Oscillating head mechanism of fiber winding machine

A technology of fiber winding machine and swinging head, which is applied in the field of fiber winding machines, can solve the problems of poor yarn spreading effect and affecting the surface quality of winding products, etc., achieves easier control of glue content and shape and size, and meets the requirements of production of high-voltage insulation products, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

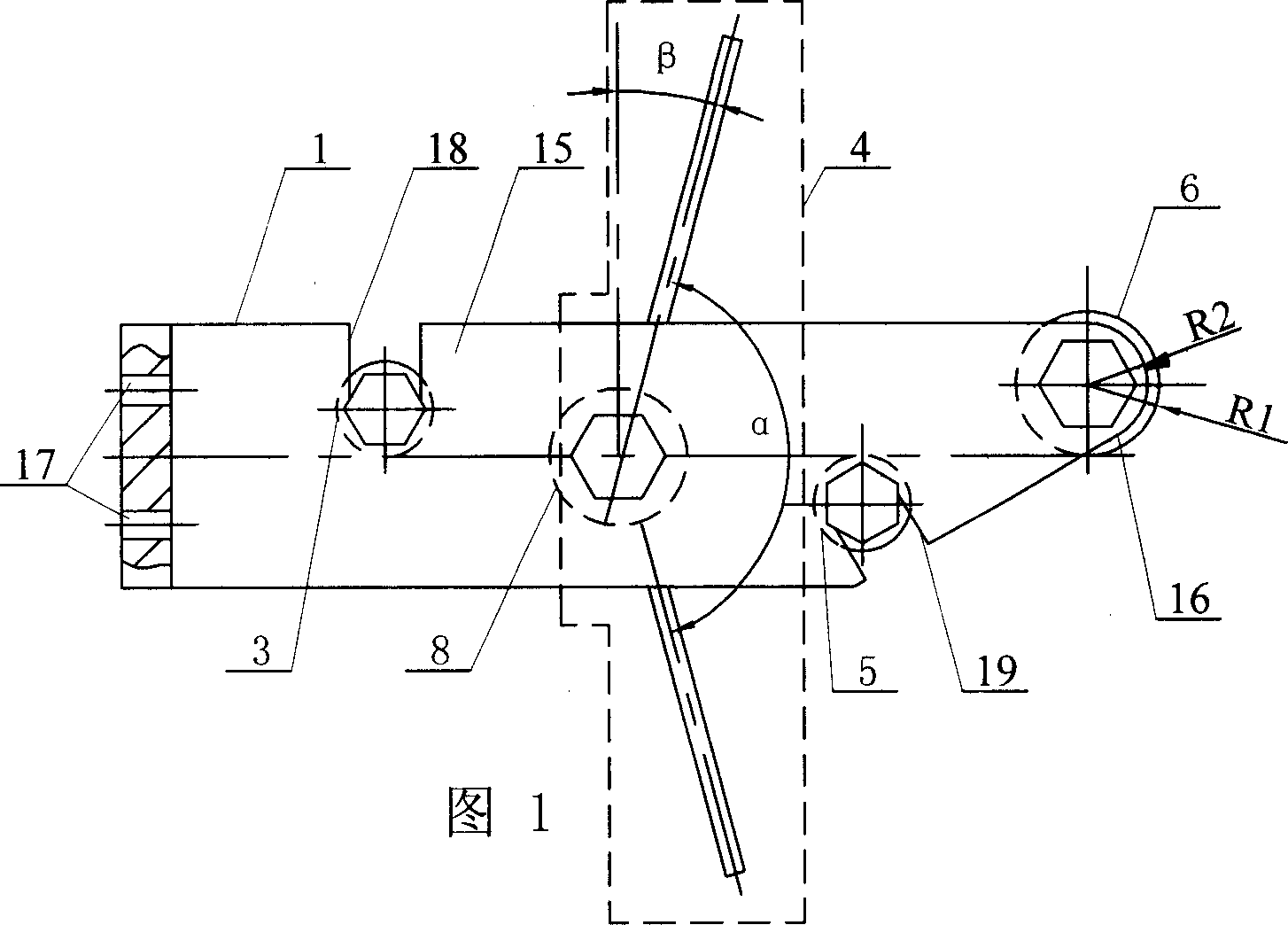

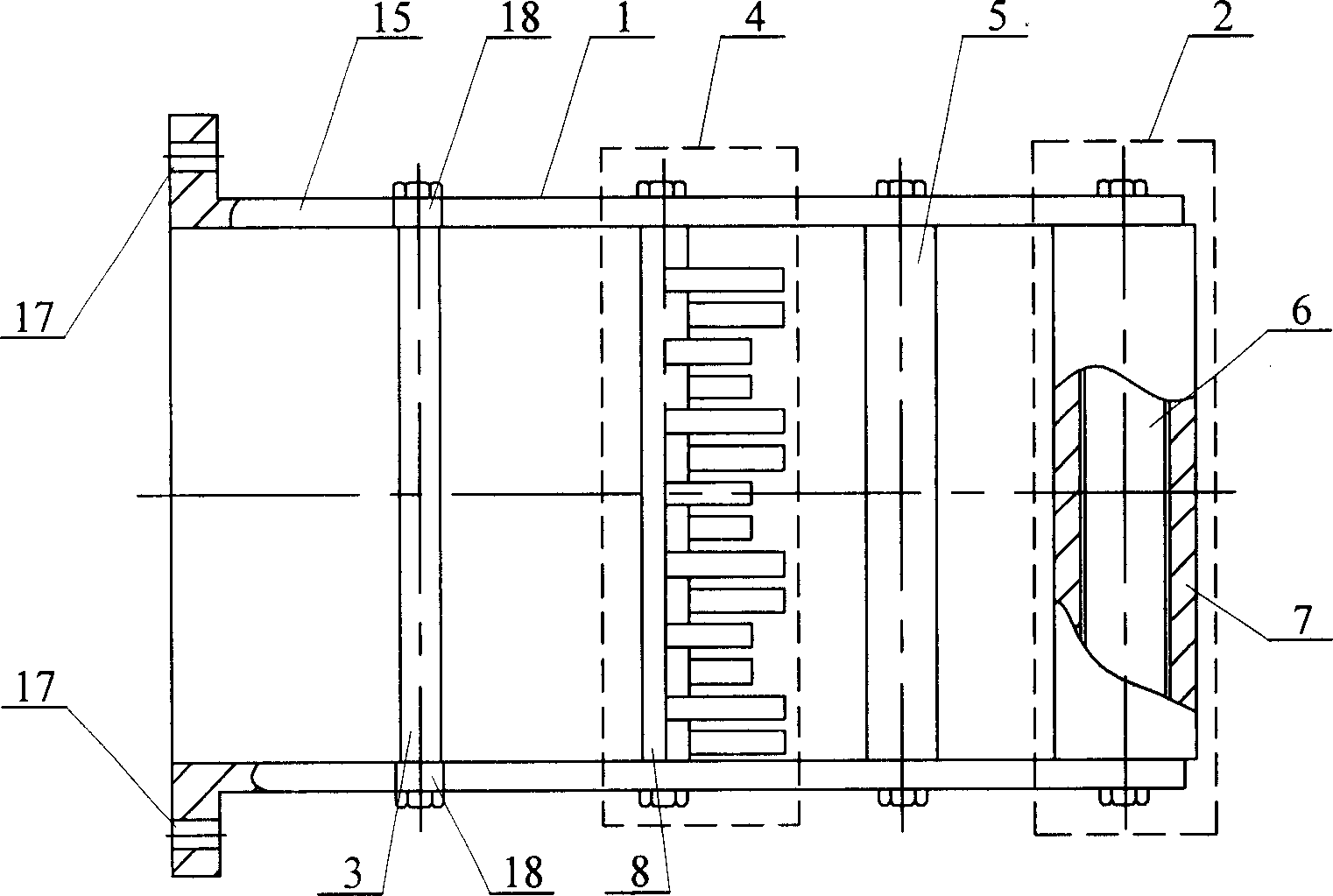

[0007] Specific implementation mode one: in conjunction with Fig. 1~ image 3 Describe this embodiment, this embodiment is made up of bracket 1, yarn discharge roller assembly 2, upper yarn pressing roller 3 that is arranged in bracket 1 and is fixedly connected with bracket 1, yarn dividing roller assembly 4 and lower yarn pressing roller 5 ; The yarn discharge roller assembly 2 is arranged at the yarn outlet end in the support 1, the upper yarn pressing roller 3 is arranged at the yarn inlet end in the support 1, and the yarn dividing roller assembly 4 is arranged at the upper yarn pressing roller 3 and the row Between the yarn roller assembly 2, the lower pressing roller 5 is arranged between the yarn dividing roller assembly 4 and the yarn discharge roller assembly 2; the yarn discharge roller assembly 2 is composed of the yarn discharge roller 6 and the yarn discharge roller 6 and is composed of a yarn-discharging roller sleeve 7 that rotates with the yarn-discharging rol...

