Multi-station variable-angle removing template for die spotting machine

A multi-station, clamping machine technology, which is applied in the field of moving out the template from the lower seat of the clamping machine, can solve the problems of inability to turn over and the template can only be moved out in parallel, so as to improve product quality, facilitate comparison and observation, and enhance market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

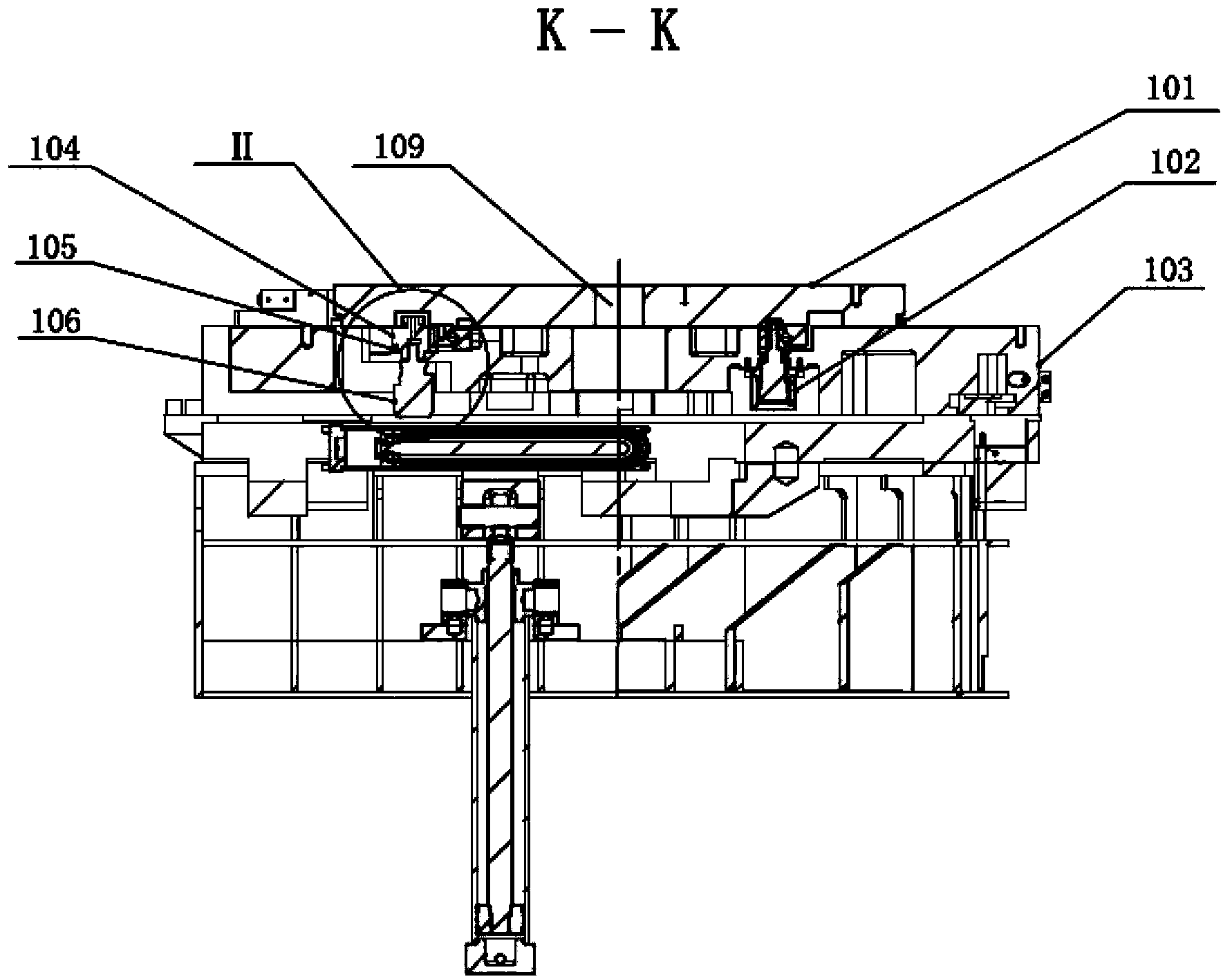

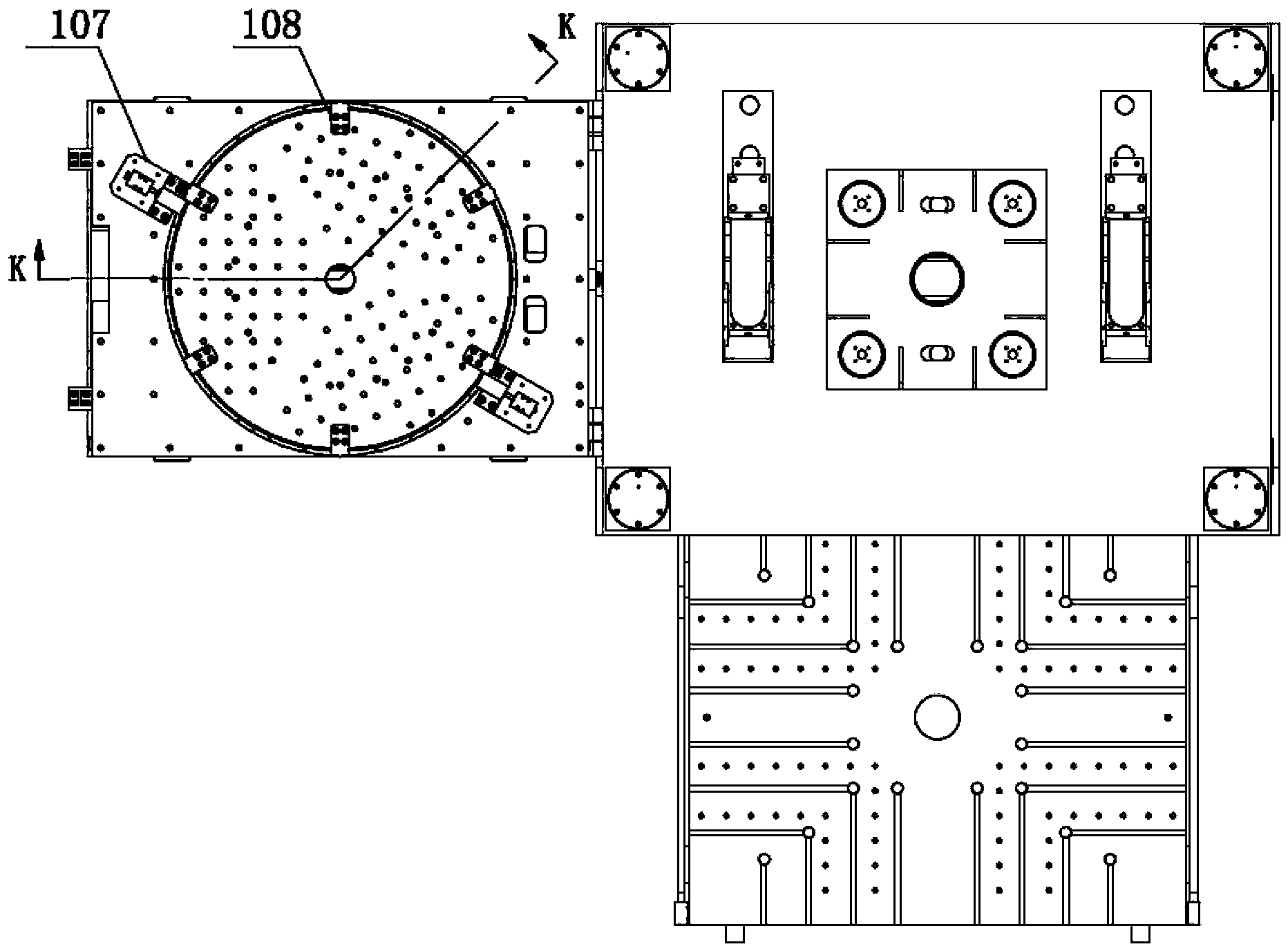

[0026] For the multi-station switching of the mold clamping machine to move out the template, a turntable rotation mechanism is set on the lower base of the mold clamping machine to move out the template. When switching between stations, firstly, the jack cylinder 102 located at the lower part of the turntable body 101 will turn the turntable body 101 is jacked up to separate the turntable body 101 from the removal template 103, and the drive motor 106 starts to drive the turntable body 101 to rotate around the central shaft 109, and at the same time, the motor gear 104 drives the counting gear 105 to move, and the counting gear 105 counts the rotation of the turntable body 101. Angle, and by locking the positioning lock 107 and the positioning block 108, the rotation angle of the turntable body 101 can be accurately positioned, wherein the turntable body 101 can respectively carry out three positions of 0°-120°-240°-0° and 0° °-180°-0° two-position switching.

