Multifunctional reinforcing steel bar automatic hoop-bending machine bending from two ends of reinforcing steel bar

A multi-functional, hoop bending machine technology, applied in the field of automatic bar hoop bending machines, can solve the problems of inability to quickly bend stirrup products with hooks at both ends, inability to bend steel bars, and high production costs, achieving simple structure and wide production range. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

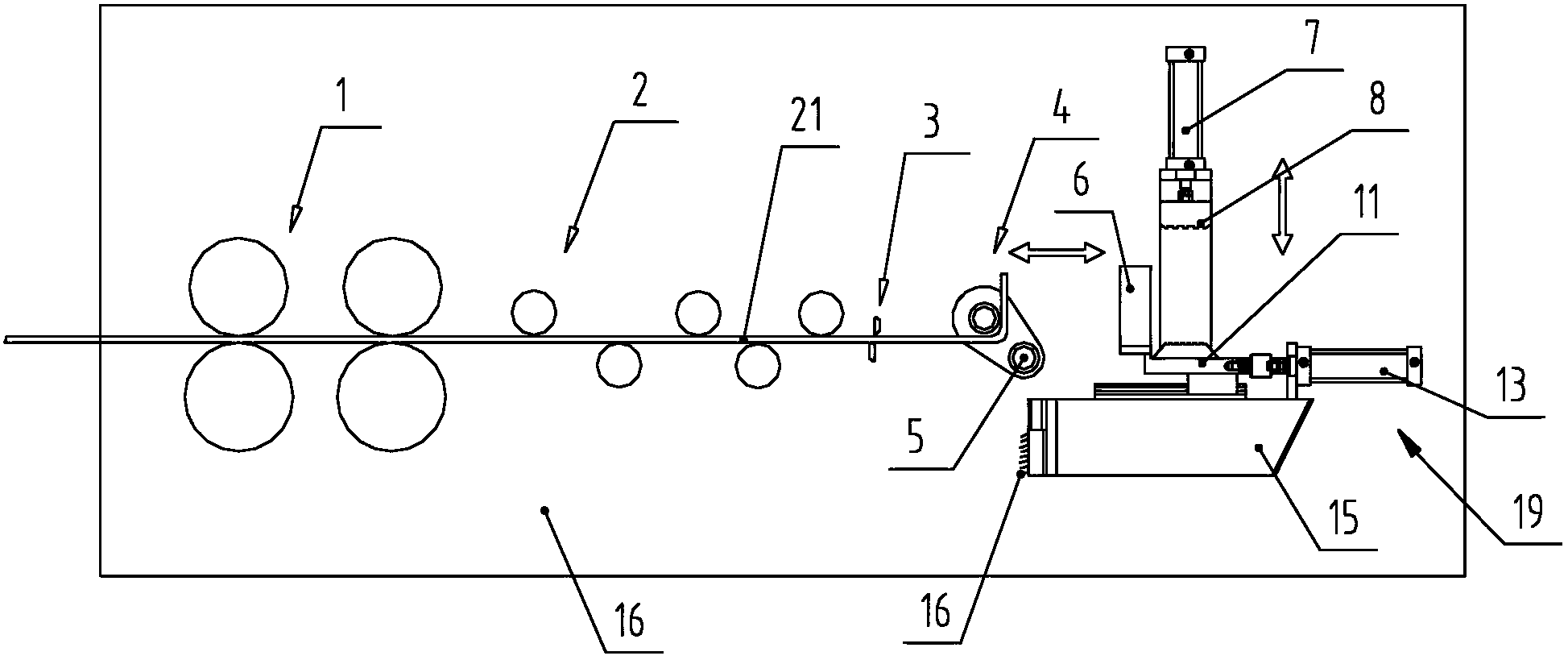

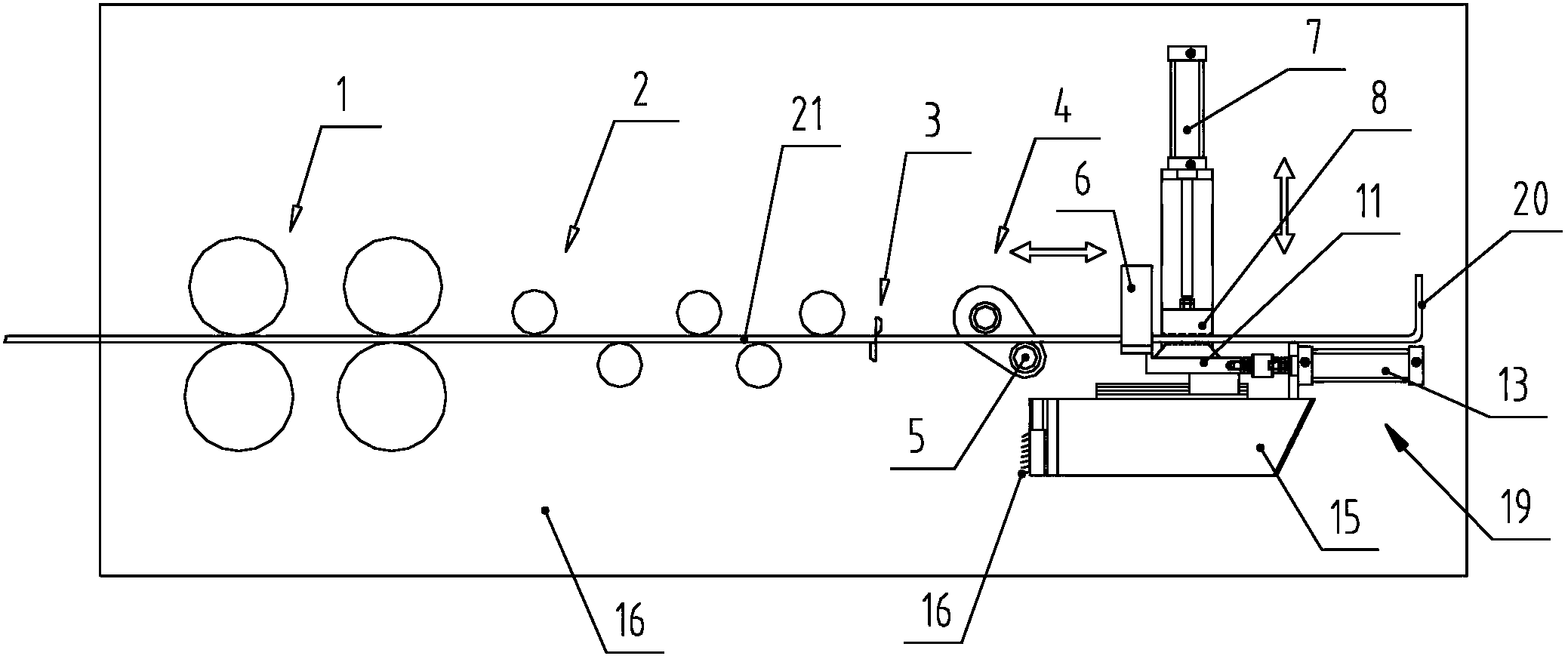

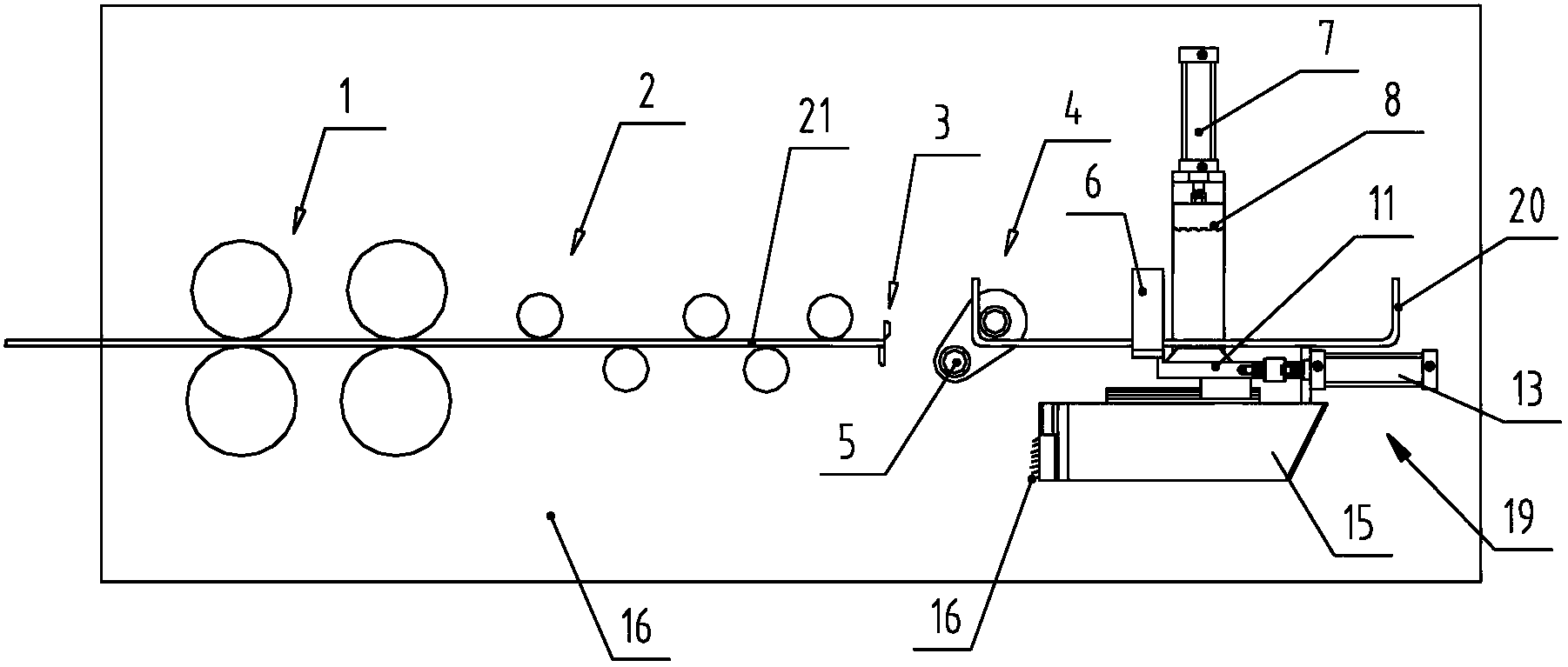

[0021] As shown in the figure, the present invention provides a multifunctional steel bar automatic hoop bending machine that bends from both ends of the steel bar. The multifunctional steel bar automatic hoop bending machine includes: a frame 16; on the frame 16, it moves upstream along the steel bar 21 In the axial direction, there are: a traction mechanism 1, a straightening mechanism 2, a shearing mechanism 3, and a two-way bending mechanism 4.

[0022] The frame 16 upstream of the two-way bending mechanism 4 is also provided with a multifunctional mechanism 19 that makes the steel bar bend from the cut end, and the multifunctional mechanism 19 includes: clamping the steel bar 21 and transferring the cut end of the steel bar The two-way bending mechanism 4 at its downstream position bends the compression transfer mechanism, pushes the bent and formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com