Method and device for treating a fibre cable

A technology of tow and equipment, applied in the field of equipment for implementing the method, can solve problems such as uneven liquid distribution, and achieve the effects of reducing equipment cost and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

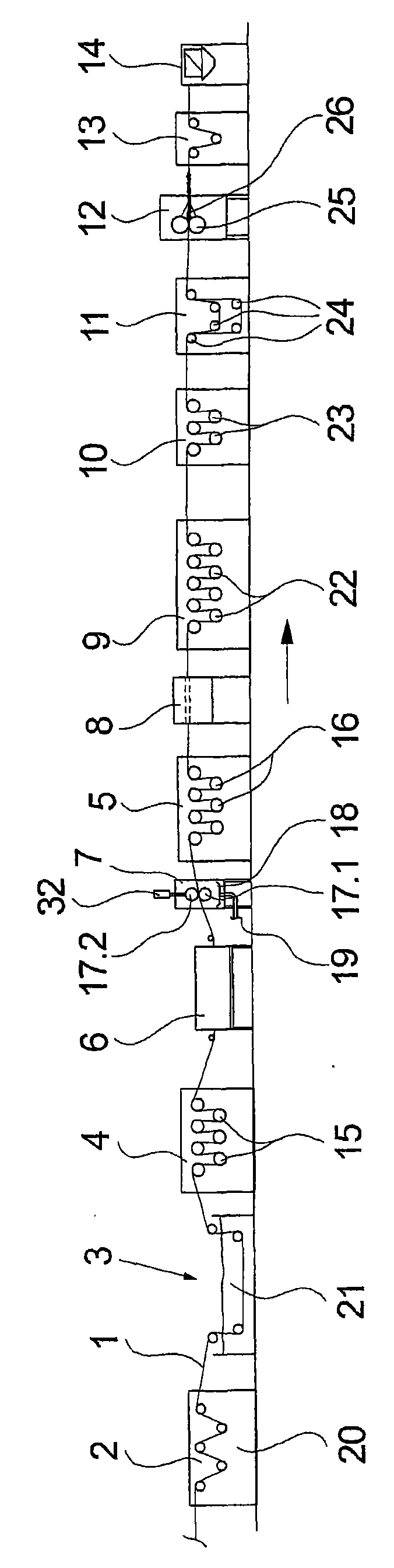

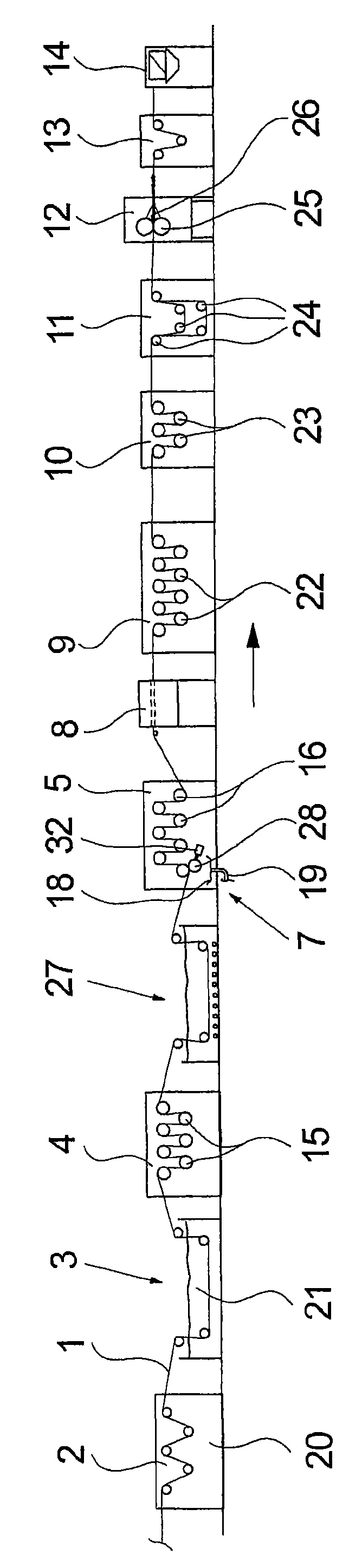

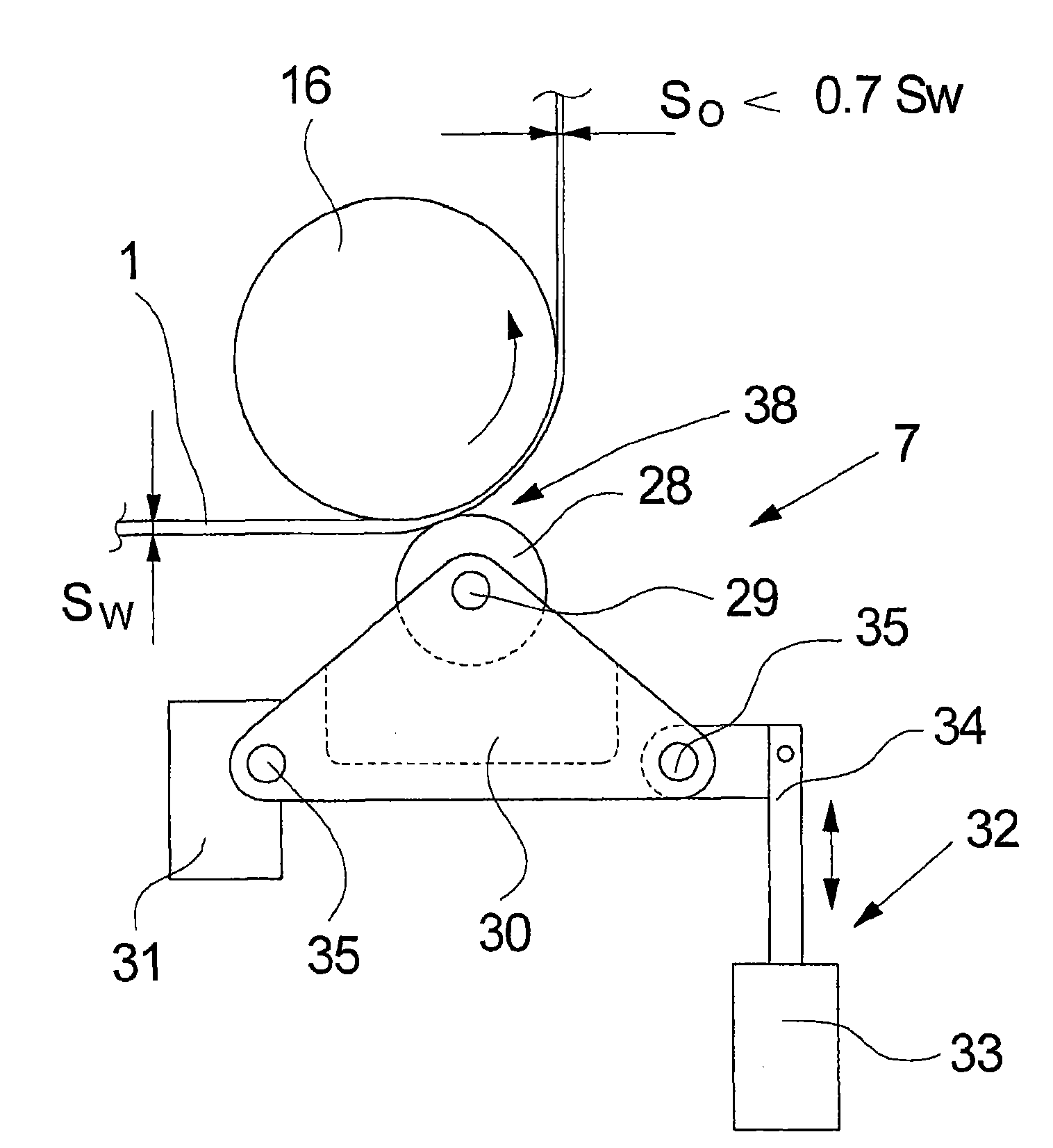

[0033] exist figure 1 A first exemplary embodiment of an apparatus according to the invention for carrying out the method according to the invention for processing tows for the production of staple fibers is schematically shown in side view. The apparatus has a plurality of processing devices which are successively arranged to form a fiber production line in which the direction of travel of the tow is between figure 1 Indicated by arrows.

[0034]At the beginning of the fiber production line there is a drawing device 2 on which a plurality of drawing rollers 20 are arranged to advance the filaments. The tow 1 , which consists of a plurality of strands of synthetic monofilaments, is guided in the form of a belt on a take-off roll 20 . Synthetic monofilament strands are drawn, for example, from can creels with a large number of cans. Each of the cans contains a tow-like monofilament sliver with a large number of individual monofilaments and laid down in a tow at the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com