Patents

Literature

61results about How to "Meet the needs of manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

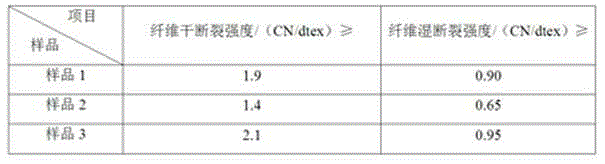

Photochromic viscose fiber and preparation method thereof

ActiveCN104357936AProtect strong baseProtect from strong acidsArtificial filaments from viscoseEmulsionColor changes

The invention relates to a photochromic viscose fiber and a preparation method thereof, belonging to the technical field of textile. The photochromic viscose fiber is prepared from an adhesive, photochromic microcapsules and a fiber reinforced agent, wherein the content of the photochromic microcapsules is 1-20wt%, and the content of the fiber reinforced agent is 0.1-10wt%. The preparation method of the photochromic viscose fiber comprises the following steps: (1) dissolving the photochromic microcapsules and the fiber reinforced agent into water to form dispersed viscose emulsion; (2) feeding the dispersed viscose emulsion into viscose to be spun, and mixing; (3) molding by spinning in an acid bath to obtain a photochromic viscose fiber product. The photochromic viscose fiber is simple and reasonable in components and simple in preparation method; the obtained fiber is uniform in whole color change; the strength of the photochromic viscose fiber reaches or exceeds that of the conventional viscose fiber, so that the demand of fabric manufacture can be met.

Owner:XINXIANG CHEM FIBER

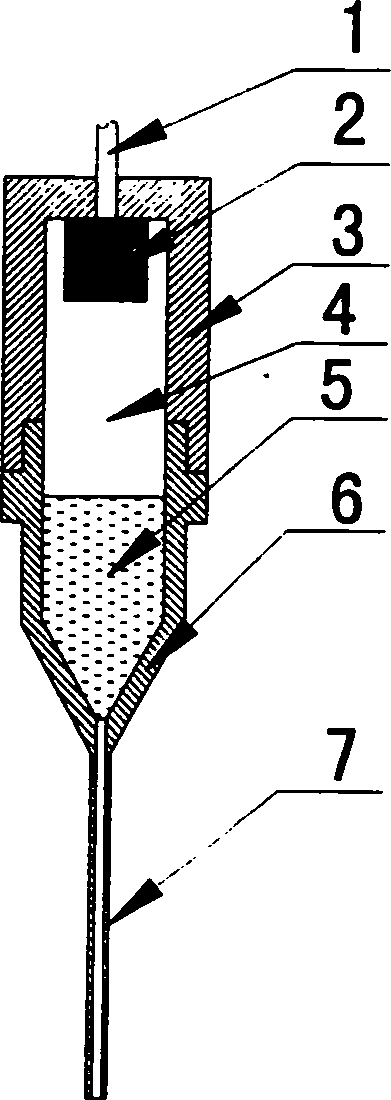

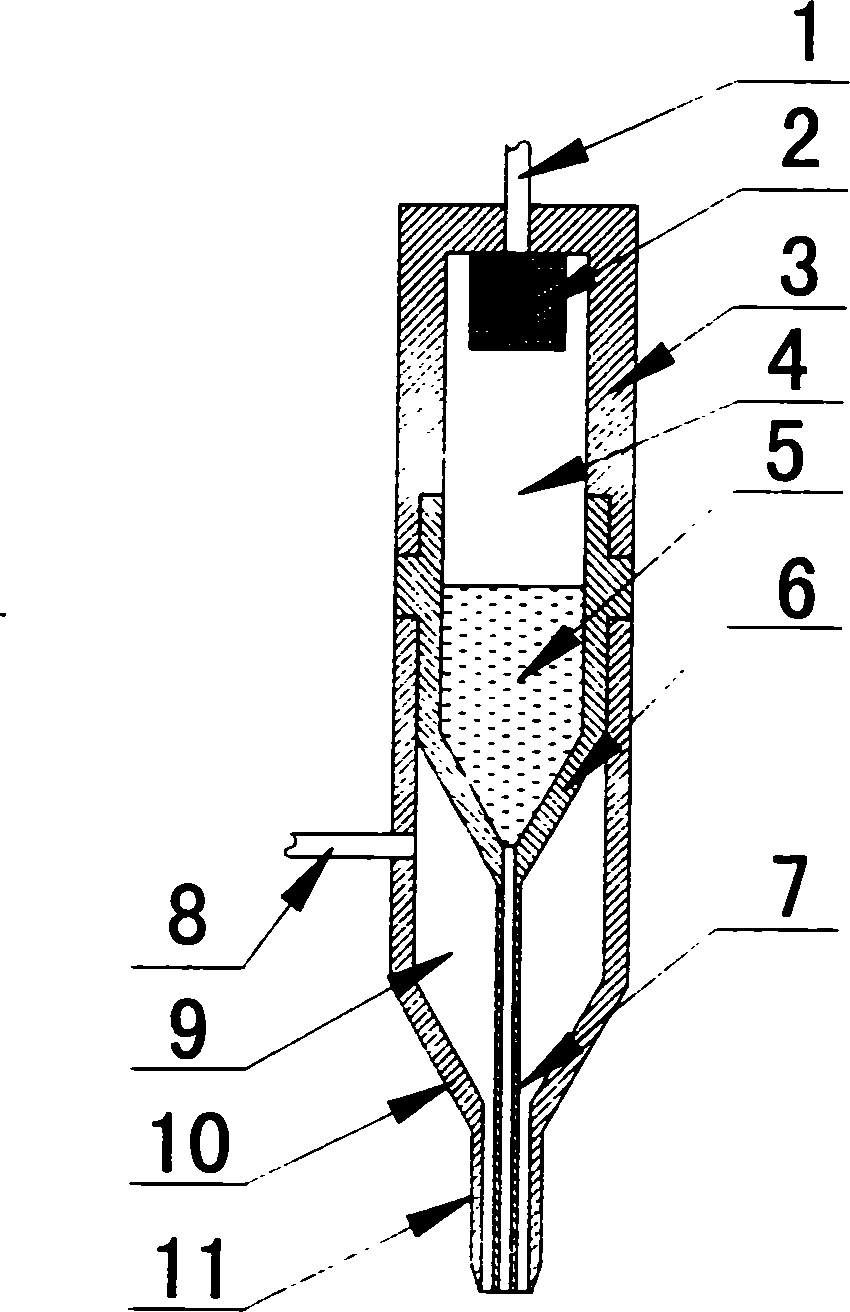

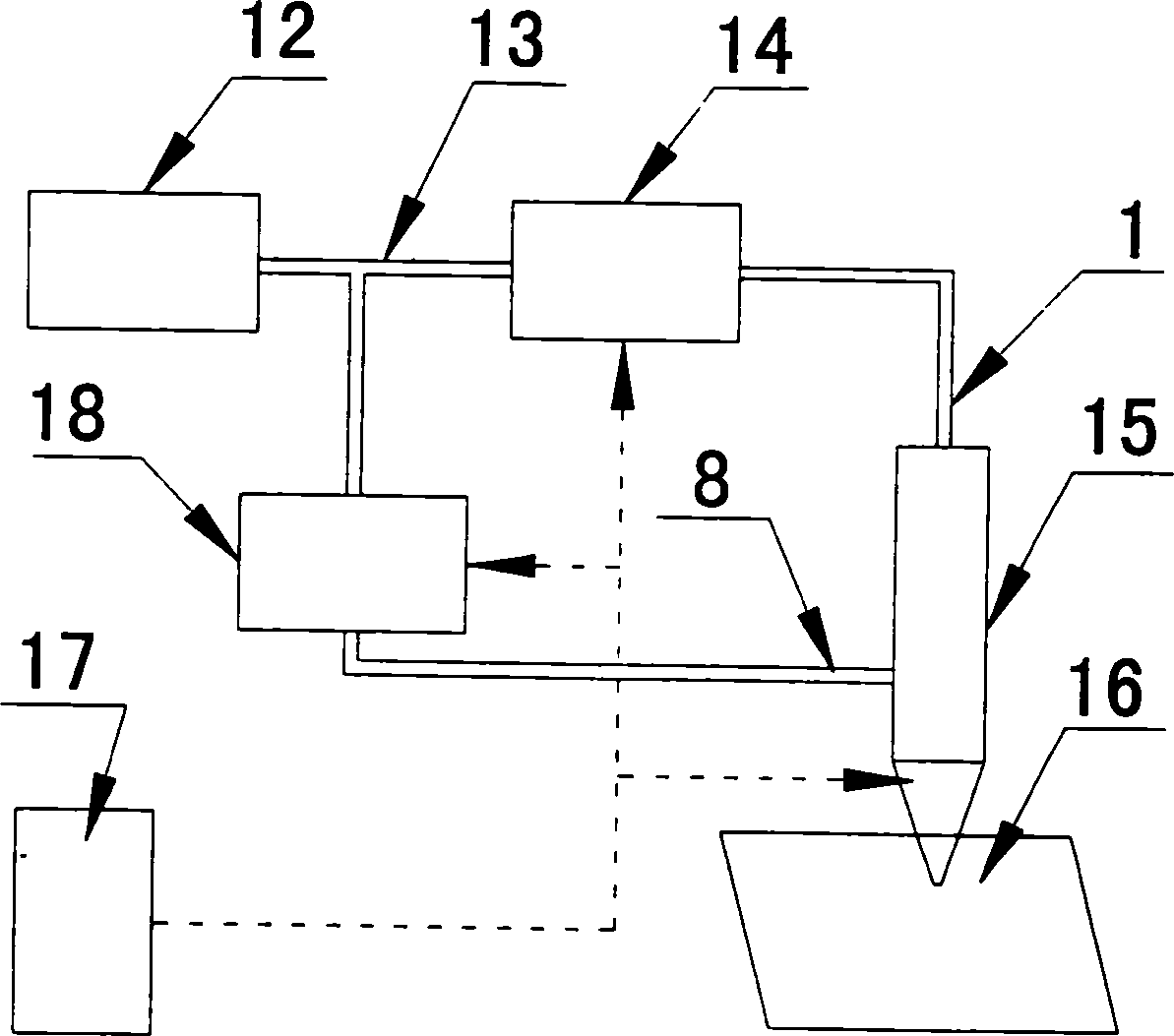

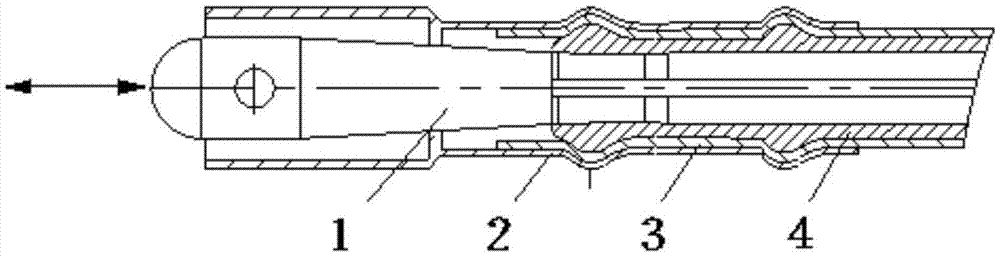

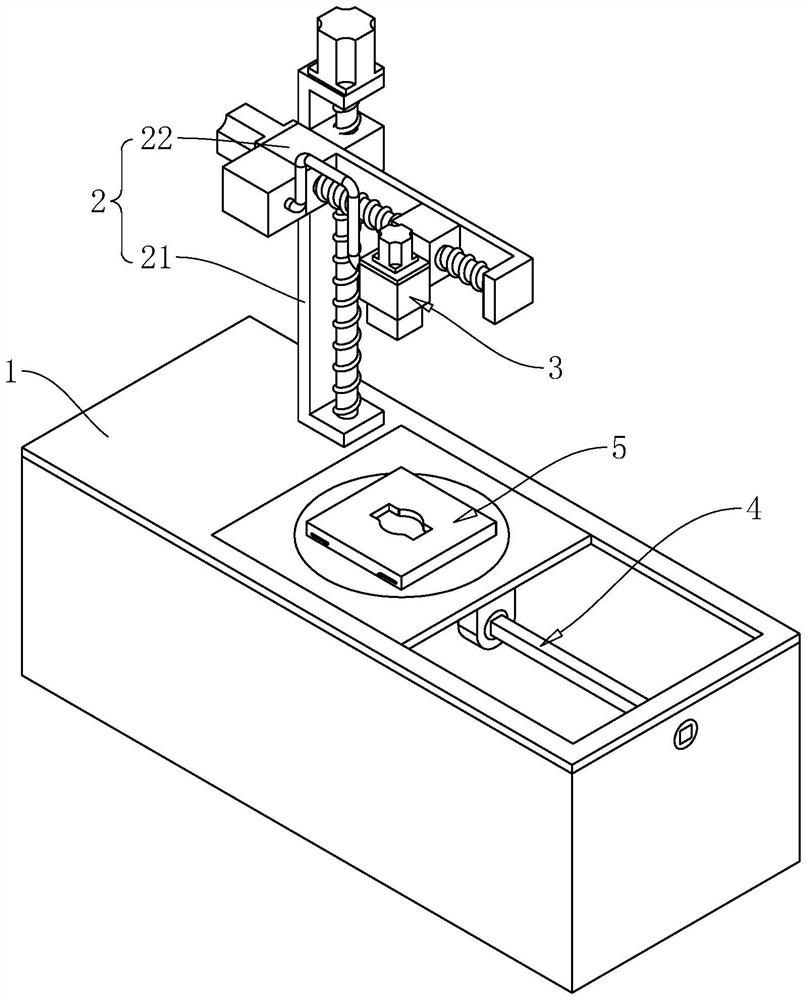

Micro-thin pen for direct writing electronical photoelectronic component and its constituting device

ActiveCN1889231AOvercome the disadvantages of complex structure, high cost, poor applicability, etc.Simple structureSemiconductor/solid-state device manufacturingWire widthPolymer optical waveguide

The invention discloses a mini pen of direct-writing electronic / photoelectronic component and its structure. The decompression device is located in the cap of the pen and connected with the pressing pipe on the top of the cap. The lower end of the cap is connected airtightly and movably with the upper end of the brush stand to form the bunker used to deposit the material that needs to deposit. The lower end of the brush stand is penpoint. The mini pen links with the air supply by two shunt-wound press controlling devices. The controller controls two gas paths and the relative movement of the mini pen to the base to form the direct-writing device. The mini pen can be used to create the electronic component and the photoelectronic component, for example, the polymer filter waveguide. Depending on the structure and polymer character of the mini pen, the polymer material can be put into the mini pen and direct write the filter waveguide. The wiring speed is rapid; the span of the wire width is large; the cost of producing and operating is low. The wiring speed is between 2 and 15mm / s and the wire width is between 0.06 and 2mm.

Owner:WUHAN XINRUIDA LASER ENG

Ultralimit magnesium alloy and preparation method thereof

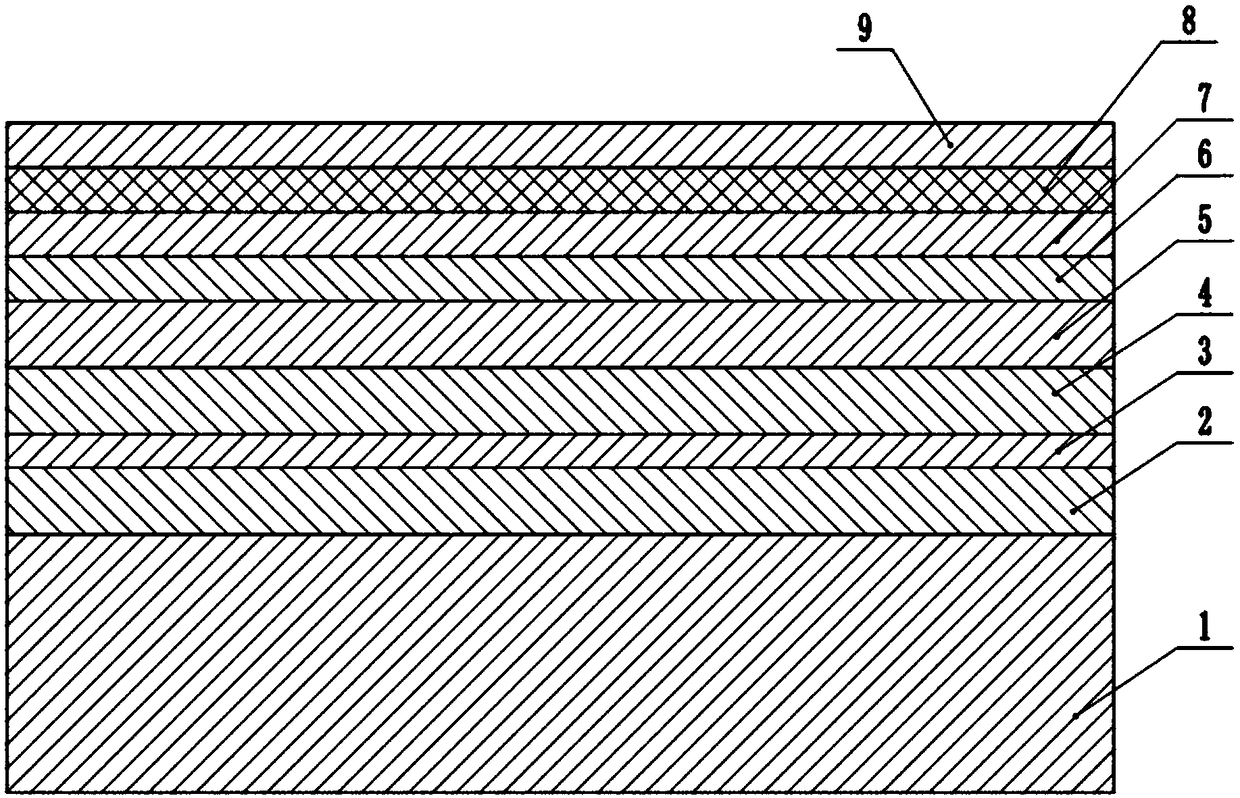

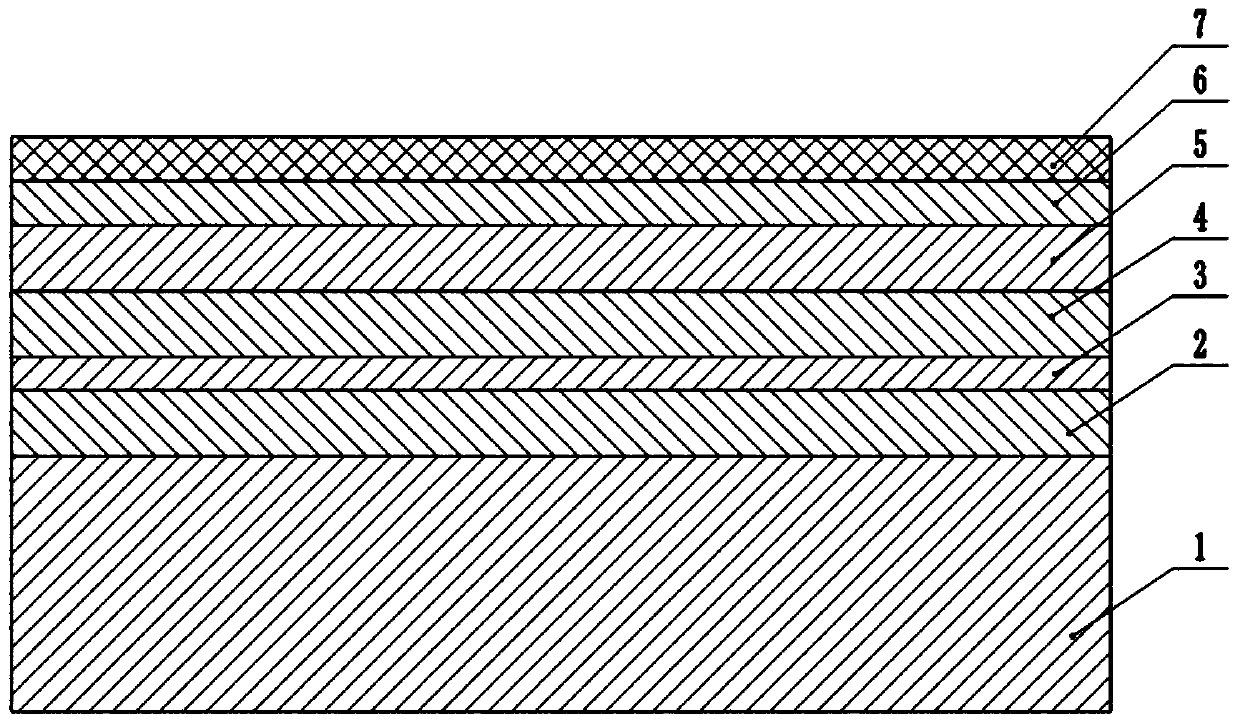

ActiveCN109609952AIncrease temperatureMeet the needs of manufacturingLiquid surface applicatorsMolten spray coatingCarbon layerComposite ceramic

The invention belongs to the technical field of magnesium alloy metal materials, and discloses an ultralimit magnesium alloy and a preparation method thereof. The ultralimit magnesium alloy comprisesa magnesium alloy matrix, and an anti-oxidation composite bonding layer, a composite ceramic layer, a reflective layer, an anti-refraction layer, an insulating layer and a foamed carbon layer are sequentially deposited to the surface of the magnesium alloy matrix; the anti-oxidation composite bonding layer comprises a bonding layer deposited on the surface of the magnesium alloy matrix and a precious metal layer deposited on the surface of the bonding layer; and the composite ceramic layer comprises a ceramic layer A and a ceramic layer B. During preparation, the anti-oxidation composite bonding layer, the composite ceramic layer, the reflective layer, the anti-refraction layer, the insulating layer and the foamed carbon layer are sequentially deposited on the surface of the magnesium alloy to form the ultralimit magnesium alloy. The use temperature of the ultralimit magnesium alloy is increased to be higher than the melting point of the original magnesium alloy by 100 DEG C to 500 DEGC, and the ultralimit magnesium alloy can be used at the ultralimit temperature.

