Production process of foamed polyolefin wool with high hygroscopicity and air permeability

A technology of polyolefin foam and manufacturing method, which is applied in the field of manufacturing polyolefin foam with water absorption and air permeability, and can solve problems such as poor air permeability, non-connected cells, and limited shrinkage of the foam product range. , to achieve the effect of excellent air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

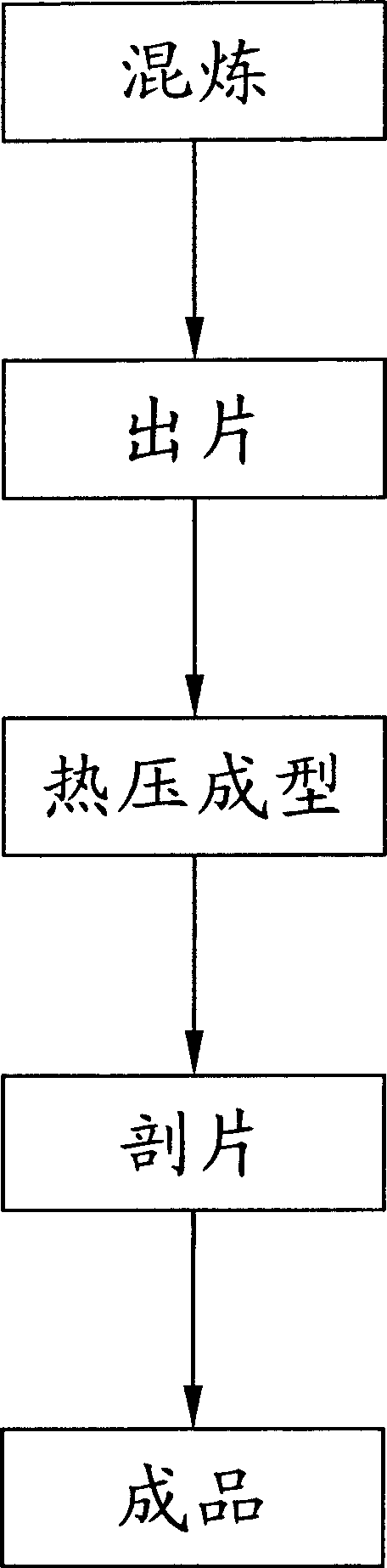

Image

Examples

Embodiment 1

[0012] (1). Mixing: At first, this embodiment uses polyethylene vinyl acetate (EVA) as the main base material, and utilizes balls, wood flour and surfactants as reaction materials, wherein the balls can be Aluminum silicate hollow beads, aluminum silicate solid beads, glass hollow beads or glass solid beads, aluminum silicate hollow beads are used in this embodiment, and then a predetermined proportion of substrate raw materials, reaction raw materials, bridging agent, foaming agent and All other processing aids are poured into a kneader and mixed evenly. The above-mentioned raw material components and weight ratios of the present embodiment are as follows:

[0013] Ethylene vinyl acetate (EVA): 73.1%

[0014] Aluminum silicate hollow beads: 7.3%

[0015] Wood flour: 11%

[0016] Surfactant: 2%

[0017] Bridging agent: 0.4%

[0018] Fine-core foaming agent: 3.2%

[0019] Coarse core foaming agent: 2.2%

[0020] Bridging aids: 0.3%

[0021] Zinc oxide powder: 0.5%

[00...

Embodiment 2

[0028] The base materials used in this embodiment are polyethylene vinyl acetate (EVA) and polyethylene (PE), and the following are the configurations of all raw material components and weight ratios.

[0029] Polyethylene vinyl acetate (EVA): 51.2%

[0030] Polyethylene (PE): 21.9%

[0031] Aluminum silicate hollow beads: 7.3%

[0032] Wood flour: 11%

[0033] Surfactant: 2%

[0034] Bridging agent: 0.4%

[0035] Fine-core foaming agent: 3.2%

[0036] Coarse core foaming agent: 2.2%

[0037] Bridging aids: 0.3%

Embodiment 3

[0040] The base materials used in this embodiment are polyethylene vinyl acetate (EVA) and ethylene-octene copolymer (POE) (or ethylene propylene rubber (IP)). The following are the configurations of all raw material components and weight ratios.

[0041] Polyethylene vinyl acetate (EVA): 58.5%

[0042] Ethylene-octene copolymer (POE): 14.6%

[0043] Aluminum silicate hollow beads: 7.3%

[0044] Wood flour: 11%

[0045] Surfactant: 2%

[0046] Bridging agent: 0.4%

[0047] Fine-core foaming agent: 3.2%

[0048] Coarse core foaming agent: 2.2%

[0049] Bridging aids: 0.3%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com