Fiber shearing device

A shearing device and fiber technology, used in fiber cutting, fiber processing, textiles and papermaking, etc., can solve problems such as increasing labor intensity of workers, reducing processing efficiency, and increasing production costs, achieving low production costs and long service life. , the effect of improving work efficiency

Inactive Publication Date: 2012-07-04

HUNAN UNIV

View PDF8 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Because the speed of the shearing roller is relatively fast, the friction between it and the rubber wheel is relatively serious, causing the blade on the roller to wear faster, and the blade needs to be changed every two hours, which reduces the processing efficiency and increases Increased production costs, but also increased the labor intensity of workers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] Raw materials: alkali-free long glass fiber 2400tex (twisted roving, density 2.35g / cm 3 , 13 μm in diameter).

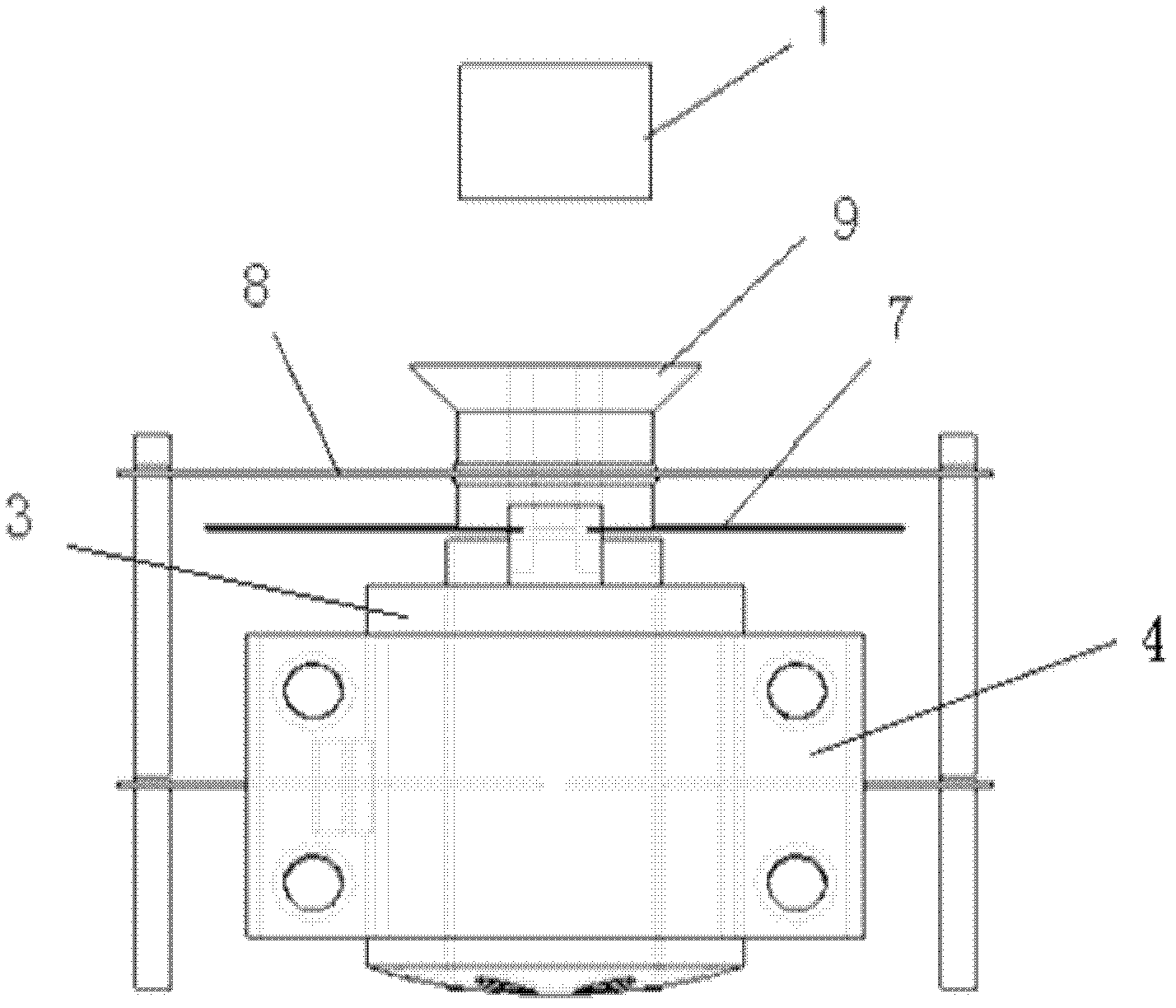

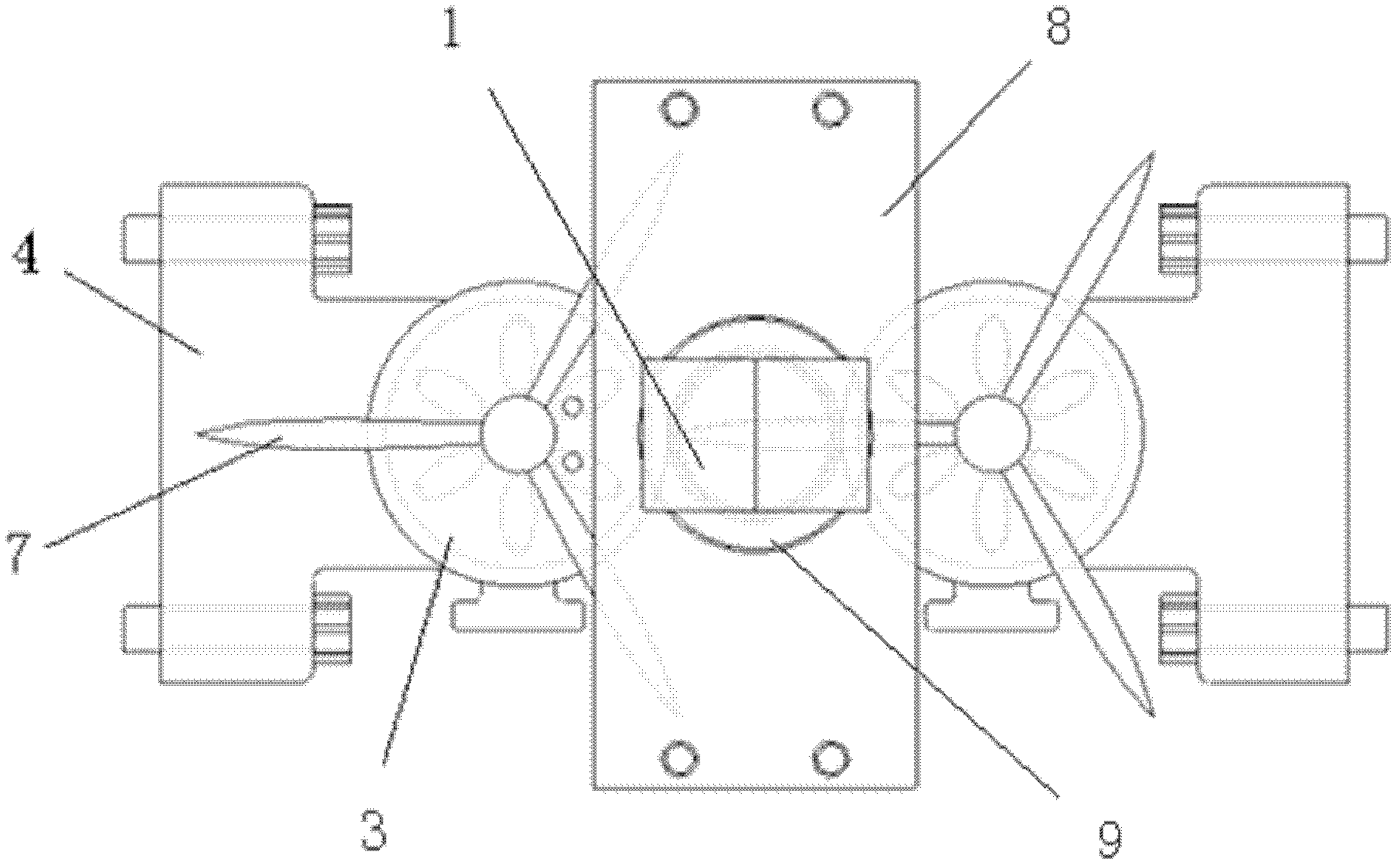

[0023] The rotating speed of the guide wheel 1 of the present invention is 1000r / min, and the rotating speed of the motor 3 is 2400r / min. By cutting the long glass fibers, the glass fibers with a length of 6cm are obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