specific Embodiment approach 2

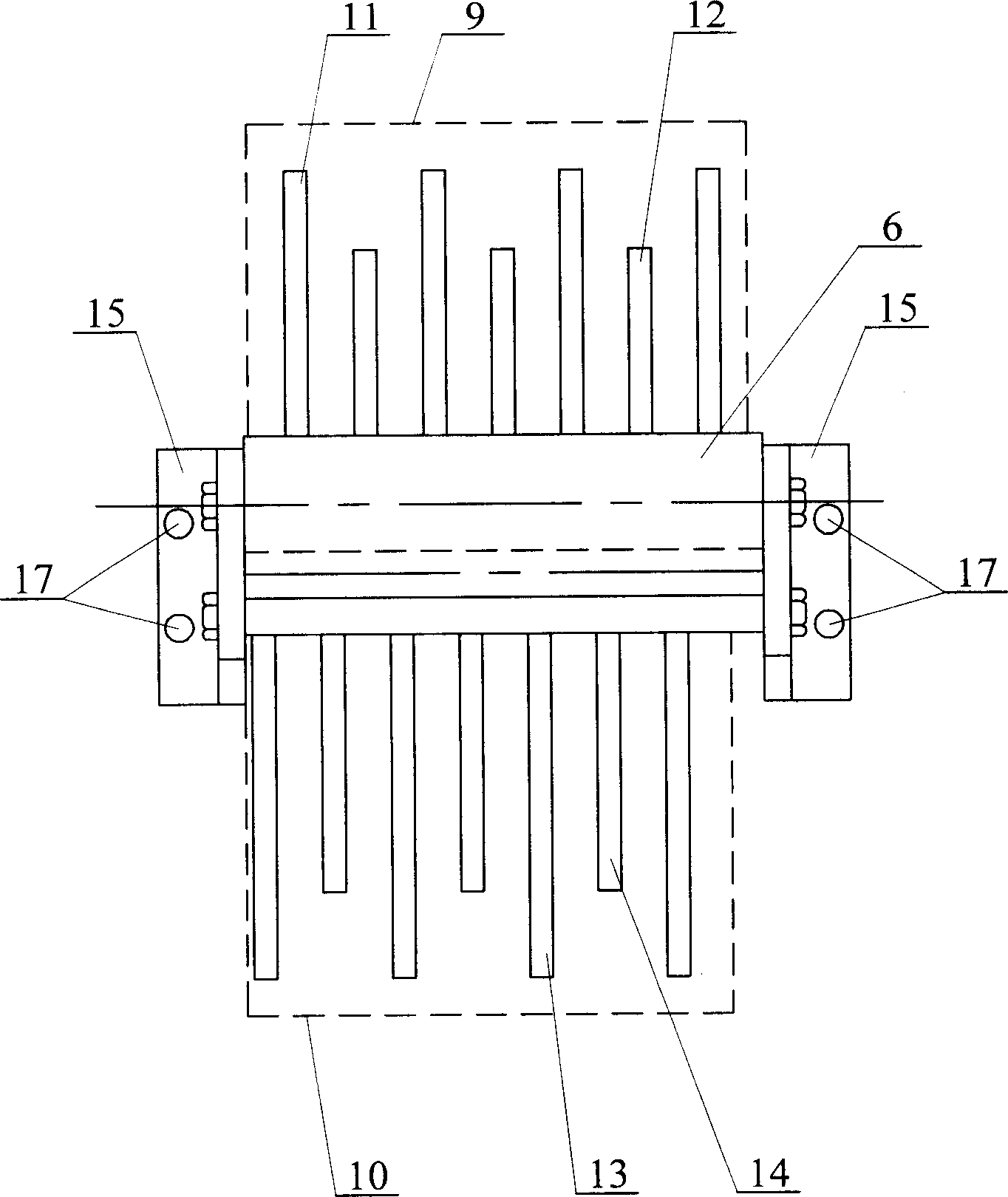

[0008] Specific implementation mode two: in conjunction with Fig. 1~ image 3 Describe this embodiment, the splitting roller assembly 4 of this embodiment is made up of splitting roller 8, upper splitting needle 9 and lower splitting needle 10; A group of upper yarn dividing needles 9 and a group of lower yarn dividing needles 10 arranged equidistantly with the upper yarn dividing needles 9 are fixedly installed equidistantly along the axial direction, and the angle between the upper yarn dividing needles 9 and the lower yarn dividing needles 10 is α is 120°, so that the yarn is staggered up and down. After the yarn is combined on the yarn discharge roller 6, the effect of not leaving the seam and not overlapping can be achieved. The angle β is 30°, which can avoid the defect that the upper and lower yarn-dividing needles rub against the yarn and cause yarn breakage. The upper yarn-dividing needle 9 consists of a group of upper yarn-dividing long needles 11 and a group of The...

specific Embodiment approach 3

[0009] Specific embodiment three: this embodiment is described in conjunction with Fig. 1, the bottom end of the outer wall of the upper yarn pressing roller 3 of the present embodiment and the top end of the outer wall of the yarn dividing roller 8 are on the same plane, and the top end of the outer wall of the lower yarn pressing roller 5 is on the same plane as the yarn discharger. The bottom end of the outer wall of the roller 6 and the horizontal central axis of the spinning roller 8 are on the same plane. Such setting can ensure that the yarns will not leave the seam or overlap after they are combined on the yarn discharge roller, and the flattening effect will be good. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com