Owner:KUNMING UNIV OF SCI & TECH

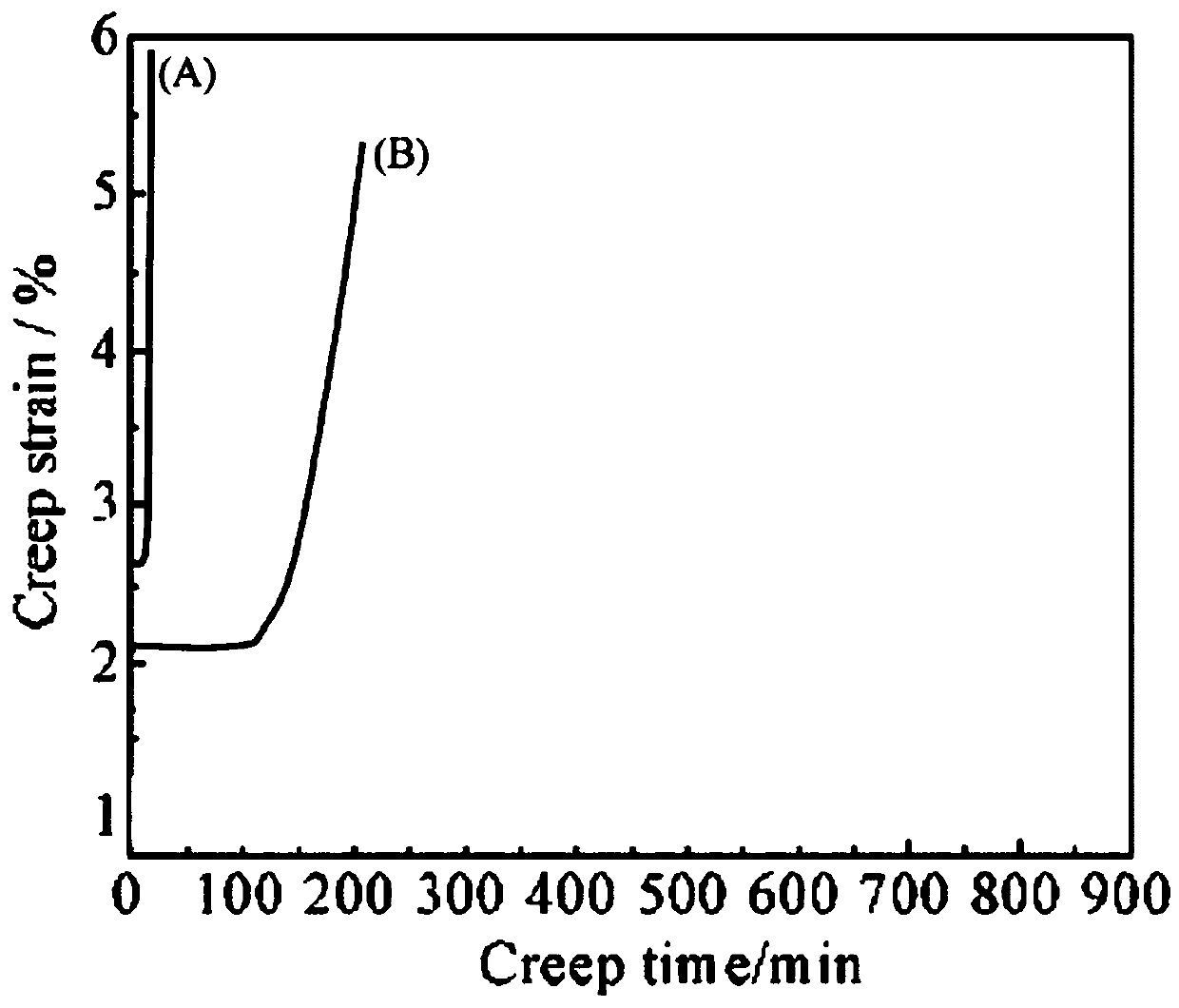

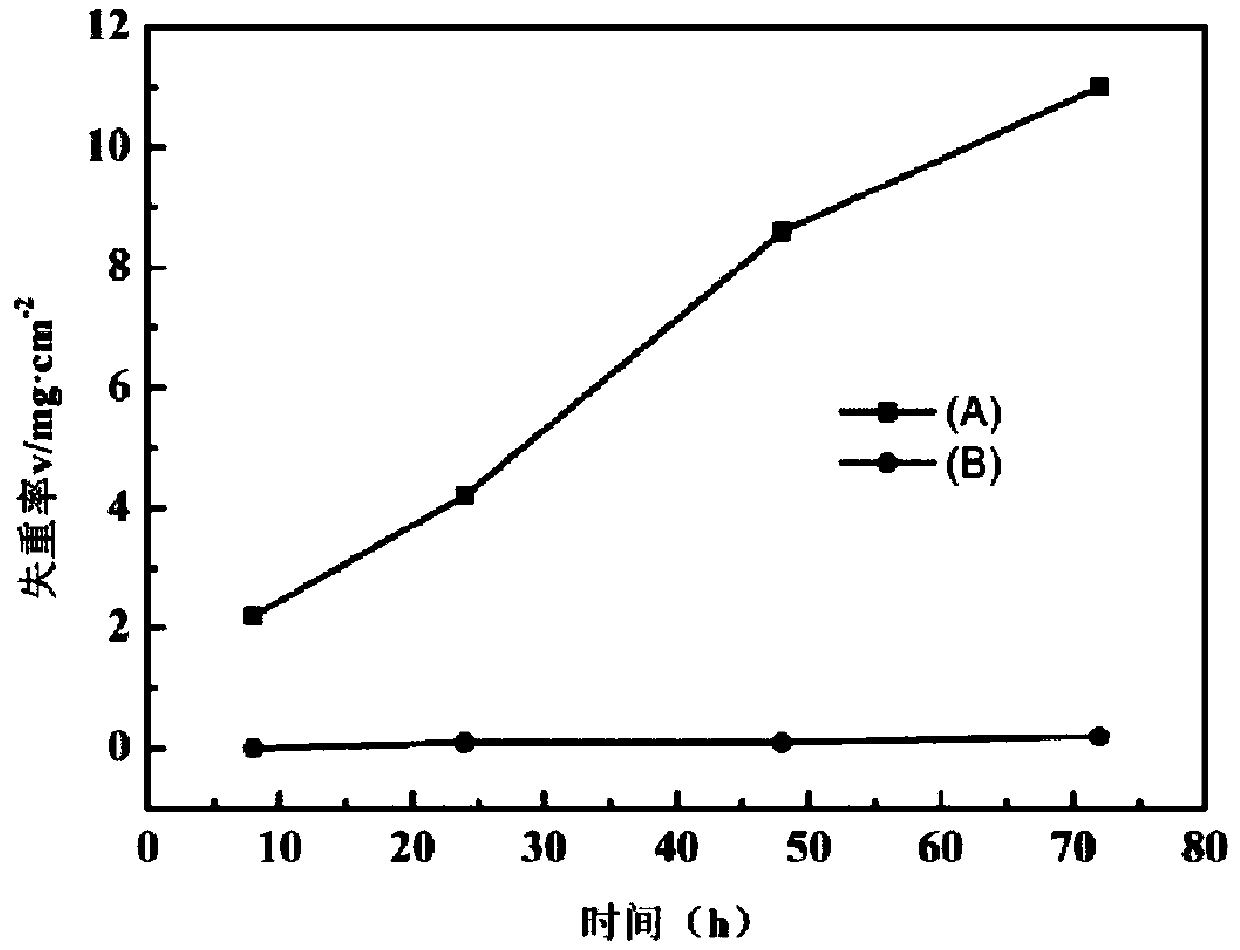

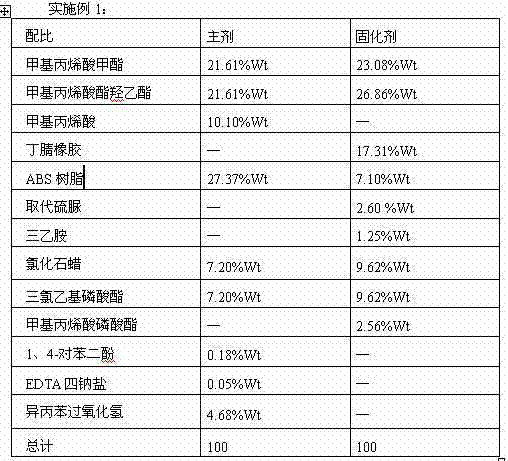

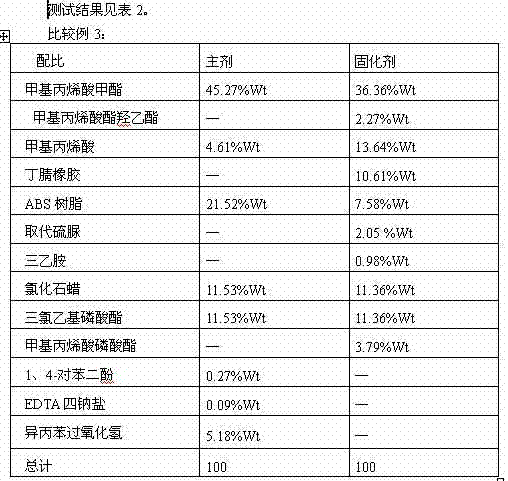

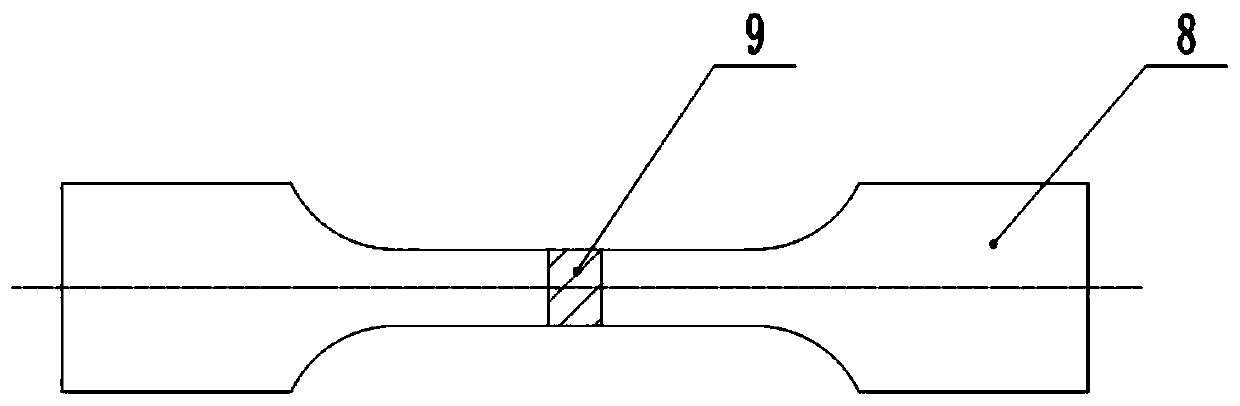

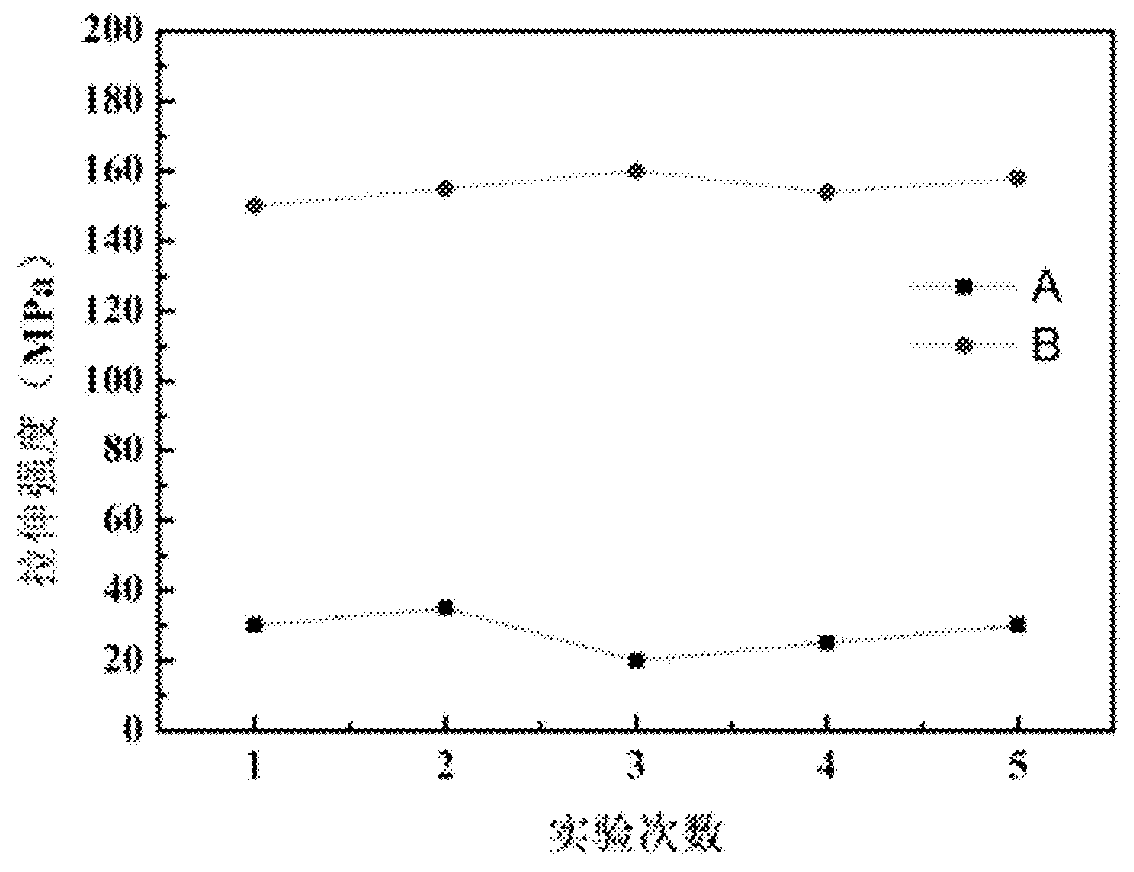

Acrylate adhesive for spot welding process

ActiveCN102533131AImprove flame retardancyNot easy to catch fireOrganic non-macromolecular adhesiveFire retardantAdhesive

The invention relates to an acrylate adhesive for a spot welding process and belongs to the technical field of a double-component acrylate structural adhesive, and is mainly used for solving the problems that the existing acrylate adhesive is extremely easy to ignite and burn when in spot welding. The acrylate adhesive is characterized by mainly comprising a main agent component and a solidifyingagent component, wherein (1) the main agent component comprises the following raw materials by weight percent: 42%-85% of acrylate monomer containing at least one vinyl group, 0%-12% of methacrylic acid, 0%-30% of elastomer, 0.01%-1% of stabilizing agent, 0%-30% of toughening resin, 0%-20% of fire retardant and 0.5%-8% of peroxide; (2) the solidifying agent component comprises the following raw materials by weight percent: 40%-90% of acrylate monomer containing at least one vinyl group, 0%-23% of elastomer, 0%-20% of methacrylic acid, 1%-10% of accelerating agent, 0%-30% of toughening resin and 0%-20% of fire retardant; and (3) at least one component in the main agent and the solidifying agent contains 10%-30% of elastomer. The acrylate adhesive disclosed by the invention has the characteristic that the adhesive can be used for the spot welding process and can be widely applied to the fields of machinery manufacturing and maintenance.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

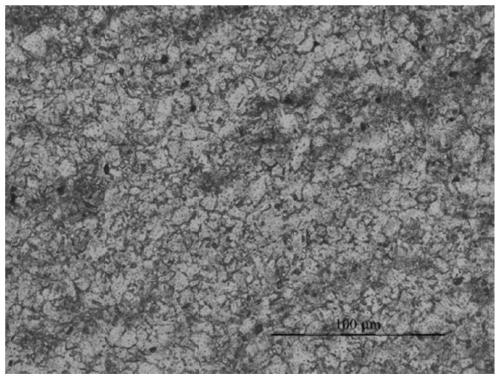

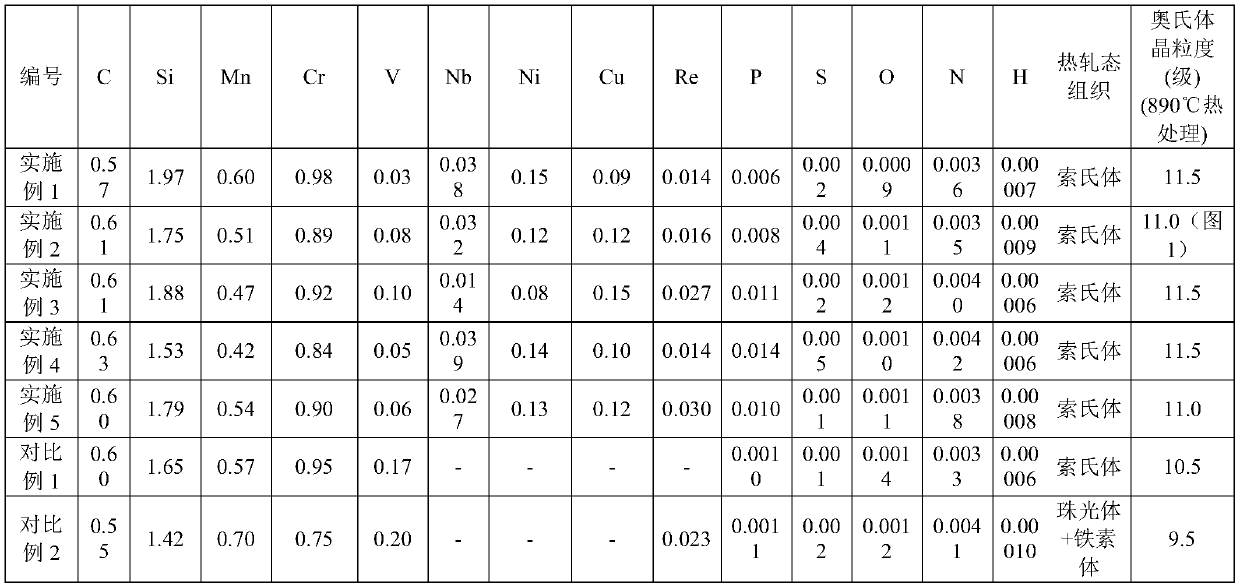

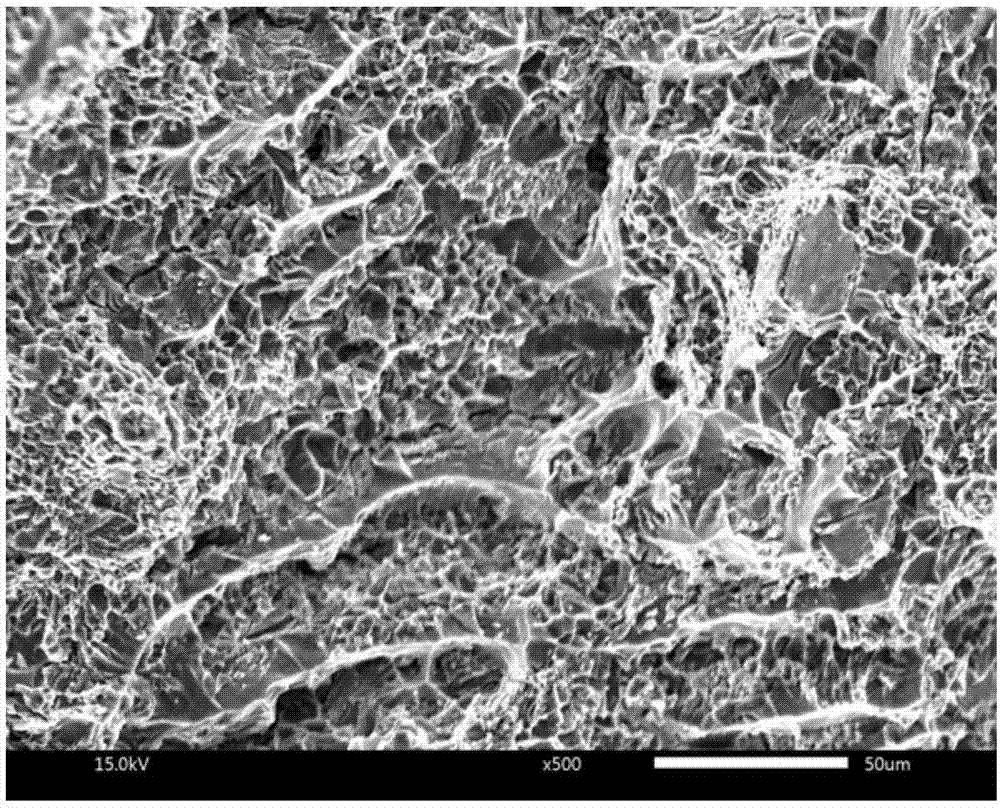

Corrosion resistant spring steel with tensile strength of more than or equal to 2100 MPa and production method thereof

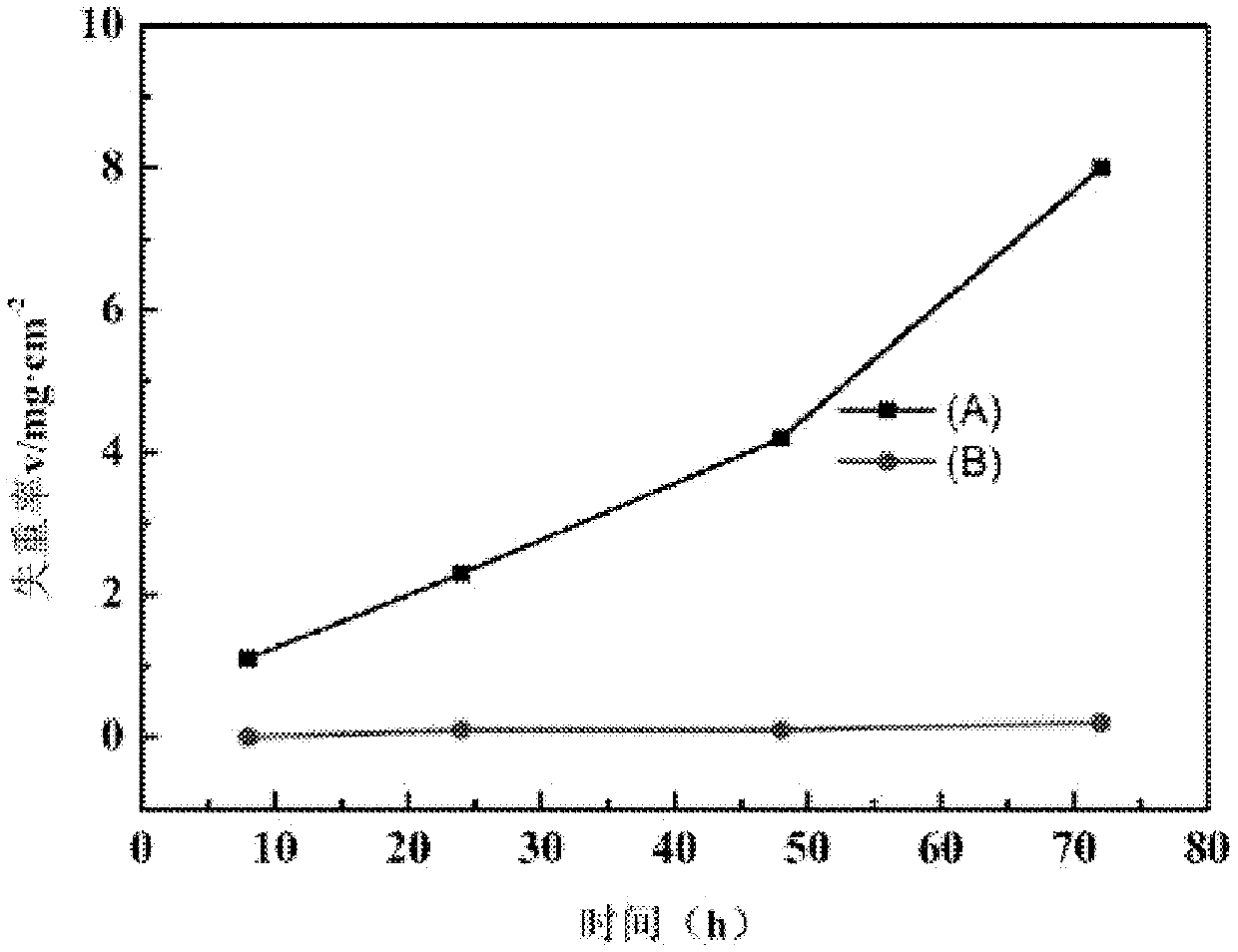

InactiveCN109881101AMeet the needs of manufacturingImprove corrosion resistanceLow internal friction springsWire rodChemical composition

The invention belongs to the field of spring steel and production methods thereof, and particularly relates to corrosion resistant spring steel with tensile strength of more than or equal to 2100 MPaand a production method thereof. The corrosion resistant spring steel comprises the following chemical components of, in percentage by weight, 0.57-0.63% of C, 1.50-2.00% of Si, 0.40-0.60% of Mn, 0.80-1.00% of Cr, 0.02-0.10% of V, 0.015-0.04% of Nb, 0.05-0.15% of Ni, 0.05-0.15% of Cu, 0.01-0.03% of Re, less than or equal to 0.015% of P trace, less than or equal to 0.015% of S trace, less than or equal to 0.0015% of O, less than or equal to 0.006% of N, less than or equal to 0.00015% of [H], and balance Fe and other inevitable impurities. The production method comprises the following steps of smelting, refining, vacuum degassing, continuous casting and wire rod rolling; and after the heat treatment, the tensile strength is 2100-2200 MPa, the grain size of the steel is larger than or equal to 10 grade, the elongation after fracture is larger than or equal to 12%, the cross-section shrinkage is larger than or equal to 42%, the fatigue resistance is larger than or equal to 850 MPa, and thecorrosion resistance is good.

Owner:MAANSHAN IRON & STEEL CO LTD

Martensitic stainless steel and manufacturing method thereof

InactiveCN101845594AGood processing performanceGood corrosion resistanceHeat treatment process controlMartensitic stainless steelAustenitic stainless steel

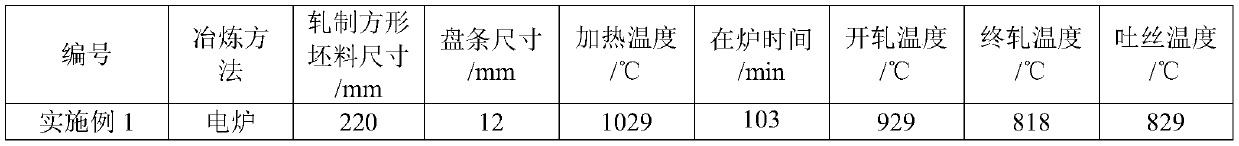

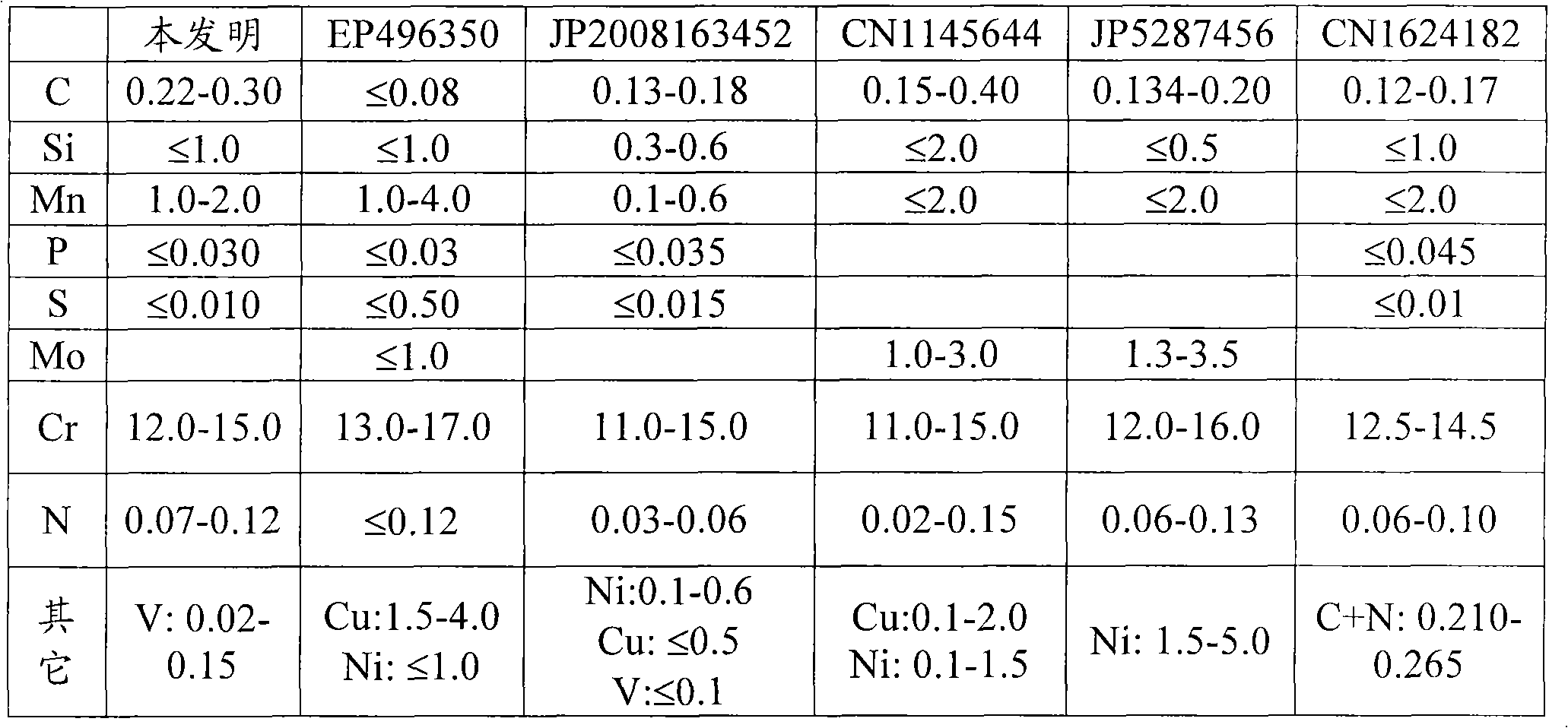

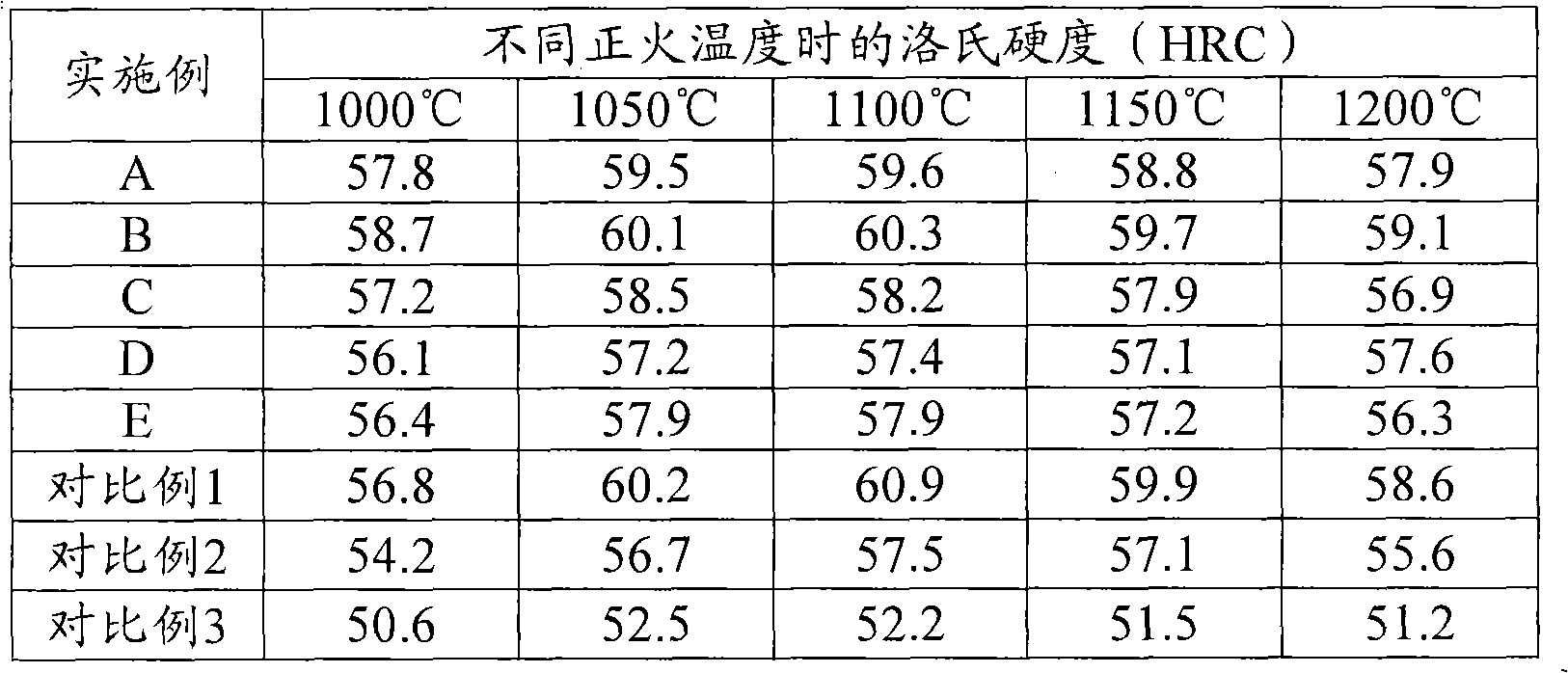

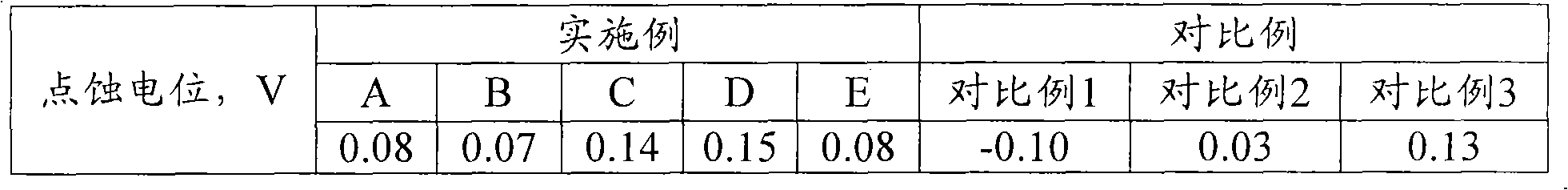

The invention discloses martensitic stainless steel, which has the characteristics of high hardness, high corrosion resistance, excellent processing performance and low production cost and comprises the following components in percentage by mass: 0.22 to 0.30 percent of C, less than 1.0 percent of Si, 1.0 to 2.0 percent of Mn, less than 0.030 percent of P, less than 0.010 percent of S, 12.0 to 15.0 percent of Cr, 0.070 to 0.120 percent of N, 0.02 to 0.15 percent of V, the balance of Fe and inevitable impurities. The invention also discloses a method for manufacturing the martensitic stainless steel. The method does not add any production process, is easy to control and comprises the following steps of: (1) heating billet steel or continuous casting billet at the temperature of between 1,100 and 1,250 DEG C; (2) finishing final rolling at the temperature of over 900 DEG C; (3) annealing at the temperature of between 800 and 900 DEG C; and (4) performing normalizing treatment at the temperature of between 1,000 and 1,200 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

