Wool top stretch breaking machine

A technology of wool tops and rollers, applied in textiles and papermaking, fiber processing, fiber cutting, etc., can solve the problems of labor-intensive, high production costs, complex equipment structure, etc., to reduce human labor, low production costs, simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

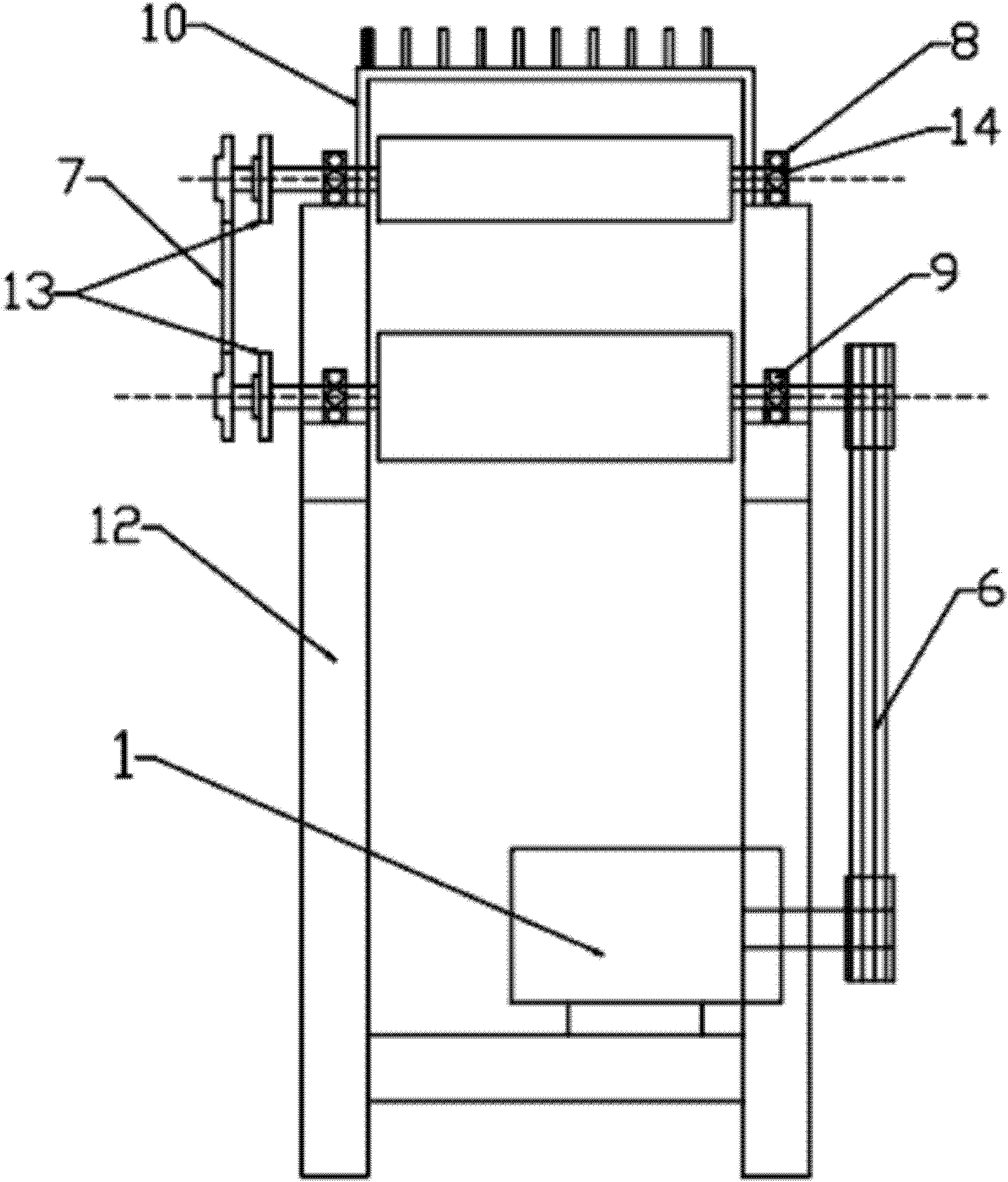

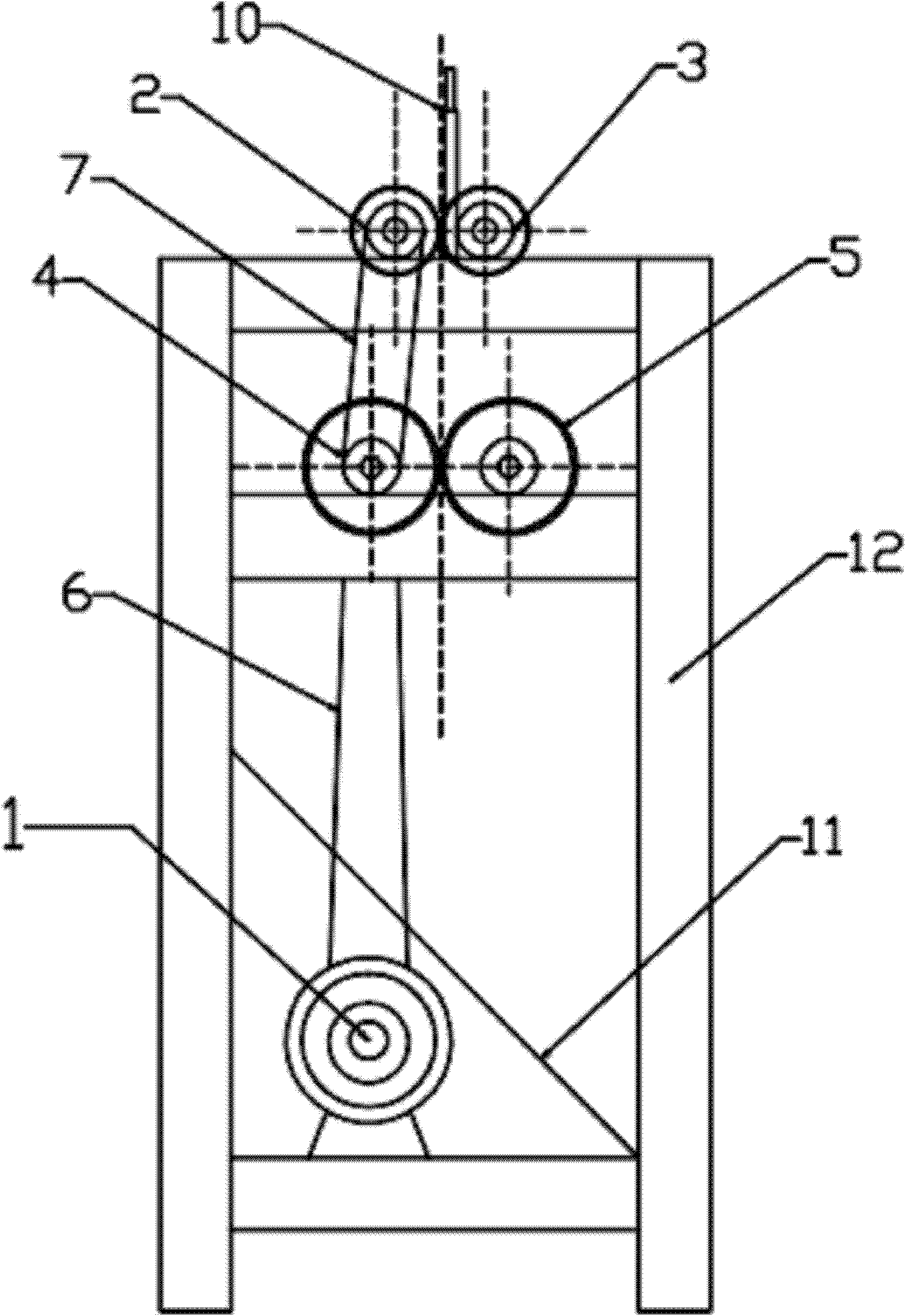

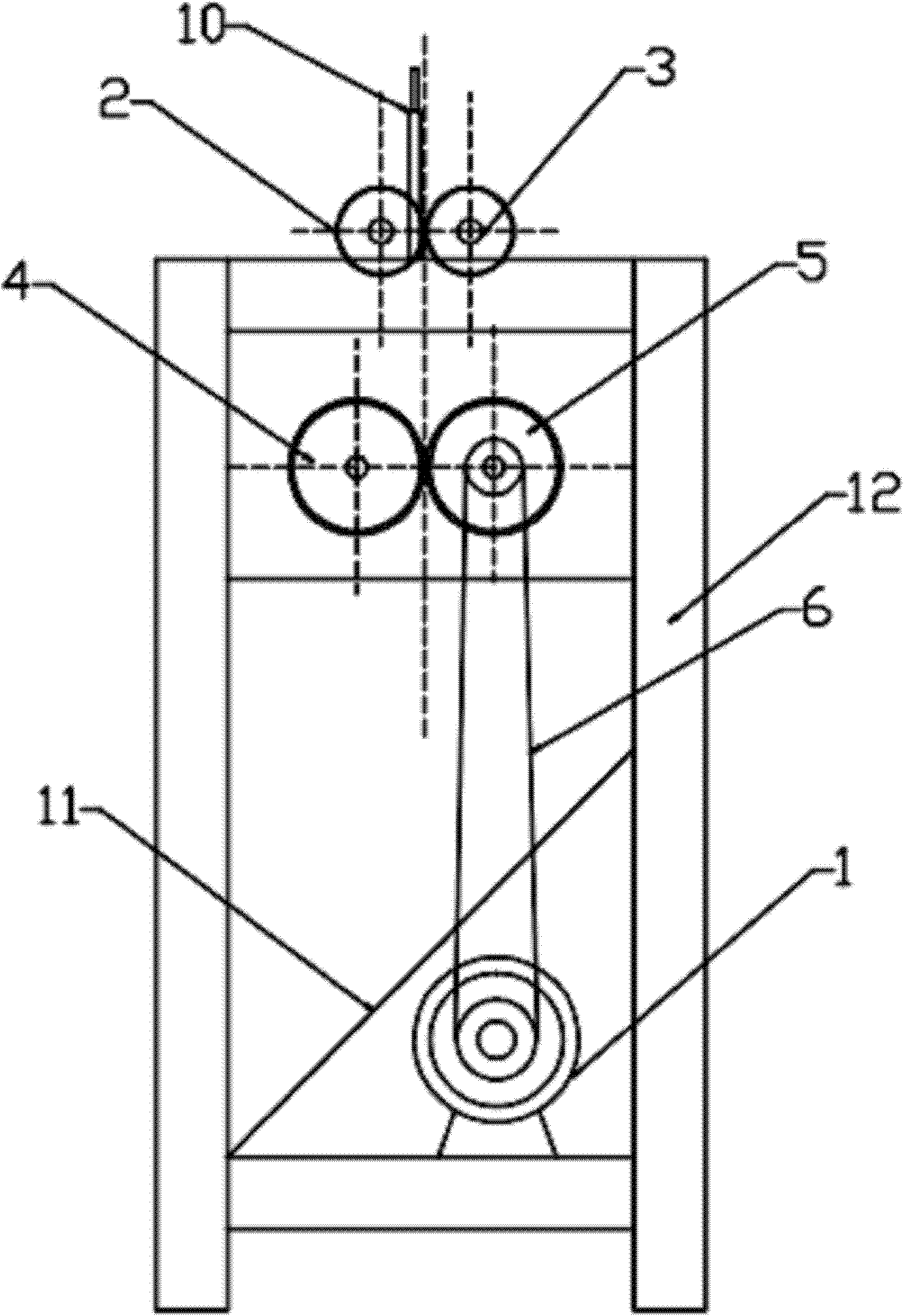

[0014] Such as figure 1 As shown, the present invention is through a kind of top breaking machine, which mainly includes motor 1, small driving roller 2, small driven roller 3, large driving roller 4, large driven roller 5, and small driving roller is set on the top of frame 12. For roller 2 and small driven roller 3, set the corresponding large driving roller 4 and large driven roller 5 directly below the contact point of small driving roller 2 and small driven roller 3, and pull them by the difference in line speed between them. To break wool tops, the motor 1 is leveled with the large driving roller 4 through the belt 6, the large driving roller 4 is connected with the large driven roller 5 through the gear 13, and at the same time is connected with the small driving roller 2 through the chain 7, and the small driving roller 2 is connected with the small driving roller through the gear 13. Connect to the small driven roller 3, the large driving roller 4, the large driven ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com