Preparation method of flame retardation spandex fibers

A technology of spandex fiber and polyurethane polymer is applied in the field of textile fibers, which can solve the problems affecting the reaction process and physical properties of spandex, and achieve the effects of ensuring uniformity and spinnability, good flame retardant performance and good flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: In DMAC solution, polyether diol and diisocyanate are reacted at a molar ratio of 1: (1.55~2.15) to prepare a prepolymer, and the prepolymer is then reacted with a mixed amine chain extender. A polyurethane polymer solution of desired viscosity is prepared. Then add antioxidants, anti-yellowing agents and other additives to the polyurethane polymer solution, mix well, mature, and spin.

Embodiment 2

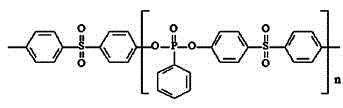

[0025] Example 2: In DMAC solution, polyether diol and diisocyanate are reacted at a molar ratio of 1: (1.55~2.15) to prepare a prepolymer, and the prepolymer is then reacted with a mixed amine chain extender for chain extension. A polyurethane polymer solution of desired viscosity is prepared. Then add the flame retardant and other additives such as antioxidant and anti-yellow agent to the polyurethane polymer solution, mix evenly, mature and spin. Among them, the halogen-free phosphorus-based flame retardant is preferably polyphenylsulfone diphenylphosphonate (PSPPP), and the addition amount of PSPPP is 1% of the total weight of the flame-retardant spandex fiber. PSPPP has the following structure:

[0026]

Embodiment 3

[0027] Embodiment 3: produce spandex fiber by the same method described in embodiment 2, wherein the addition amount of PSPPP is 3% of flame-retardant spandex fiber gross weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com