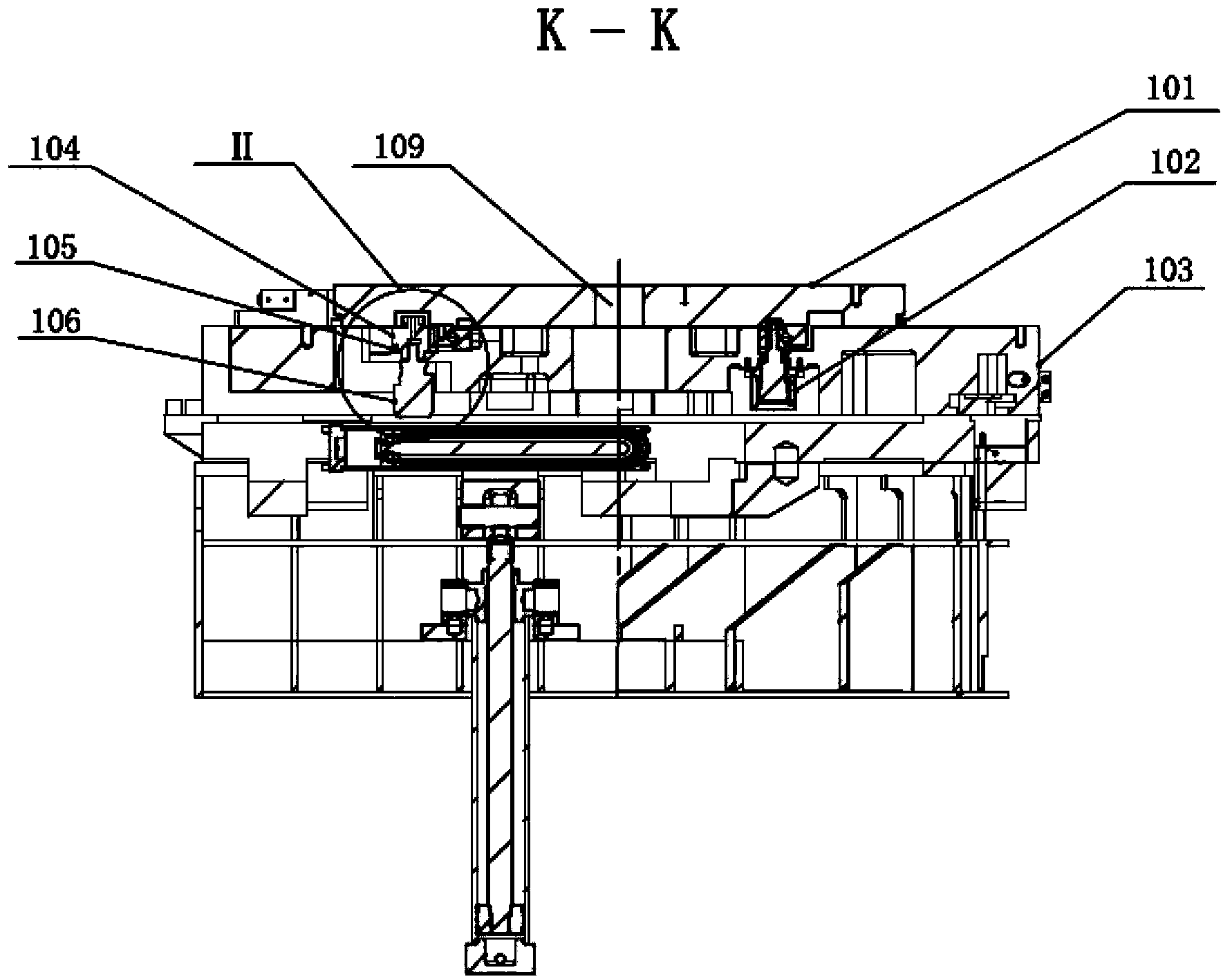

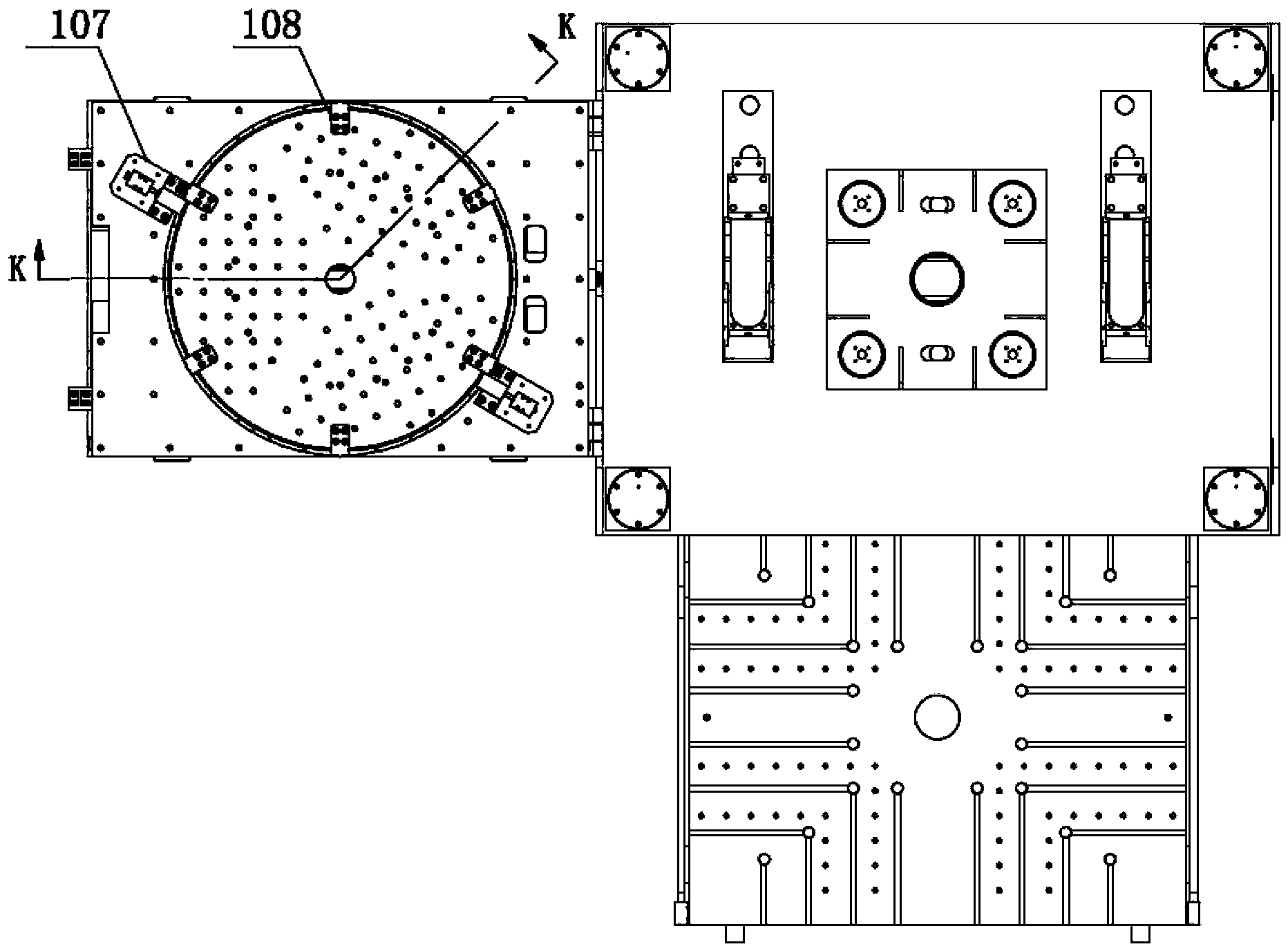

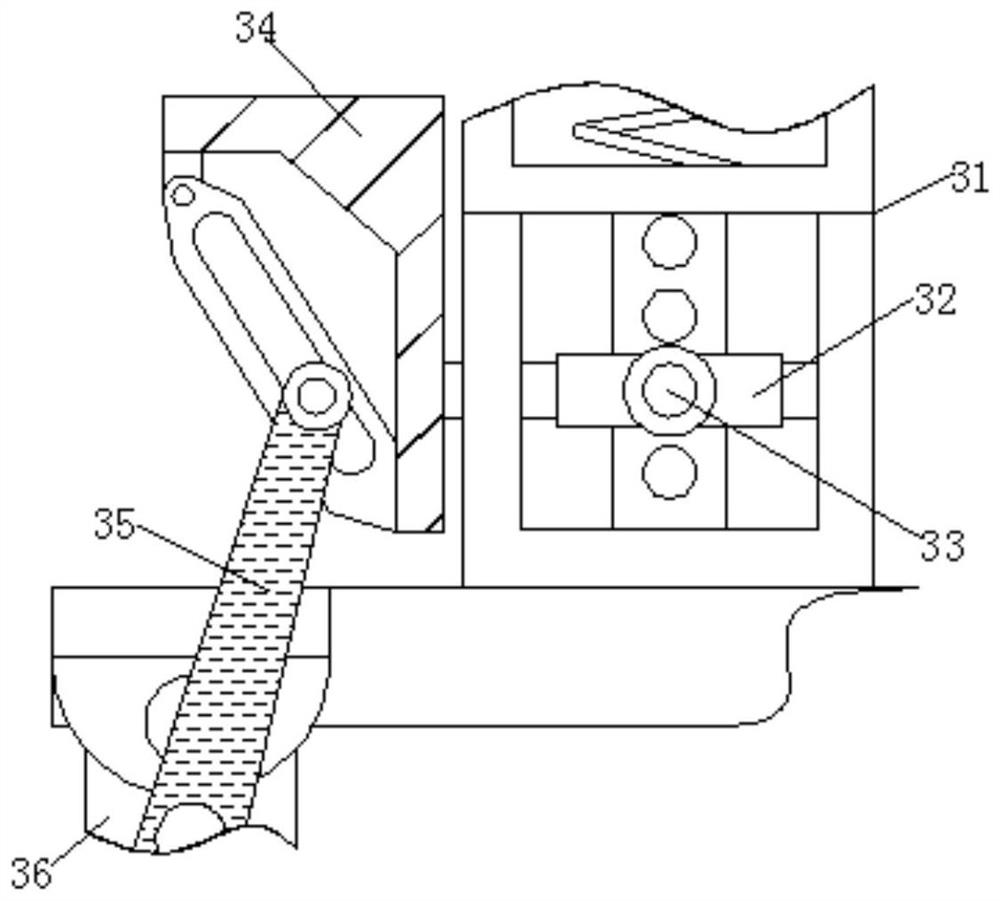

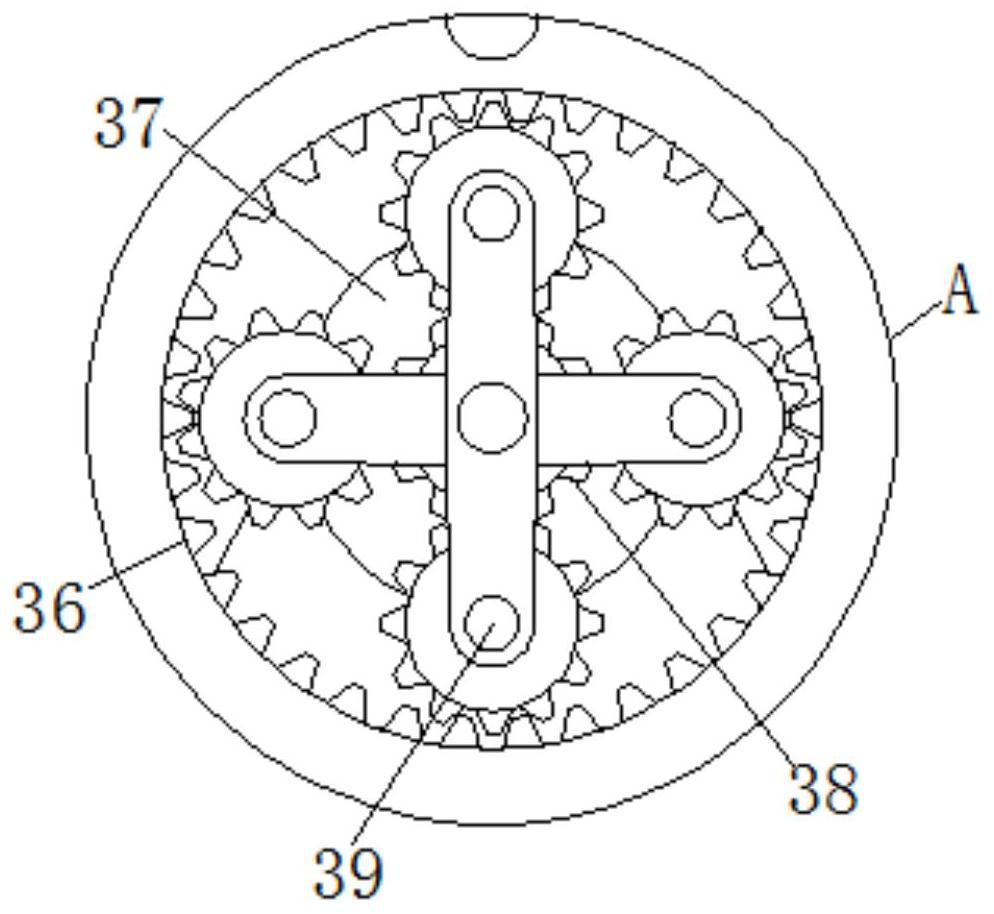

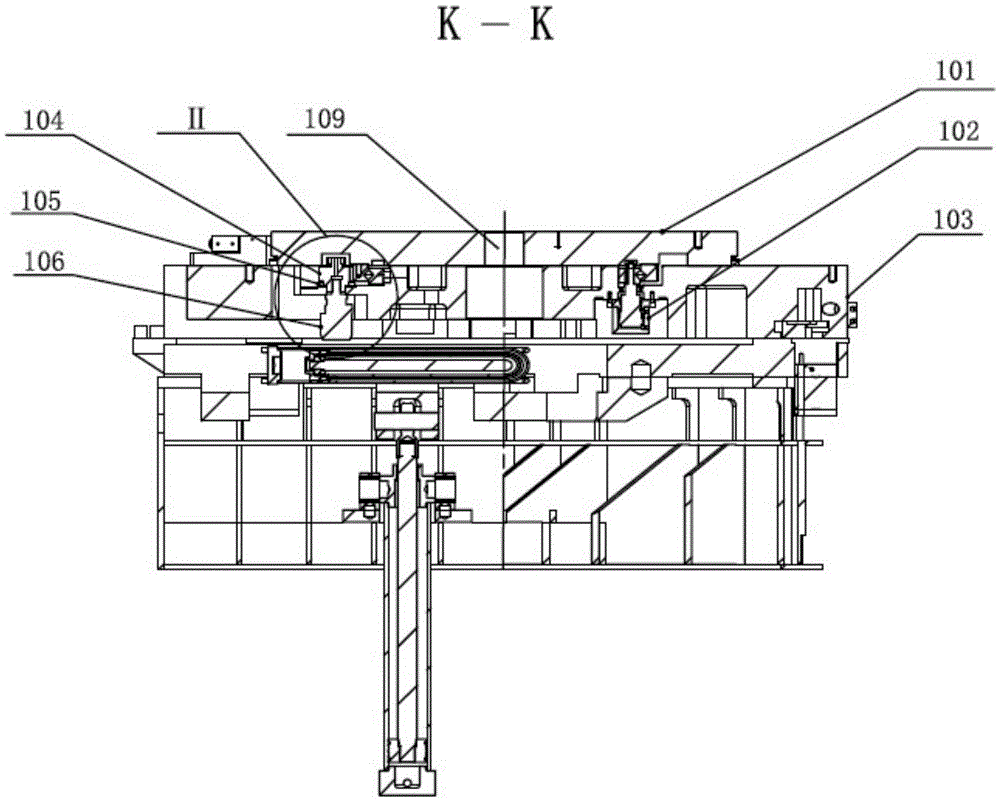

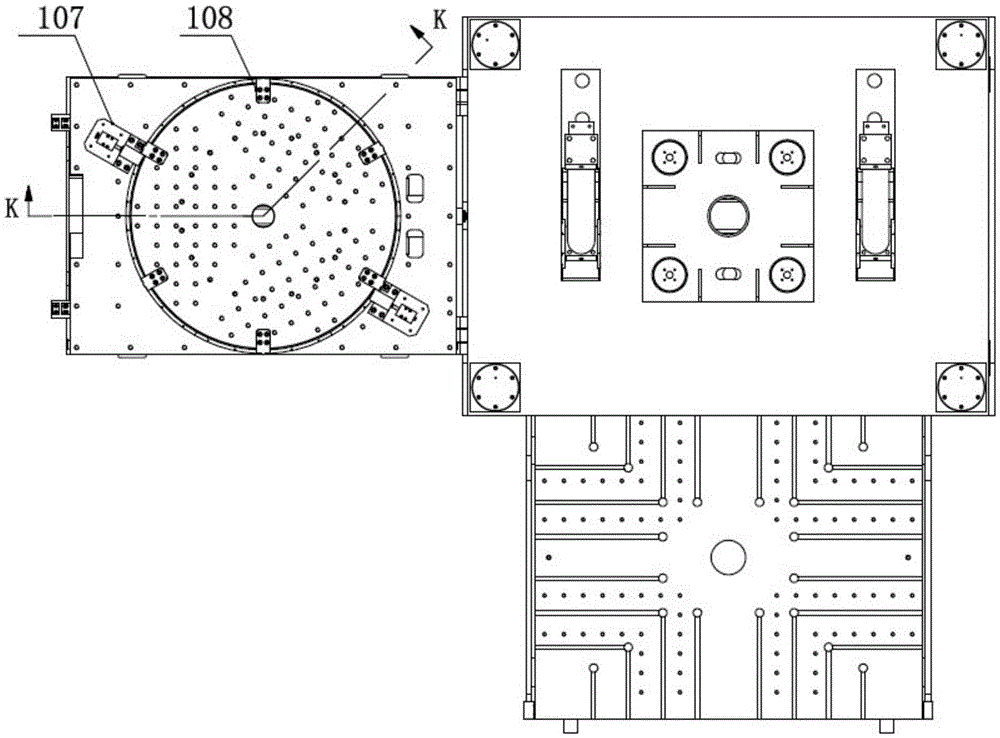

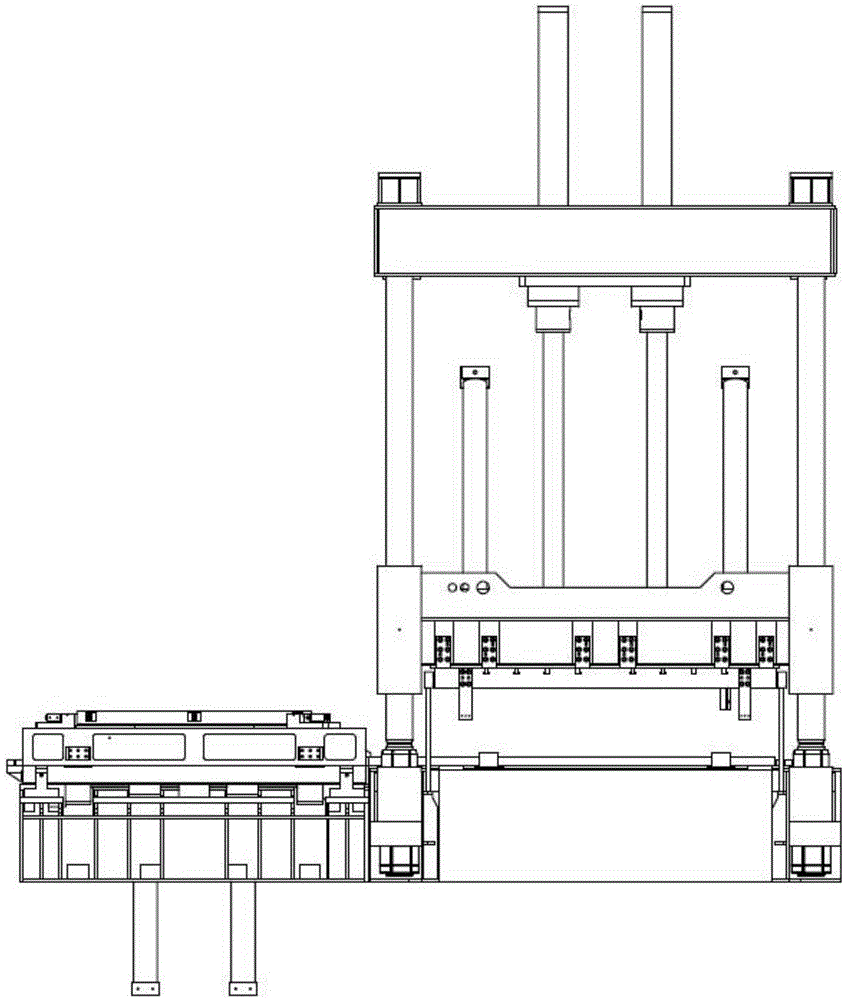

Multi-station variable-angle removing template for die spotting machine

The invention relates to a multi-station variable-angle removing template for a die spotting machine. The die spotting machine is composed of a rotating disk rotating mechanism and a template flip mechanism, and comprises rotating disk body and a removing flip template; the disk surface of the rotating disk body is provided with locking blocks around the disk center; the disk center of the rotating disk body is provided with a center rotating shaft connected with the removing template; positioning locks are arranged on the removing template; a jacking oil cylinder and a driving motor are arranged in the removing template; locking oil cylinders are arranged on the four corners of the lower surface of the removing flip template, and the lower surface is connected to a removing flip template drive pin which is connected with a removing pedestal; the removing flip template is provided with symmetrical double-ear pedestals; a flip oil cylinder connecting pin is arranged in ear-holes of the double-ear pedestals; the flip oil cylinder connecting pin is connected with a flip oil cylinder piston rod; and the flip oil cylinder is fixed on the removing pedestal obliquely. According to the multi-station variable-angle removing template for the die spotting machine, the rotating disk rotating mechanism is arranged on the removing template, so that the removing template is capable of switching stations; the template flip mechanism is arranged on the removing template, so that the removing template is capable of switching angels.

Owner:宁波顺兴机械制造有限公司

Ultralimit nickel alloy and preparation method thereof

ActiveCN109487196AExpand the scope of useStrong corrosion resistanceMolten spray coatingVacuum evaporation coatingComposite ceramicMetal

The invention belongs to the technical field of nickel alloy metal materials, and discloses an ultralimit nickel alloy and a preparation method thereof. The ultralimit nickel alloy comprises a nickelalloy matrix, and a composite bonding layer, a composite ceramic layer, a reflecting layer, a reverse refraction layer, an insulating layer and a foam carbon layer are deposited on the surface of thenickel alloy matrix in sequence. The preparation method of the ultralimit nickel alloy comprises the step that the composite bonding layer, the composite ceramic layer, the reflecting layer, the reverse refraction layer, the insulating layer and the foam carbon layer are deposited on the surface of the nickel alloy matrix in sequence, so that the ultralimit nickel alloy is formed. According to theultralimit nickel alloy and the preparation method, the problem that existing nickel alloy can not be used at ultralimit temperature is solved.

Owner:KUNMING UNIV OF SCI & TECH

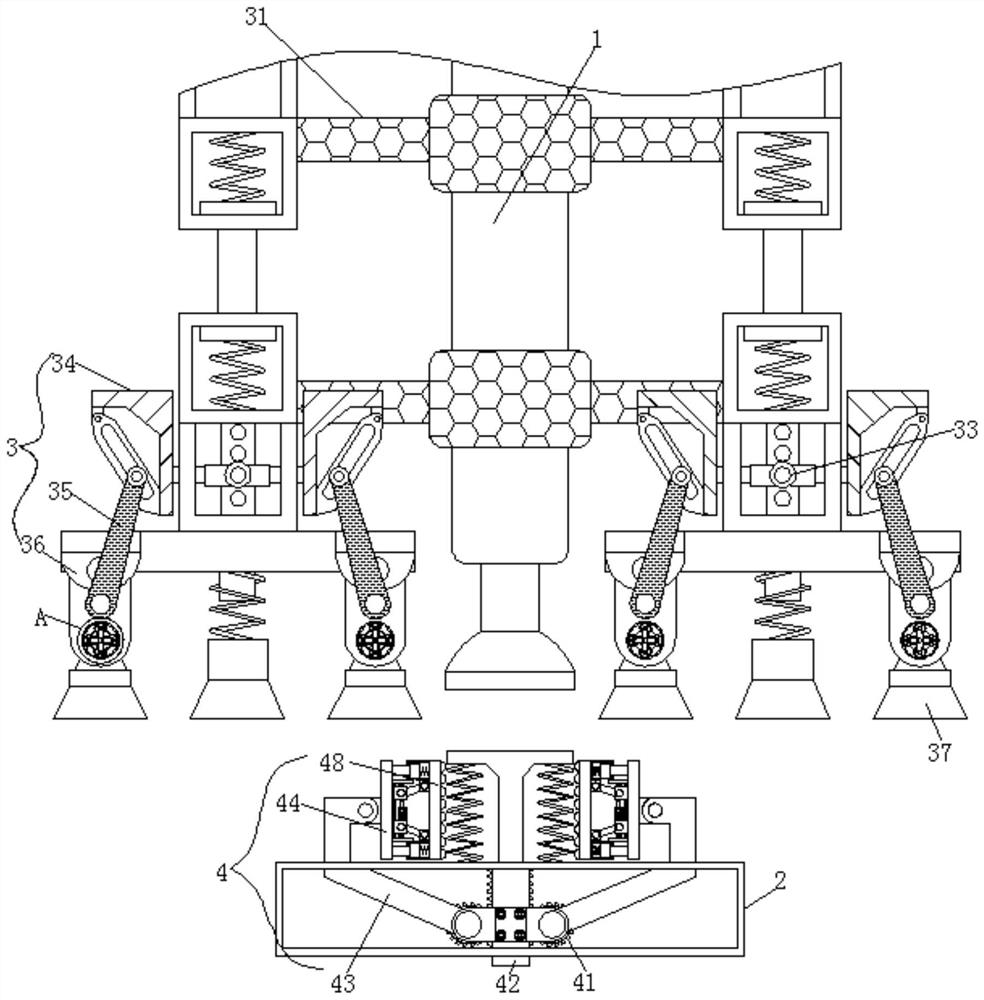

Overall expansion-joint device for fuel assembly skeleton

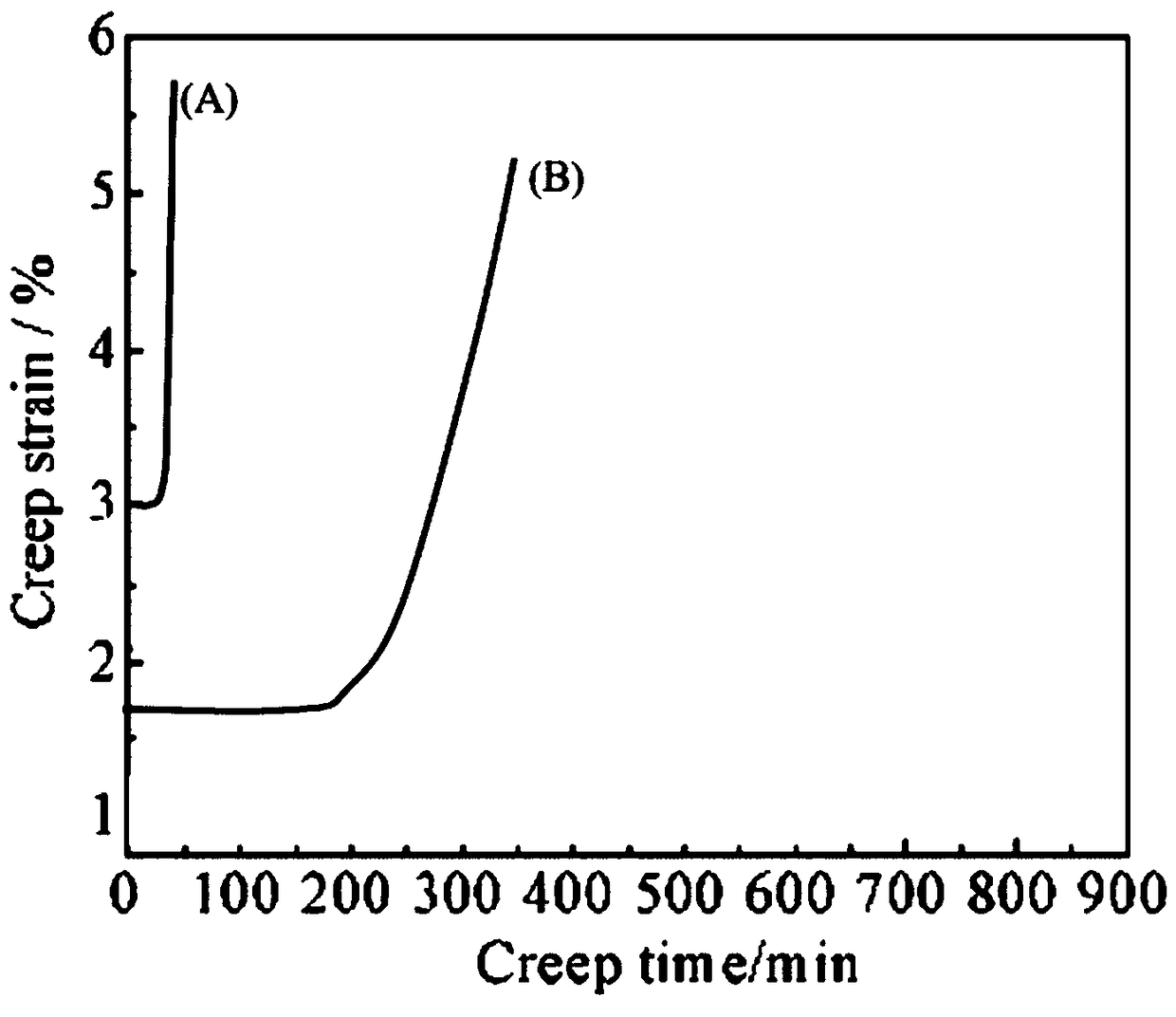

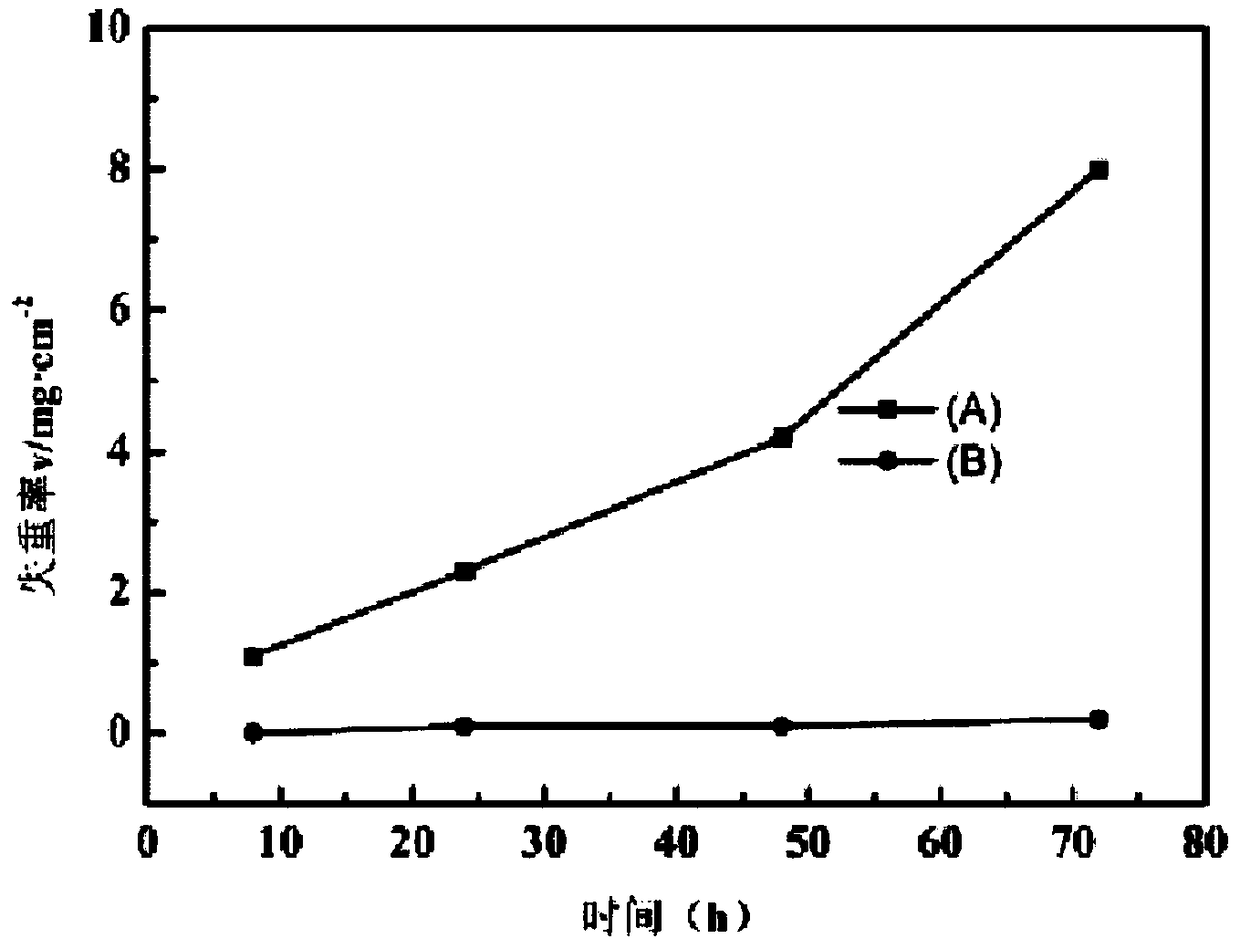

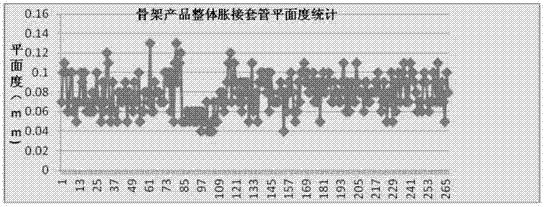

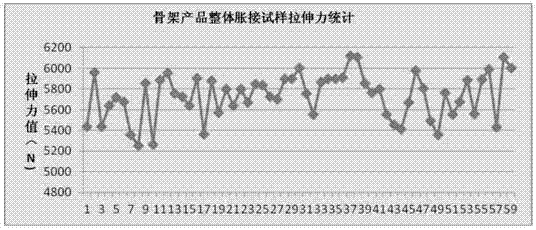

InactiveCN106925683AAvoid safety hazardsAvoid deviationMetal-working feeding devicesPositioning devicesExpansion jointIndustrial engineering

The invention belongs to an expansion-joint device, and specifically relates to an overall expansion-joint device for a fuel assembly skeleton. The overall expansion-joint device for the fuel assembly skeleton comprises an expansion-joint assembly, a lifting assembly, a support and a location assembly, wherein the support is located at the bottommost end and supports the whole expansion-joint device; the lifting assembly is arranged on the support and capable of lifting and driving the expansion-joint assembly and the location assembly to lift together; the location assembly is arranged at the foremost end of the lifting assembly and used for locating a position to be subjected to expansion joint; and the expansion-joint assembly is further arranged on the lifting assembly and comprises a plurality of expansion-joint pipes, and each expansion-joint pipe is capable of independently completing one-process expansion joint. The overall expansion-joint device for the fuel assembly skeleton has the following remarkable effects: 700 and more groups of overall expansion joint is carried out through applying a new process of overall expansion joint for a guide pipe and a sleeve pipe of the skeleton, the dimensions of an expansion-joint specimen and stretching inspections are both qualified, planeness inspections on the sleeve-pipe end of the skeleton product are all qualified (the planeness is required to be not greater than 0.15mm), and the value of an expansion-joint stretching force is high (the value is required to be greater than 4500N).

