Preparation method of halogen-free flame retarding PETG composite fibers

A composite fiber and flame-retardant fiber technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, fiber processing, and chemical characteristics of fibers. , The effect of stable and reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

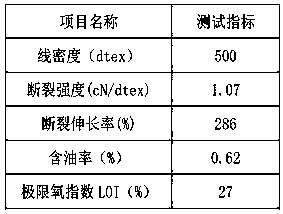

Embodiment 1

[0020] The preparation method of a halogen-free flame-retardant PETG composite fiber described in this embodiment described in this embodiment, the specific steps are as follows:

[0021] (1) Preparation of halogen-free flame retardant masterbatch

[0022] Add PETG polyester chips to the main feeding port of the twin-screw extruder, add the halogen-free flame retardant, compatibilizer, antioxidant, lubricant, and light stabilizer into the spherical high-efficiency dynamic mixer and mix evenly. After being fully mixed and uniform, the material is discharged into the side feeding port of the twin-screw extruder, and melted and extruded by the twin-screw extruder to obtain the halogen-free flame-retardant masterbatch. The viscosity of the halogen-free flame retardant masterbatch is 0.60dl / g. Wherein, the PETG polyester chip mass fraction is 80%; the halogen-free flame retardant is a compound of polyphenylsulfone diphenyl phosphonate oligomer and polydimethylsiloxane with a mass ...

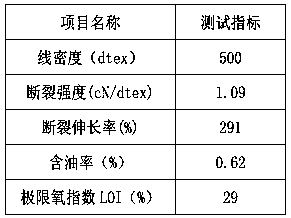

Embodiment 2

[0030] The preparation method of a halogen-free flame-retardant PETG composite fiber described in this example is different from that in Example 1, and the others are the same as in Example 1.

[0031] Preparation of Halogen-free Flame Retardant Spun Fiber with "Y" Shape Cross Section

[0032] Inject the halogen-free flame retardant masterbatch prepared in step (1) into the screw extruder with an online adding device, and at the same time add alkali-free glass fiber from the side feeding port 1 and side feeding port 2 of the twin-screw extruder PETG polyester chips, the three are melted and mixed for extrusion, the melt is metered by a metering pump, sent to the spinneret assembly for filtration, extruded, and cooled by ring blowing or side blowing to obtain primary fibers; wherein, the spinneret hole is "Y "Shaped cross-section, and arranged in a rhombus on the spinneret. Wherein, the mass fraction of the halogen-free flame-retardant masterbatch is 35%; the alkali-free glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com