Method for producing incombustible acrylic yarn and incombustible acrylic yarn manufactured by method

A technology of acrylic fiber and yarn, which is applied in the field of producing non-combustible acrylic fiber yarn, and can solve problems such as difficult protection of human body safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

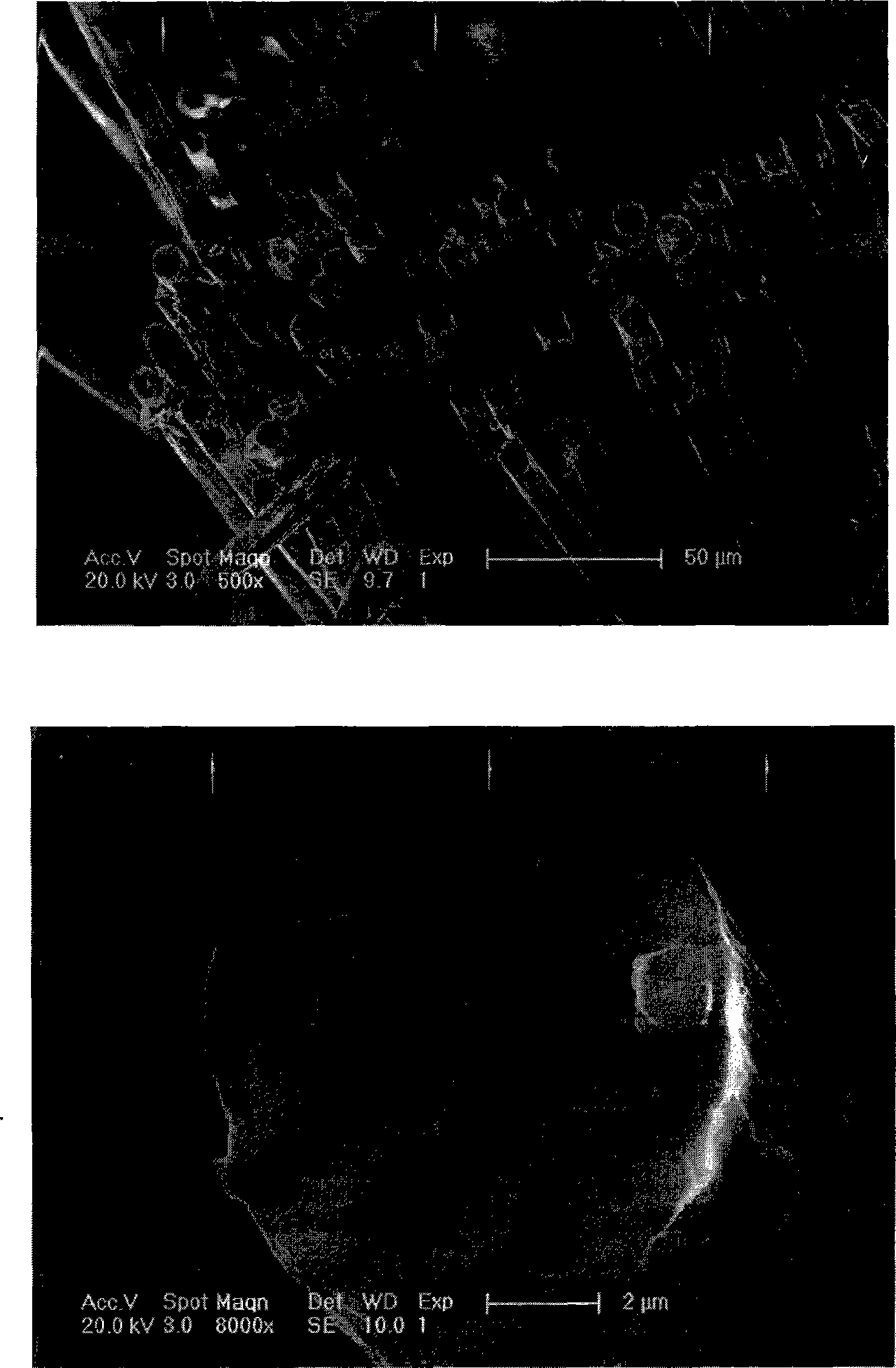

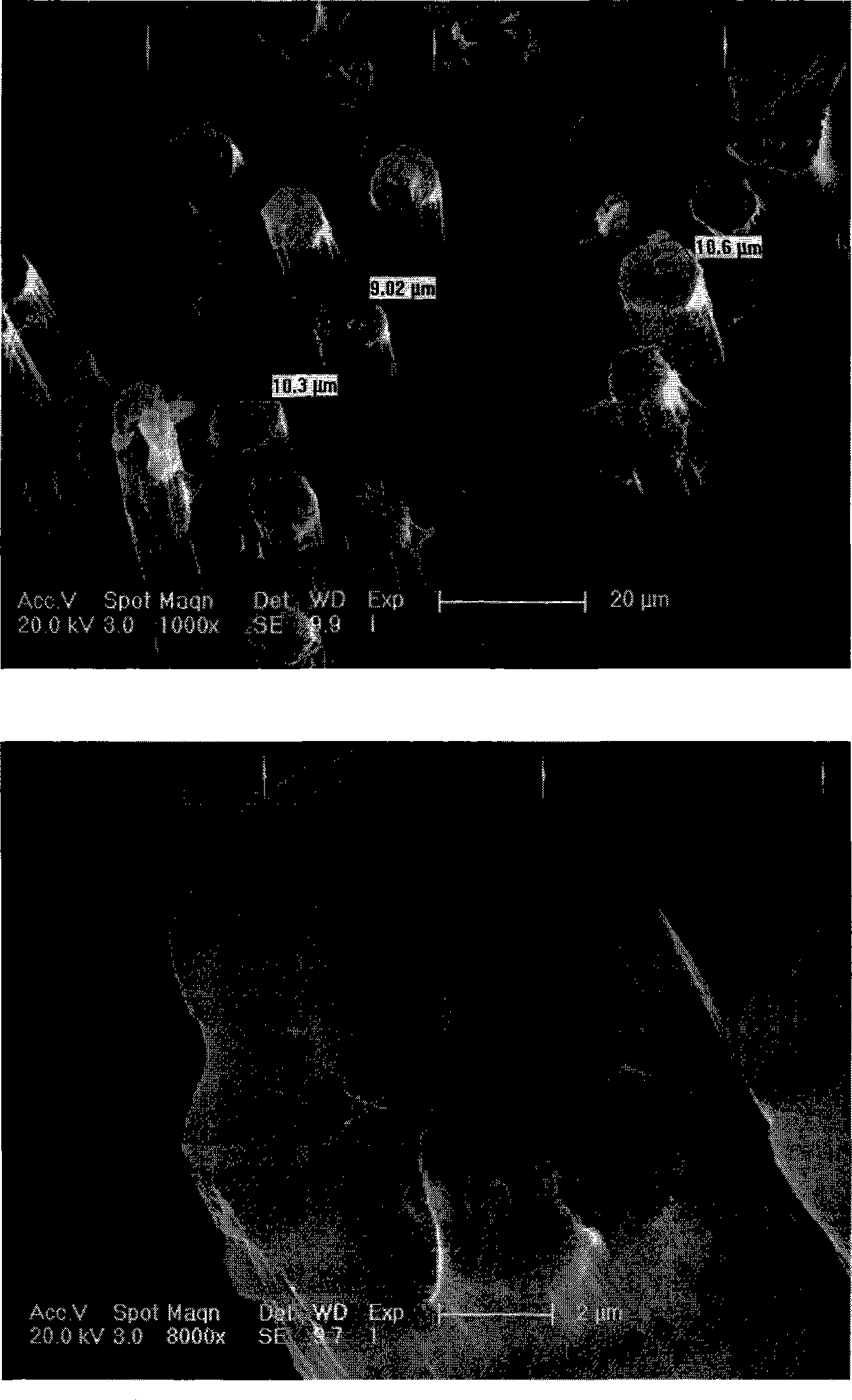

[0053] Example 1 Non-combustible spinnable acrylic fiber F1

[0054] Preparation of non-combustible spinnable acrylic fiber F1

[0055] 6k × 160 bundles of polyacrylonitrile copolymerized precursors with a fineness of 1.2 denier enter the pre-oxidation furnace, and the precursors reciprocate 4 times in a single furnace horizontally for pre-oxidation. The upper part of the pre-oxidation furnace is a heating source, and the lower part is a supply heat source. A temperature difference between layers is naturally formed from the fibers of the uppermost layer longitudinally downward, and the temperature difference is about 1°C. The pre-oxidation temperature ranges from about 200°C to about 280°C, and the heating rate is about 0.267°C / m. The running speed of the polyacrylonitrile precursor is about 2.0m / min, the pre-oxidation time in the furnace is about 319min, and the total draft is about 2.5%, to obtain the non-combustible spinnable acrylic fiber F1.

[0056] Characteriza...

Embodiment 2

[0063] Example 2 Non-combustible spinnable acrylic fiber F2

[0064] Preparation of non-combustible spinnable acrylic fiber F2

[0065] 6k × 160 bundles of polyacrylonitrile copolymerized precursors with a fineness of 1.2 denier enter the pre-oxidation furnace, and the precursors reciprocate 4 times in a single furnace horizontally for pre-oxidation. The upper part of the pre-oxidation furnace is a heating source, and the lower part is a supply heat source. A temperature difference between the layers is naturally formed longitudinally downward from the fibers of the uppermost layer, and the temperature difference is about 2°C. The pre-oxidation temperature ranges from about 200°C to about 280°C, and the heating rate is about 0.267°C / m. The running speed of the polyacrylonitrile precursor is about 1.0m / min, the time for pre-oxidation in the furnace is about 220min, and the total draft is about 2.5%, to obtain non-combustible spinnable acrylic fiber F2.