Owner:CNNC JIANZHONG NUCLEAR FUEL

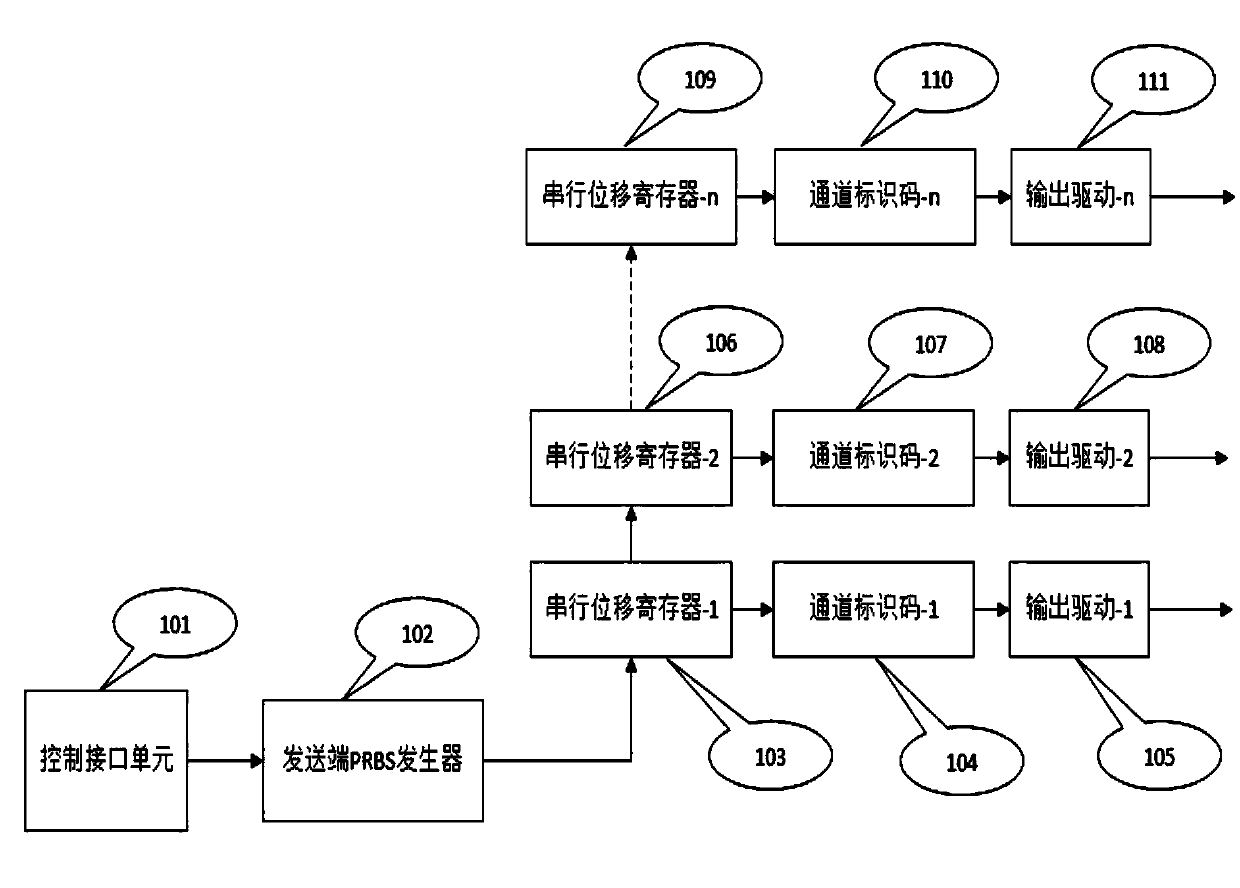

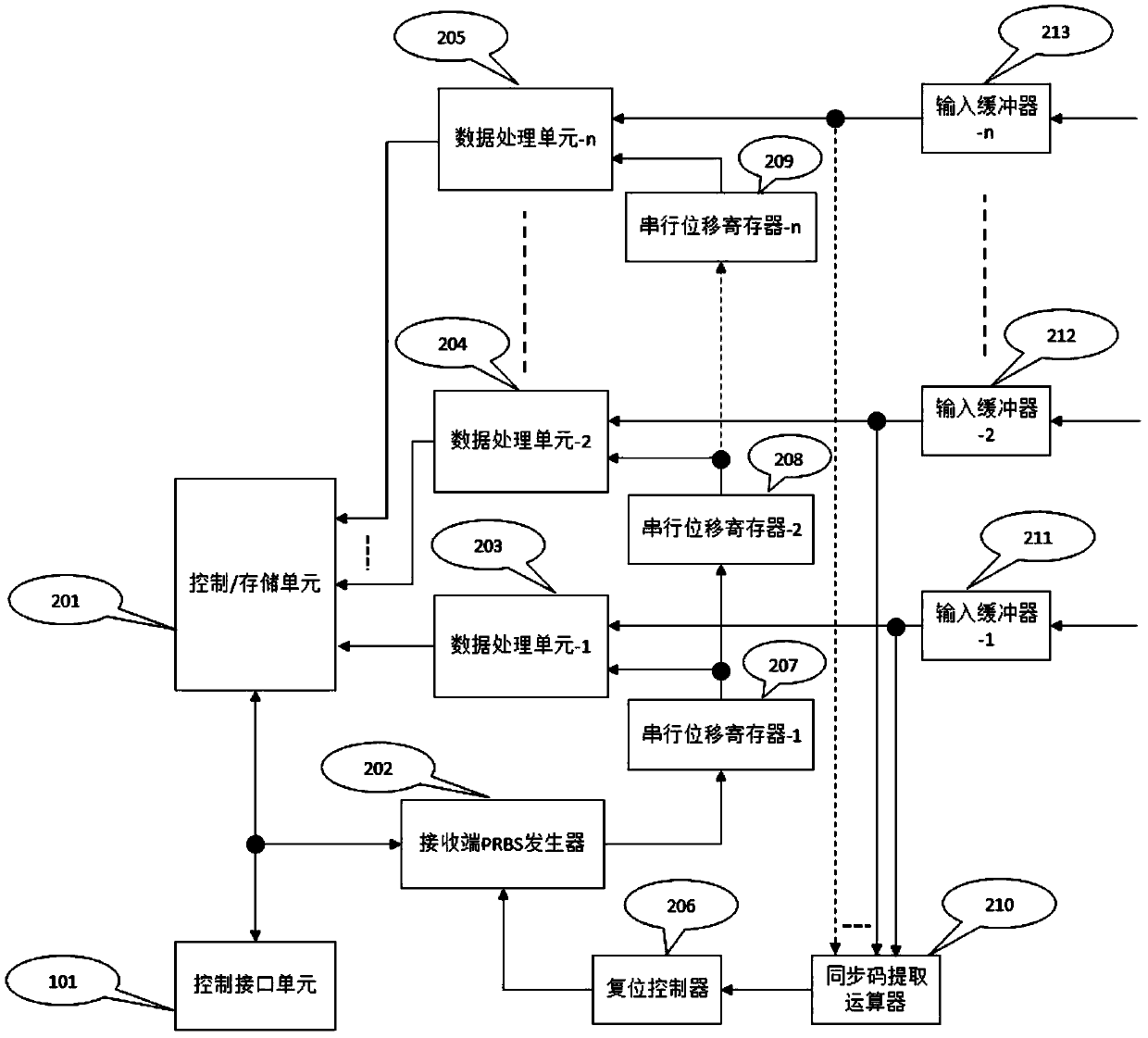

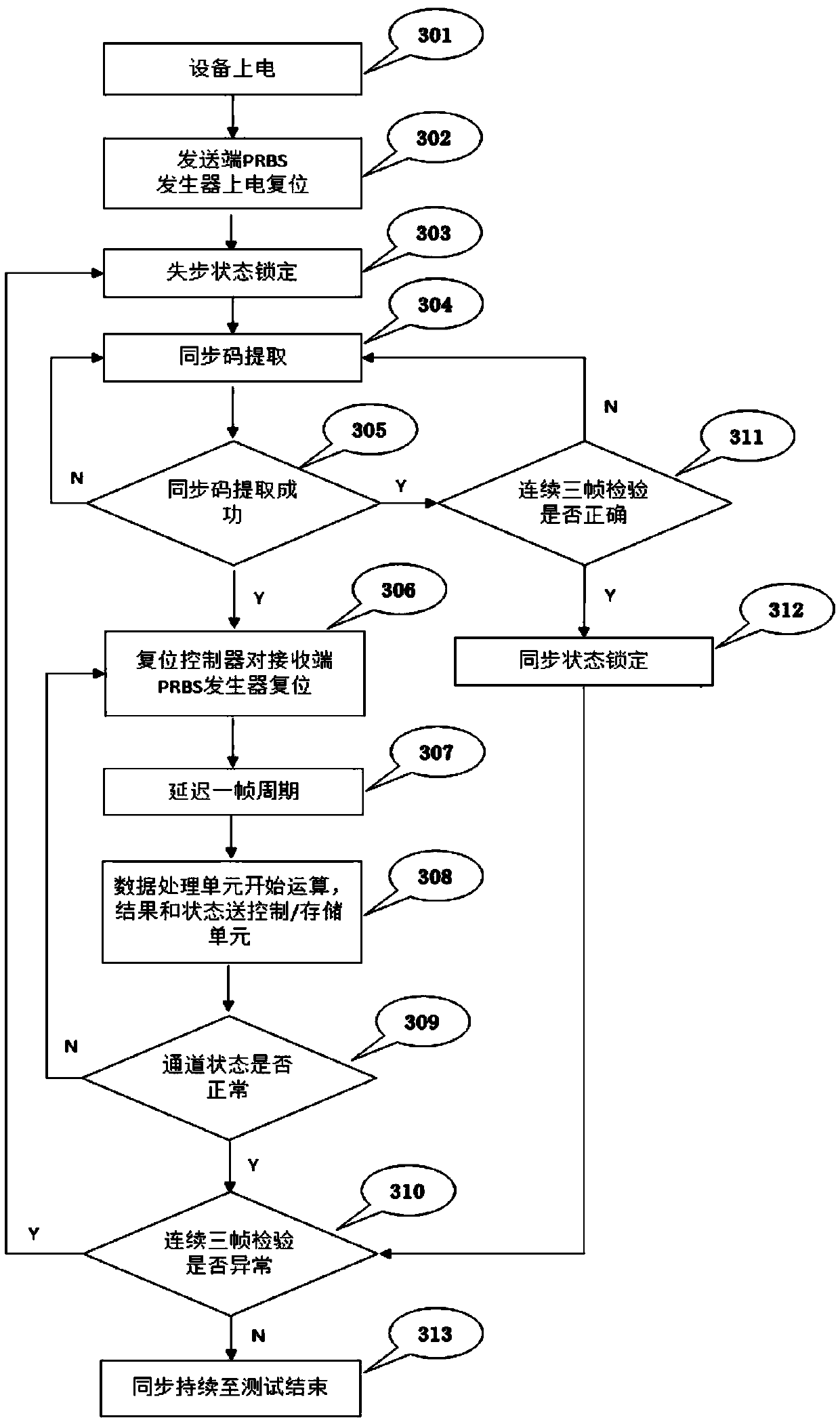

Embedded large-capacity parallel multi-channel optical module error code test system and test method

ActiveCN109672473AIncrease the number of channelsImprove scalabilityElectromagnetic transmissionOptical ModuleSoftware engineering

The invention relates to an embedded large-capacity parallel multi-channel optical module error code test system and test method. The embedded large-capacity parallel multi-channel optical module error code test system includes a sending part and a receiving part; the sending part uses PRBS sequence equalization and characteristics of shift addition to achieve parallel expansion through serial shift or intermediate extraction; and the receiving part uses the method of multi-channel operation and combined channel re-synchronizing, which has the characteristics of parallel multi-channel independent channels, and can fully utilize the timing sequence correlation of each independent channel; so that the large-capacity optical module error test is realized. The embedded large-capacity parallelmulti-channel optical module error code test system and test method satisfies the mass test of communication components and modules, and solves the false test caused by the error of the jumper connection of a common code error tester at the same time; and the design is optimized and facilitates the monolithic integration.

Owner:WUHAN HENGTAITONG TECH

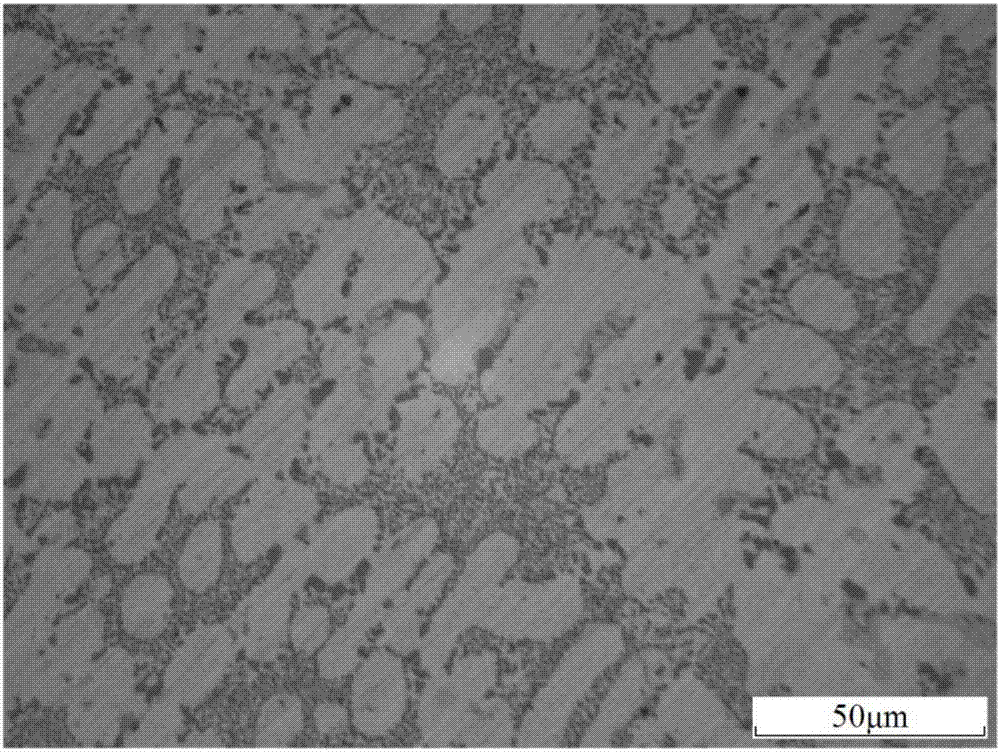

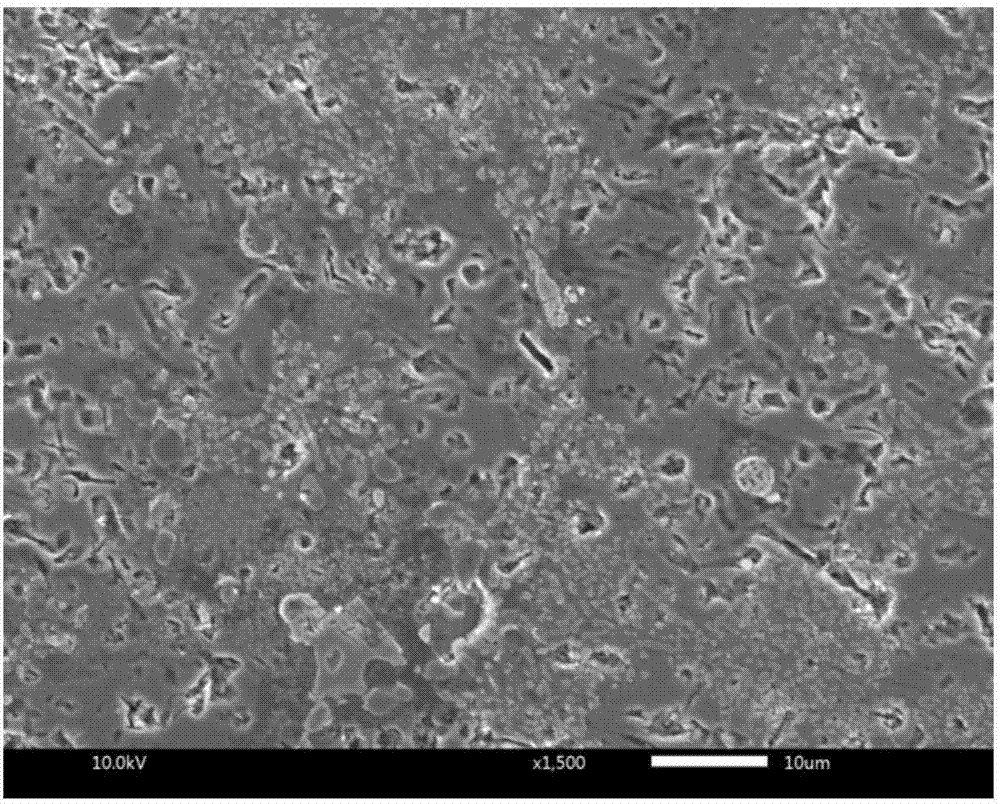

Zr and Sr compound microalloyed and Mn microalloyed high toughness Al-Si-Cu serial cast aluminum alloy and preparation method thereof

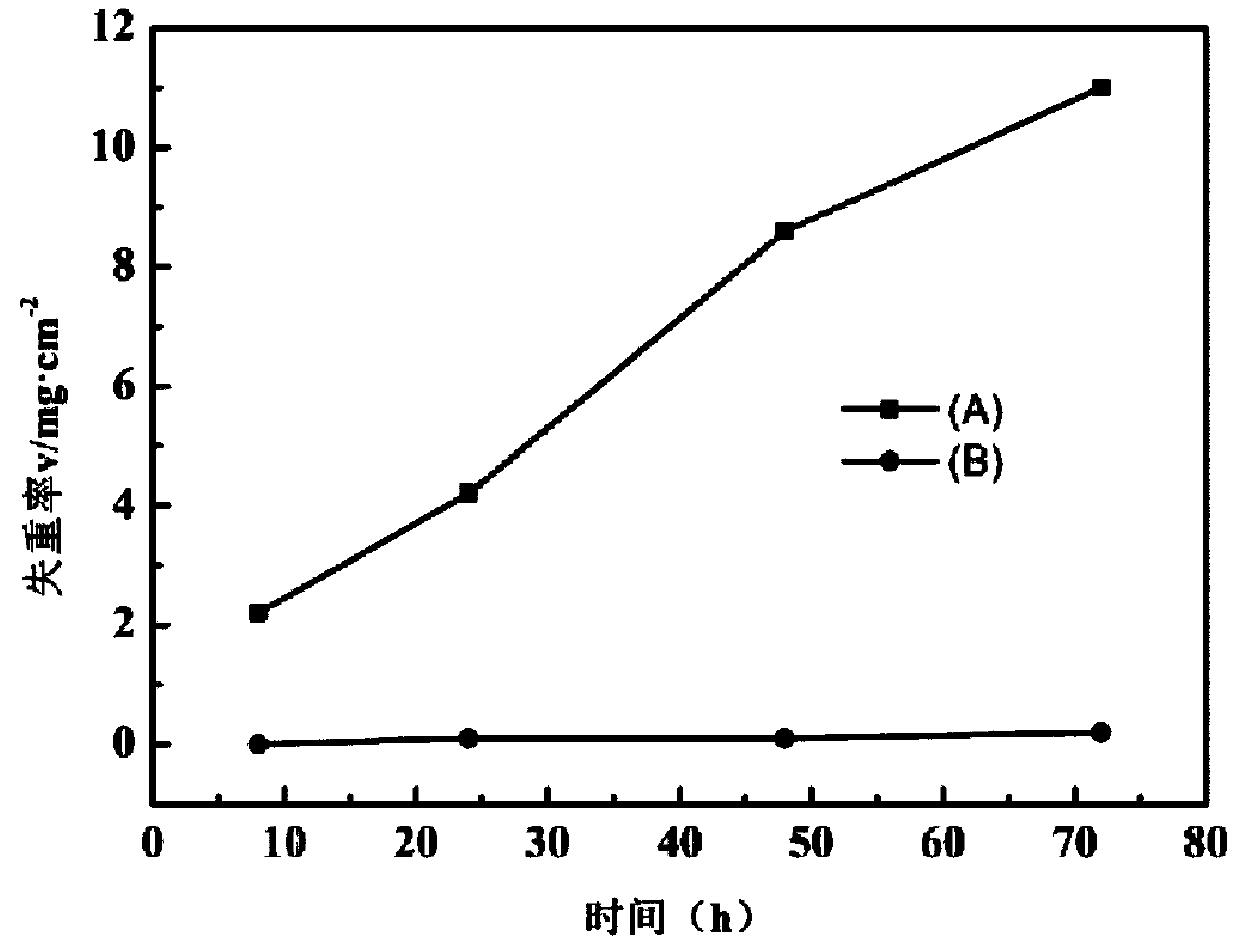

A Zr, Sr composite micro-alloyed and Mn-alloyed high-strength Al-Si-Cu cast aluminum alloy and a preparation method thereof, characterized in that the aluminum alloy is mainly composed of aluminum, silicon, copper, manganese, magnesium, Composed of zinc, zirconium, strontium and iron, wherein the mass percentage of silicon (Si) is 8.28-8.41%, the mass percentage of copper is 2.06-2.29%, the mass percentage of manganese is 0.472-0.483%, and the mass percentage of zirconium is 0.187 ~0.192%, the mass percentage of strontium is 0.0334~0.0378%, the mass percentage of iron is 0.142~0.147%, and the balance is aluminum and a small amount of impurity elements. The as-cast structure of the aluminum alloy of the present invention is dense, and the average value of the unnotched impact toughness at room temperature measured by the as-cast alloy is 18.386366 J / cm2, and its tensile strength is 238.85 MPa, elongation is 7.06%, and the temperature is 37 ° C in 3.5% NaCl aqueous solution. The average uniform corrosion rate is 0.324870443 mm / y, which can meet the manufacturing needs of large complex thin-walled high-strength cast aluminum alloy structural parts.

