Process and apparatus for manufacturing vinylon filament

A manufacturing method and filament tow technology, applied in the field of vinylon filament tow manufacturing, can solve the problems of improving production capacity, long spinning machine length, low production capacity, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

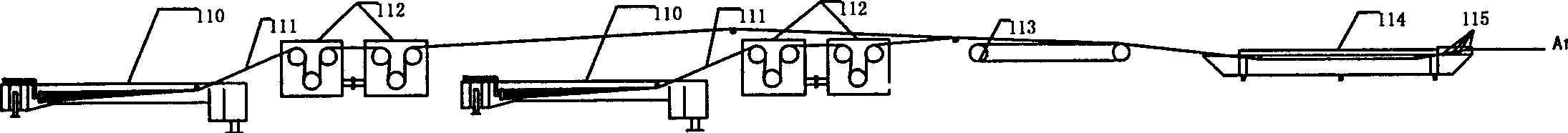

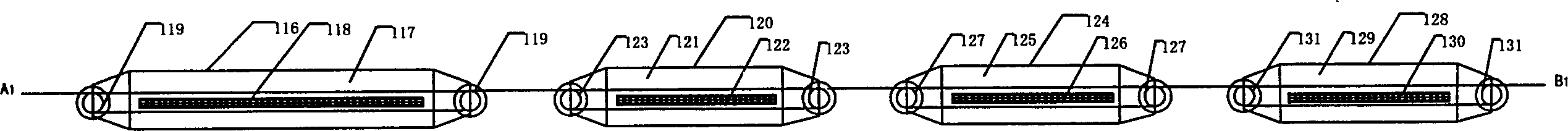

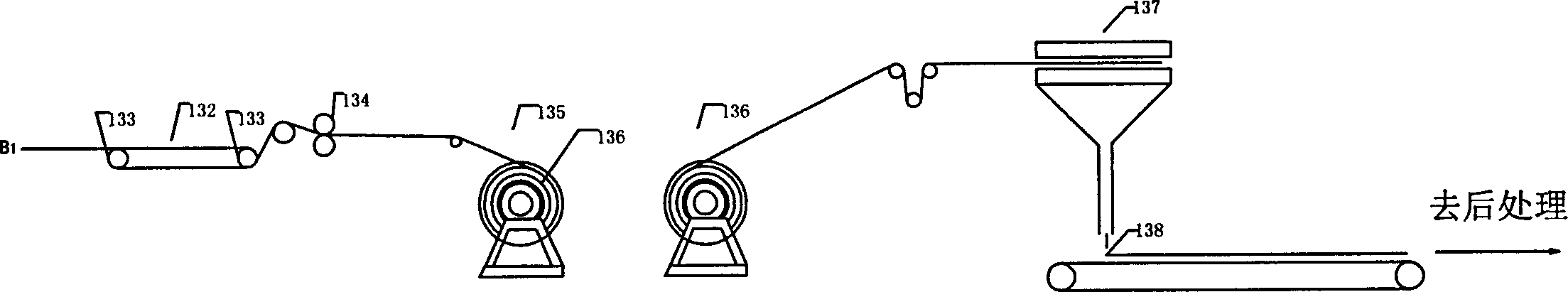

[0047] Example: see Figure 3-1 to Figure 3-3 and Figure 4-1 to Figure 4-3 , a manufacturing device for vinylon filament bundles, which includes a wet steering spinning machine 210, a guide roll drafting machine 215, a wet heat drafting bath 218, a drying preheating device 220, a first drafting machine 222, a tension heat treatment drying Warehouse 224, the second drafting machine 225, shrinkage heat treatment drying bin 227, the third drafting machine 228, stacking wire machine 230, winding machine 232, tension controller 233 and cutting machine 234; Wherein the wet method turns to spinning machine 210 Each spinning unit is arranged horizontally, and the spun primary tow 211 forms a large tow 214 in the second bath 213 after being turned by the upper and lower turning rollers, and the large tow 214 is then drawn by the guide roller drafting machine 215 , Introduced into the following wet heat drawing bath 218.

[0048] Its manufacturing method is: at first polyvinyl alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com