Convenient-to-adjust automatic surface mounting device for electronic component production

An electronic component, automatic patch technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of low production efficiency, occurrence, affecting work efficiency, etc., to achieve the effect of increasing functionality and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

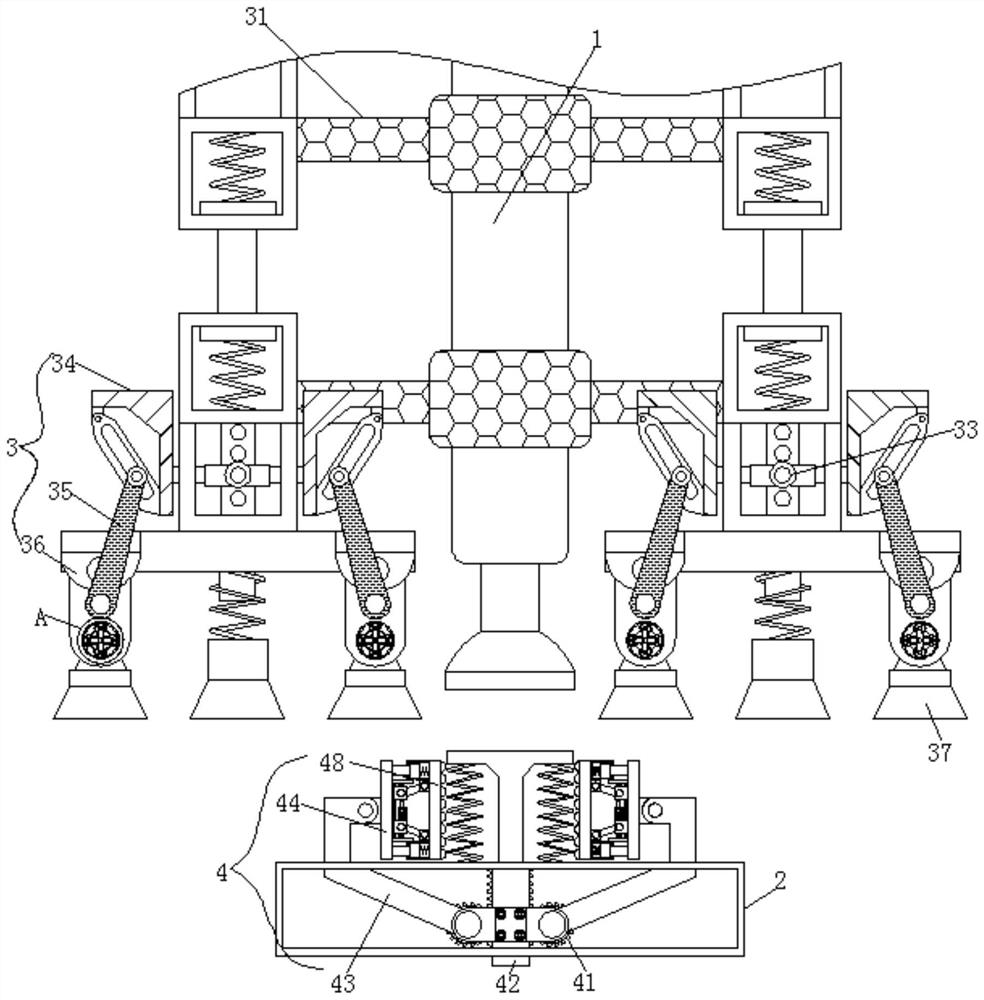

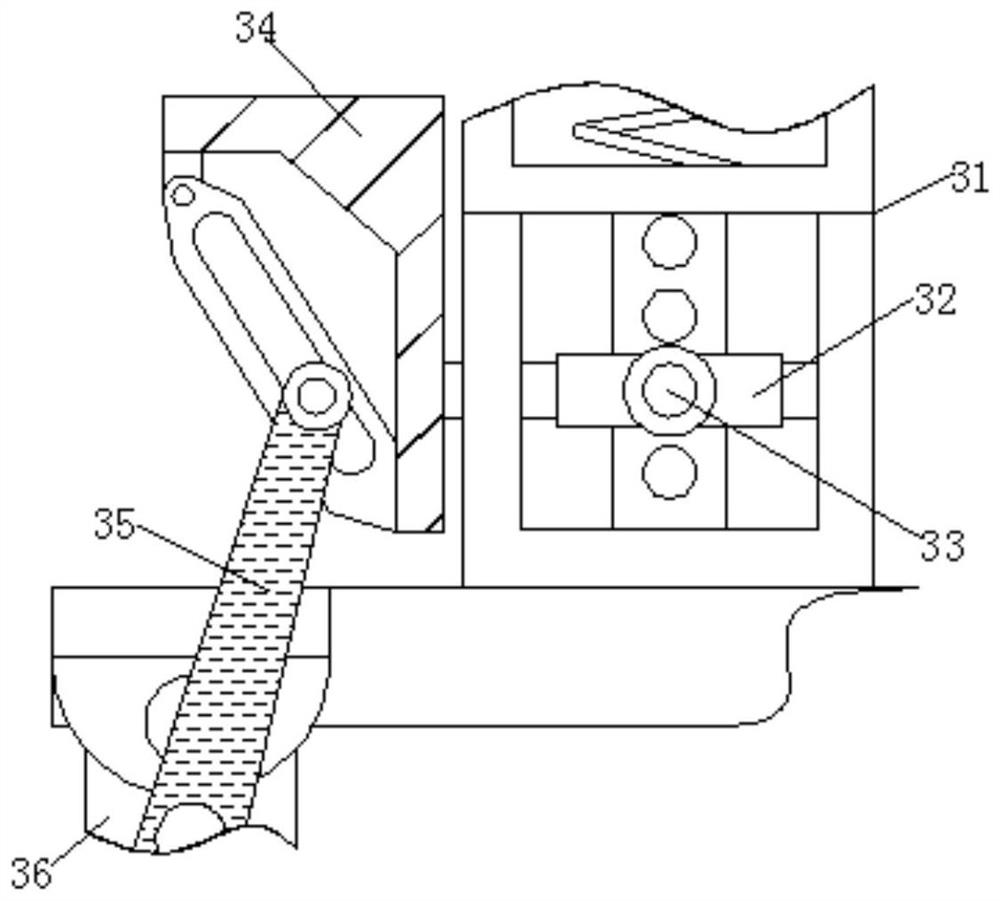

[0026] see Figure 1-3 , a conveniently adjustable automatic placement device for the production of electronic components, comprising a rotating shaft 1 and a platform 2, the surface of the rotating shaft 1 is fixedly connected with an adsorption mechanism 3, the adsorption mechanism 3 includes a turret 31, the left and right sides of the turret 31 are integrally It is set as a telescopic structure to avoid damage to the electronic components when the device absorbs the electronic components. A slide bar is arranged inside the turret 31, and the slide plate 32 slides on its surface, and the slide bar is provided with a hole, and the insertion rod 33 Interlocking with the hole slot, using the snap connection between the hole slot and the insertion rod 33 to control the height of the slide plate 32 sliding on the slide bar, the inside of the turret 31 is slidingly connected with the slide plate 32, and the surface of the slide plate 32 is plugged with a Insert bar 33, the surfac...

