Tank edge welding structure for full-sealed transformer

A welding structure and transformer technology, applied in the field of power transformers, can solve problems such as poor sealing and oil leakage, and achieve the effects of convenient operation, improved work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

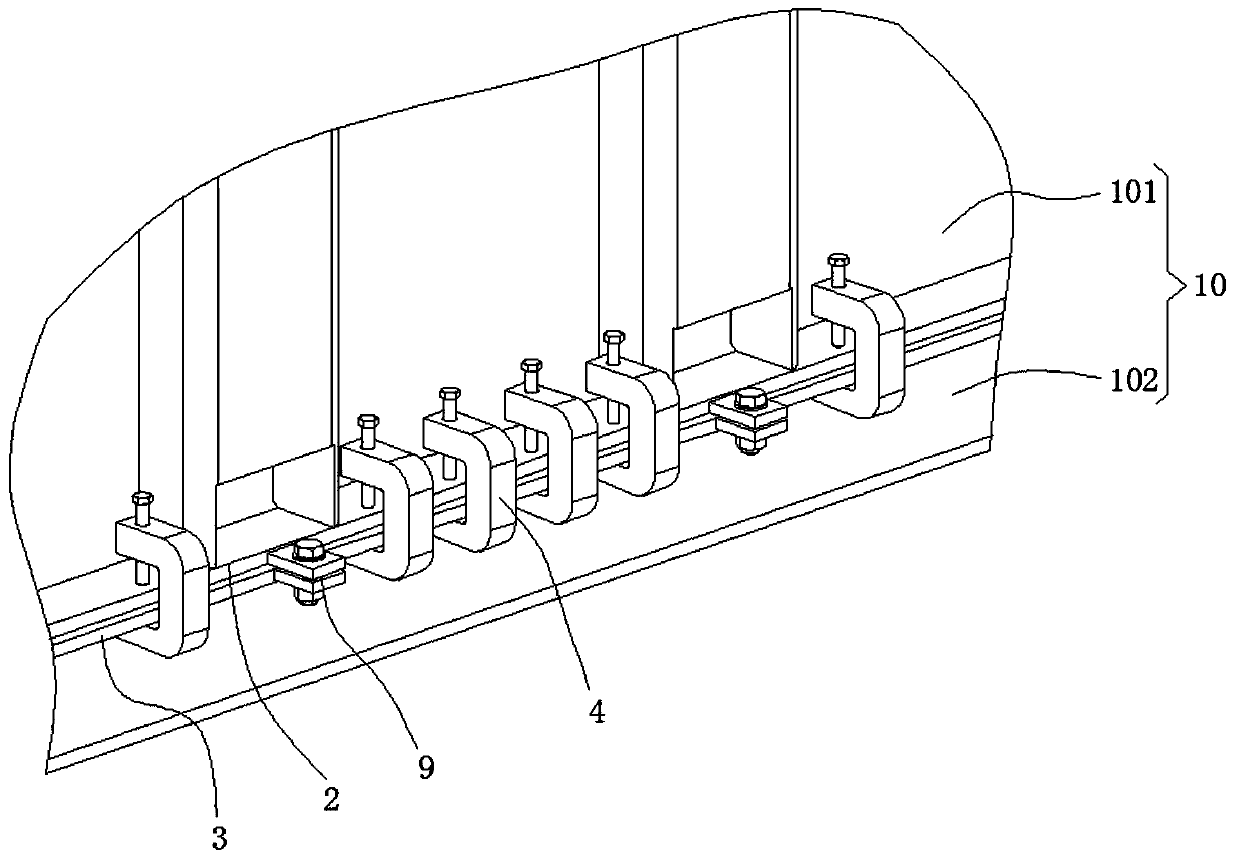

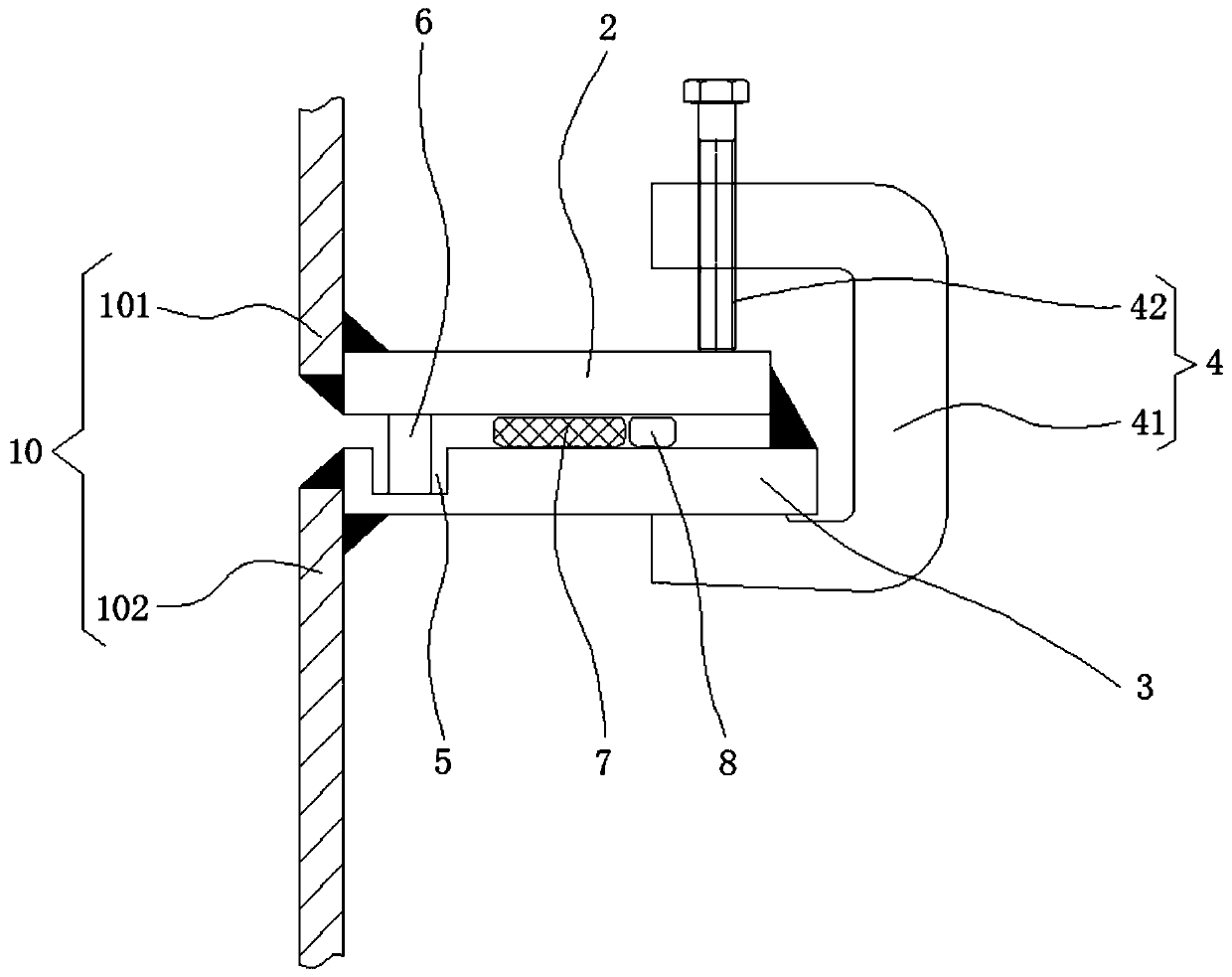

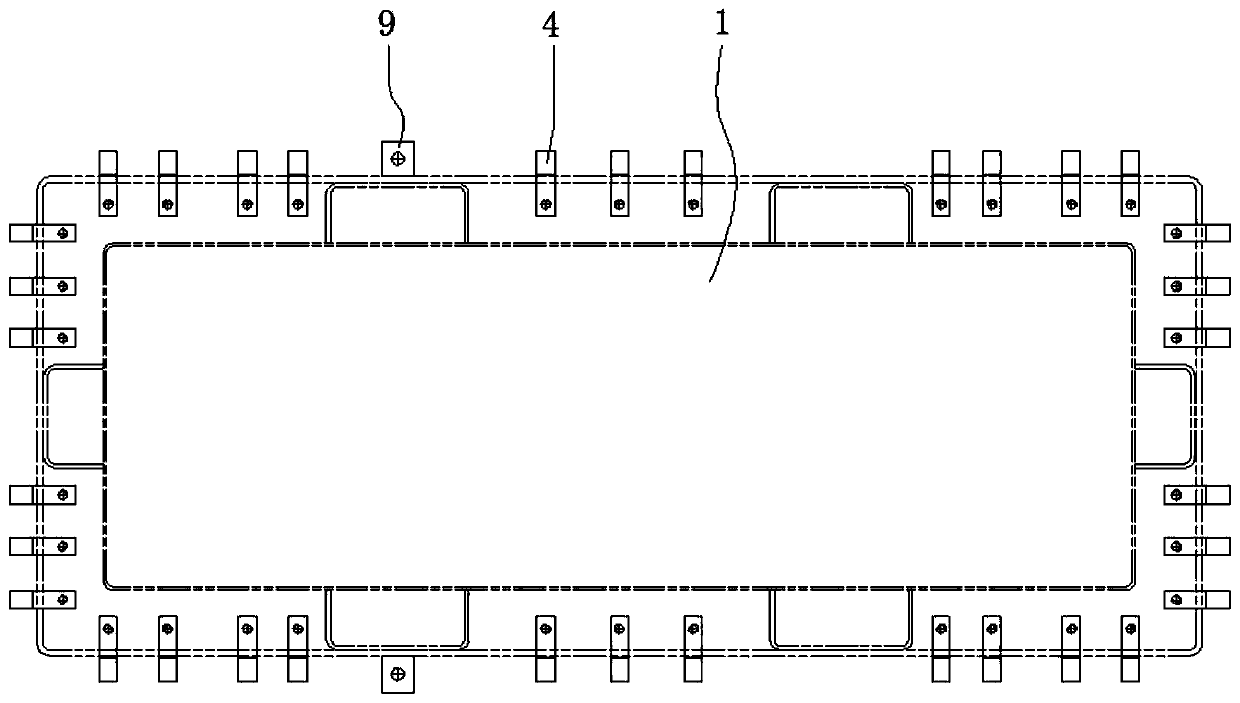

[0035] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 Schematic diagram of the structure of the first embodiment of the welded structure for the box edge of the hermetic transformer provided by the present invention; figure 2 for figure 1 The combined schematic diagram of the upper box edge and the lower box edge shown; image 3 for figure 1 A top view of the structure of the fuel tank shown. The welded structure of the box edge for hermetically sealed transformers includes:

[0036] Fuel tank 1, described fuel tank 1 comprises upper box body 101 and lower box body 102, and described upper box body 101 is arranged on the top of described lower box body 102, and the outer surface of the bottom of described upper box body 101 is provided with upper box body Along 2, the outer surface of the top of the lower box body 102 is provided with a lower box edge 3;

[0037] A fixture 4, the fixture 4 is arranged between the upper box edge 2 and one side of the l...

no. 2 example

[0063] Please refer to Figure 4 and Figure 5 , based on the tank edge welding structure for a hermetic transformer provided in the first embodiment of the present application, the second embodiment of the present application proposes another tank edge welding structure for a hermetic transformer. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0064] Specifically, the difference of the welded structure for the box edge of the fully sealed transformer provided by the second embodiment of the present application is that: it also includes a U-shaped frame 10, and the bottom of the inner wall of the U-shaped frame 10 is provided with an anti-skid block 11 A threaded rod 12 is threadedly connected to the top of the inner wall of the U-shaped frame 10 , and the top end of the threaded rod 12 passes through the U-shaped frame 10 and exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com