Owner:JIANGSU UNIV

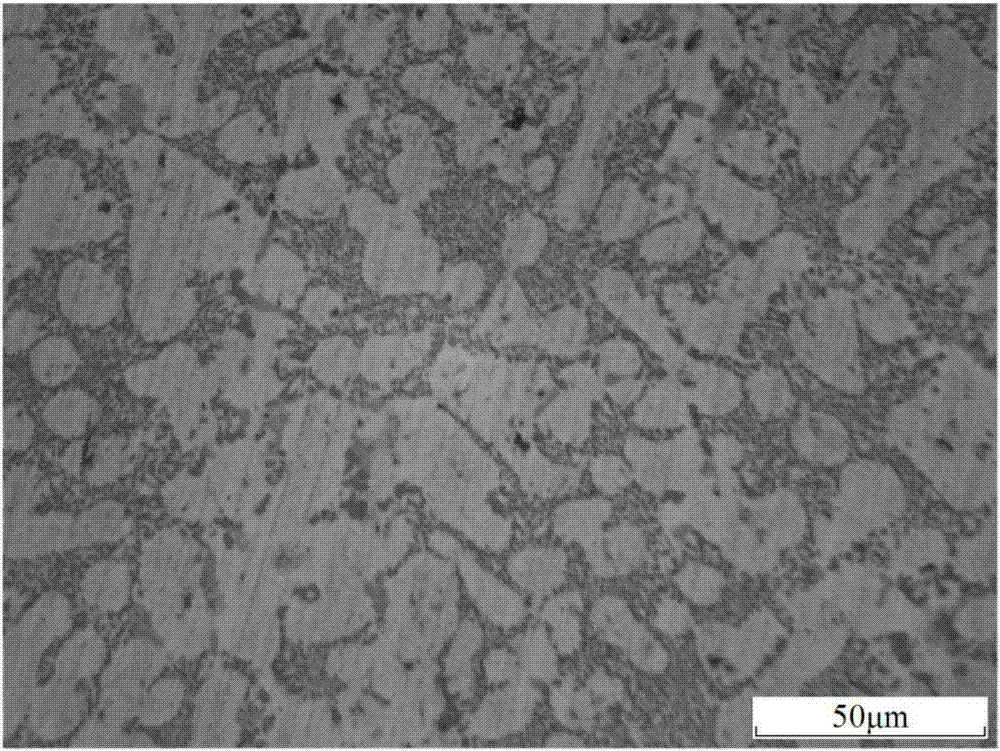

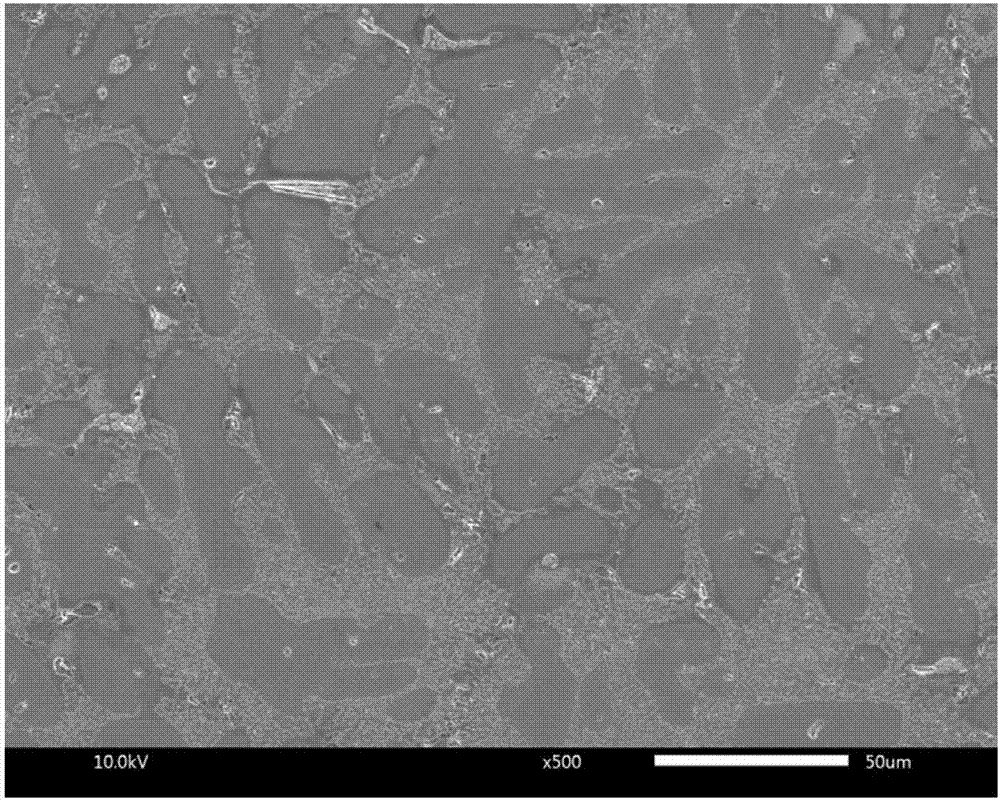

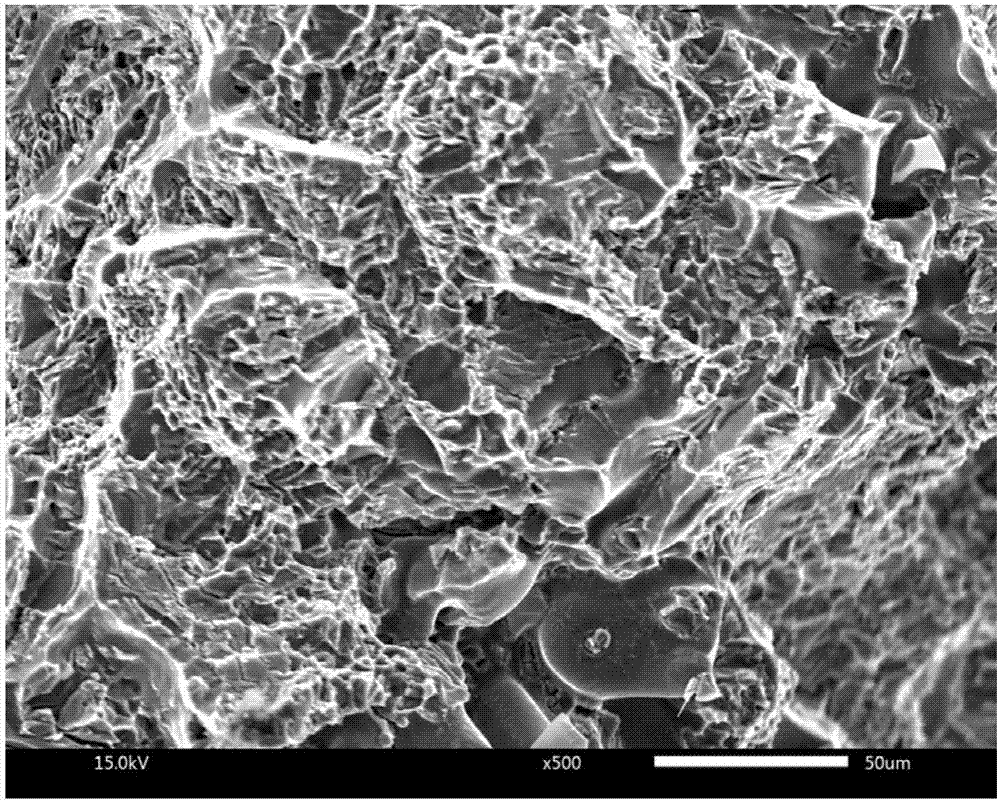

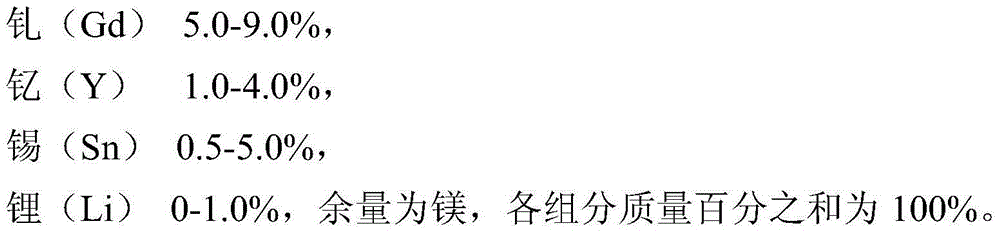

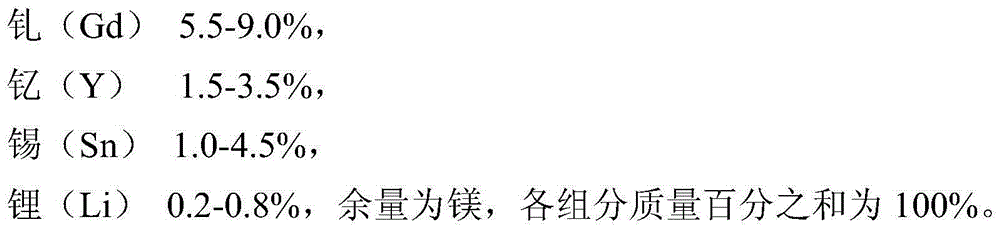

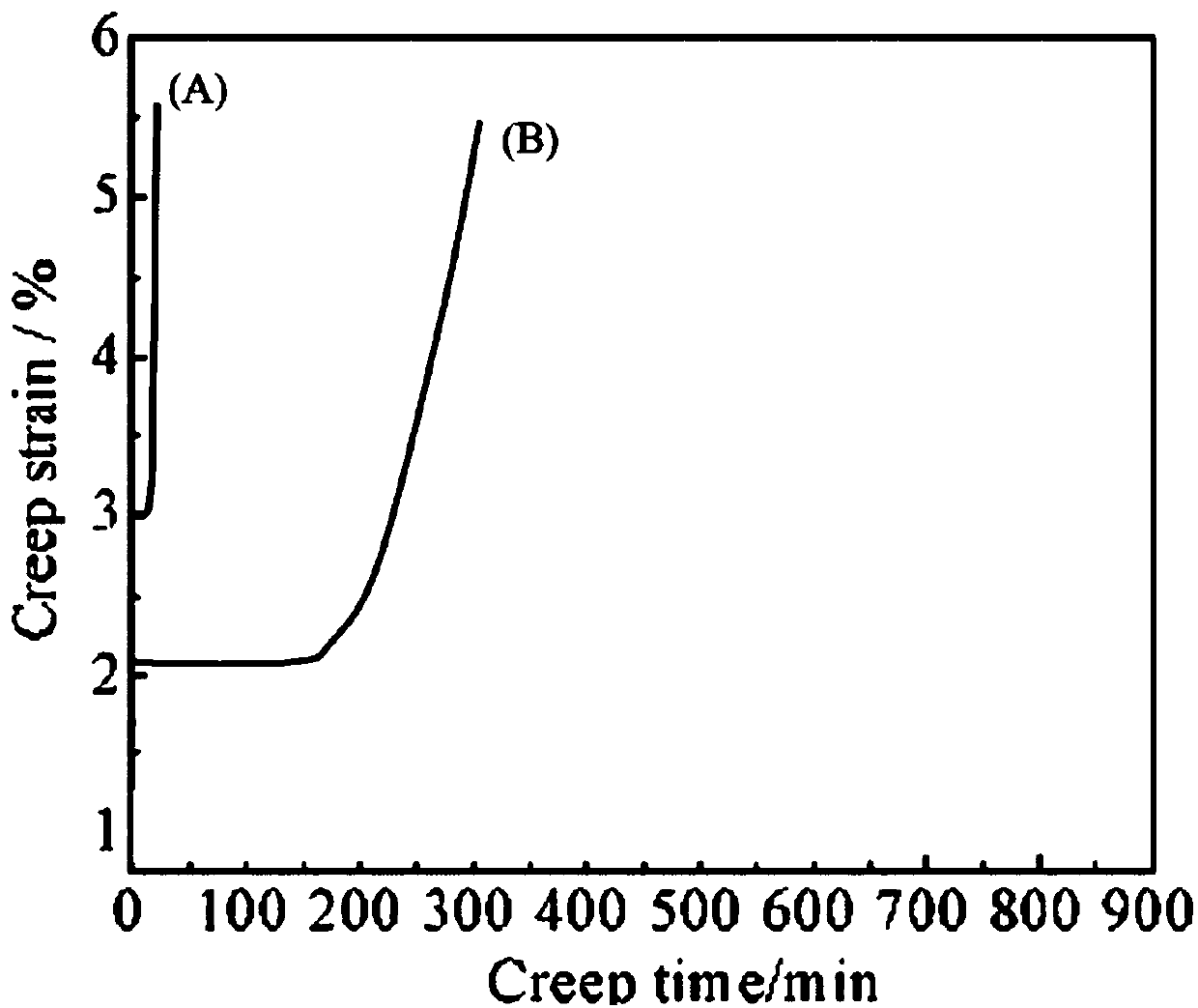

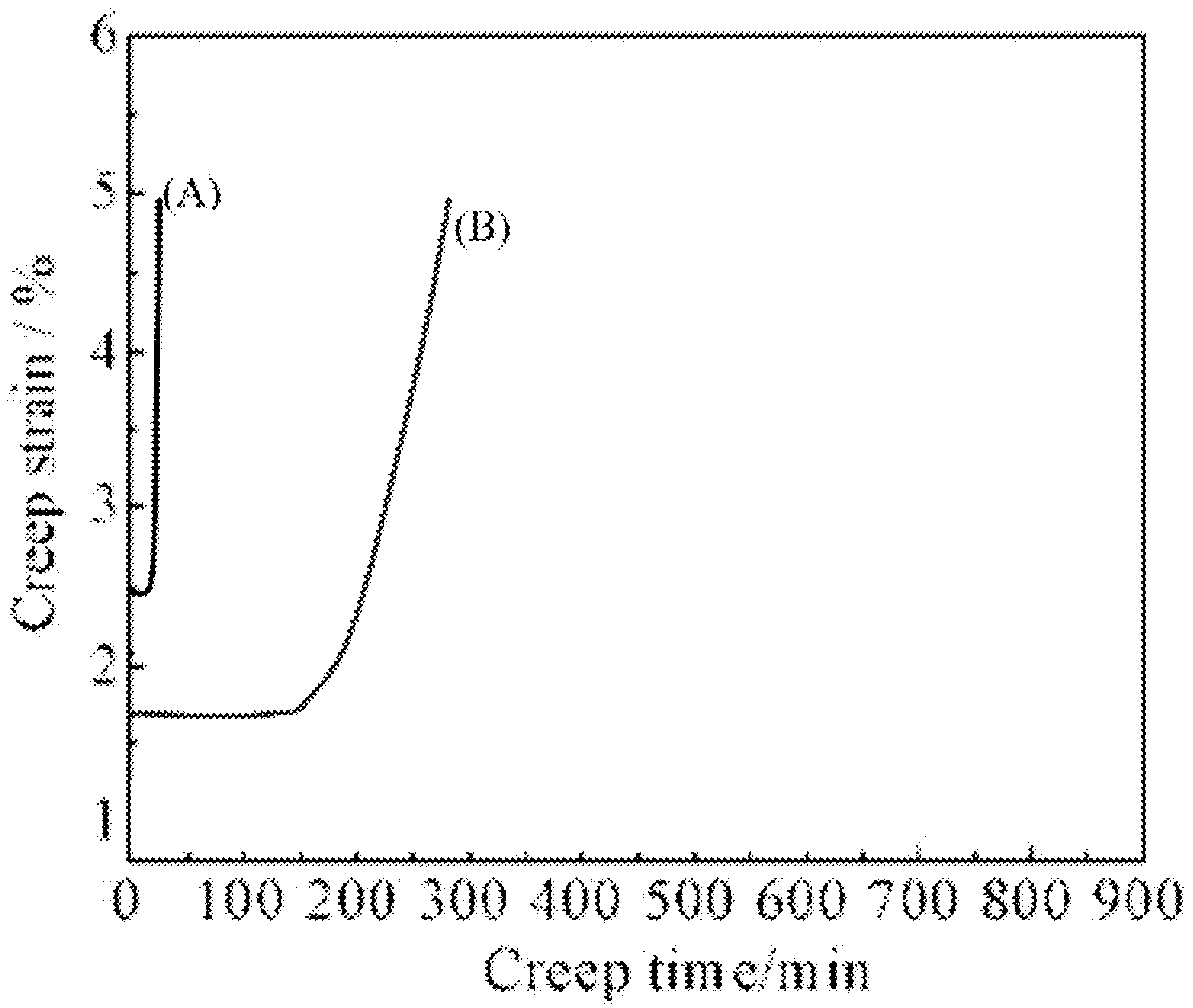

High-strength high-damping magnesium alloy containing rare-earth elements

A high-strength high-damping magnesium alloy containing rare-earth elements comprises the following components: gadolinium, yttrium, stannum, lithium and the balance of magnesium. A material prepared from the alloy disclosed by the invention, under the condition of room temperature, has an ultimate tensile strength (sigma b) larger than 250 MPa, an elongation percentage (delta) larger than 2%, damping performance (Q-1) higher than 0.01. Through reasonable alloying of components and ratio of the metal magnesium, the alloy crystal grain size can be effectively fined, the plasticity of the magnesium alloy is increased, meanwhile, the varieties and numbers of alloy elements in the alloy are effectively improved, a great amount of second phases are formed; after an alloy cast is subjected to solid solution strengthening and artificial aging, a great amount of strengthened second phases can be uniformly distributed inside grain and can be accumulated at boundary of grain; through the synergetic function, the alloy provided by the invention has relatively high damping performance and good strength.

Owner:CENT SOUTH UNIV

Super-limit aluminum alloy and preparation method thereof

ActiveCN109554707AIncrease temperatureMeet the needs of manufacturingSuperimposed coating processCarbon layerComposite ceramic

The invention belongs to the technical field of aluminum alloy metal materials, and discloses a super-limit aluminum alloy and a preparation method thereof. The super-limit aluminum alloy comprises analuminum alloy base body, wherein a composite bonding layer, a composite ceramic layer, a reflecting layer, an anti-refracting layer, an insulating layer and a foam carbon layer are sequentially deposited on the surface of the aluminum alloy base body; the composite bonding layer comprises a bonding layer deposited on the surface of the aluminum alloy base body and a noble metal layer deposited on the surface of the bonding layer; and the composite ceramic layer comprises a ceramic layer A and a ceramic layer B. During preparation, the composite bonding layer, the composite ceramic layer, thereflecting layer, the anti-refracting layer, the insulating layer and the foam carbon layer are sequentially deposited on the surface of the aluminum alloy, so that the super-limit aluminum alloy isformed. The use temperature of the super-limit aluminum alloy is increased to be higher than the melting point of an original aluminum alloy by100-500 DEG C, so that the aluminum alloy can be used ina super-limit temperature.

Owner:KUNMING UNIV OF SCI & TECH

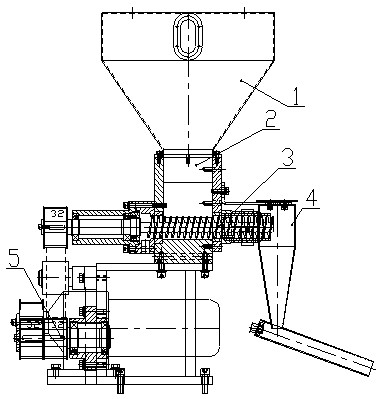

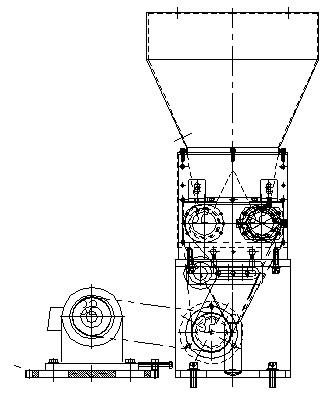

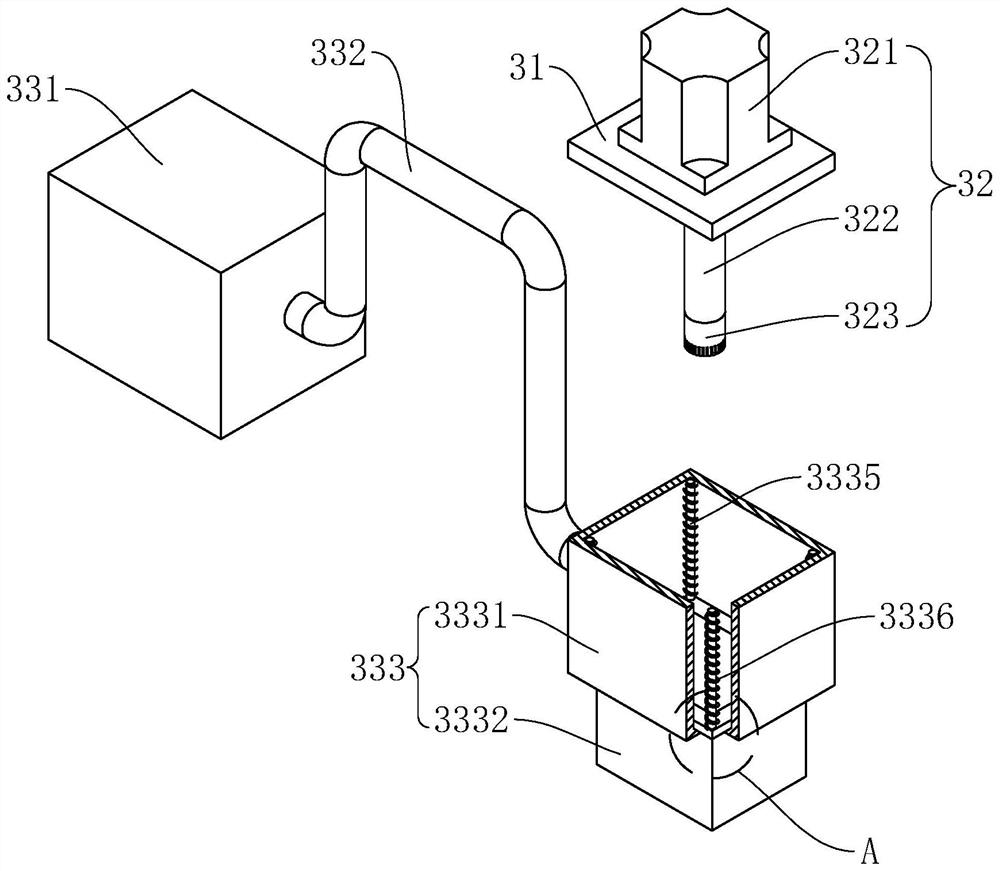

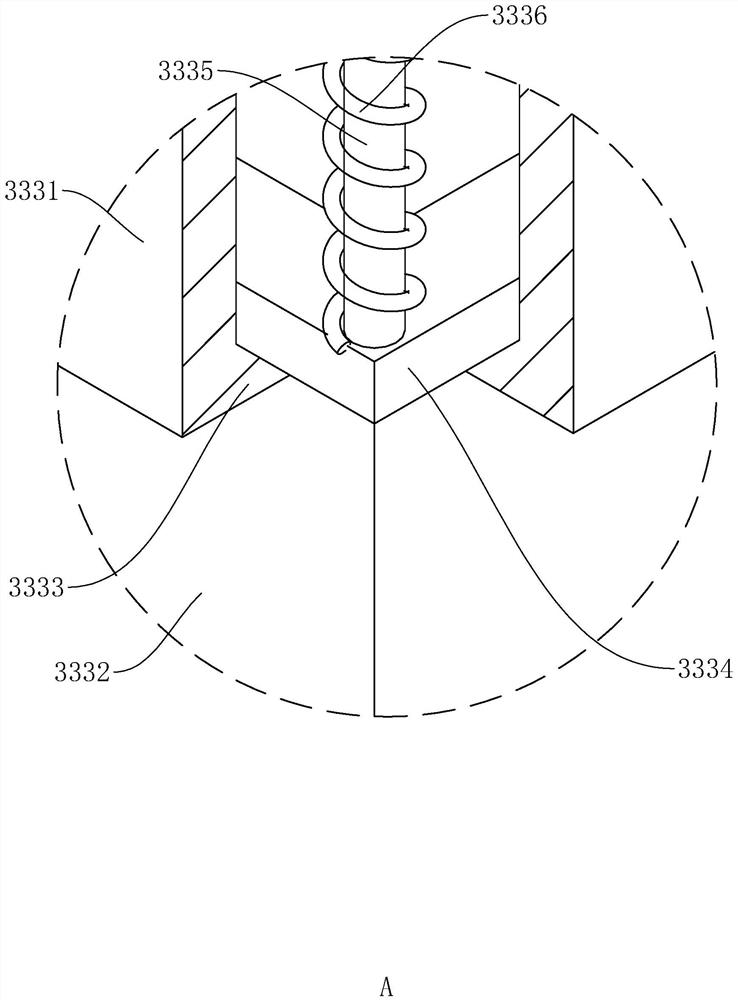

Special twin screw unload device and unload method for adult diapers and adult incontinence trousers

ActiveCN102068345AMeet the needs of manufacturingHigh precisionAbsorbent padsMotor driveTransportation capacity

The invention relates to a special twin screw unload device and unload method for adult diapers and adult incontinence trousers, which can quickly exert polymer and can exert polymer transportation capacity relatively accurately. A polymer material pumper is installed on a material barn, the outlet of the material barn is communicated with a material box, the lower part of the material box is transversely provided with twin screw installation holes which penetrate the wall plates of the material box, a twin screw transversely penetrates the twin screw installation holes on the lower part of the material box, a motor drives one end of the twin screw to rotate through a traversing module, and the other end of the twin screw is communicated with an outlet hopper through a twin screw passage. The invention has the following advantages: first, the twin screw is adopted for transporting the polymer in high-speed operation, the transportation capacity is uniform and stable, and the manufacturing requirements of the adult diapers and the adult incontinence trousers are satisfied; second, in the invention, the requirements of the polymer transportation capacity, which are put forward by different clients, can be met by only changing the diameter and the lead of the screw; therefore, the invention has the characteristics of simple structure, good interchangeability, high precision and large throughout.

Owner:ZHEJIANG YONGCHUANG MACHINERY

Ultralimit ferroalloy and preparation method thereof

ActiveCN109487195AGood mechanical stabilityGood chemical stabilityMolten spray coatingVacuum evaporation coatingCarbon layerComposite ceramic

The invention belongs to the technical field of preparation, and discloses an ultralimit ferroalloy and a preparation method thereof. The ultralimit ferroalloy comprises a ferroalloy matrix, and a composite bonding layer, a composite ceramic layer, a reflecting layer, a reverse refraction layer, an insulating layer and a foam carbon layer are deposited on the surface of the ferroalloy matrix in sequence; the composite bonding layer comprises a bonding layer deposited on the surface of an aluminium alloy matrix, and a precious metal layer deposited on the surface of the binding layer; and the composite ceramic layer comprises a ceramic layer A and a ceramic layer B. According to the ultralimit ferroalloy, through deposition of a plurality of coatings on the surface of the ferroalloy matrix,the service temperature of the ultralimit ferroalloy can be increased to 100 DEGC-500 DEGC higher than the melting point of the original ferroalloy matrix, so that the application of the ferroalloy in ultralimit environment is achieved. The ultralimit ferroalloy provided by the invention has excellent high-temperature mechanical and chemical stability, and can be used under the condition of exceeding the melting point of the ferroalloy matrix; and the application range is expanded.

Owner:KUNMING UNIV OF SCI & TECH

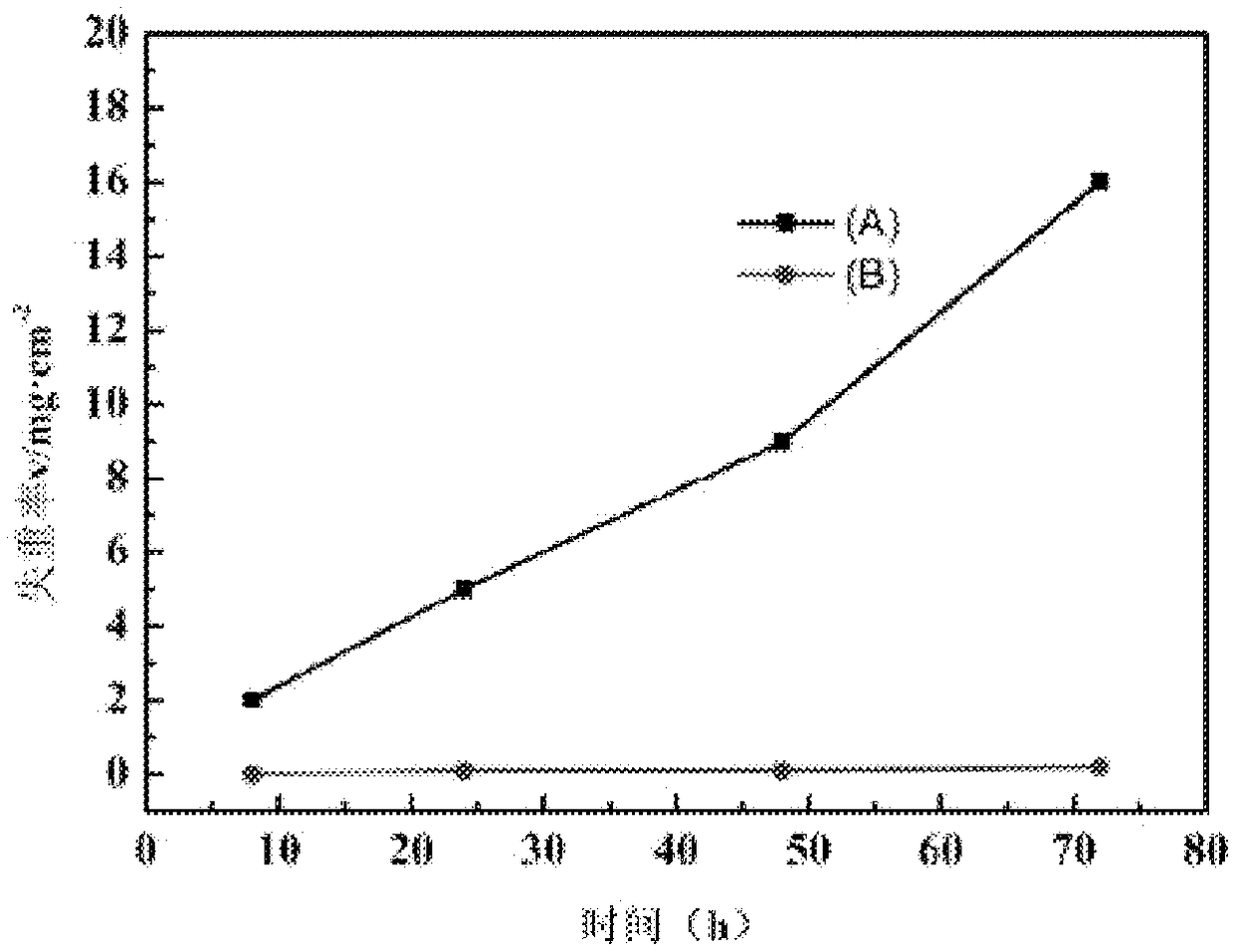

Zr and Sr compound microalloyed high-strength/toughness corrosion resisting Al-Si-Cu cast aluminum alloy and preparation method

A Zr and Sr composite microalloyed high-strength, toughness, corrosion-resistant Al-Si-Cu cast aluminum alloy and a preparation method thereof, characterized in that the aluminum alloy is mainly composed of aluminum (Al), silicon (Si), copper ( Cu), zirconium (Zr), strontium (Sr) and iron (Fe), the mass percentage of silicon (Si) is 7.9-8.18%, the mass percentage of copper (Cu) is 1.95-2.11%, and the mass percentage of zirconium (Zr) The mass percentage is 0.169-0.187%, the mass percentage of strontium (Sr) is 0.0253-0.035%, the mass percentage of iron (Fe) is 0.133-0.153%, and the balance is aluminum and a small amount of impurity elements. The aluminum alloy of the present invention has a dense as-cast structure, and the measured impact toughness at room temperature of the as-cast alloy is 24.151438~39.312583 J / cm2, while its tensile strength is 217.228~234.7 MPa, elongation is 9~9.529%, and 37% in 3.5% NaCl aqueous solution The uniform corrosion rate at ℃ temperature is 0.239345219~0.27074376 mm / y, which can meet the manufacturing needs of large complex thin-walled high-strength and corrosion-resistant cast aluminum alloy structural parts.

Owner:JIANGSU UNIV

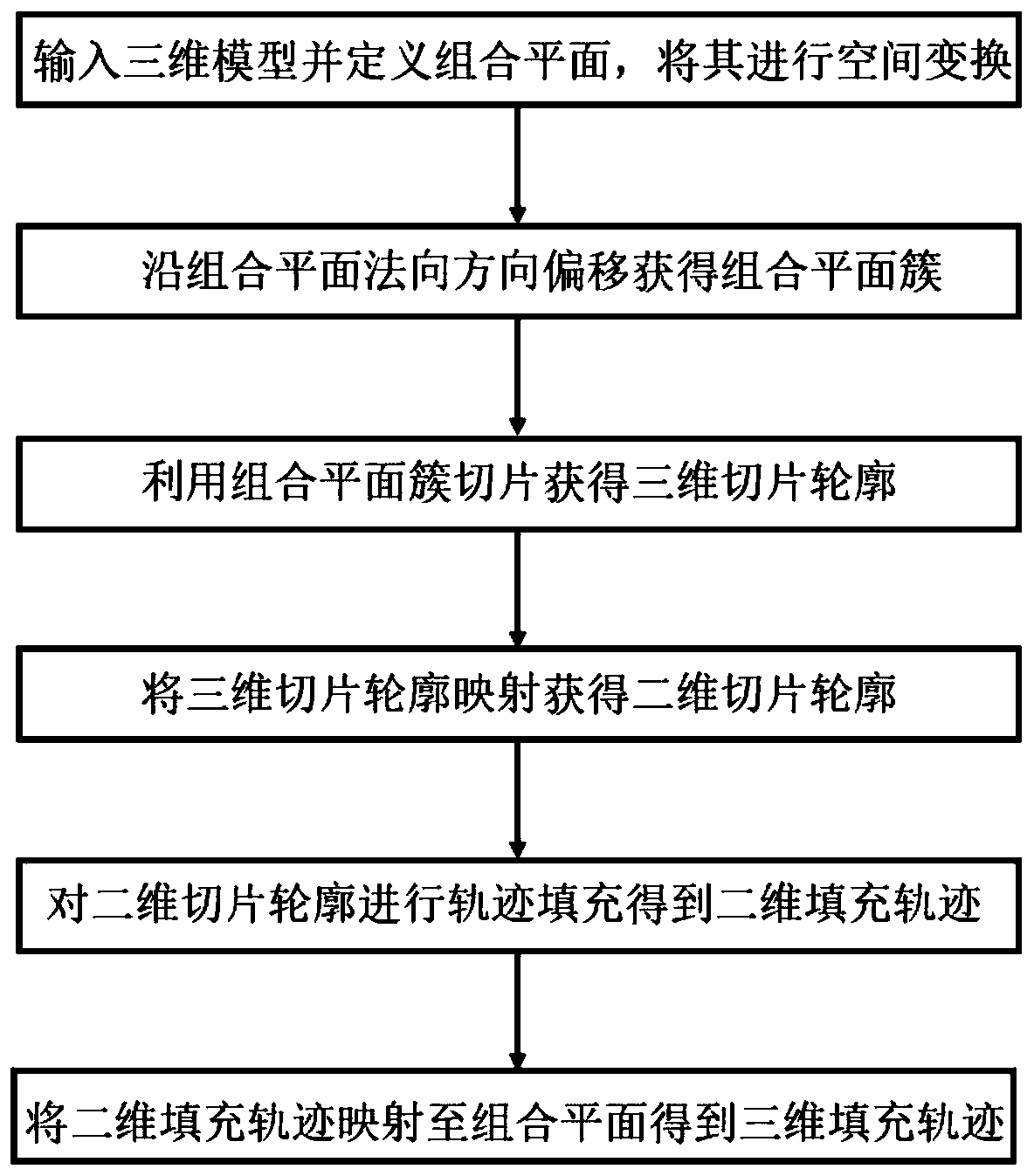

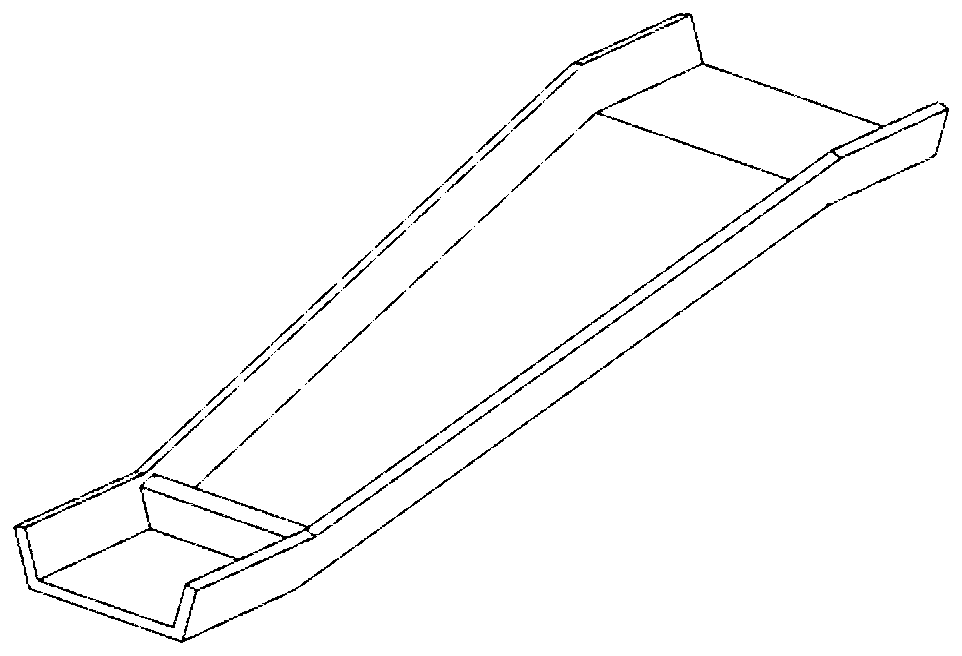

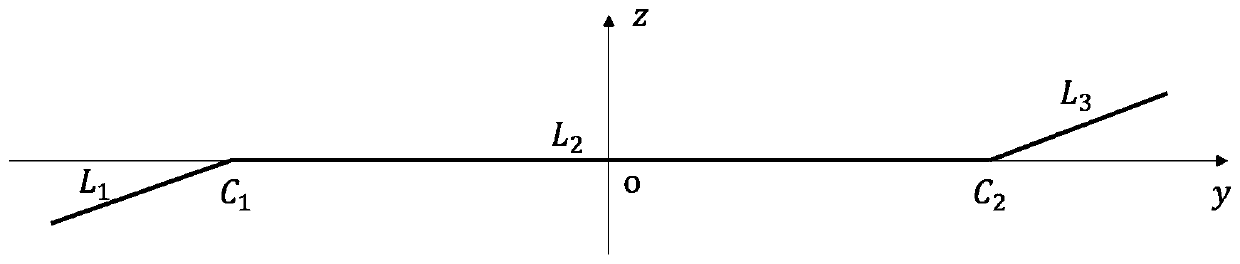

Trajectory planning method based on combined plane slicing and product

ActiveCN110722798AMeet the needs of manufacturingImprove accuracyAdditive manufacturing apparatusDomestic articlesProcess engineeringTrajectory planning

The invention belongs to the field of additive manufacturing, and particularly discloses a trajectory planning method based on combined plane slicing and a product. The trajectory planning method comprises the steps that a three-dimensional model is input and a combined plane is defined, and spatial alternation is simultaneously carried out on the three-dimensional model and the combined plane; the preset times of the combined plane is skewed with a preset interval in the normal direction of the combined plane, so that a combined plane cluster is obtained; the combined plane cluster is used for slicing the three-dimensional model, and a three-dimensional slicing profile located on the combined plane cluster is obtained; the three-dimensional slicing profile is mapped to a horizontal planeto obtain a two-dimensional slicing profile; trajectory filling is carried out on the two-dimensional slicing profile on the horizontal plane to obtain a two-dimensional filling trajectory; and the two-dimensional filling trajectory is mapped to the combined plane to obtain a three-dimensional filling trajectory. According to the trajectory planning method based on combined plane slicing, by building the combined plane similar to the three-dimensional model and using a mapping relation of the combined plane and the horizontal plane to obtain an additive manufacturing trajectory located on thecombined plane, the requirements of special structural additive manufacturing can be effectively met.