Embodiment 2

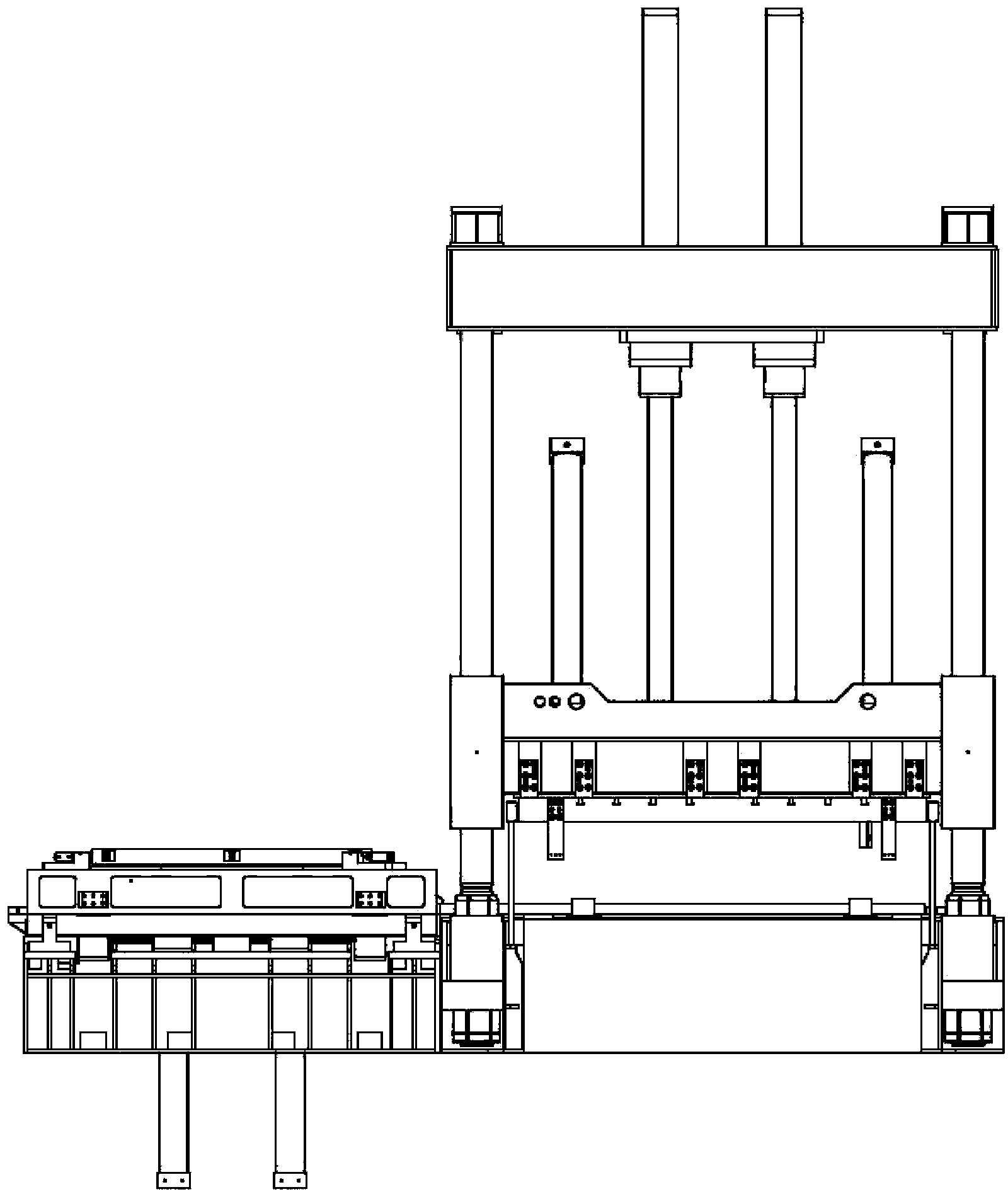

[0028] In view of the multi-angle transformation of the mold clamping machine moving out the template, a template turning mechanism is set on the moving out template of the lower seat of the mold clamping machine. The template 103 and the flip-out template 201 are locked, and the flip cylinder 206 starts to drive the flip-out template 201 and the template 103 to rotate around the drive pin 202 of the flip-out template together, so that the flip-out template 103 is turned over to the operating side. The template 103 stops after turning over 60° together, and the working plane on the template 103 is moved out at the same direction as the working plane of the overturned template in the middle seat of the clamping machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com