Method for preparing regenerated return polypropylene fibrilled film fibers

A technology of polypropylene and polypropylene filaments, which is applied in fiber processing, fiber cutting, stretch spinning, etc., and can solve the problem of inability to use polypropylene, unavailable price polypropylene staple fibers, and clogging of spinneret holes in melt spinning, etc. problems, achieve good application prospects and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

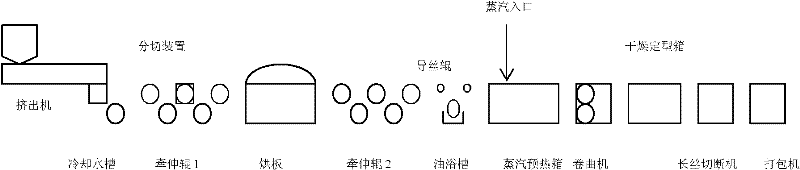

[0020] After the polypropylene regrind is extruded through the polypropylene extruder, it quickly enters the water bath tank, and the water bath is cooled to form a film. The cooled film is pulled out of the water bath by the first drafting roller, and then cut into by the film cutting device. The polypropylene film is cracked, the polypropylene filament is passed through the heated baking plate, and then passed through the second drafting roller, and the polypropylene filament is thermally drawn by using the speed difference between the first drafting roller and the second drafting roller, and then Oil the polypropylene yarn, preheat the oiled polypropylene yarn with steam and curl the polypropylene yarn with a fiber crimper, pass the crimped polypropylene yarn through the oven, and then the polypropylene yarn is dried and shaped. Finally, it is cut into fixed lengths according to the requirements and packed.

Embodiment 2

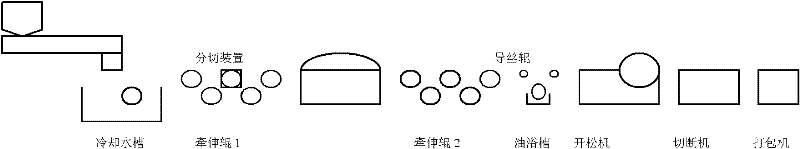

[0022] After the polypropylene regrind is extruded through the polypropylene extruder, it quickly enters the water bath tank, and the water bath is cooled to form a polypropylene film. The cooled film is pulled out of the water bath by the first drafting roller, and then separated by the film cutting device. Cut into polypropylene filaments, make the polypropylene filaments pass through the heated baking plate, and then pass through the second drafting roller, using the speed difference between the first drafting roller and the second drafting roller, the polypropylene filaments are thermally drawn, and at the same time Oil the polypropylene yarn at the second drafting roller, and then use the opener to open the polypropylene yarn into finer polypropylene yarns, and then cut the polypropylene yarns into required lengths through the fiber cutter, and finally pack them .

Embodiment 3

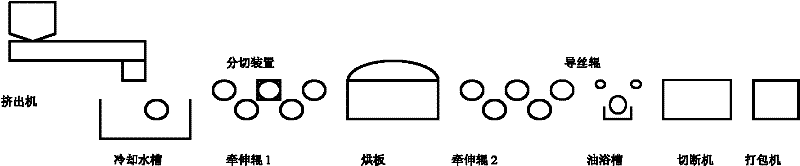

[0024] After the polypropylene return material is extruded through the polypropylene extruder, it quickly enters the water bath tank and is cooled to form a polypropylene film. The cooled film is pulled out of the water bath by the first drafting roller, and then cut by the film cutting device. into polypropylene filaments, the polypropylene filaments are passed through a heated oven, and then passed through the second drafting roller, using the speed difference between the first drafting roller and the second drafting roller, the polypropylene filaments are thermally drawn, and at the same time Oil the polypropylene filament in the oil bath, then cut the polypropylene filament to the required length by the fiber cutter, and finally pack it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com