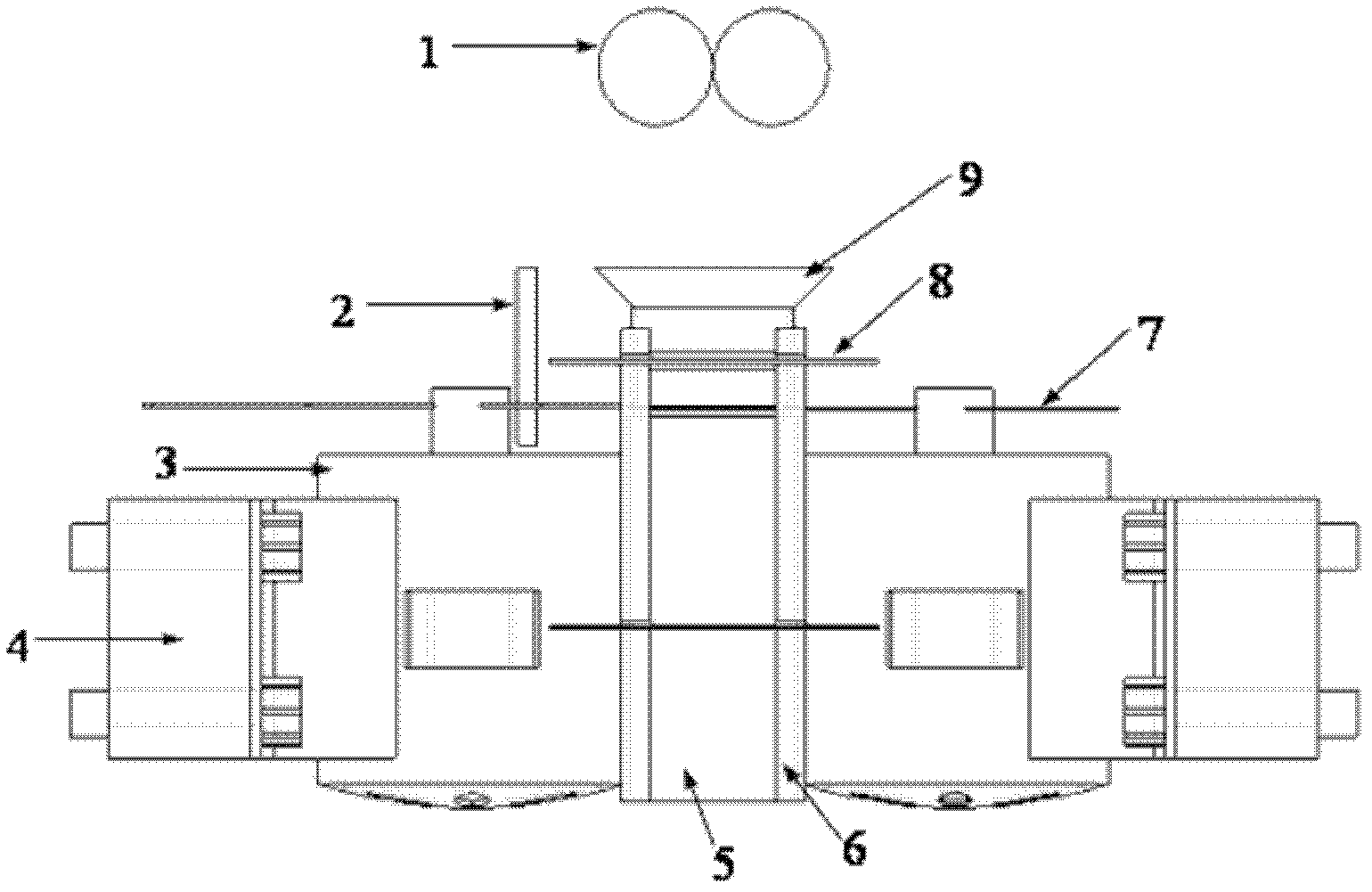

The invention discloses a fiber shearing device. An inlet of a conveying pipeline (5) aligns to an outlet of a guider (9), and a movable shearing tool (7) is mounted on a rotary shaft of a motor (3),arranged between the guider (9) and the conveying pipeline (5) and close to the outlet of the guider (9). The fiber shearing device is long in service life, high in production efficiency, low in production cost and labor intensity. Long fibers can be sheared into short fibers of a certain length, shearing efficiency is improved and abrasion of the movable shearing tool is reduced.

Description

technical field [0001] The invention relates to a shearing device, in particular to a fiber shearing device. Background technique [0002] At present, when cutting silky and flexible fibers such as glass fiber, chemical fiber, polypropylene fiber, cotton fiber, polyester and acrylic fiber, manual cutting or mechanical cutting is often used. The manual cutting method has low efficiency, high labor intensity and poor cutting accuracy. However, the fiber shearing machine used in the mechanical cutting method is generally complex in structure, single in function, high in cost, and high in production cost. Most of the shearing knives used are rotary twisting knives. The use cost of the shearing machine is increased, and during the cutting process, the fiber is prone to slipping, which reduces the cutting accuracy. For example, glass fiber reinforced thermoplastic composite panels commonly used in domestic and foreign automotive interiors, referred to as GMT panels, are processe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01G1/00B26D1/20B26D7/26B26D7/00

Inventor 戴宏亮董升顺颜湘蒋豪杰

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com