Continuous brick building block forming system

A block forming machine and continuous technology, applied in the field of continuous brick and block forming systems, can solve the problems of burning bricks and burning coal to pollute the atmospheric environment, different standards for forming bricks, and unobvious integration effects, etc., and achieve reduction The effect of concrete solid waste, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

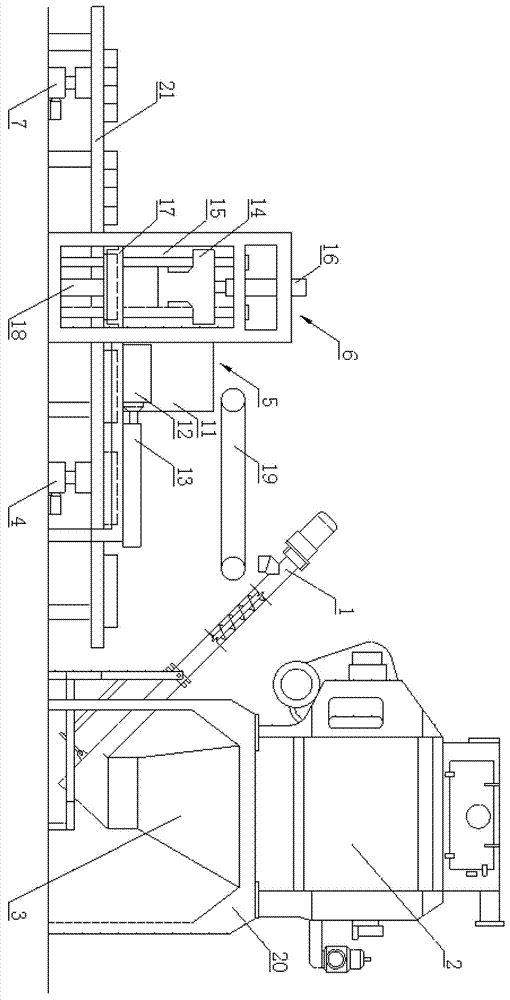

[0021] The continuous brick block forming system of the present invention includes a stirring device consisting of a mixer 2 and a concrete storage hopper 3, a screw hoist 1, an automatic plate feeder 4, an automatic distributing machine 5, a block forming machine 6 and an automatic brick discharger. A brick-making block device composed of machine 7; wherein the stirring device, the screw hoist and the brick-making block device are arranged in sequence, and a concrete storage hopper 3 is sealed and installed under the mixer 2; the feeding end of the screw hoist 1 is sealed and connected The discharge port of the concrete storage hopper 3 is provided with an automatic distributing machine 5 below the discharge end; the automatic board feeding machine 4 is connected and arranged under the automatic feeding machine 5; One side; the automatic brick machine 7 is arranged on the other side of the block forming machine 6 .

[0022] When using the present invention to make bricks and ...

example 2

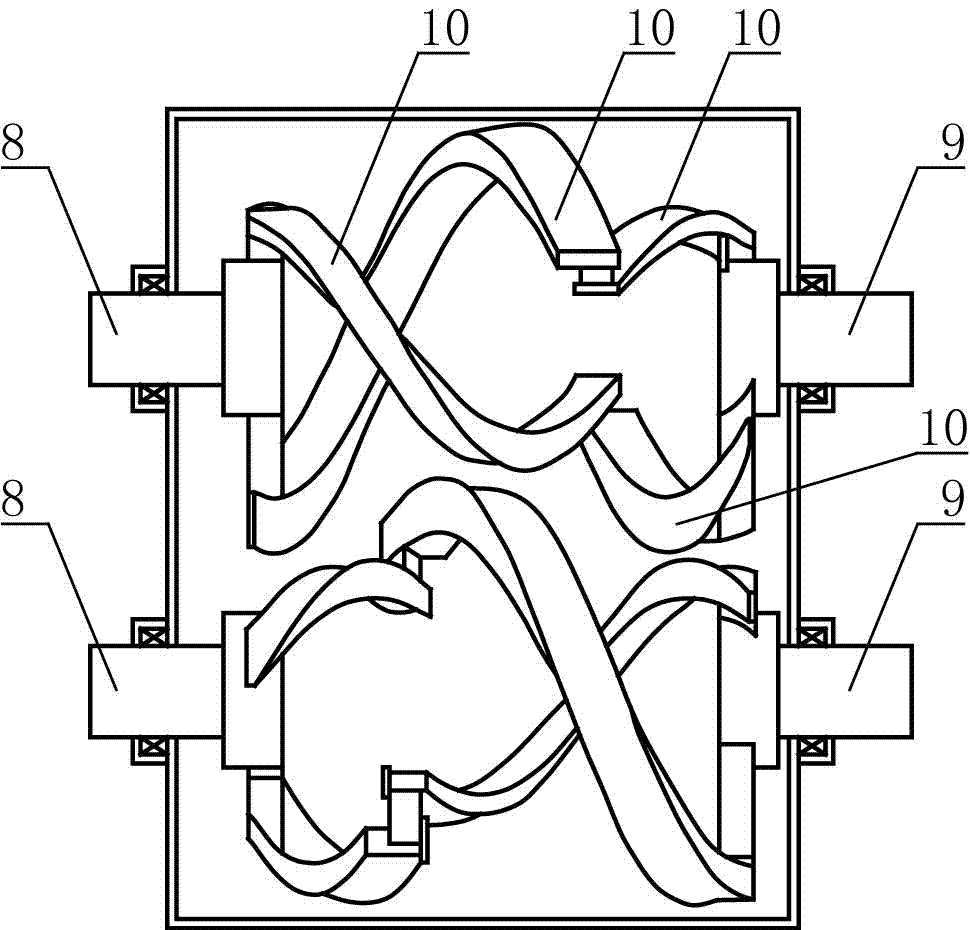

[0024] Continuous brick block forming system of the present invention, such as figure 1 , figure 2 As shown, the mixer 2 is a double-helix concrete mixer with two double-helix mixing systems arranged side by side inside the machine body. The double-helix mixing system is respectively provided with a left shaft head 8, a right shaft head 9 and four helical shafts 10. Two helical shafts 10 form a group, which are respectively spirally connected to form a double helix, and the two ends of the double helix are respectively connected with the left shaft head 8 and the right shaft head 9; Bearing seat connection; using this kind of double helix shaft concrete mixer, because there is no horizontal and horizontal main shaft, there will be no agglomeration on the central shaft of concrete orthopedic bonding and the formation of shaft holding, and the combination of the helical shaft 10 makes the mixing speed Faster, the mixing efficiency of the stirring device is doubled, and the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com