Light covered yarn with warmth-keeping and cooling functions and preparation method of yarn

A lightweight, yarn technology, applied in the direction of yarn, melt spinning, rayon manufacturing, etc., can solve the problems of rough yarn, feeling stuffy, poor air permeability, etc., and achieve the effect of stable body temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

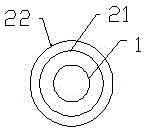

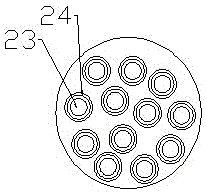

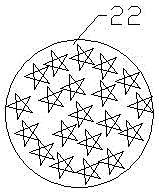

[0027] A lightweight covered yarn with functions of keeping warm and cool, comprising a core wire 1 and a covered wire wrapped in the outer layer of the core wire, the covered wire is provided with two layers, the first layer is a circular hollow cross-section Spandex yarn 21, the second layer is nylon yarn 22 with star-shaped hollow section, and the core thread 1 is spandex yarn.

[0028] Further, the circular hollow section 21 includes a central circular surface 23 and an outer ring 24 fitted on the central circular surface, and the star-shaped hollow section 22 is a five-pointed star structure.

[0029] The preparation method of the lightweight covered yarn with warming and cool functions comprises the following steps:

[0030] (1) Preparation of spandex yarn with circular cross-section: Put the polyurethane into the rod extruder for melt extrusion, the melting temperature is 310°C, pass through the spinning assembly, and then spray it out on the spinneret, Then spray wate...

Embodiment 2

[0041] The preparation method of the lightweight covered yarn with warming and cool functions comprises the following steps:

[0042] (1) Preparation of spandex yarn with circular cross-section: put the polyurethane into the rod extruder for melt extrusion, the melting temperature is 340°C, pass through the spinning assembly, and then spray it out on the spinneret, Then spray water-cooling through the spinning tunnel, the water-cooling temperature is 2°C, and turn into spandex yarn with circular cross-section for later use;

[0043] (2) Preparation of nylon yarn with star-shaped air cross-section: polyhexamethylene adipate is produced by melt spinning, first put polyhexamethylene adipate into a double-rod extruder for melt extrusion out, where the melting temperature is 400°C, and then sprayed out through the spinneret, and then air-cooled through the spinning tunnel to become a star-shaped nylon yarn with an air cross section for use;

[0044] (3) Spandex yarn winding: adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com