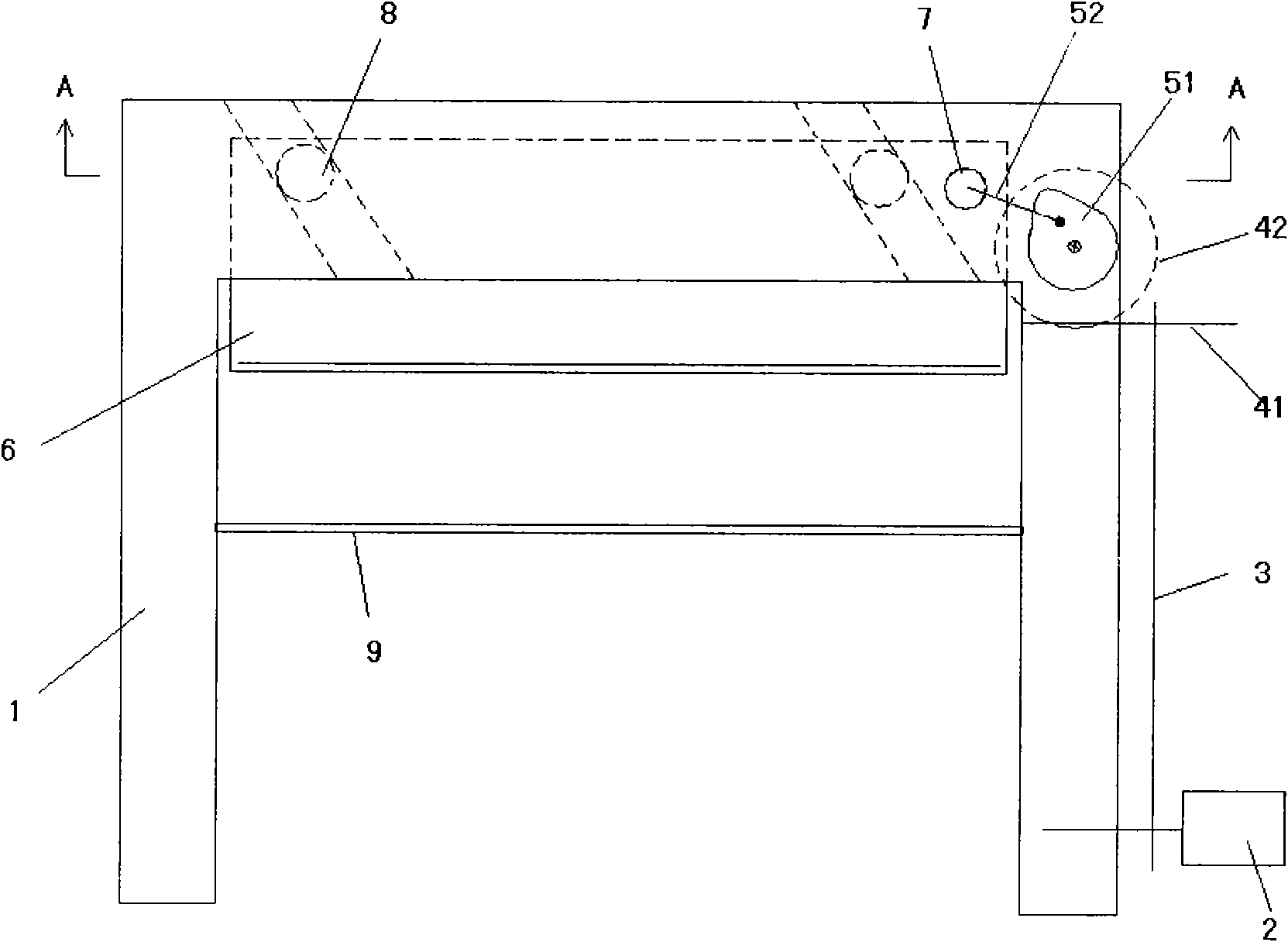

[0018] The bast fiber cutting device provided by the present invention adopts the principle that the motor drives the crank-link mechanism to rotate, and the crank-link mechanism drives the cutter to reciprocate obliquely upwards and downwards to cut fibers. Specific examples are as follows:

