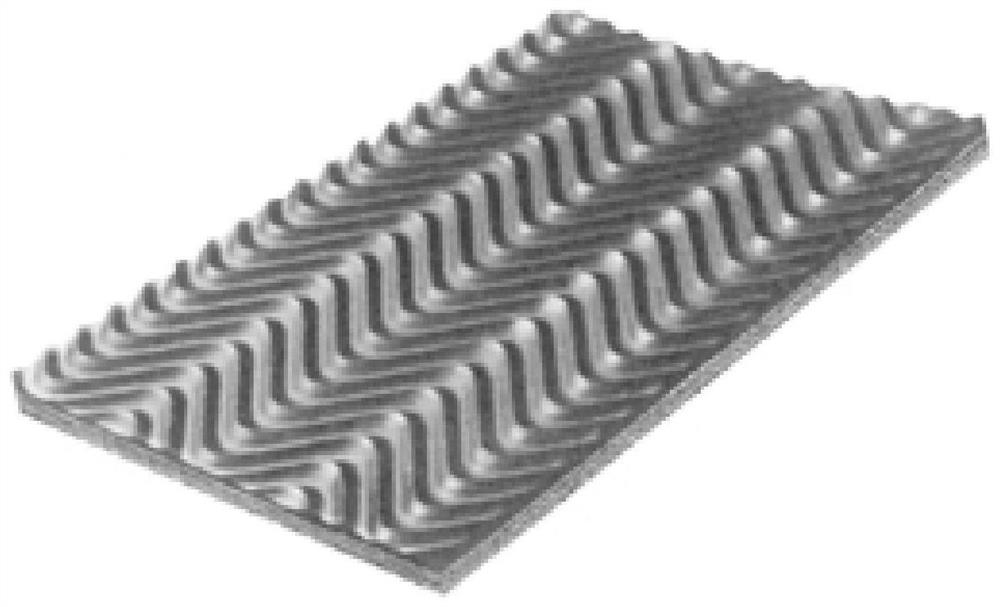

A kind of mold canvas for pressing herringbone pattern on the surface of conveyor belt and its application

A technology of herringbone pattern and conveyor belt, which is applied in textile, textile, papermaking, fabric and other directions, can solve the problems of easy cracking and falling of horizontal bars, affecting the performance of conveyor belt grooves, complicated processing technology of conveyor belt, etc., so as to increase frictional force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

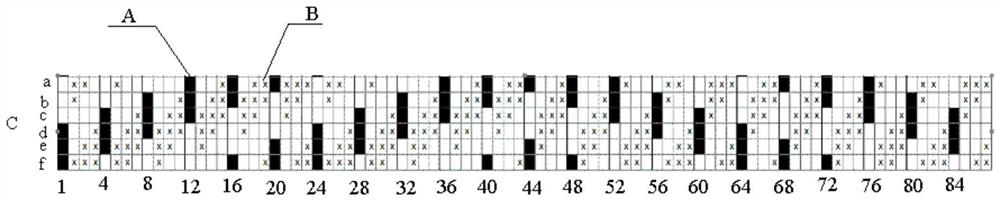

[0032] Such as figure 1 As shown, a mold canvas for pressing the herringbone pattern on the surface of the conveyor belt, the canvas is composed of several cyclic unit structures to form a positive and negative herringbone twill structure, and each unit structure includes several groups of warp and weft structures , formed by interweaving warp yarns and weft yarns; the warp yarns include first warp yarns A and second warp yarns B, and the weft yarns include a structure of weft yarns C; the warp yarns include 88 groups, and the weft yarns include 6 groups.

[0033] The warp yarns are numbered sequentially from left to right, named warp yarn 1 to warp yarn 88, wherein warp yarn 1, warp yarn 5, warp yarn 9, warp yarn 13, warp yarn 17, warp yarn 21, warp yarn 25, warp yarn 29, warp yarn 33, warp yarn 37. Warp yarn 41, warp yarn 45, warp yarn 49, warp yarn 53, warp yarn 57, warp yarn 61, warp yarn 65, warp yarn 69, warp yarn 73, warp yarn 77, warp yarn 81 and warp yarn 88 are the f...

Embodiment 2

[0042] Example 2 A mold canvas with a width of 1000 mm was produced.

[0043] Twisting process:

[0044] The primary twister is the R814 twister from Yichang Textile Machinery, and the double twister is the KV301 heavy-duty twister from Changzhou Kaizhou.

[0045] The warp yarns are of 2 different structures:

[0046] Warp yarn A, as the main warp yarn forming the positive and negative concave-convex effects: first, the single-strand 940dtex nylon 66 industrial yarn is twisted into 180 twists / m, and the twist direction is the primary twisted line of S, and then the above-mentioned 12 strands of nylon 66 industrial yarn, After ply twisting with 120 twists / m, twisting in Z direction, and then plying and double-twisting the above-mentioned 3 twisted yarns, twisting degree 120 twists / m, twisting in S direction, plying into: 940dtex X 12 X 3 twine.

[0047] Warp yarn B, as the matrix for forming the mold canvas, adopts nylon 66 industrial yarn, single-strand 940dtex nylon 66 ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com