Process for producing dry and air-permeable colorful polyester cloth

A production process and fabric technology, applied in the field of fabric production, can solve the problems of increased fabric production cost, no pattern pattern, high printing cost, low production cost, reduced use of auxiliaries, and beautiful and comfortable wearing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A dry and breathable colored polyester fabric production process, comprising the following steps: weaving → greige cloth degreasing → presetting → disperse dyeing → reduction cleaning → finalizing, wherein the disperse dyeing is to add Yutai product to the fabric (disperse orange dye) Elitecolor Orange SFN-4R200% 0.8wt%, Yutai (disperse green dye) ElitecolorGreen SFN200% 2.7wt%, acetic acid 0.5g / L, Advanle CWD high temperature disperse leveling agent 0.3g / L.

[0040] Use Fong's Monforts stenter setting machine (10 boxes) for pre-setting, the machine speed is 26 yards / minute, and the pre-setting temperature is 195°C.

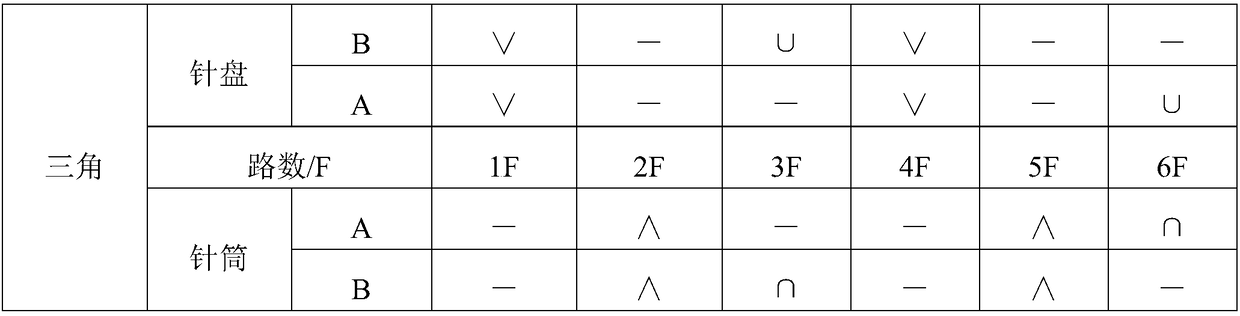

[0041] (1) Selection of embryonic yarn: A.100D / 144F "Tuntelon" brand SD DTY (star rain) polyester (polyester), 30D / 12F "Far East" brand SD FDY polyester (polyester); B.30D "HYOSUNG" " brand spandex. Double-sided fabric with double-sided fabric, using double-sided knitting method, and the corners and corners are arranged in a triangle.

[0042] (2) Cloth ...

Embodiment 2

[0049] A dry and breathable colored polyester fabric production process, comprising the following steps: weaving → greige cloth degreasing → presetting → disperse dyeing → reduction cleaning → finalizing, wherein the disperse dyeing is to add Yutai product to the fabric (disperse orange dye) Elitecolor Orange SFN-4R200% 0.6wt%, Yutai (disperse green dye) ElitecolorGreen SFN200% 2.0wt%, acetic acid 0.2g / L, Advanle CWD high temperature disperse leveling agent 0g / L.

[0050] Use Fong's Monforts stenter setting machine (10 boxes) for presetting, the machine speed is 24 yards / min, and the presetting temperature is 192°C.

[0051] (1) Selection of embryo yarn: A.100D / 144F SD DTY (star rain) polyester (polyester), 30D / 12F SDFDY polyester (polyester); B.30D spandex. Double-sided fabric with double-sided fabric, using double-sided knitting method, and the corners and corners are arranged in a triangle.

[0052] (2) Cloth design and weaving process:

[0053] Use Lida brand loom, kni...

Embodiment 3

[0059] A dry and breathable colored polyester fabric production process, comprising the following steps: weaving → greige cloth degreasing → presetting → disperse dyeing → reduction cleaning → finalizing, wherein the disperse dyeing is to add Yutai product to the fabric (disperse orange dye) Elitecolor Orange SFN-4R200% 1.0wt%, Yutai (disperse green dye) ElitecolorGreen SFN200% 3.0wt%, acetic acid 0.6g / L, Advanle CWD high temperature disperse leveling agent 0g / L.

[0060] Use Fong's Monforts stenter setting machine (10 boxes) for presetting, the machine speed is 26 yards / min, and the presetting temperature is 200°C.

[0061] (1) Selection of embryo yarn: A.100D / 144F SD DTY (star rain) polyester (polyester), 30D / 12F SDFDY polyester (polyester); B.30D spandex. Double-sided fabric with double-sided fabric, using double-sided knitting method, and the corners and corners are arranged in a triangle.

[0062] (2) Cloth design and weaving process:

[0063] Use Lida brand loom, kni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com