Owner:HUAZHONG UNIV OF SCI & TECH

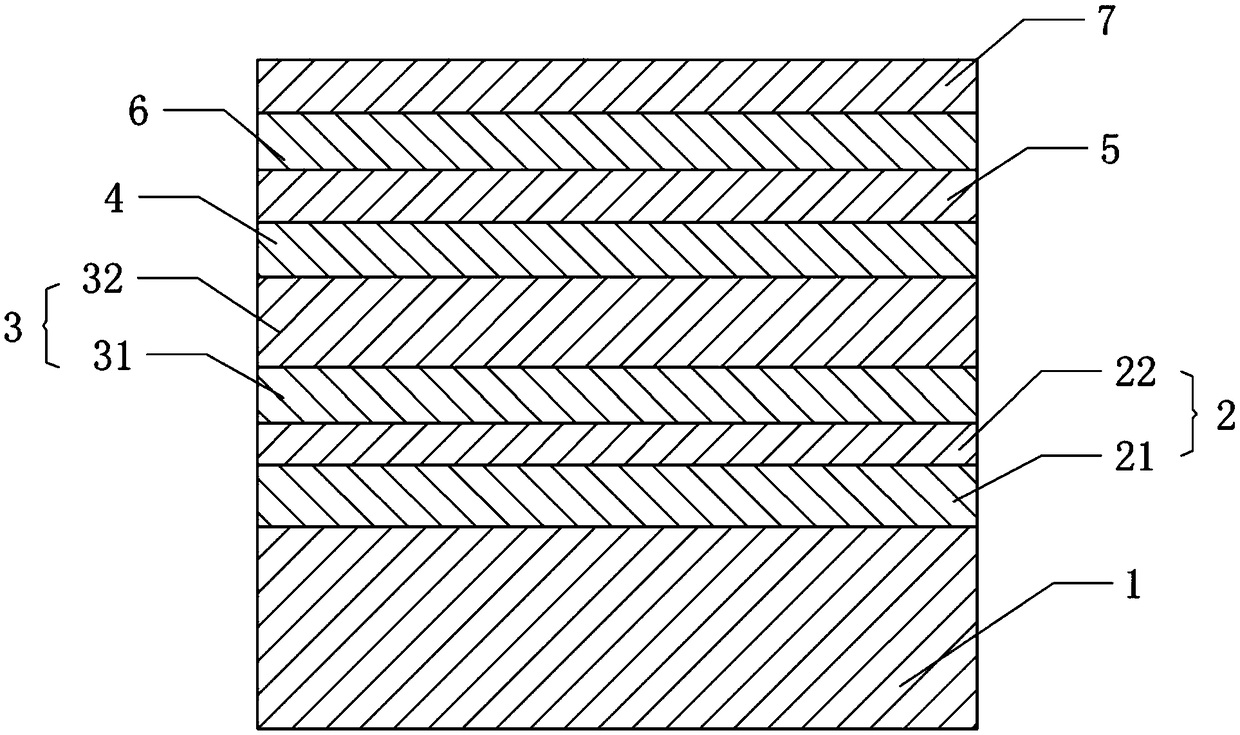

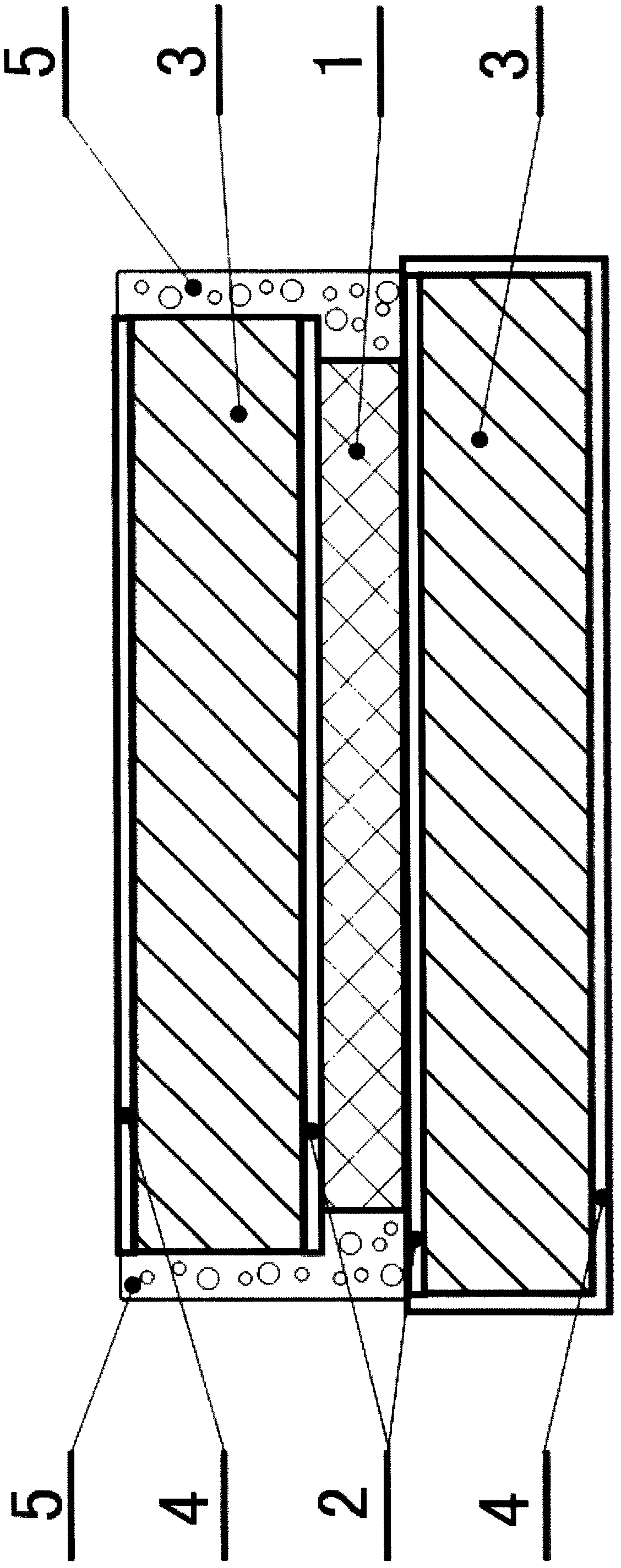

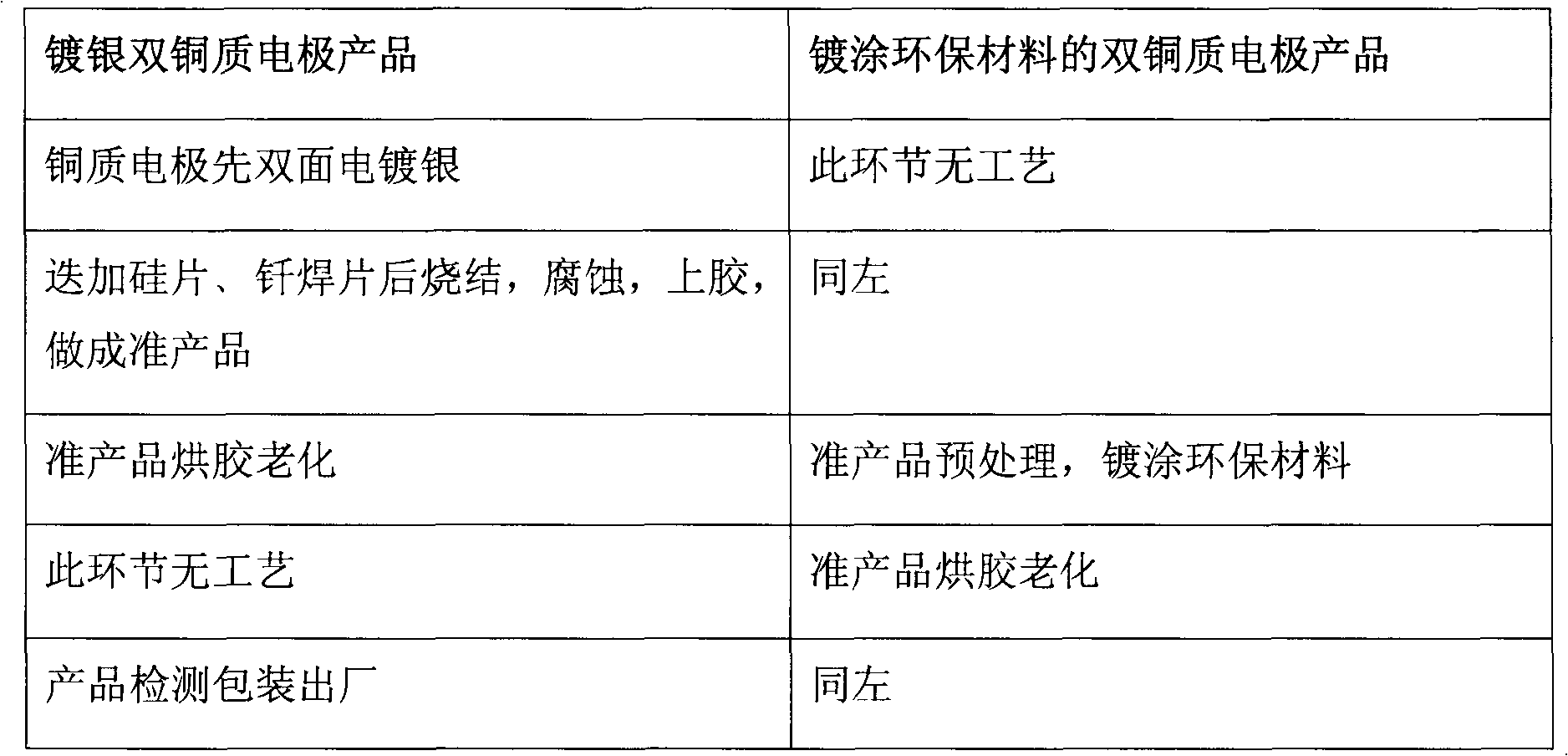

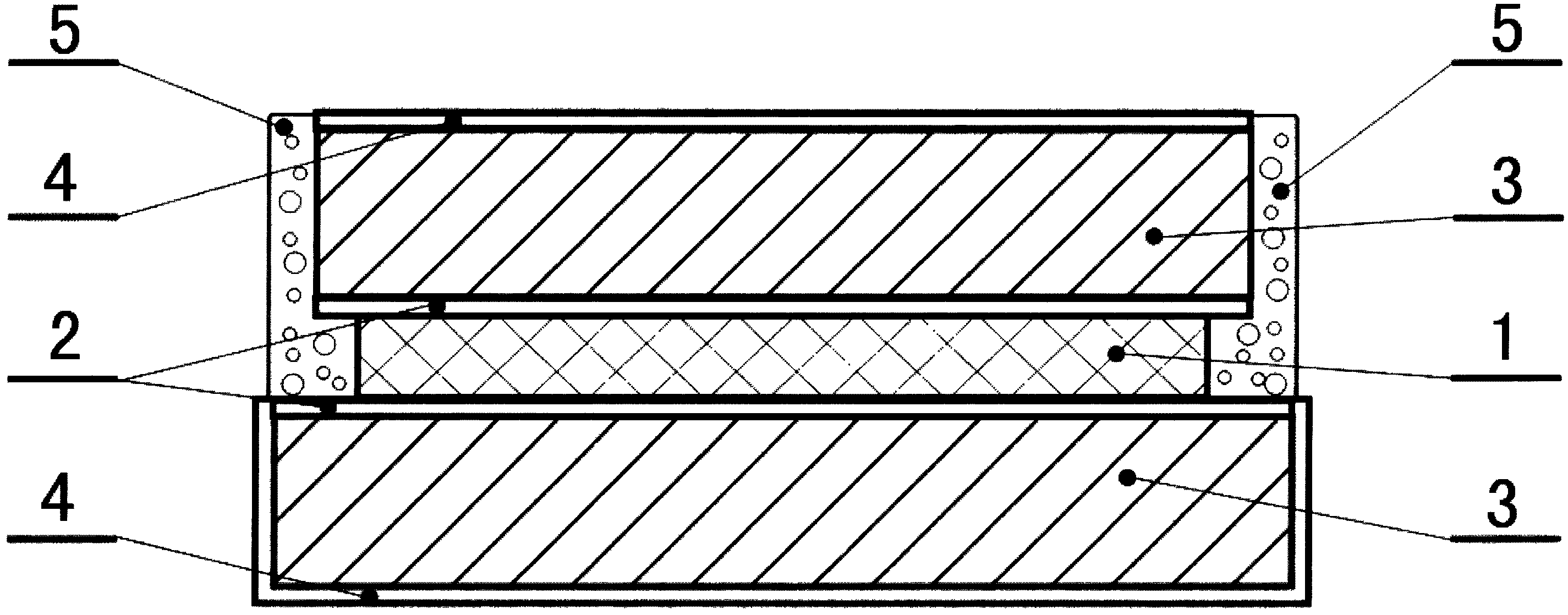

Double-copper-electrode rectifying tube chip made of coated environment-friendly material, and coating process

InactiveCN102637747ALow priceReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesResource consumptionCopper electrode

The invention relates to a process structure with a double-copper-electrode rectifying tube chip coated made of a coated environment-friendly material. Rectifying tube chip products about multiple contradictions, such as the quality, the cost, the resource consumption and the environment protection, can be well coordinated. The process structure has the advantages of low production cost of the conventional lead-surface process structure product and high electrothermal performance of a silver-coated double-copper-electrode product, is environment-friendly during production, does not waste noble metal and is a great technical innovation during production of the rectifying tube chip home and abroad within recent 20 years. A solid structure of the product consists of a silicon slice (1) with a rectification characteristic, a brazing layer (2), copper electrodes (3), a coated environment-friendly material layer (4) and insulative protection rubber (5).

Owner:HUANGSHAN GUIDING ELECTRONICS

High-entropy alloy containing aluminum and iron components suitable for additive manufacturing and modification method thereof

InactiveCN110899712AModification method is simpleLow modification costAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysManganese

The invention provides a modification method of a high-entropy alloy containing aluminum and iron components suitable for additive manufacturing. The method comprises the following steps of: S1: proportioning: preparing high-purity metals and beryllium, wherein the high-purity metals are 4-5 of aluminum, iron, cobalt, chromium, nickel, manganese and titanium, and the aluminum and iron elements account for 40-50 wt% of the high-entropy alloy; and S2, smelting and atomizing to prepare powder, namely smelting high-purity metal and beryllium, and performing atomizing to prepare powder to obtain powder, wherein the smelting temperature is 1100-1300 DEG C, heat preservation is conducted for 15-35 min, after deterioration, atomization is conducted, and beryllium is high-purity beryllium beads. The modification method of the aluminum-iron-based high-entropy alloy powder material is simple, modification can be completed only by adding beryllium as a modified alloy element in the process of preparing the aluminum-iron-based high-entropy alloy powder, and the modification cost is low; and moreover, an amorphous structure can be obtained through additive manufacturing of the modified aluminum-iron-based high-entropy alloy powder material, the density of a formed high-entropy alloy product can reach 99.9% or above, and the requirement for high-entropy alloy additive manufacturing is met.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

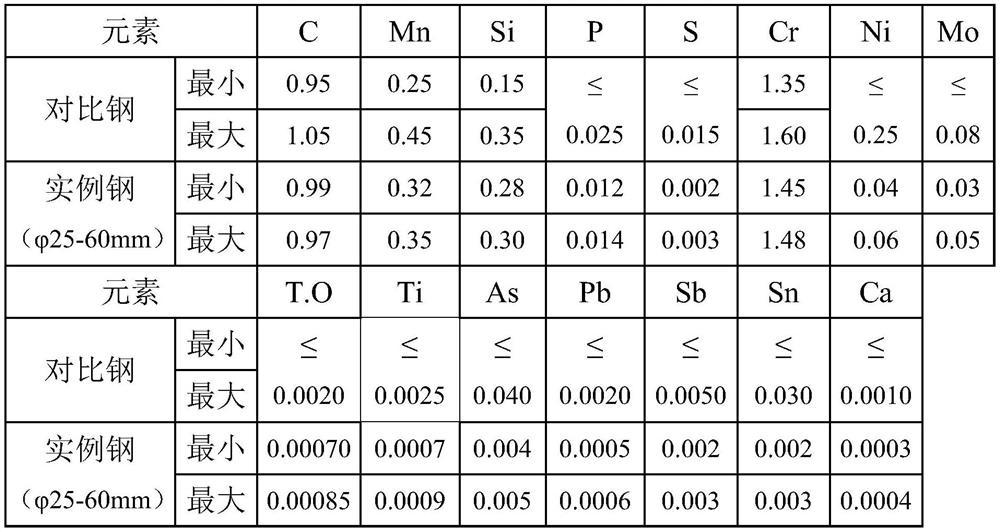

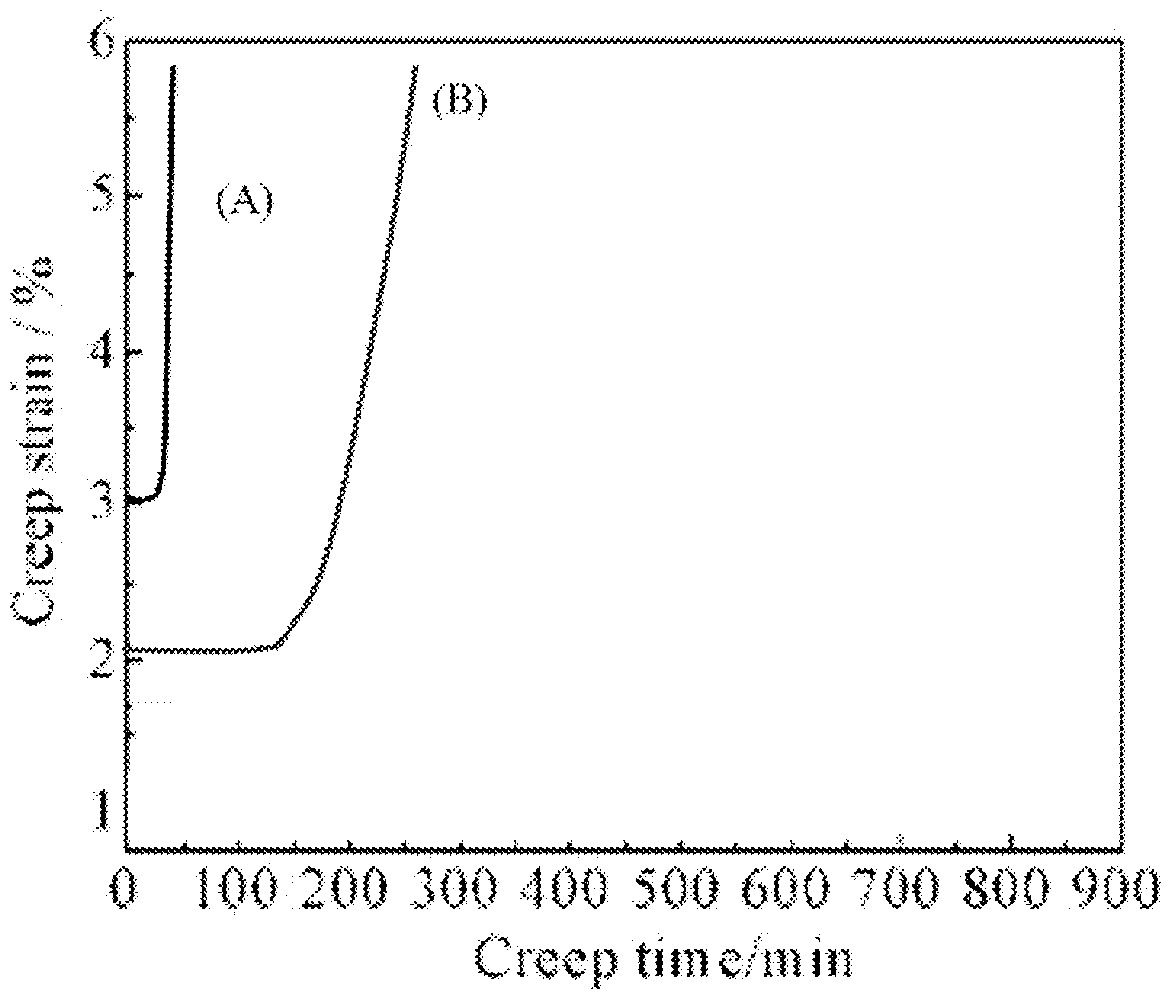

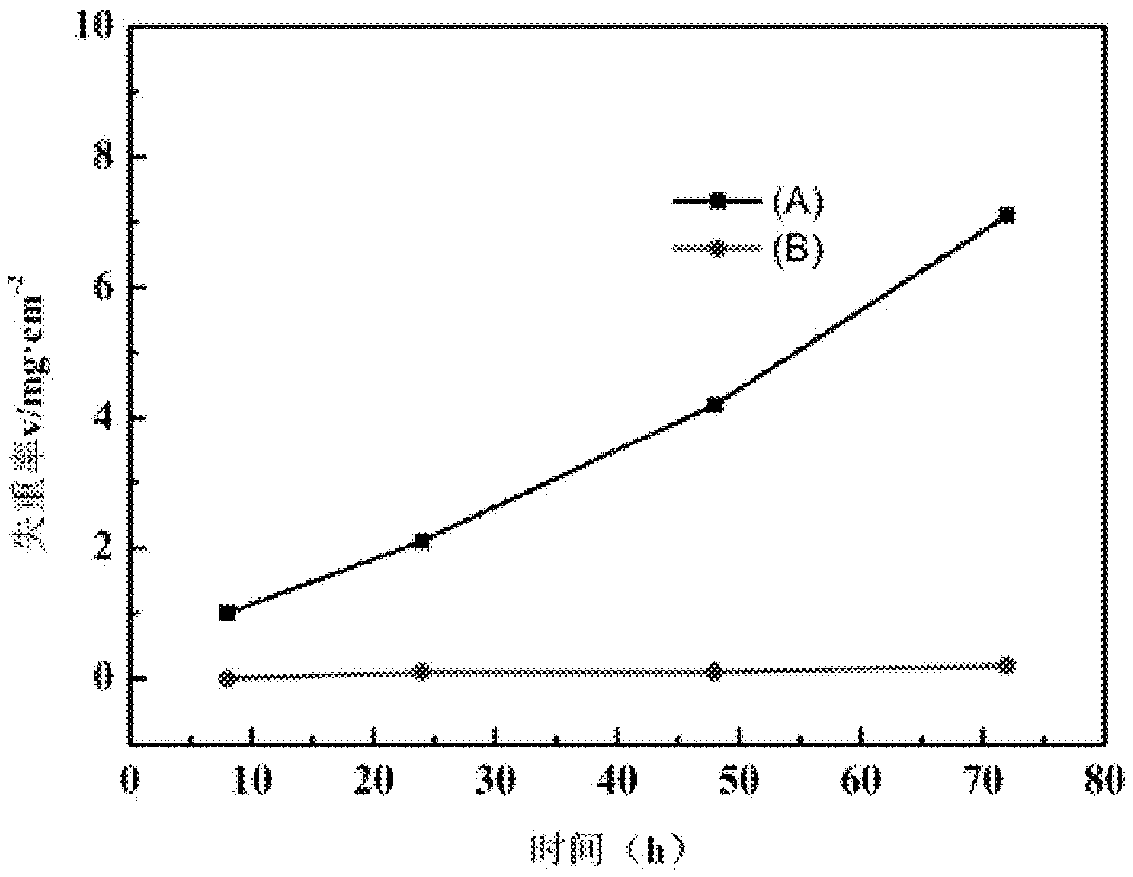

Production method of ultra-pure and ultra-homogeneous high-carbon chromium electroslag bearing steel

ActiveCN113249635AImprove purityImprove homogeneityManufacturing convertersMetal rolling arrangementsNon-metallic inclusionsCarbide

The invention belongs to the technical field of special steel metallurgy, and particularly relates to a production method of ultra-pure and ultra-homogeneous high-carbon chromium electroslag bearing steel. The production method sequentially comprises the steps of round billet continuous casting, electroslag remelting, heating, cogging and rolling. According to the production method, through reasonable production process design and key process technology implementation and control, the produced steel has ultrahigh purity and homogeneity, lower oxygen, titanium and sulfur contents, fewer non-metallic inclusions, finer particles, compact macrostructures, uniform carbides and the like, and meets the requirements of manufacturing of matched high-end bearings in key fields.

Owner:DAYE SPECIAL STEEL CO LTD

Ultralimit copper alloy and preparation method thereof

ActiveCN109609953AExpand the scope of useStrong corrosion resistanceLiquid surface applicatorsMolten spray coatingPrecious metalComposite ceramic

The invention belongs to the technical field of copper alloy material preparation and discloses ultralimit copper alloy and a preparation method thereof. The ultralimit copper alloy comprises a copperalloy matrix, wherein a composite bonding layer, a composite ceramic layer, a reflecting layer, a catadioptric layer, an insulating layer and a foamy carbon layer are successively deposited on the surface of the copper alloy matrix; the composite bonding layer comprises a bonding layer deposited on the surface of the copper alloy matrix and a precious metal layer deposited on the surface of the bonding layer; and the composite ceramic layer comprises a ceramic A layer and a ceramic B layer. Through depositing multiple layers of coatings on the surface of the copper alloy matrix, the usage temperature of the ultralimit copper alloy is increased by 100-500 DEG C higher than a melting point of the original copper alloy matrix, so that the copper alloy can be used under an ultralimit environment. The ultralimit copper alloy is excellent in high temperature mechanical and chemical stability, can be used under the condition of exceeding the melting point of the copper alloy matrix and increases the using range.