Embodiment 2

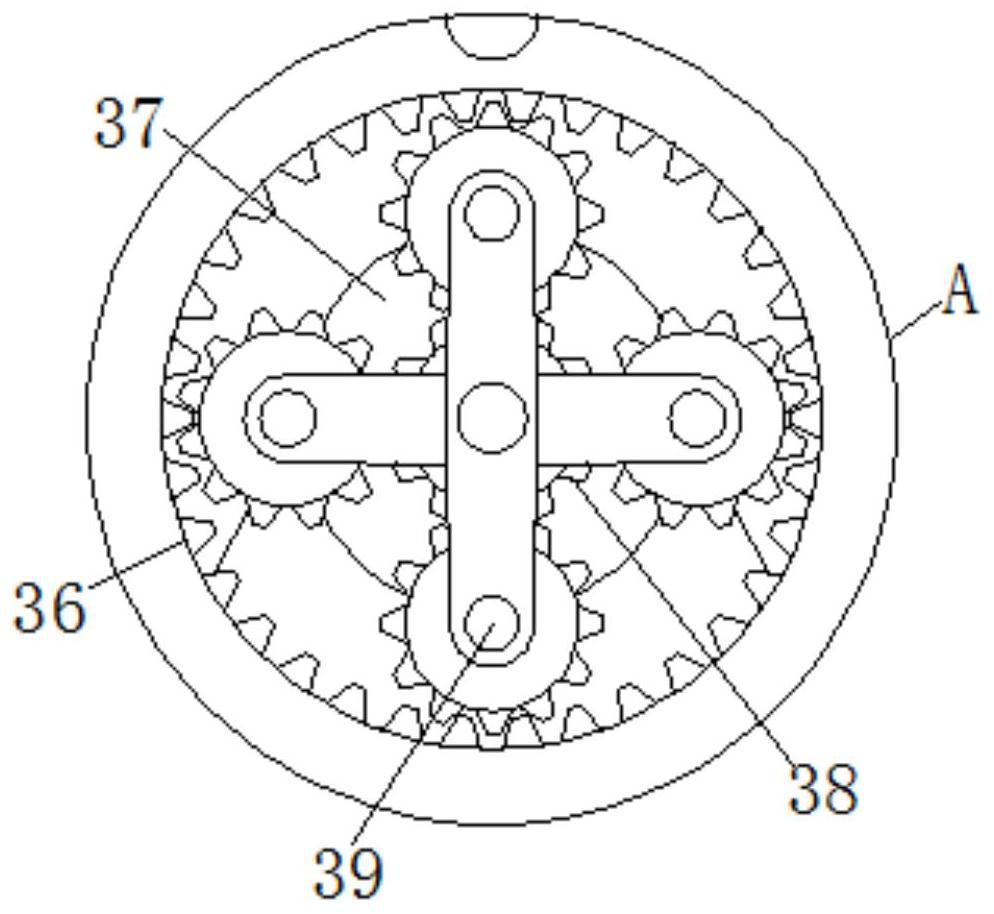

[0028] see figure 1 and Figure 4 , a conveniently adjustable automatic placement device for the production of electronic components, comprising a rotating shaft 1 and a platform 2, the surface of the rotating shaft 1 is fixedly connected with an adsorption mechanism 3, the adsorption mechanism 3 includes a turret 31, and the interior of the turret 31 is slidingly connected with Sliding plate 32, the surface of sliding plate 32 is plugged with insertion rod 33, the surface of sliding plate 32 is fixedly connected with moving block 34, the surface of moving block 34 is slidably connected with connecting rod 35, and the bottom end of turret 31 is fixedly connected with connecting rod 34. Plate 36, the inside of connecting plate 36 is connected with suction cup 37 for rotation, the surface of suction cup 37 is provided with first gear 38, the surface of first gear 38 is connected with rotation tooth 39, and the inside of platform 2 is connected with clamping mechanism 4 for rotat...

Embodiment 3

[0030] see Figure 1-4, a conveniently adjustable automatic placement device for the production of electronic components, comprising a rotating shaft 1 and a platform 2, the surface of the rotating shaft 1 is fixedly connected with an adsorption mechanism 3, the adsorption mechanism 3 includes a turret 31, the left and right sides of the turret 31 are integrally It is set as a telescopic structure to avoid damage to the electronic components when the device absorbs the electronic components. A slide bar is arranged inside the turret 31, and the slide plate 32 slides on its surface, and the slide bar is provided with a hole, and the insertion rod 33 Interlocking with the hole slot, using the snap connection between the hole slot and the insertion rod 33 to control the height of the slide plate 32 sliding on the slide bar, the inside of the turret 31 is slidingly connected with the slide plate 32, and the surface of the slide plate 32 is plugged with a Insert bar 33, the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com