Crude fiber regeneration equipment for synchronous organization treatment and vacuum adsorption

A technology for tissue processing and regeneration equipment, which is applied in raw material separation, papermaking, paper recycling, etc. It can solve the problems of unmanufacturability and limited application, and achieve the effects of cost saving, strong applicability, and rapid heating and heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

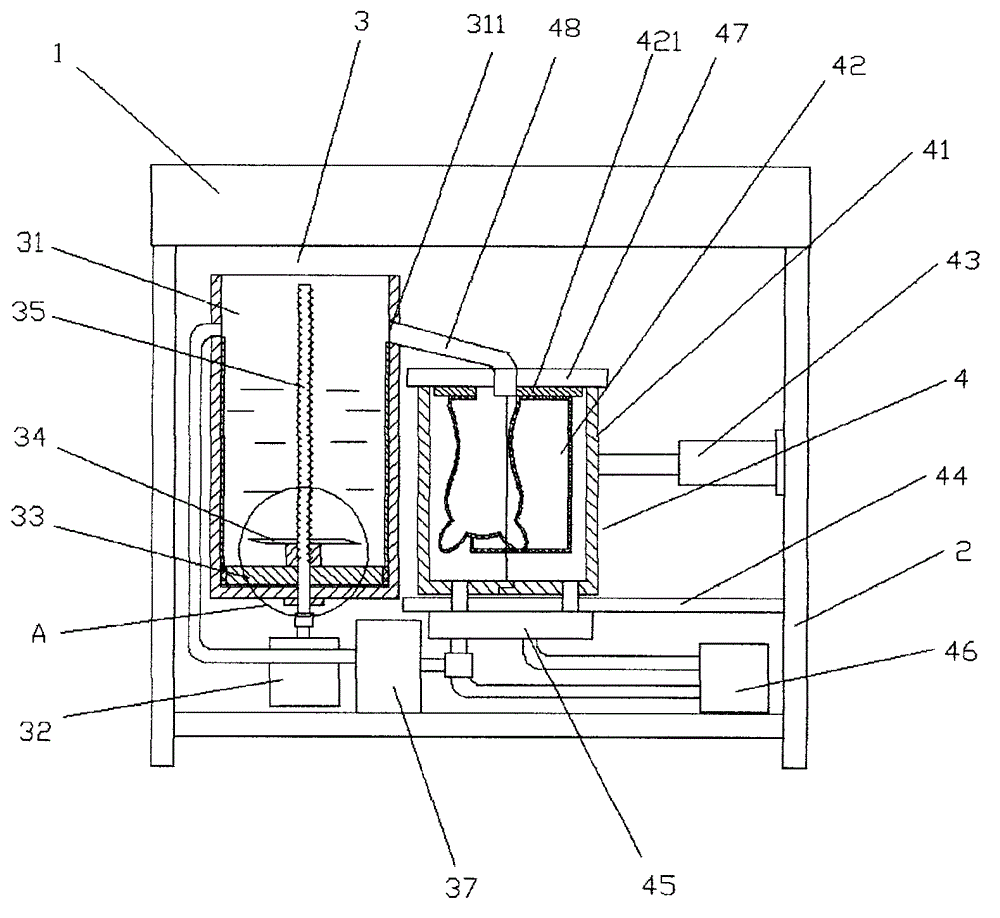

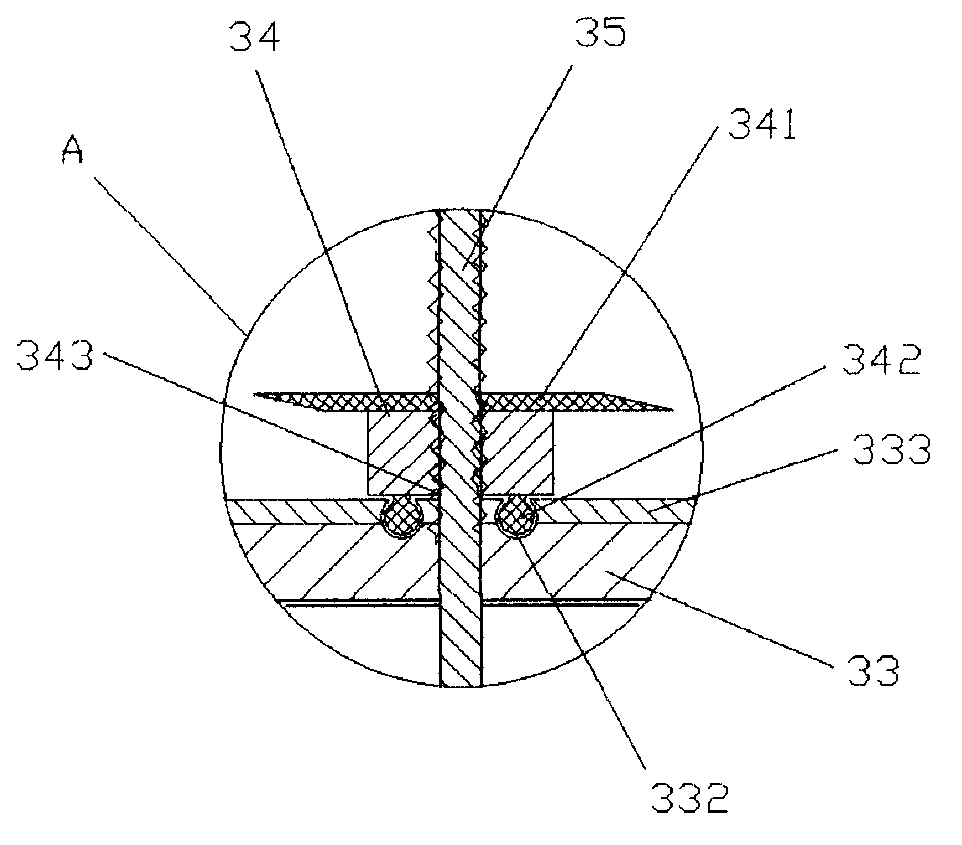

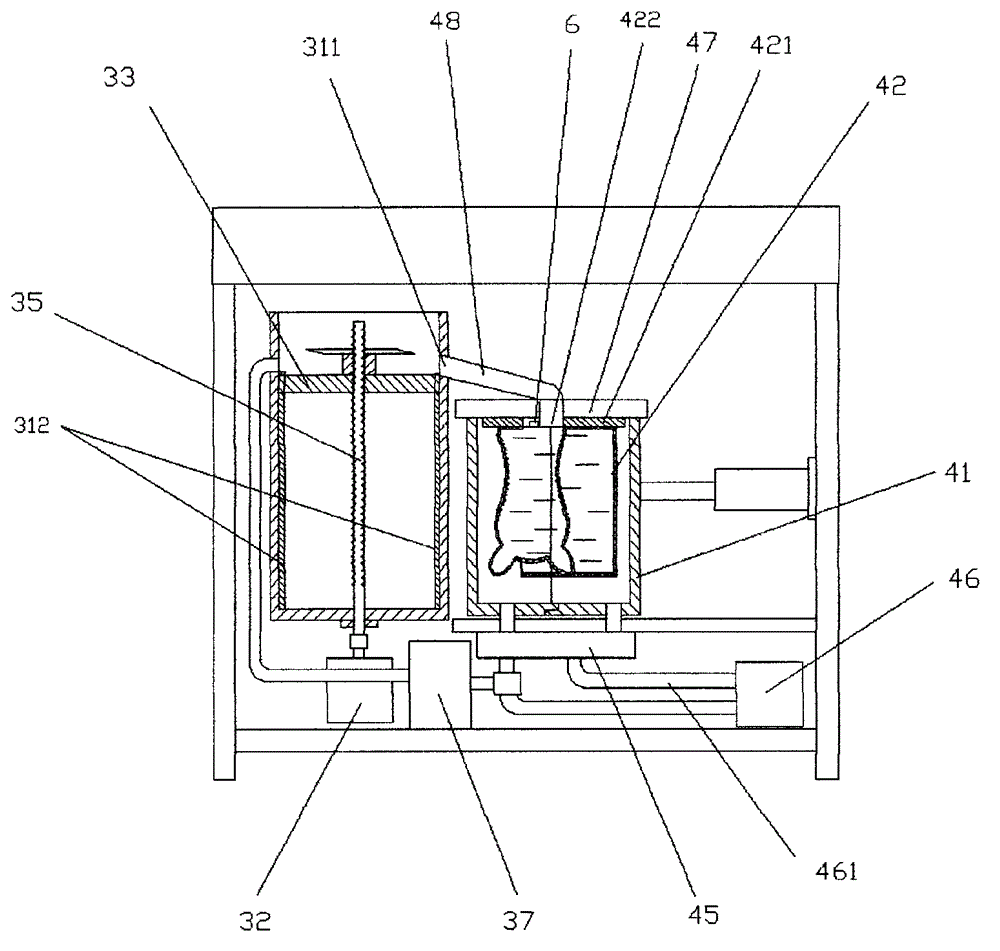

[0023] Such as Figure 1-5 As shown, a crude fiber regeneration device for synchronous tissue processing vacuum adsorption, including an upper cover body 1, a lower body 2, a slurry processing device 3, and a molding device 4, the slurry processing device and the molding device are located at the bottom In the body, the upper cover body 1 is provided with an electric control system and an operation switch. In the inner cavity of the beating barrel 31 of the slurry processing device 3, a lifting plate 33 that is radially attached to the wall of the beating barrel 31 and can move up and down is provided. Symmetrical grooves are arranged on both sides of the outer edge of the lifting plate. Compatible with the guide column 312 on the wall of the beating barrel, the outer periphery of the lifting plate 33 is provided with a sealing ring 331 that is attached to the wall of the beating barrel. The top of the lifting disc 33 is provided with a beating cutter 34 concentric with its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com