Owner:KUNMING UNIV OF SCI & TECH

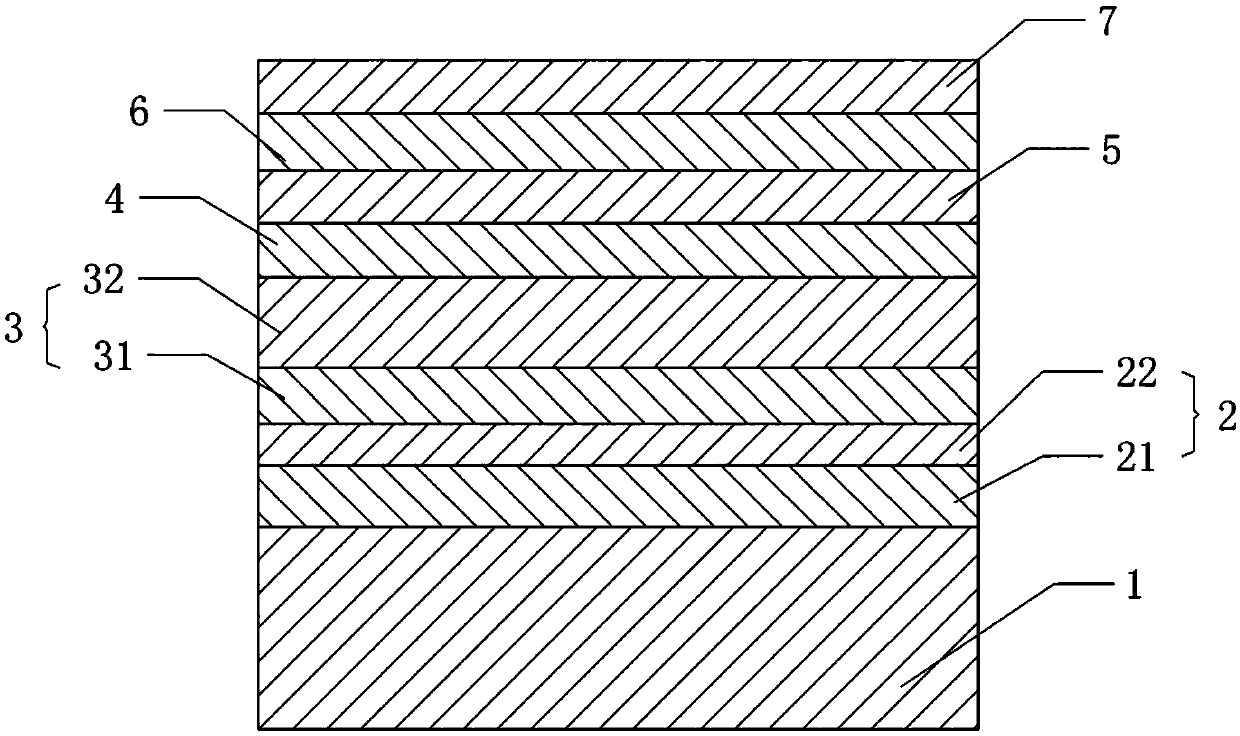

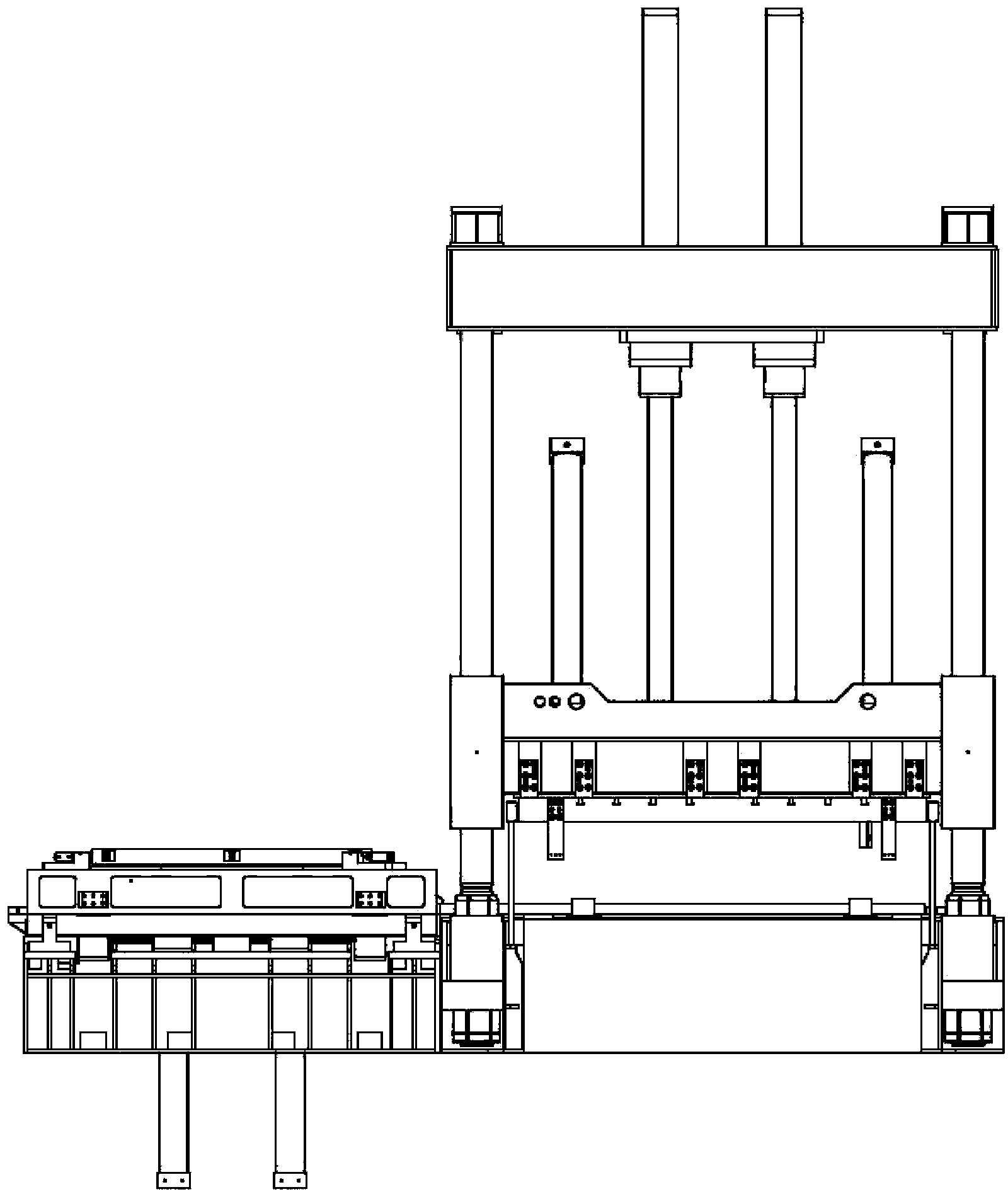

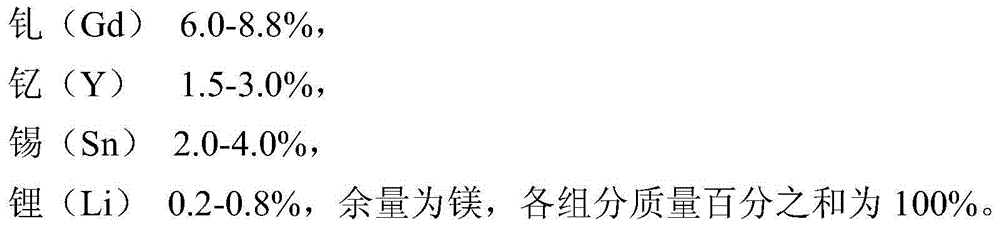

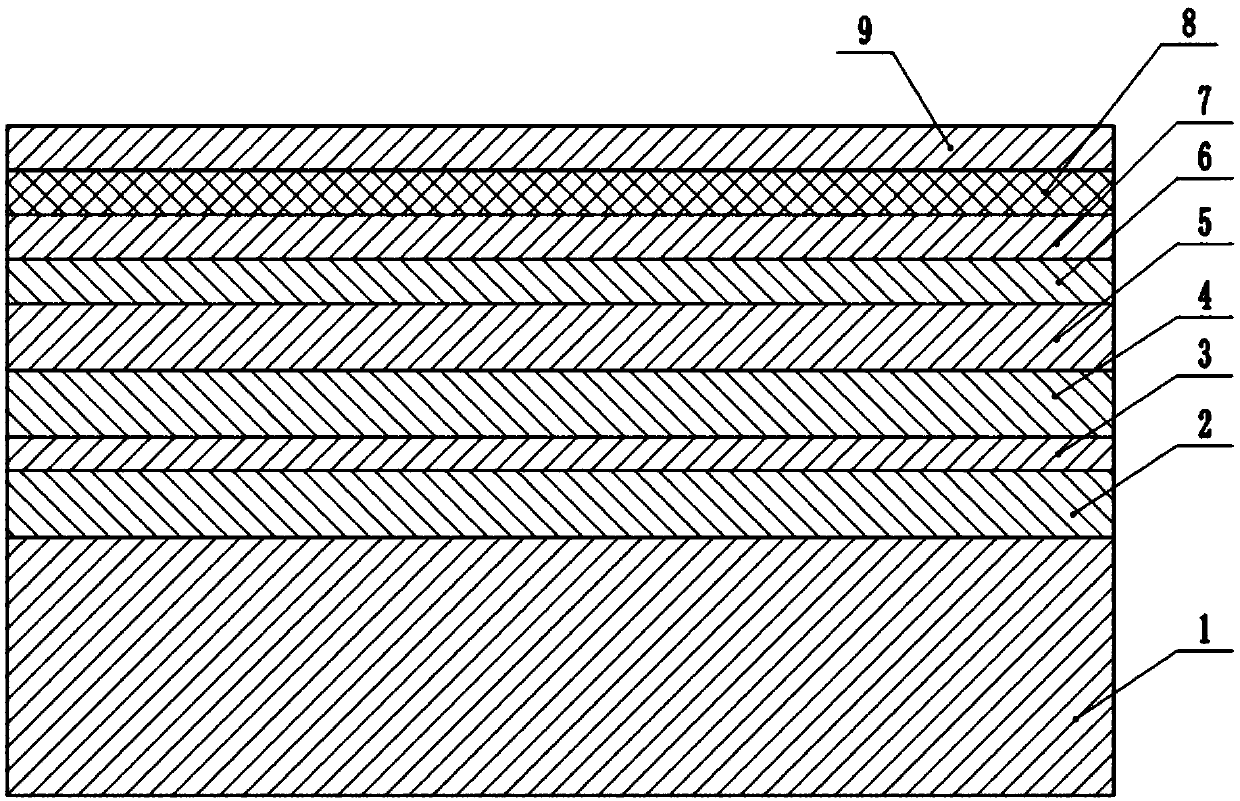

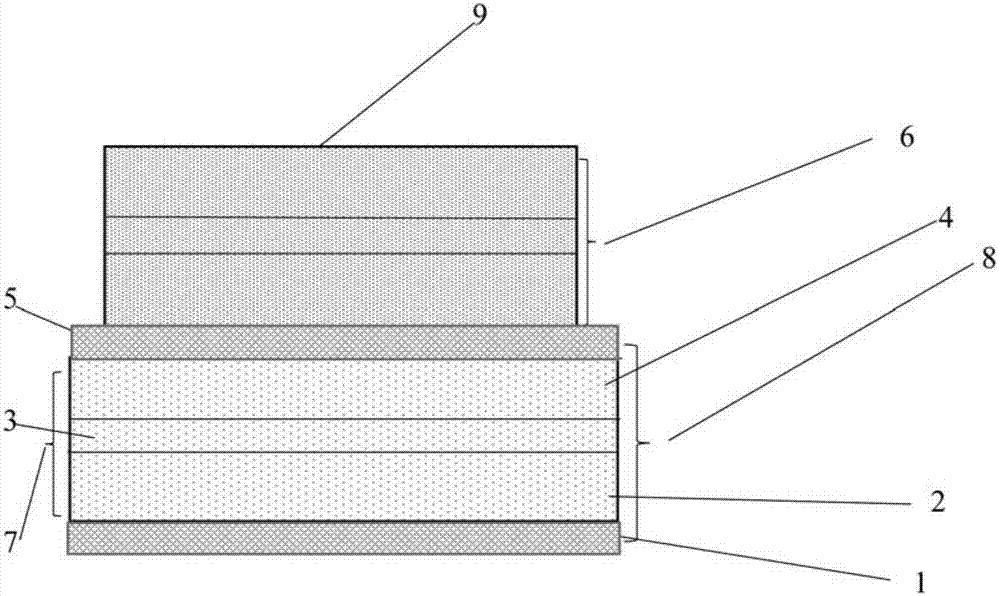

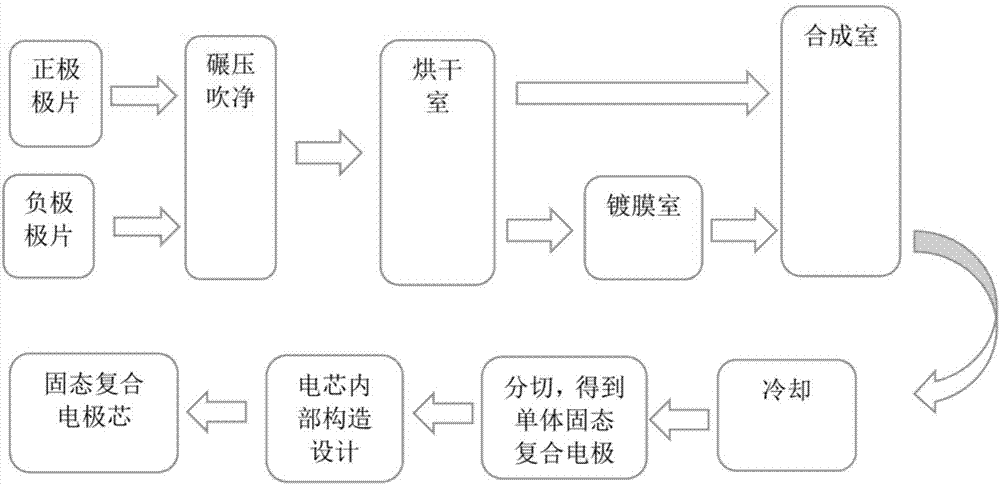

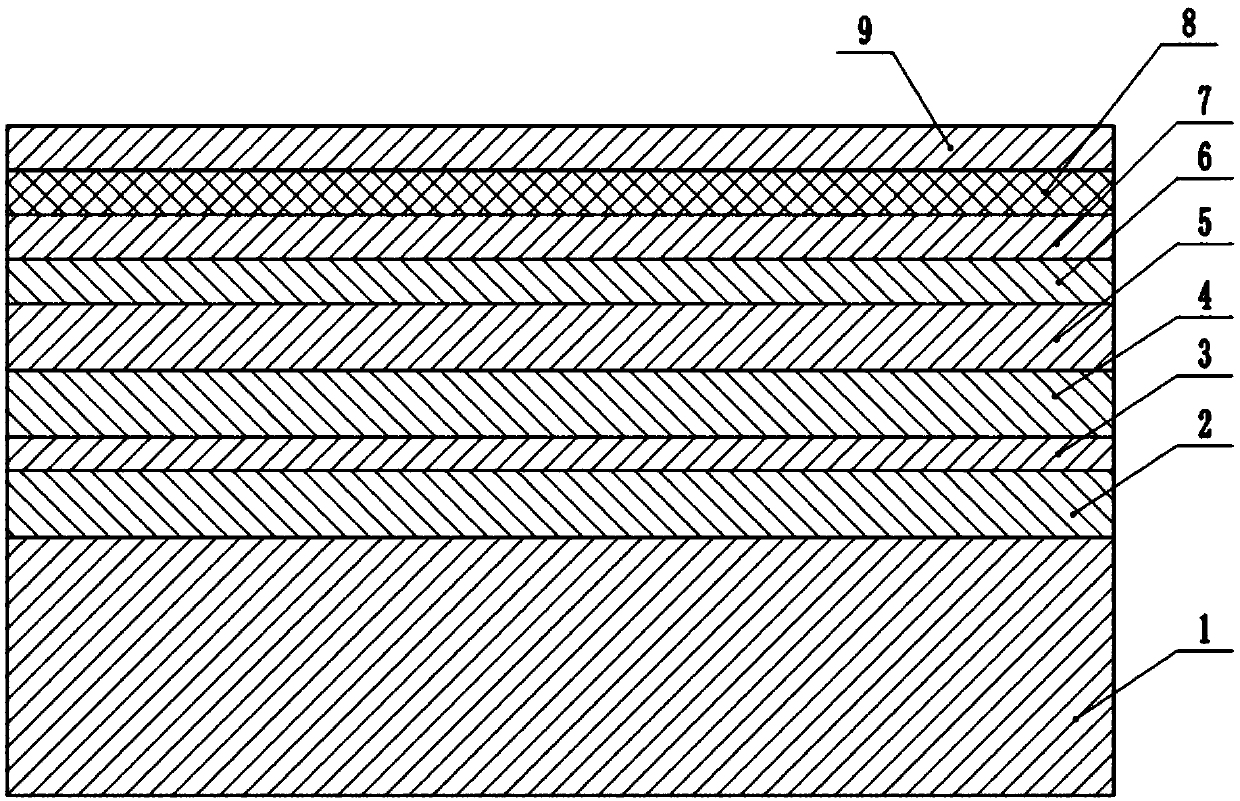

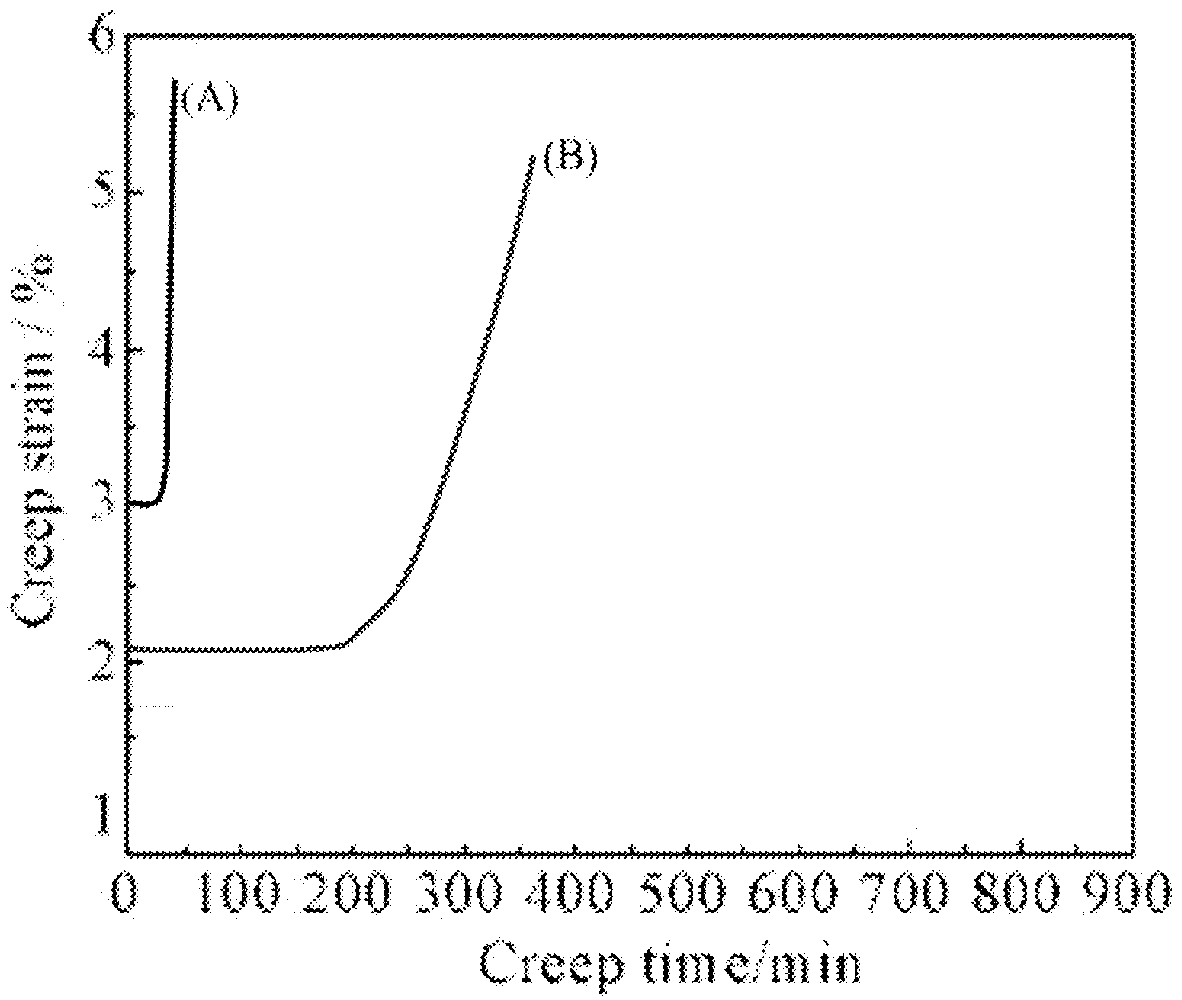

All-solid-state lithium-ion battery and preparation method thereof

PendingCN107425176AMeet the needs of manufacturingAvoid short circuitSolid electrolytesFinal product manufactureSolid state electrolyteAll solid state

The invention discloses an all-solid-state lithium-ion battery and a preparation method thereof. The all-solid-state lithium-ion battery comprises a housing, an insulating diaphragm and a solid-state composite electrode core, wherein the solid-state composite electrode core comprises at least one group of single solid-state composite electrode plates; each single solid-state composite electrode plate comprises a first all-solid-state electrolyte layer, a negative pole piece, a second all-solid-state electrolyte layer and a positive pole piece; each negative pole piece is provided with an A-side active coating and a B-side active coating; each first all-solid-state electrolyte layer is arranged on the corresponding A-side active coating; each second all-solid-state electrolyte layer is arranged on the corresponding B-side active coating; each positive pole piece is arranged on the corresponding second all-solid-state electrolyte layer; and the solid-state composite electrode core is sleeved with the insulating diaphragm and is packaged into the housing. The all-solid-state lithium-ion battery has the advantages that a combinational design of double all-solid-state electrolyte layers, a positive electrode, a negative electrode and an electrolyte is adopted by the all-solid-state lithium-ion battery, and the producing and manufacturing requirements of the all-solid-state lithium-ion batteries of different shapes can be met.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

Ultralimit titanium alloy and preparation method thereof

ActiveCN109554708AGood mechanical stabilityGood chemical stabilitySpecial surfacesSuperimposed coating processCarbon layerComposite ceramic

The invention belongs to the technical field of titanium alloy materials, and discloses an ultralimit titanium alloy and a preparation method thereof. The ultralimit titanium alloy comprises a titanium alloy base body, wherein a composite bonding layer, a composite ceramic layer, a reflecting layer, an anti-refracting layer, an insulating layer and a foamy carbon layer are sequentially deposited on the surface of the titanium alloy base body; the composite bonding layer comprises a bonding layer deposited on the surface of the titanium alloy base body and a noble metal layer deposited on the surface of the bonding layer; and the composite ceramic layer comprises a ceramic layer A and a ceramic layer B. According to the method, the multiple layers of coatings are deposited on the surface ofthe titanium alloy base body, the use temperature of the titanium alloy can be increased to be higher than the melting point of the original titanium alloy base body by 100-500 DEG C so that the titanium alloy can be used in an untralimit environment. The ultralimit titanium alloy has excellent high-temperature mechanical property and chemical stability, can be used under the condition that the temperature is higher than the titanium alloy base body melting point of the titanium alloy, and the application range is enlarged.

Owner:KUNMING UNIV OF SCI & TECH

Super-limit tin alloy and preparation method thereof

ActiveCN109719414ANo problems of cracking or even falling offMeet the needs of manufacturingMolten spray coatingVacuum evaporation coatingWeld seamAlloy

The invention belongs to the technical field of welding, and discloses a super-limit tin alloy and a preparation method thereof. The tin alloy is a welding seam material, and comprises a tin alloy base body, and a bonding layer, a ceramic layer, a sealing coating, a reflecting layer, an anti-refracting layer and an insulating layer are sequentially deposited on the surface of the tin alloy base body. According to the super-limit tin alloy and the preparation method thereof, the limit of the traditional idea that when the environment temperature is higher than the using temperature of a material, the material has to be replaced is broken through, the coating is deposited on the surface of the material, so that the using temperature of the material is improved, then the super-limit tin alloywelding seam material can be used for a long time under an ultra-high temperature environment, the use requirements of the temperature rise of an engine during the acceleration of air vehicles such as an aircraft are met, and the acceleration of the aircraft and other air vehicles is realized.

Owner:陕西天璇涂层科技有限公司

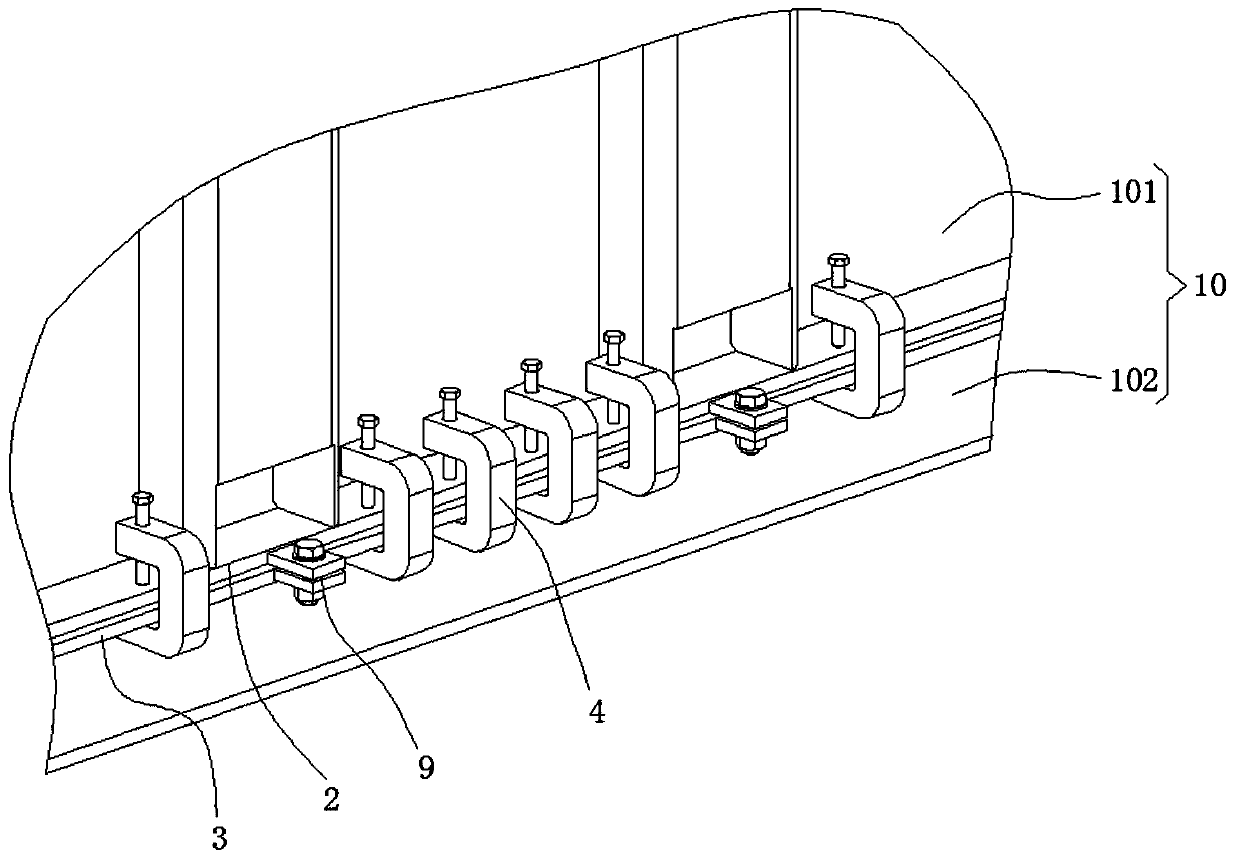

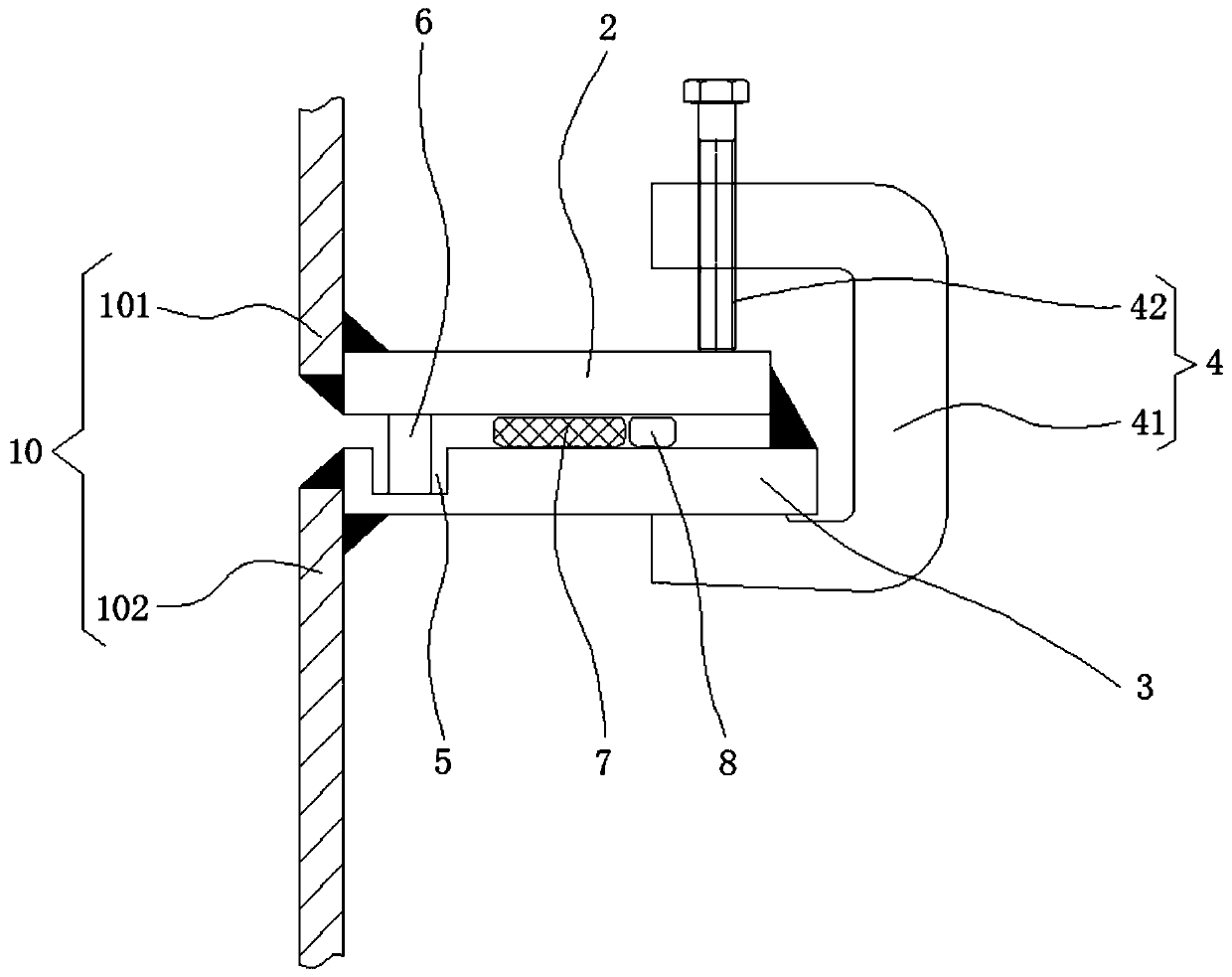

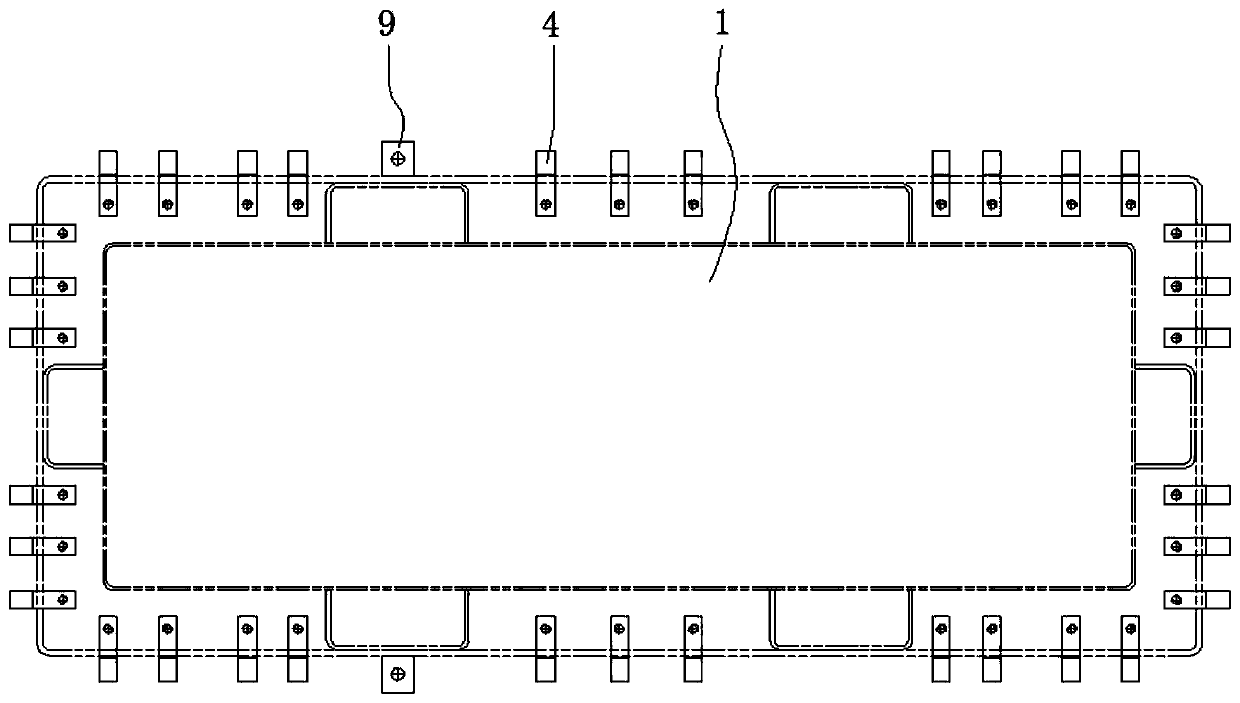

Tank edge welding structure for full-sealed transformer

PendingCN111009390AMeet the needs of manufacturingSimple structureTransformers/inductances coolingTransformerEngineering

