Non-abrasion fiber cutting equipment

A fiber cutting equipment, non-abrasive technology, applied in fiber cutting, fiber processing, textiles and papermaking, etc., can solve the problems of yarn cutting blade damage, unusability, increased labor costs and financial costs, etc., to improve yarn cutting efficiency , prolong service life and save labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These exemplary embodiments are provided so that those of ordinary skill in the art can clearly understand the present invention and implement the present invention from the description herein. The drawings and specific examples are not intended to limit the invention, the scope of which is defined by the appended claims.

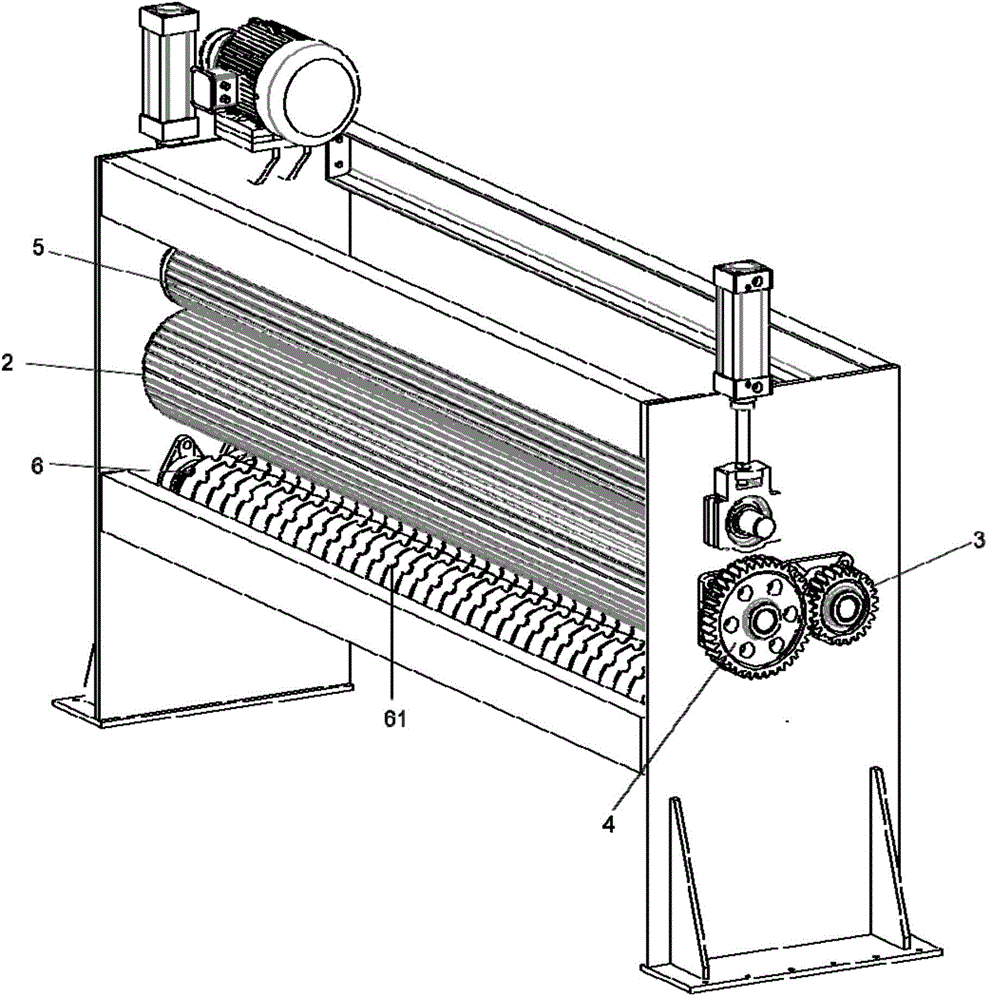

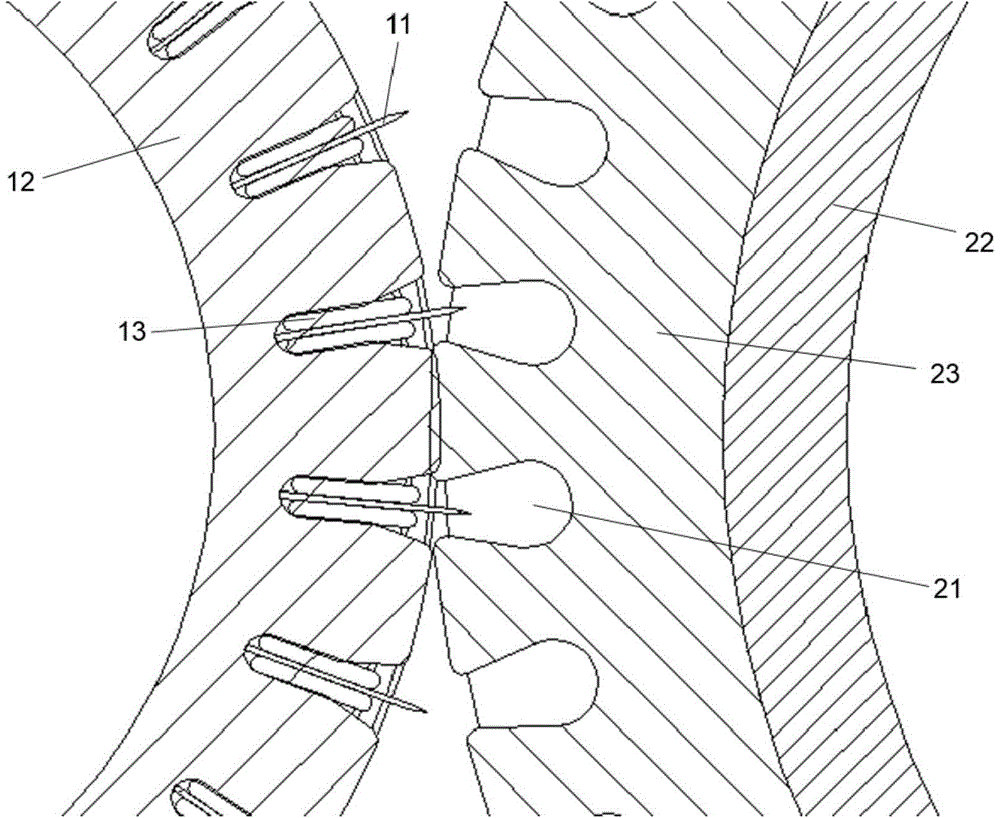

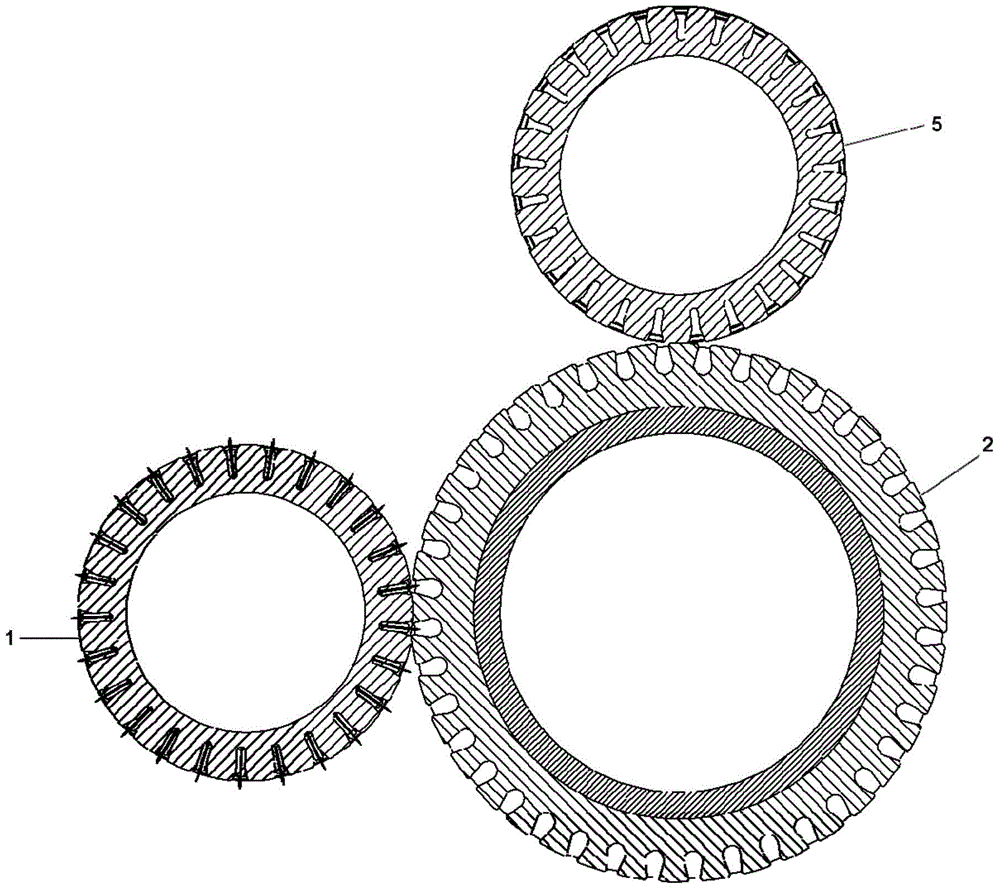

[0022] figure 1 A schematic diagram of the three-dimensional structure of the non-abrasive fiber cutting equipment provided by the embodiment of the present invention is shown; figure 2 show figure 1 A partially enlarged view of part of the structure of the non-abrasive fiber cutting equipment shown; image 3 show figure 1 Positional diagram of parts of the wear-free fiber cutting machine shown. refer to Figure 1 to Figure 3 The non-abrasive fiber cutting equipment provided by the present invention comprises a yarn cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com