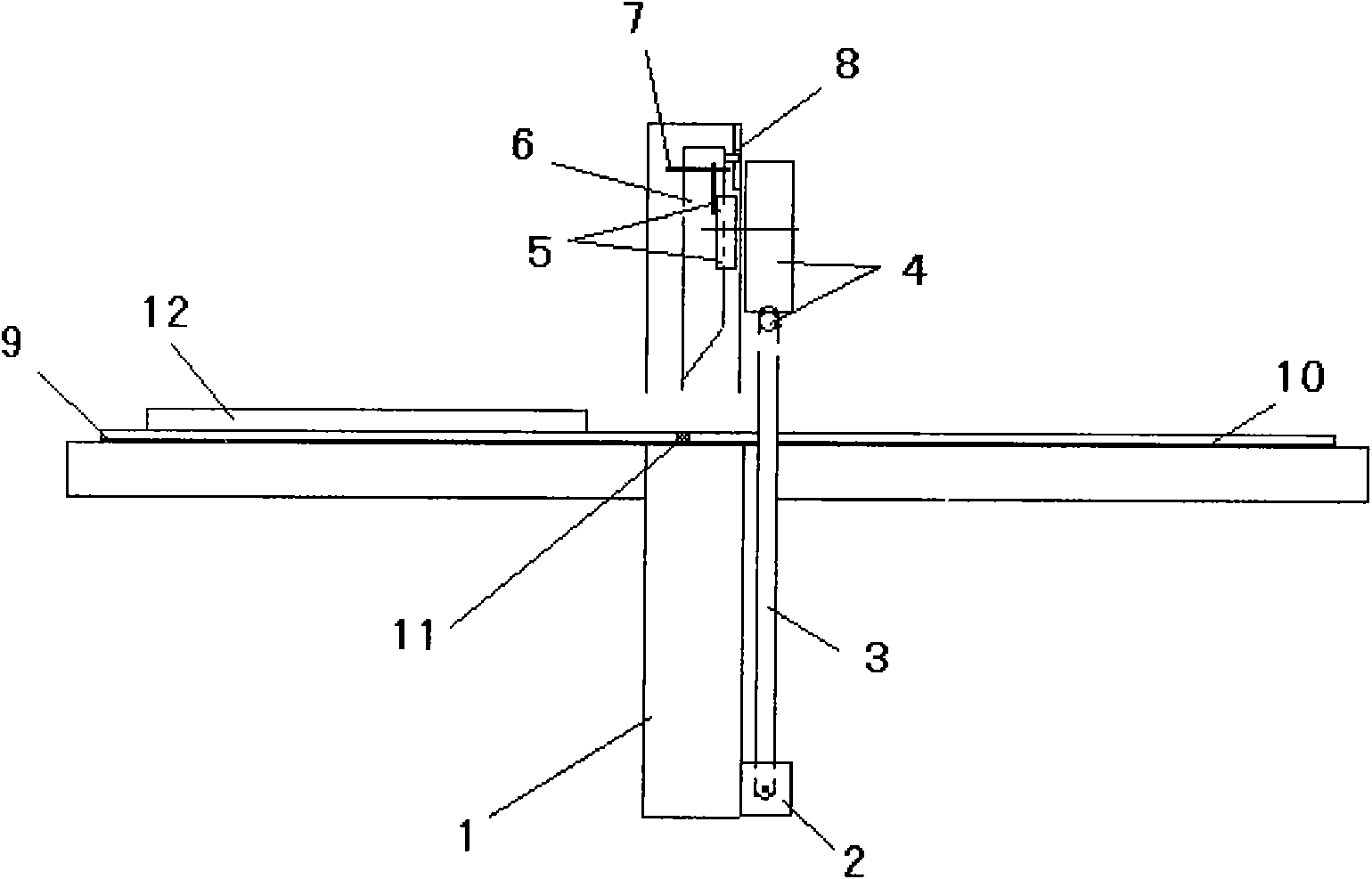

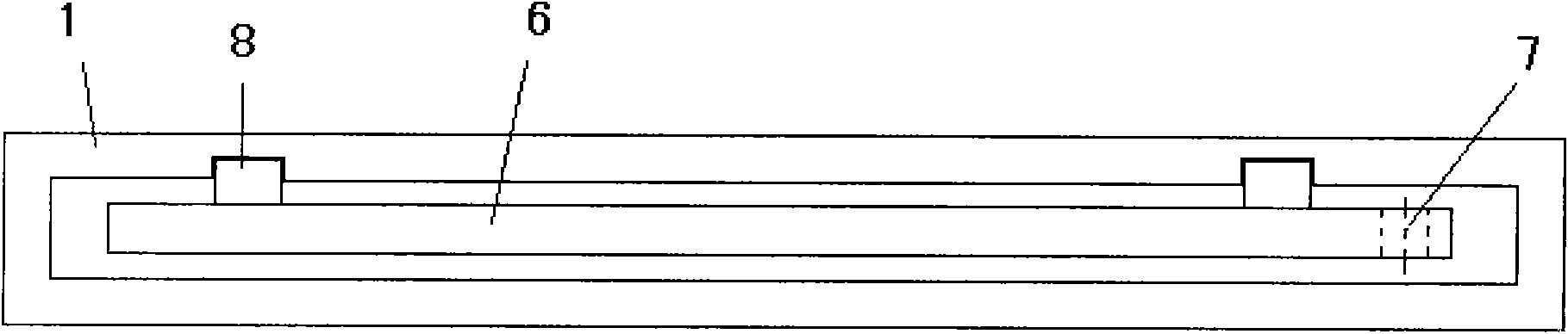

[0019] Such as figure 1 , figure 2 Shown, a kind of bast fiber cutting device, it comprises a " door " font frame 1, is provided with a motor 2 at the bottom of frame 1, connects a group of transmission mechanism 3 on the transmission shaft of motor 2, as a group of A pulley driven by a belt, or a set of sprockets driven by a chain, or a set of meshing gears. The output end of the transmission mechanism 3 is connected to a group of worm gear mechanisms 4 , that is, the output shaft of the transmission mechanism 3 is connected to a worm 41 , and the worm 41 engages with a worm wheel 42 . The output end of the worm gear mechanism 4 is connected with a set of crank linkage mechanisms 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com