The invention provides a tank edge welding structure for a full-sealed transformer. The tank edge welding structure for the fully-sealed transformer comprises an oil tank, the oil tank comprises an upper tank body and a lower tank body, the upper tank body is arranged at the top of the lower tank body, an upper tank edge is arranged on the outer surface of the bottom of the upper tank body, and alower tank edge is arranged on the outer surface of the top of the lower tank body; and a clamp is arranged between one side of the upper tank edge and one side of the lower tank edge. The invention provides the tank edge welding structure for the full-sealed transformer, the reasonable arrangement can be realized according to actual requirements of products; the upper tank edge and the lower tankedge are uniformly stressed; the tank edge welding structure has the advantages of simplifying in-plant operation, reducing manufacturing difficulty of the tank edge welding structure, enabling manufacturing of the fully-sealed transformer to be simpler and more convenient, achieving sealing and positioning through mutual embedding of the upper tank edge and the lower tank edge, meeting requirements of transformer production and manufacturing, being simple in structure and convenient to operate, reducing manufacturing cost and improving working efficiency.

Owner:TIANWEI BAOBIAN HEFEI TRANSFORMER

Convenient-to-adjust automatic surface mounting device for electronic component production

InactiveCN113490407AMeet the needs of manufacturingEasy to absorb and moveElectrical componentsSurface mountingGear wheel

The invention relates to the technical field of electronic components, and discloses a convenient-to-adjust automatic surface mounting device for electronic component production, which comprises a rotating shaft and a platform, the surface of the rotating shaft is fixedly connected with an adsorption mechanism, the adsorption mechanism comprises a rotating frame, and the interior of the rotating frame is slidably connected with a sliding plate. An inserting rod is inserted into the surface of the sliding plate, a moving block is fixedly connected to the surface of the sliding plate, a connecting rod is slidably connected to the surface of the moving block, a connecting plate is fixedly connected to the bottom end of the rotating frame, a suction cup is rotatably connected to the interior of the connecting plate, and a first gear is arranged on the surface of the suction cup. Through the adsorption mechanism, the adsorption area of the suction cup can be properly adjusted, so that the requirements of electronic elements with different sizes and areas can be met, the electronic elements can be better adsorbed and moved, the manufacturing requirements are better met, and the functionality and practicability of the device are improved.

Owner:于春梅

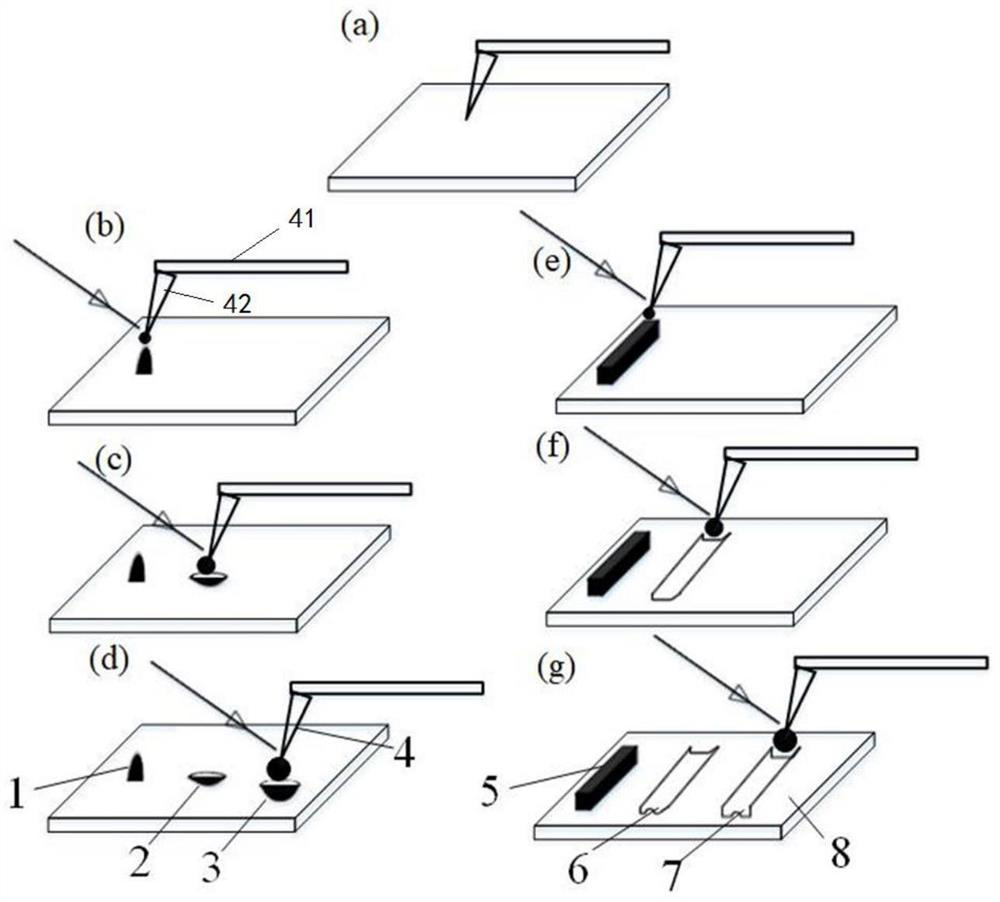

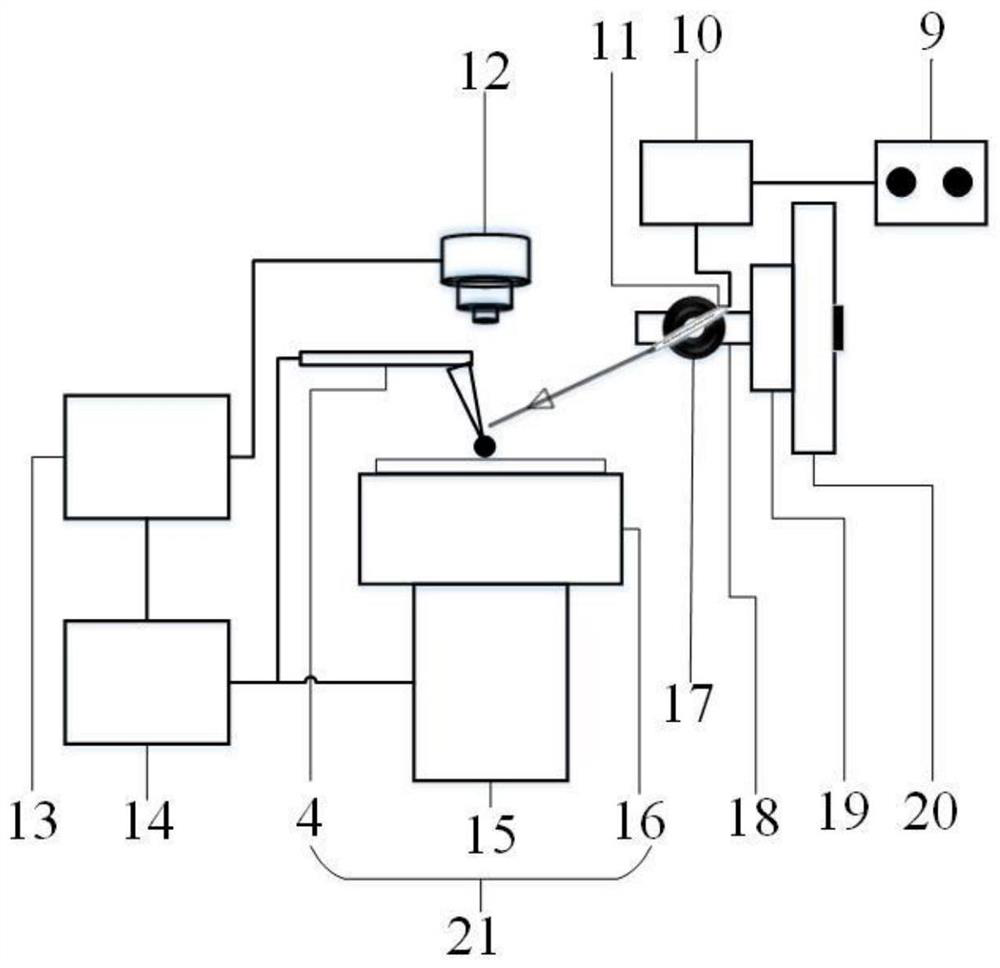

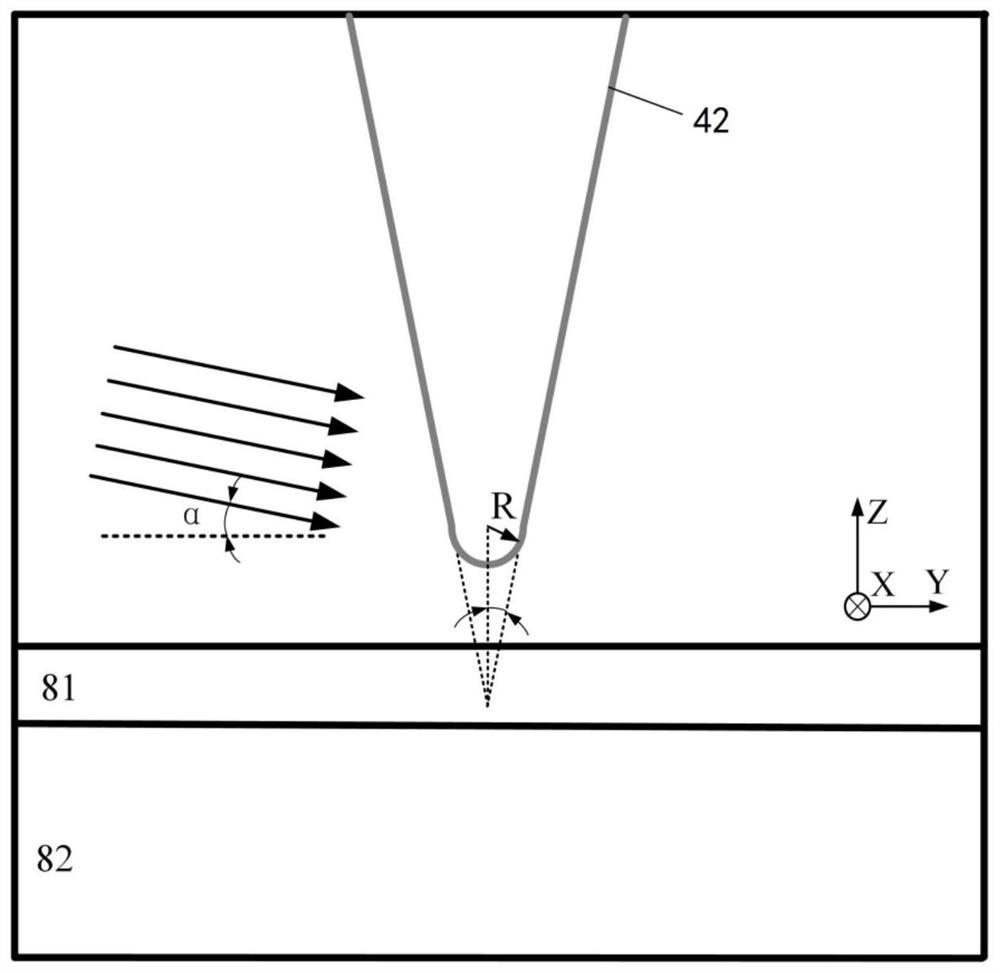

Device and method for processing two-dimensional nanostructure

The invention discloses a device and method for processing a two-dimensional nano structure, belongs to the field of near-field optics and nano photoetching, and aims to overcome the defects in the prior art, an optical fiber continuous laser composite AFM probe induction near field enhancement technology is adopted, a controllable form of a two-dimensional nanostructure is manufactured by adjusting the laser wavelength and inducing a controllable enhanced near field, the change of the laser wavelength can cause an AFM probe enhanced electromagnetic field to generate a het-bond, the AFM probe enhanced electromagnetic field can generate a het-bond, the morphological change of the nanostructure is determined according to the relative magnitude of energy required for enhancing the near field and the surface structure change of the sample. According to the method, the probe does not need to be replaced and damaged, nanostructures in different forms are rapidly and accurately manufactured in a non-contact mode, the pattern writing time is in the microsecond level, and the requirement of device manufacturing can be met.

Owner:XI AN JIAOTONG UNIV

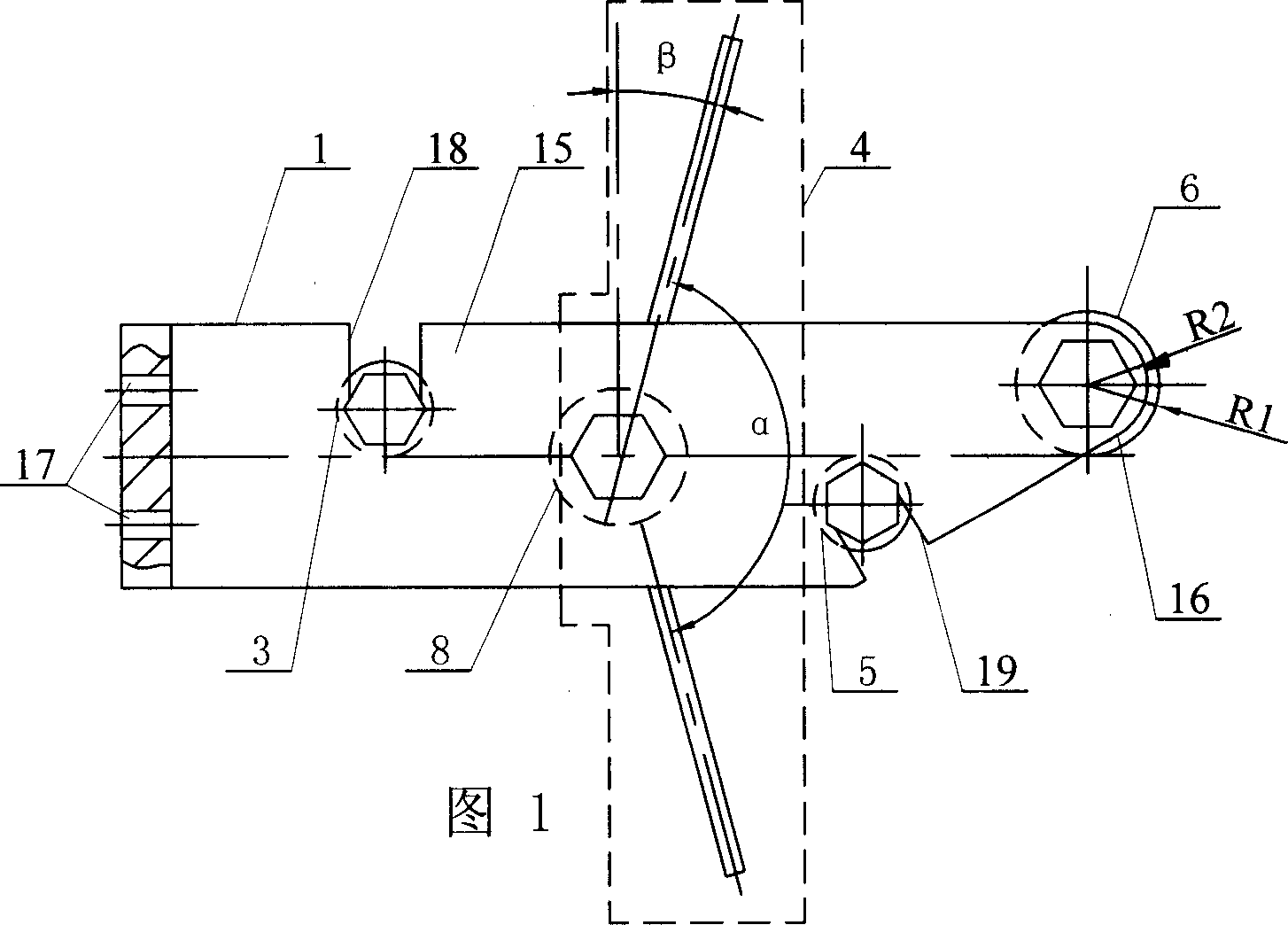

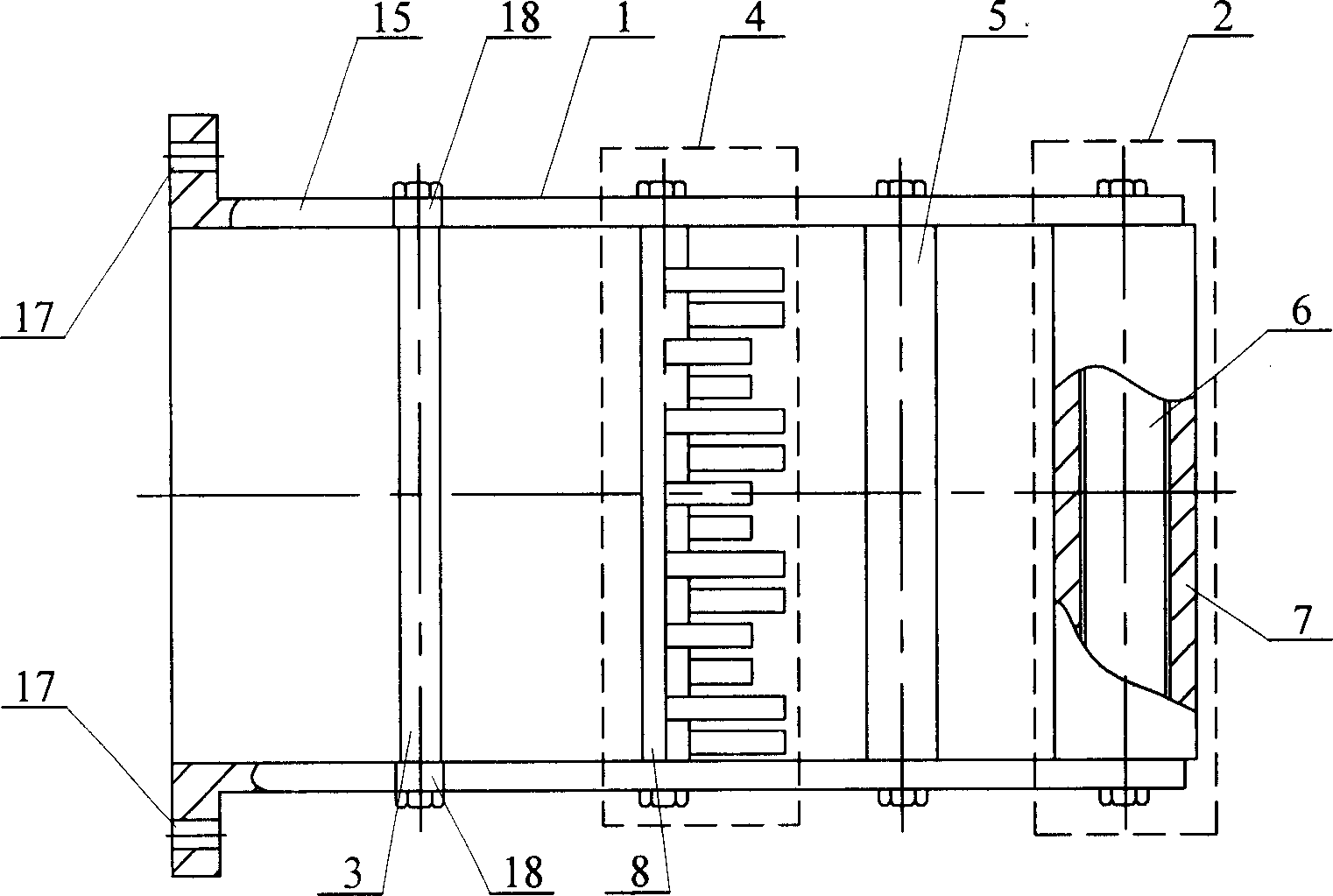

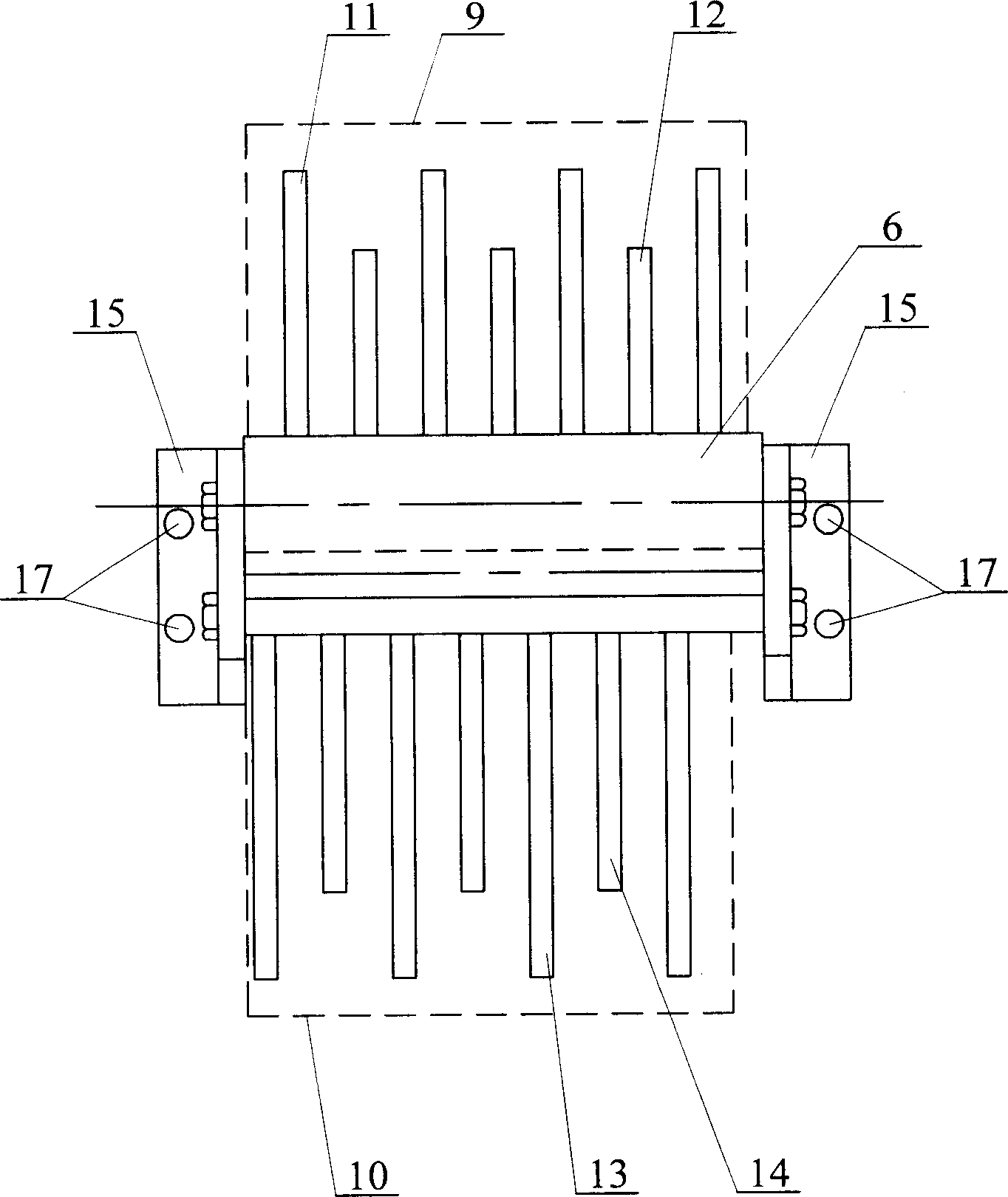

Oscillating head mechanism of fiber winding machine

The present invention relates to fiber winding machine, and is especially the swinging mechanism of fiber winding machine. The present invention includes a yarn arranging roller assembly set on the yarn discharging end on the frame, an upper yarn pressing roller set inside the yarn feeding end of the frame, a yarn separating roller assembly set between the upper yarn pressing roller and the yarn arranging roller assembly, and a lower yarn pressing roller set between the yarn separating roller assembly and the yarn arranging roller assembly. The yarn arranging roller assembly consists of a yarn arranging roller and a yarn arranging roller sleeve set on the yarn arranging roller and rotation fitting with the yarn arranging roller, and the yarn arranging roller has ends fixed to the frame. The present invention has excellent yarn expanding effect, and can meet the requirement of making composite material member in aeronautical and astronautical industry.

Owner:HARBIN INST OF TECH

Multi-station angle changeable moving-out template capable of achieving positioning and locking of die spotting machine

InactiveCN105598829AMeet the needs of manufacturingReduce use costWork carriersDrive motorEngineering

The invention relates to a multi-station angle changeable moving-out template capable of achieving positioning and locking of a die spotting machine. The multi-station angle changeable moving-out template is composed of a rotary table rotating mechanism and a template overturning mechanism, and comprises a rotary table body and a moving-out overturning template. Positioning blocks surrounding the table center are arranged on a table face of the rotary table body. A center rotating shaft connected with the moving-out template is arranged in the table center of the rotary table body. The moving-out template is provided with positioning locks. The moving-out template is internally provided with a jacking oil cylinder and a drive motor. The slope of the lower end face of a moving-out base is connected with overturning oil cylinders. The two positioning locks are symmetrical about the table center of the rotary table body. Each positioning lock comprises a positioning lock block and a positioning oil cylinder, wherein an extending rod of the positioning oil cylinder points at the circle center of the rotary table body and is connected with the positioning lock block, and the positioning lock block abuts against the side wall of the positioning block when extending out. Due to the fact that the moving-out template is provided with the rotary table rotating mechanism, the moving-out template has a station switching function; due to the fact that the moving-out template is provided with the overturning mechanism, the moving-out template has an angle changing function.

Owner:宁波顺兴机械制造有限公司

Manufacturing process of precious metal solid watch case

PendingCN114779602AAccelerate solidificationReduce exposureVacuum evaporation coatingSputtering coatingMetal particleMachining

The invention relates to the technical field of watch case machining, in particular to a precious metal solid watch case manufacturing process which is characterized by comprising the steps that 1, a blank drawing is designed for a product needing to be machined, and a mold is designed according to the blank drawing; 2, precious metal is cut into metal particles, the mold is installed on a rough blank machine, the mold is electrically connected with the rough blank machine, and the metal particles are fed into the mold; 3, the metal particles in the mold are heated into molten metal; 4, inert gas is filled into the cavity until the molten metal is cooled to the normal temperature; 5, taking out the rough blank from the cavity, and polishing the rough blank; 6, an inlaying hole is formed in the rough blank through a tapping machine; 7, plating a layer of titanium film on the outer surface of the rough blank; 8, the jade is pressed into the rough blank, and then the rough blank is subjected to fine carving; and 9, the rough blank is put into a centrifugal finishing machine to be subjected to finishing, and the finished watch case is obtained. The watch case has the effect of meeting the requirement for manufacturing the watch case jointly made of precious metal and jade.

Owner:东莞塘厦泰兴表业制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com