Integrated structure of crude fiber regenerative intelligent barrel-manufacturing machine

A crude fiber, integrated technology, which is applied in the construction field of an integrated crude fiber regeneration intelligent drum making machine, can solve the problems of inability to manufacture and not widely applicable, and achieve the effects of cost saving, strong applicability and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

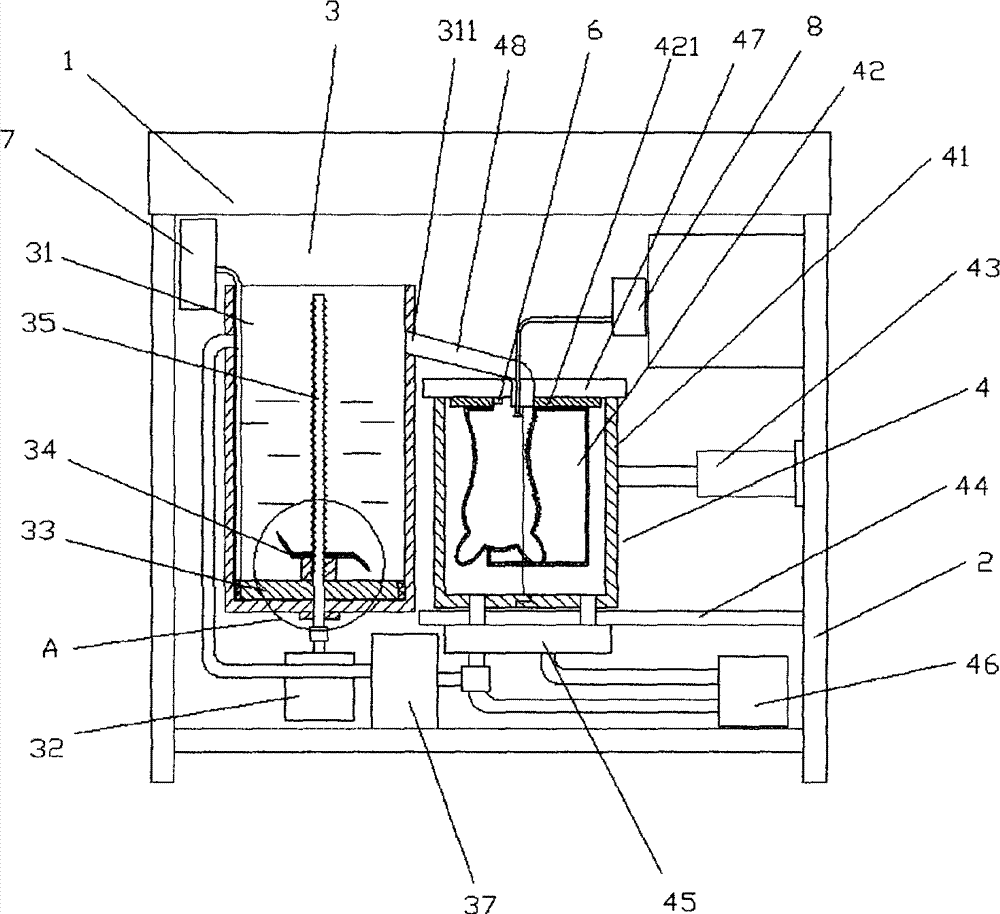

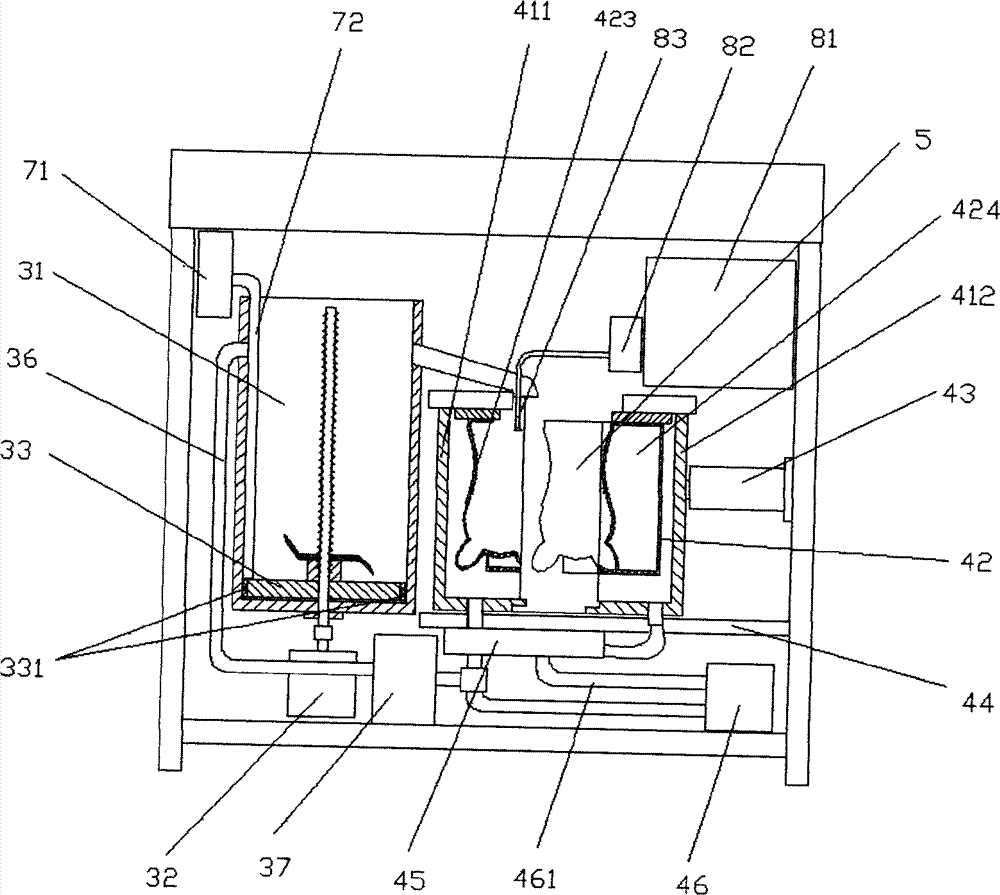

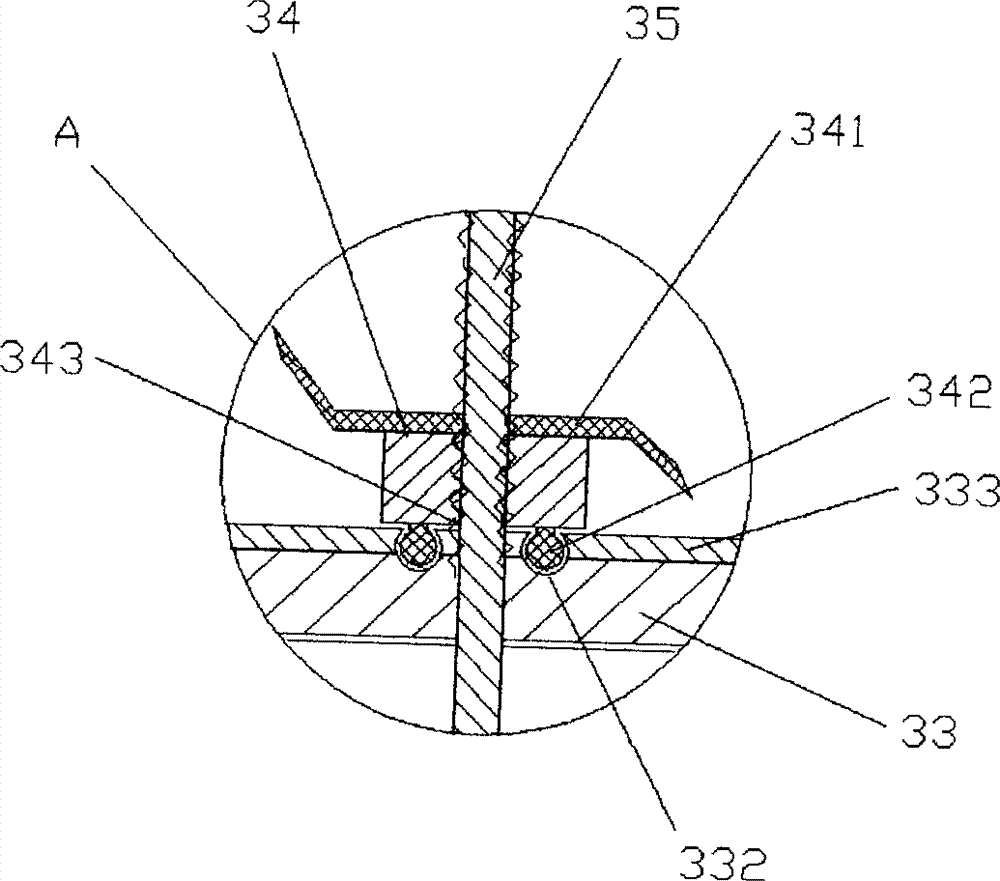

[0022] like Figure 1-5 As shown, the structure of an integrated crude fiber regeneration intelligent barrel making machine includes an upper cover body 1, a lower body 2, a waste beating device 3, a molding mechanism 4, a disinfection device 7 and a plasticizing device 8, and a waste beating device 1. The molding mechanism, the disinfection device and the plasticizing device are located in the lower body, and the upper cover body 1 is provided with an electric control system and an operation switch. In the beating barrel 31 inner cavity of the waste material beating device, there is a lifting disc 33 concentrically connected with the screw hole 343 of the beating cutter 34. The lifting disc is radially attached to the wall of the beating barrel and can move up and down. There is a sealing ring 331 attached to the barrel wall of the beating barrel 31 . The screw rod 35 passes through the beating cutter 34, the lifting disc 33 and the bottom of the beating barrel 31 to be conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com