[0066] Characte...

Embodiment 3

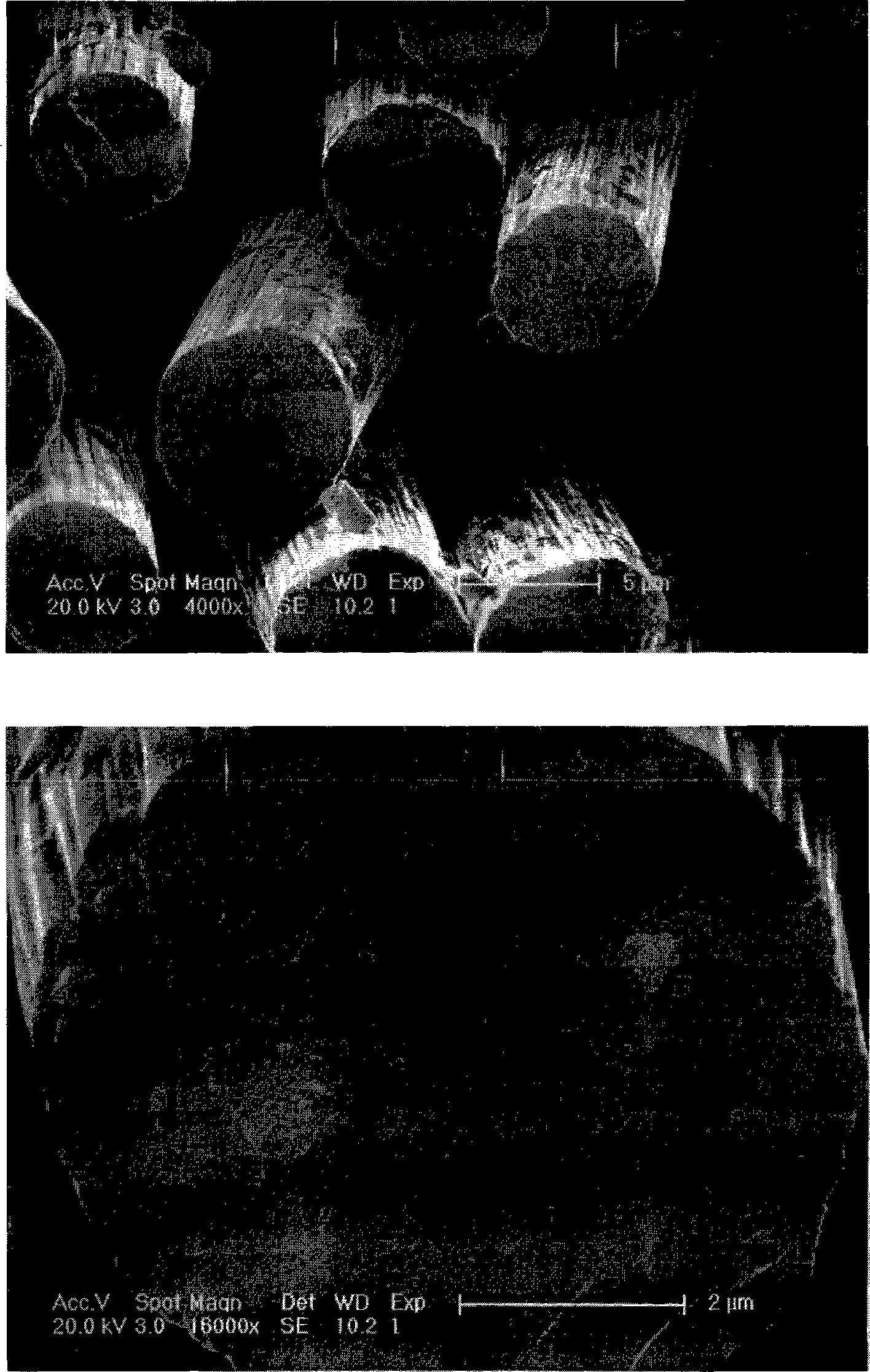

[0071] Example 3 Non-combustible spinnable acrylic carbon fiber

[0072] Preparation of non-combustible spinnable acrylic carbon fiber

[0073] Make 6k×160 bundles of polyacrylonitrile copolymerized precursors with a fineness of 1.2 denier enter the pre-oxidation furnace, and the precursors reciprocate horizontally for 3 times in a single furnace for pre-oxidation. The upper part of the pre-oxidation furnace is a heating source, and the lower part is a supply heat source. A temperature difference between layers is naturally formed from the fibers of the uppermost layer longitudinally downward, and the temperature difference is about 5°C. The pre-oxidation temperature ranges from about 200°C to about 280°C, and the heating rate is about 0.267°C / m. The running speed of the polyacrylonitrile precursor is about 3.5m / min, the pre-oxidation time in the furnace is about 99min, and the total draft is about 1.5%. After leaving the pre-oxidation furnace, the acrylic fiber obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com