Photochromic viscose fiber and preparation method thereof

A photochromic and viscose fiber technology, applied in the textile field, can solve the problems of difficulty in meeting fabric manufacturing and use requirements, low strength of fiber materials in dry and wet states, low strength in dry and wet states, etc., and achieve good gloss Effects of color-changing performance, soft and smooth feel, and good eating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

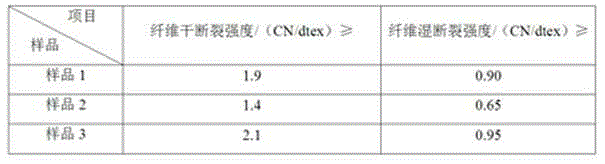

Embodiment 1

[0028] A photochromic viscose fiber, made of viscose, photochromic microcapsules and fiber reinforcement (cellulose acetate), wherein the content of photochromic microcapsules in the fiber is 1wt%, and the average particle size is 1.2μm, the content of fiber reinforcement is 0.1wt%.

[0029] Its preparation method is:

[0030] 1) Dissolve the fiber reinforcing agent in water first, and then mix it with photochromic microcapsules to form a dispersion latex;

[0031] 2) Add the dispersion glue emulsion to the viscose liquid at a uniform speed and mix evenly;

[0032] 3) Acid bath spinning to obtain photochromic viscose fiber products.

Embodiment 2

[0034] A photochromic viscose fiber, made of viscose, photochromic microcapsules and fiber reinforcement (cellulose acetate butyrate), wherein the content of photochromic microcapsules in the fiber is 4wt%, and the average particle diameter is 1.2 μm, and the content of fiber reinforcement is 1 wt%.

[0035] Its preparation method is with embodiment 1.

Embodiment 3

[0037] A photochromic viscose fiber, made of viscose, photochromic microcapsules and fiber reinforcement (methyl cellulose), wherein the content of photochromic microcapsules in the fiber is 6wt%, and the average particle size is 1.2 μm, the content of fiber reinforcement is 4wt%.

[0038] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com